Research Article: 2022 Vol: 26 Issue: 1

Developing a model for improving construction small and medium enterprise road initiative projects in South African local governments.

Kgashane Stephen Nyakala, Tshwane University of Technology

Citation Information: Nyakala K. S. (2022). Developing a model for improving construction small and medium enterprise road initiative projects in South African local governments. International Journal of Entrepreneurship, 26(1), 1-11.

Abstract

Construction small and medium enterprise (SMEs) faces numerous deficiencies preventing their sustainable growth and development in South Africa. These deficiencies include: operational factors; limited road infrastructure; financial constraints; inadequate project planning; and ineffective technical innovation in construction SMEs. These factors are all controlling to the stagnated growth of these SMEs road initiative projects, typically privately owned enterprises. In an attempt to enhance the growth opportunities of SMEs, this paper firstly presents a conceptual framework incorporating the above-mentioned deficiencies. Secondly, the paper sharpens in on the construction quality assurance process implementation in order to target road initiative specific-challenges facing SMEs. Finally, the paper proposes some possible coping strategies to ensure more effective implementation of construction quality assurance process in construction SMEs

Keywords

Challenges and Opportunities, Innovations, Road Initiative Project, Small and Medium Enterprise, South Africa

Introduction

Researchers continuously emphasise the significance of developing unique road quality dimension mechanisms within construction organisations, to create new products/ services and to differentiate them from competitors (Vanhoucke, 2012; Jogdand & Deskmukh, 2017). South Africa has achieved substantial expansion in infrastructure investments in both the public and private sector accounting for about 65% to 70% of construction projects (Statistics South Africa, 2017). Efficient road initiative project remains essential for economic development (Nkomo, 2014). Road quality reassurance measurement is therefore vital for construction projects, to avoid cost overruns, abandonment of important projects and time overruns (Nyakala et al., 2017). SME contractors deliver unique facilities/products to customers and contribute to improved customer satisfaction, and thus project-based organisations have viewed the influence of quality improvement on performance (Jarkas & Younes, 2014). SME construction organisations around the world have observed this necessity, and have started to implement new building standards in order to assess and solve construction project difficulties. Hence, for the successful execution of a project, effective planning is important. In order to develop key success criteria for road development initiatives in the context of construction project delivery, quality management systems must be understood and applied from the viewpoint of quality engineering. Many construction organisations find developing a road quality assurance process tool to be challenging, although the success of construction projects is often assessed by quality experts from the perspective of quality procedures and requirements. Enhancing competitiveness in the construction project delivery is a critical step towards integrating engineering management principles and practice (Freeman Bell & Balkwill, 1996). However, most construction project managers come from technical positions and are inexperienced as managers (Badu & Owusu Manu, 2011).The work by Arditi and Gunaydin (1997); Thiagaragan et al. (2001); Jarkas and Younes (2014) reveals values of total quality management (TQM) implementation studies in the construction industry, but there is currently an absence of information about how SME construction organisations, could improve their road infrastructure. One possible reason for the lack of information is that the industry consists of different managerial positions, such as project managers, architects, advisors and sub-contractors, all of which are unique, countless and multifaceted within their business environment. Nonetheless, the awareness that project quality reassurances may have positive influences related to construction project delivery cannot be overlooked. As a result, the purpose of this paper is to contribute to the understanding of the road construction project delivery model in a SME based business. Thus, we set the following research question:

RQ: What is the impact of road initiative project in a construction SMEs?

The study argues that because of the nature of construction project delivery and its important influence in development of any given country, road projects need a measurement tool particularly developed for SME construction organisations. Generic tools do not provide for the distinctive characteristics of road building. However, drawing on preceding studies and evaluations and through use of a survey, this paper develops a road quality assurance measurement process model for SME construction organisations. The structure of the study is outlined as follows. First, a literature review explains the critical success aspects and difficulties thereof, the quality control practices and the road quality assurance process measurement instrument as the hypothetical point of departure. Next, research approaches and the design of the study are discussed. Afterwards the findings of the study and discussion on these findings are presented. The research concludes with underlining the contributions of the study, acknowledging and recommending future study potential.

