Research Article: 2021 Vol: 25 Issue: 4S

Framework for Development of Recycled Sneakers From Footwear Industrial Waste

Chakrapol Chandavimol, Chulalongkorn University

Tatri Taiphapoon, Chulalongkorn University

Sanong Ekgasit, Chulalongkorn University

Abstract

This study aims to create a conceptual framework that will be used in future research to develop sneakers from footwear industrial waste in order to lower environmental impact and create additional value. This can be achieved by reclaiming manufacturing waste, mostly natural rubber, to produce shoe soles. A systematic review of sustainable development in the manufacturing industry, waste management in the shoe industry, environmentally friendly products and new product development case studies and theories were conducted. The plan for future study will include new product development for the recycled sneakers from footwear industrial waste and quantitative studies of customers’ attitude and consumers’ acceptance. This practice will lead to the production of high-quality prototype sneakers which cuts costs by more than fifty percent and reduces industrial waste, while also meeting the needs of customers and fulfilling the objectives of the Sustainable Development Goals.

Keywords

Sustainable Development, Recycle, Zero Waste, Environmentally Friendly Products, Footwear

Introduction

Current business entrepreneurs face multi-dimensional problems that inhibit them from achieving their business goals. In particular, the outbreak of the novel coronavirus (COVID-2019) resulted in a pandemic that led the global economy into its most severe recession since the Great Depression (WorldBank, 2020). Products and services need to be different and more valuable than those of their competitors’ and must meet the needs of consumers to successfully generate income for the business. However, the measurement of an organization’s financial performance alone may not be sufficient for sustainable business operations today, as it must consider the triple bottom line: economy, society, and environment. In 2015, the United Nations set up a collection of goals, namely the Sustainable Development Goals (SDGs) for their 2030 agenda. The goals cover issues like responsible consumption and production, life below water and on land, and economic growth stimulus, all while tackling climate change and working to preserve our oceans and forests. They can be divided into three main categories: economy, society, and environment.

Resources, energy, supply chain, and waste management are essential for productive manufacturing sustainable development (Giannetti, 2020). The zero waste concepts was designed to systematically manage products, production processes, and consumption to avoid or reduce pollution from both products and their waste by-product by recycling available resources to reduce waste sent for incineration or the landfill (Franco-García, Carpio-Aguilar, & Bressers, 2019). Industry practitioners play an important role in supporting or delaying the achievement of the SDGs such as employment, income distribution or industrial waste that causes air and water pollution (Cai & Choi, 2020; Lopes de Sousa Jabbour, 2020; Van Rensburg, 2020). It is necessary to consider social and environmental aspects along with accounting value. Creating innovative, environmentally friendly products with the goal of reducing pollution, saving resources and adapting to changing norms will help businesses gain a competitive advantage (Qiu, 2020). In order to develop new products that achieve both business success and contribute to sustainable development, businesses need to systematically collect data through market surveys, and apply marketing principles and tools to better understand the market situation, consumer needs, and competitor capabilities ((Kotler & Keller, 2016). Marketing communication also plays an important role in sustainable development, providing consumers with accurate product information through the right channels. Businesses are obligated to inform consumers of the product’s environmental impact, which includes information regarding the manufacturing process, raw material acquisition, industrial waste management, and overall environmental impact (Skiltere & Bormane, 2018).

Footwear is one of the world’s major industries. In 2019, 24,300 million pairs of shoes were produced (WorldFootwear, 2020). However, the footwear industry generates a considerable amount of environmental impact. The carbon footprint of a pair of sport shoes is approximately 14 ± 2.7 kg CO2‐equivalent, accounting for five stages of a shoe’s lifecycle: materials, manufacture, use, transport, and end-of-life. The majority of the environmental impact is generated during the materials processing and manufacturing stages, accounting for 29% and 68%, respectively, of total impact (Cheah et al., 2013). Some examples of shoe components include rubbers, synthetic materials, textiles, and leather. Soles account for about 50% of the cost of shoes, and 30% of the shoe sole is made from rubber (Zhang et al., 2018). Without proper waste management, shoe manufacturing will have a negative impact on society and the environment.

In order to bridge the gap between the growths of the footwear industry and achieve the targets set in the SDGs, this research aims to develop a conceptual framework that will be used in future research to develop recycled sneakers from footwear industrial waste. The process of reclaiming natural rubber waste to produce shoe soles can greatly lower environmental impact and create additional value.