Literature Review

Challenges and Opportunities Related To Construction SMEs

Several authors such as Chambers (2014) and Kerzner (2013) have noted that quality is a key element of construction to ensure customer satisfaction. Quality management practices have been indicated to be related to high performance in a number of studies of world class construction (Crescenzi et al., 2016; Obare et al., 2016). Further reviews of related studies confirm that effective implementation of total quality management (TQM) is continually linked with improvements in organisational performance. The most commonly cited benefits from applying TQM are improvements in labour efficiency and quality, besides reduction in manufacturing costs, cycle time, and customer lead time (Thiagaragan et al., 2001; Oakland & Marosszeky, 2006; Panuwatwanich & Nguyen, 2017). Very importantly, this philosophy provides several ways of improving quality of products and services in any organisation. Various researchers contend that a total quality system is an integrated manufacturing approach necessitating application of a different set of manufacturing practices (Rao et al., 1996). The efficiency of road building construction projects depends on the method used by the organization to identify critical success aspects (Rumane, 2011). The purpose should be on what to control, determining measurement standards with the respective methods for measurement, collecting comprising indicating corrective action where necessary (Olawale & Sun, 2015). Measures of operational efficiency differ across and within industries.

Reviewing the existing literature suggests that numerous aspects have been identified as crucial to the successful implementation of road project in an SME construction organisation when measuring quality of a construction project (Nyakala et al., 2017). Most construction organisations have encountered problems during and after the construction process (Arditi & Gunaydin, 1997; Van Wyk, 2003; Windapo & Cattell, 2013). In particular, a poor quality of road project, cost and time overruns have been identified as key obstacles to the success of the implementation of the quality assurance process in road building. This is associated with inadequate technical skill perceptions of construction projects on the part of most employees together with resource limitations, and lack of senior-management commitment (Dallasega et al., 2015; Aziz & Abdel-Hakam, 2016). Bowen et al. (2012) also identified inadequate training with respect to quality matters as obstacles to the successful implementation of a quality assurance process during construction. Arditi and Gunaydin (1997) pointed out such obstacles as inadequate training and support, lack of management commitment, a failure to prepare and meet project teams and inadequate total quality management implementation throughout construction process.

Road Initiative Project

There have been very limited studies on practices for implementing the quality assurance process of construction projects in practice. One such study is Mahmood et al. (2010), who indicated that cost control planning using the statistical quality control, sampling and probability eliminates unsatisfactory performance, processes and products. More recently, Dallasega et al. (2015) argued that quality control practice has conventionally concentrated on measuring quality outputs and argues that experts in the fields of project and statistical quality control need to shift the emphasis towards finding and eliminating causes of quality problems.

Studies on quality control practices particular to South Africa are even scarcer, with most studies focusing on just the process of project control. Windapo and Cattell (2013) focused only on obstacles hindering the development of emerging contractors and not the monitoring of specific project results evaluating compliance with standards of quality. A key aspect of quality control practice during the construction process would be monitoring specific project results to determine if they adhere to specifications and classify ways to eliminate the causes of incompetency (Jarkas & Younes, 2014). Cost estimating within SME construction organisations in South Africa is utilized primarily to monitor project execution, prepare bids to customers and audit the success of the project.

It is essential to understand the quality control which includes observing actual performance remedial action to determine if there are deviations (Juran & Gryna, 1993). Construction managers are at the centre of describing what to measure and implementing a measurement system for delivering projects with a great impact on project stakeholders (Olawale & Sun, 2015). Construction managers should consider comparing the measurement with a standard and take the required corrective action if there is a deviation from the standard (Thiagaragan et al., 2001). A major focus of the project control practices would be on building awareness of need and opportunity for improvement, communicating outcomes, and report progress of a construction project (Oakland & Marosszeky, 2006; Kerzner, 2013).

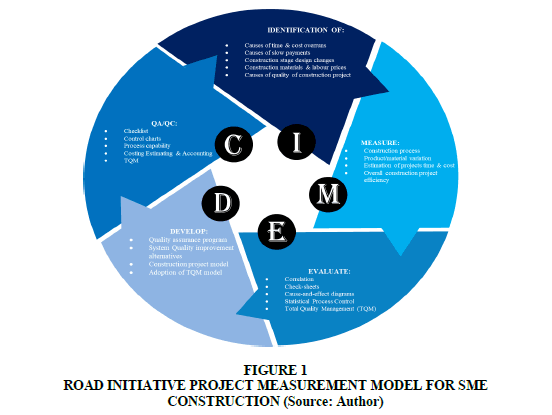

Road Initiative Project Measurement Model

Applying quality improvement techniques and project management methods to resolve construction road quality is needed (Thiagaragan et al., 2001). Quality improvement techniques are first developed in industry, noticeably with some connections and modifications. Construction administrators subsequently develop quality assurance processes to supplement construction project delivery and performance. Such models help to evaluate the quality of road construction processes, thus optimising the resource establishment and delivering the without any cost overruns and scheduled time. These models are used to identify poor quality construction projects and then make improvements in the current system to improve the quality of the construction project.

Figure 1 presents the critical success aspects which were identified in our review of research relating to quality reassurance of SME construction initiative. We used these aspects as a model for integrating the components of assuring quality of road construction projects of SMEs and controlling the process implementation. We linked these aspects to key literature references which identified eight Critical Aspects identified impacting on QA process. We then developed a measurement model to determine the effectiveness of SME construction organisation QA creativity. Thiagaragan et al. (2001) demonstrated empirically that this example proved useful in showing how construction businesses sought out new services and revealed a proposed model of TQM implementation in the construction industry. Mahmood et al. (2010) described the strategies for poor cost of quality and their impact on productivity and profitability in project and asset management. SME construction organisations can develop operational capabilities through a quality assurance process measurement model made to identify measure, evaluate, and develop QA/QC strategies as demonstrated in Figure 1.

Methodology

A quantitative design using a cross-sectional survey approach was adopted for the empirical portion of the study. Research literature was reviewed which was relevant to the quality assurance process within construction project delivery. Bryman (2014) states that the quantitative or positivist research approach stresses observable facts and eliminates subjective thought. The data used to measure the dimensions of SME construction organisations and their quality assurance process was obtained through a distributed questionnaire survey and from published sources (Bryman, 2014). These data were gathered as part of a study on road construction projects among South Africa SME contractors, since they are more likely to adopt a formal road quality assurance process measurement model. The questionnaire was comprised of open-ended questions, which assisted the respondents to answer in their own words, as well as close-ended questions that provided the respondents with various choices. A total of 250 questionnaires were distributed with 160 participants finally indicated their willingness to participate in the study representing a 64% response rate.

A simple random sampling technique was used to select participants, which ensured that all elements within the population had an equal opportunity for selection as sample elements (Welman et al., 2012). Information in the questionnaire assessed road infrastructure and the obstacles that the SME contractors were facing as well as the road building measurement techniques in construction project delivery. Experts in the same field validated the instrument, and the Cronbach Alpha coefficient was utilized to measure its reliability. Question responses were measured with a five-point Likert scale ranging from 1 to 5. The responses to the questions posed and data were analysed using the Statistical Package for the Social Sciences version 24.0 for Windows. Factor analysis was adopted to uncover the underlying dimensions of the interview schedule (Field, 2013). The data collected was also analysed using frequency and percentage statistics.

Results and Discussion

The study has indicated that through the improvement of more Small and Medium Enterprises in their construction projects, construction managers would be able to implement strategies to ensure that quality assurance process are optimised with regard to planning, quality control practices and be aligned with road construction projects. Therefore, the improvement of Small and Medium Enterprises construction organisations extends beyond measuring the process of quality in terms of road construction projects. They need to become more robust in their efforts at implementing the process of quality assurance, execution of strategies and effective operational levels. Evidence shows the need for developing a road construction quality assurance process measurement instrument. A study conducted by Nyakala et al. (2017) found that effectively implemented quality permitted international quality systems to be integrated in a more convenient manner, allowing the systems to be ratified widely.

Characteristics of Sampled SME contractors

The study reports demographic information regarding the SME construction managers, project administrators, and local government managers. The respondent’s information comprises gender distribution, highest educational level, and number of years working in road construction, while the enterprises’ information comprised of the quality of road building systems. The data generated from the information acquired about the gender distribution is listed in Table 1 (Source: Field work 2016).