This research aims to (1) investigate the current problems and obstacles of footwear industrial waste management in terms of environmentally friendly product development, by conducting a systematic literature review, and (2) develop the conceptual framework of the research to conduct future studies. The framework will determine the direction of the formation of a model for new product development – The Recycled Sneaker from Footwear Industrial Waste. This practice will lead to the production of high-quality prototype sneakers which can cut costs by more than 50% and reduces industrial waste, while also meeting the needs of customers and fulfilling the objectives set under the SDGs.

Sustainable Development in the Manufacturing Industry

Sustainable development is a major challenge and a core concept in modern times, making it necessary to understand and find solutions at the global level. The Industrial Revolution resulted in a massive increase in consumption and as a result, increased pressure on natural sources. Global population currently exceeds 7.2 billion people and is expected to continue to grow, leading to the continued depletion of natural resources (Sachs, 2015; Tang & Zhou, 2012). A sustainable and environmentally friendly supply chain is an important part of today's business operations (Geissdoerfer, 2017). Financial figures have been the only measurement of success in the past, but organizations have now expanded their measure of success to consider the Triple Bottom Line (TBL). After setting the 2030 agenda for SDGs, the United Nations Framework Convention on Climate Change (UNFCC) agreed upon the first legally binding international treaty on climate change: the Paris Agreement, which set a long-term temperature goal to keep the rise in average global temperature to well below 2 °C (UnitedNations, 2015). The Dow Jones Sustainability Indices (DJSI) play an important part in helping global companies succeed in their sustainability efforts, and in evaluating companies around the world for their sustainability practices in terms of Environmental, Social and Governance (S&PGlobal). Certified B Corporations (BCORP) is widely accepted with 4,000 companies in 74 countries. Similar to the DJSI in objective, BCORPs are often used for small and medium-sized enterprises that balance profit and purpose, and consider the impact of their decisions on their workers, customers, suppliers, community, and the natural environment (BLab, 2021).

The manufacturing industry has consistently become more connected to sustainable development, especially in the development of innovative conceptual frameworks. There are four areas of sustainability: manufacturing technology, product development, value creation network, and impact of global production (Bonvoisin, 2017; Halstenberg, 2017). The textile and apparel industries are particularly interested in SDGs pertaining to responsible consumption and production, clean water and hygiene, and global warming solutions (Cai & Choi, 2020). Circular Economy (CE) is a well-intentioned industrial system designed to bring products to life with regeneration. It is intended for waste disposal with advanced design of the material, products, systems, and business models (EllenMacArthurFoundation, 2013).

eissdoerfer, et al., (2017) argued that the CE is a system that transforms the product life cycle by minimizing resources imported into production, waste, pollution, and energy leakage by slowing down, limiting, and narrowing the chain of materials and energy. These can be achieved by sustainable design, and consist of principles of repair, reuse, remanufacturing, refurbishing, and recycle. Recycling is the transformation processes of waste materials into new materials or objects that can be reused, which reduces waste disposal and greenhouse gas emissions. Recycling can help prevent waste generation and reduce the amount of consumption made from new materials; therefore, it reduces energy consumption, air pollution from burning waste and water pollution from landfills (Geissdoerfer et al., 2017). Moreover, the Zero Waste concept encourages businesses to change their approach of managing waste by landfill or incineration, to recycling at least 90% of all waste into new resources (Franco-García et al., 2019). The procedures for managing waste to avoid landfills can help stimulate sustainable production and consumption (ZWIA, 2015).

Waste Management in the Shoe Industry

The footwear industry is one of the world's most important industries. Shoe production reached a rapid growth rate of 21.2% between 2009 and 2019 and produced approximately 24,300 million pairs of shoes in 2019. This is due to the expansion of the world's population and growing popularity of health and exercise trends. 90% of footwear production and more than 50% of consumption is in Asia (WorldFootwear, 2020). The shoe market has a large number of players, making it highly competitive. As a result, shoe manufacturers must continue to introduce new models to attract consumers, creating models that serve both functional and emotional benefits (Euromonitor, 2018).