Table 1 displays the sample’s gender distribution, which reports that out of 160 respondents, 122 were males (76.3%) and 38 were females (23.8%). This response rate implied that the road construction project was dominated by males. The application of a quality assurance process does not depend on the number of employees within the SME construction organisation but on how well project-based organisations are structured to provide a more holistic account of the project control practice throughout their operations (Olawale & Sun, 2015).

| Table 1 Gender Distribution |

||||

|---|---|---|---|---|

| Frequency | Percent | Valid Percent |

Cumulative Percent |

|

| Male Female Total |

122 38 160 |

76.3 23.8 100.0 |

76.3 23.8 100.0 |

76.3 100.0 |

Table 2 presents an overview of the respondents’ highest educational level. Approximately 20.0 percent (n=32) of the respondents had Grade 11 or lower (Standard 9 or lower), 19.4 (n=31) had Grade 12 (N3) only, 34.4 percent (n=55) of the respondents had a first degree/diploma, followed by respondents with honours/B-tech (n=37; 23.1%), while five or 3.1 percent had a Masters/M-tech degree. The section also established whether employees explored all the construction industries qualification programmes available to them for further studies. This influenced their ability to understand the design and construction techniques, to become capable and have required substantial knowledge on quality procedures. Thereafter, it was investigated whether contractor SMEs had a Masters’ degree in Construction/Project Management or Civil Engineering courses. Data generated from this section indicated that the majority of respondents did not have a Masters’ qualification in this study (Source: Field work 2016).

| Table 2 Highest Educational Level Of Respondents In The Business |

||||

|---|---|---|---|---|

| Frequency | Percent | Valid Percent |

Cumulative Percent |

|

| Grade 11 or lower (Standard 9 or lower) Grade 12 (N3) only First degree/ Diploma Honours/ B-Tech Masters/M-Tech Total |

32 31 55 37 5 160 |

20.0 19.4 34.4 23.1 3.1 100.0 |

20.0 19.4 34.4 23.1 3.1 100.0 |

20.0 39.4 73.8 96.9 100.0 |

Table 3 illustrates their years’ experience and association in construction projects. The results indicated that the participants were well-qualified and experienced as shown in Table 3. Among the responding employees, 3.1 percent (n=5) had worked for less than 3 years, 26.3 percent (n=42) reported working for between 3-6 years, 23.1 percent (n=37) indicated working in the business between 6-9 years, 39.4 percent (n=63) indicated that they were employed for more than 9-12 years, while 8.1 percent (n=13) had worked for more than 12 years (Source: Field work 2016).

| Table 3 Respondents Number Of Years Working In Road Construction |

||||

|---|---|---|---|---|

| Frequency | Percent | Valid Percent |

Cumulative Percent |

|

| Less than 3 years 3- 6 years 6-9 years 9-12 years 12 or more years Total |

5 42 37 63 13 160 |

3.1 26.3 23.1 39.4 8.1 100.0 |

3.1 26.3 23.1 39.4 8.1 100.0 |

3.1 29.4 52.5 91.9 100 |

Table 4 illustrates a summary of critical success aspects descriptive statistics for this study, namely items and descriptive statistics used to analyse the data that was collected (Source: Field work 2020).

The acceptance of the 15 Critical Aspects used as the QA process measurement model was subject to in-depth statistical analysis. Reliability was determined by means of Cronbach’s Alpha. The Kaiser-Meyer-Olkin Measure of Sampling Adequacy and Bartlett’s Test of Sphericity measured sample adequacy. Their intercorrelations were determined by Eigenvalues and Factor Analysis. The results achieved using SPSS formed the basis of the theoretical construct of the QA process measurement to determine the effectiveness of construction SME construction projects (Dallasega et al., 2015). The results shown in Table 4 show that all Critical Success Aspects identified had a mean value score >3.94 to 3.97. The significance in the results established that all Critical Aspects were accepted by respondents to be relevant when implementing the QA process. In addition to the descriptive statistics data generated, modes values were either 3 or 4 indicating that most of the respondents indicated that the Critical Success Aspects were of moderate to extremely influential.

| Table 4 Critical Success Aspects Descriptive Statistics |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ITEMS-Statistics | ||||||||||||||||

| CODE | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 | B11 | B12 | B13 | B14 | B15 | |

| N | Valid | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Missing | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Mean | 3.95 | 3.97 | 3.93 | 3.96 | 3.98 | 3.96 | 3.94 | 3.95 | 3.94 | 3.94 | 3.96 | 3.94 | 3.93 | 3.94 | 3.92 | |

| Median | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | |

| Std. Deviation |

.219 | .175 | .264 | .191 | .136 | .205 | .267 | .246 | .257 | .267 | .205 | .257 | .308 | .290 | .317 | |

Quality Assurance Process: Kaiser-Meyer-Olkin Test

The Kaiser-Meyer-Olkin and Bartlett’s test statistic was used to Measure the Sampling Adequacy index and appropriateness of the Critical Success Aspects analysis and inclusive statistics for each item regarding the factor analysis, and determining correlation items (Field, 2013). The SPSS-Output of the Kaiser-Meyer (KMO) Measure of Sampling Adequacy and Bartlett’s Test of Sphericity statistics is shown in Table 5. Further to this, KMO values range from between 0 and 1 indicating that the sum of partial correlations is relative to the sum of correlations (Kaiser, 1974). If KMO values are less than 0.5, the KMO values are inadequate, and the variables need corrective remedial action, either deleting the “offending variables” or including other variables relating to the offenders (Kaiser, 1974).

Table 6 illustrates that four factors were extracted (level of skill acquisition process, project planning and control techniques, project construction design, process implementation), and 22 iterations were required. Further to this, four factors were also extracted (financial management skills, quality standards, organisational structures as well as involvement of people), which were related with quality assurance processes implementation. Pearson’s chi-square test proved that SME construction organisations did not implement QA processes in their road construction projects.

This result indicated that there was no statistical difference between the percentages of the SME construction organisations implementing a process of quality assurance in the local municipalities in the road construction projects, which could be termed as a positive moderate correlation at the given levels whereby p<.000 for all eight scales were measured. Table 5 indicates sufficient reliability on the eight coefficients. This means there was a strong relationship between the variables used in SME construction organisations, since the Cronbach was 70, which was advantageous as depicted in Table 6. As a significance positive relationship exists, therefore, there was support for this study question.

| Table 5 Kmo And Bartlett’s Tests: Extracted Factors |

||||

|---|---|---|---|---|

| Factor | KMO measures of sampling adequacy |

Bartlett’s (Chi-square) Test |

df | Sig |

| Level of skill acquisition process | .728 | 2207.910 | 105 | 0.000 |

| Project planning and control techniques | ||||

| Project construction design | ||||

| Process implementation | ||||

| Financial management skills | .929 | 9494.842 | 595 | 0.000 |

| Quality standards | ||||

| Organisational structures | ||||

| People involvement | ||||

Table 6 depicts the Kaiser-Meyer-Olkin-Bartlett’s test of Sphericity indicates that the KMO value was 0.728 and can be regarded as good, demonstrating that factor analysis is accepted for items under review as depicted in Table 6. The Bartlett’s test illustrates the strength of the relationship between items and tests whether the null hypothesis of the variables in the population correlation matrix is uncorrelated (Field, 2013). The observed significance level in the Bartlett’s Test p value =0.000> than 0.05 signifies a sufficient correlation between items. It enables the Exploratory Factory Analysis (EFA) to be done as depicted in Table 6 and is small enough to reject the hypothesis. It is concluded that the strength of the relationship between items is strong enough to proceed with a factor analysis on the data (Source: Field work 2016).

| Table 6 Kmo And Bartlett’s Test |

||

|---|---|---|

| Kaiser-Meyer-Olkin of Sampling Adequacy | .728 | |

| Bartlett’s Test Sphericity | Approx. Chi-Square | 2207.910 |

| Df | 105 | |

| Sig. | .000 | |

Conclusions

This study contributed to the development of construction SMEs in improving quality and efficient delivery of a road construction projects, and yielded meaningful findings and recommendations. The review of the literature laid the groundwork within the field of SME construction process for development of a road quality assurance measurement instrument for continuous improvement of human skills, project control techniques and planning, project construction design, process implementation, technology, quality standards, people involvement and organisational structures. The most significant findings of this study demonstrate the main difficulties faces by SME contractors in construction project deliveries. These include a lack of consistent measurement of a quality assurance process, inadequate planning and management control, lack of training in quality improvement techniques and tools, lack of government support, unskilled employees and poor quality of construction design as a result of poor organisational structures. This prevents them from improving their quality of road project and construction processes, as well as cost-saving and timely delivery to the customers. These are the main difficulties preventing SME contractors or construction managers of road projects from enhancing quality procedures by adding value activities ensuring consistency of SME construction.

The findings of this study have also examined quality improvement techniques from other researchers. Future studies should examine the need to develop software that will be used to integrate quality assurance factors with comparable tools such as Cause-and-effect diagrams, Statistical Process Control (SPC), Total Quality Management (TQM), and Lean construction which will be able to identify, differentiate and describe the extent of poor quality road project as well as reducing time and cost overruns in construction project delivery. This system will be faster and more accurate than applying traditional techniques. Conversely, the findings of this study could be beneficial to road construction managers responsible for demonstrating cost effective systems in sub-Saharan Africa. For instance, understanding the utilisation of a quality assurance process measurement instrument and the ability to identify, evaluate and improve quality of construction projects is key to improve the economic situation and the ability of road construction SME managers to deal with difficulties related to poor quality. A holistic quality assurance measurement instrument of SMEs to improve quality of road project, reduce cost and time overruns, and abandoned construction projects as well as challenges faced by project managers or supervisors in South Africa have been investigated, discussed in detail, and recommendations about these challenges were also discussed.

Recommendations

Road construction industries are important for addressing the challenges of job creation in South African cities, towns, or even rural areas. Their main concern is improving their quality of products or services, creating efficient and efficient SME construction organisations, increasing competitiveness, and developing their economies in innovative and ground-breaking ways. The government should increase its efforts to support SMSs in construction projects through application of a quality assurance measurement instrument and quality improvement techniques, which encourages continuous process improvement. Firstly, advanced quality assurance/quality control training programmes for SME construction/project managers and employees, including government project administrators, should be organised by management. Secondly, the study advises that the problem of value-adding activities be addressed by ensuring continued management commitment and support, delivery, quality, time management and reliability. When effective quality construction design is implemented in these road projects, the gross domestic product (GDP) will be improved for the nation and the growth of the economy in the country is guaranteed.

The results of this study can help SME construction organisations, local government authorities and society in implementing quality assurance measurement processes properly. This will ensure that project cost and time overruns and abandoned construction projects are identified and resolved during the planning stage. If is not done, road consultants or experts could train local communities to apply this method in order to identify, measure, evaluate, implement and control poor quality of road projects occurring in their local roads. Further to this, the evaluation method used in this study could help local government project authorities/administrators to develop a better quality management system for road construction service delivery.

References

Bryman, A. (2014). Social research methods. London: Oxford University Press.

Chambers, R. (2014). Rural development: Putting the last first. London and New York: Routledge.

Field, A. (2013). Discovering statistics using IBM SPSS statistics. 4th Ed. Thousand Oaks. CA. SAGE Publication.

Freeman-Bell, G. & Balkwill, J. (1996). Management in engineering: Principles and practice. UK: Prentice-Hall.

Jogdand, P. & Deskmukh, S.S. (2017). Development of building quality measurement tool: Building construction quality index (BCQI). International Research Journal of Engineering and Technology (IRJET), 4 (1), pp.1020-1026.

Kerzner, H.R. (2013).Project management: A systems approach to planning, scheduling, and controlling. New Jersey, USA: John Wiley & Sons.

Rao, A., Carr, L., Dambolena, I., Kopp, Martin, J., Rafii, F. & Schlesinger, P. (1996). Total Quality Management: A cross-functional perspective.John Wiley and Sons.

Rumane, A.R. (2011). Quality management in construction projects. CRC Press Taylor & Francis Group, LCC.

Van Wyk, L. (2003). A review of the South African construction industry: Economic, regulatory and public sector capacity influences on the construction industry. Boutek, CSIR (Council for Scientific and Industrial Research), Pretoria.

Welman, C., Kruger, F. & Mitchell, B. (2012). Research methodology. 3rd Ed. Cape Town: Oxford Southern Africa.