A pair of shoes consists of an average of 40 types of materials, such as leather (genuine and synthetic), fabric (natural and dyeing process), chemicals, labels, packaging, and most importantly the different raw materials required depending on the type of shoe (Cheah et al., 2013; Hengstmann, 2010). The most commonly used sole materials include natural rubber soles, which account for 30 percent of soles, followed by thermoplastic rubber (TPR), leather, Ethylene vinyl acetate (EVA), and Polyurethane (PU) (Zhang et al., 2018). Cheah, et al., (2013) reported the environmental impact of the footwear industry, with the carbon footprint of a pair of sports shoes to create approximately 14 ± 2.7 kg CO2‐equivalent in emissions throughout the five stages in a shoe’s lifecycle: materials, manufacture, use, transport, end-of-life. The majority of the impact is generated during the 65 stages of materials processing and 360 stages of manufacturing, which accounts for 29% and 68%, respectively, of total impact. Bauer, et al., (2017) insists that environmental impact starts from the product design stage. Table 1 shows an overview of the environmental impact of different types of shoe assemblies (Van Rensburg et al., 2020).

| Table 1 Synopsis Of The Environmental Pollutants Of Footwear Materials |

|||

|---|---|---|---|

| Footwear Materials | Types | Most Common Use | Environmental Pollutants |

| Rubber | Synthetic or natural. Can range from latex, crepe, virgin synthetic, and tire rubber. | Outsole and cushioning. | Rubber fume, greenhouse gases (GHGs). |

| Synthetic materials | Polyethylene, polyvinyl chloride (PVC), polyester and polyurethane. | Shoe soles, heels, and laces. | Volatile organic compounds (VOCs), solvents. |

| Textiles | Cotton, wool, nylon, viscose. | Shoe lining and upper parts. | Process chemicals, pesticides, biocides. |

| Leather | Cow, sheep, and calf hides, reptile skin. | Shoe upper, sole, and lining. | Chromium, solvents, aldehydes, GHGs. |

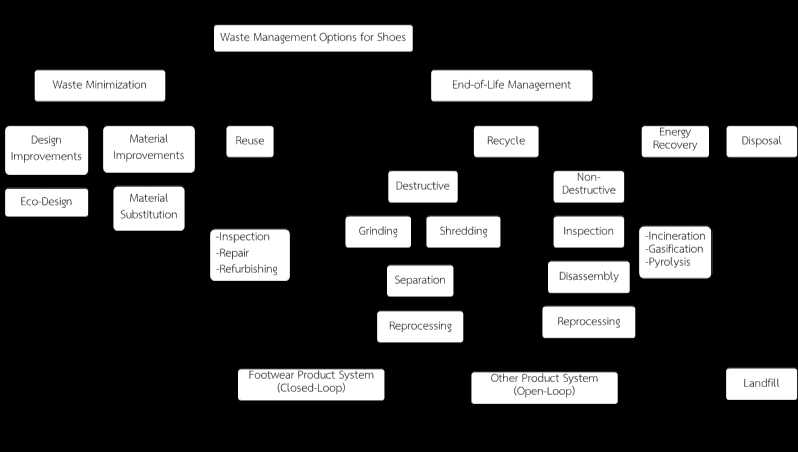

Hengstmann (2010) states that waste in the shoe supply chain may occur in five phases: raw material acquisition, raw material process, conversion of raw materials into shoe components, assembly, and distribution processes, causing environmental impact in 3 states: (1) Solid: raw material by-products, refuse, excess materials, disposed packaging materials, disposed end-of-use products (2) Liquid: wastewater, chemicals, oil (3) Gas: air pollutants. The sources of waste that occur in the shoe’s lifecycle is divided into (1) Supplier (2) Manufacturer and (3) End-of-Life (Chrobot et al., 2018). The most proactive and environmentally impact-reducing approach is to reduce waste by developing designs that will reduce material consumption and waste by as much as possible, as well as the selection of environmentally friendly materials and other forms of waste management (Staikos & Rahimifard, 2007). Figure 1 shows the waste management framework for shoes.

Rubber is the main material used in the shoe industry, especially the sole, as it has physical and mechanical properties suitable for shoes such as non-slip, high elasticity, durability and good adhesion to other materials (Chunhasawasdikul, 2014). Waste management for rubber products can be done in 3 ways: (1) energy recovery (2) reclaiming (3) preparation to become a rubber crumb (Nithi-Uthai, 1989). Most rubber waste is incinerated for energy; reclamation cases are low in volume because of rubber’s poor physical properties and warp quality that occurs due to the different elements of vulcanized rubber; the utilization of rubber crumbs also has complex forming processes and procedures (Nithi-Uthai et al., 2007). However, a study of crumb rubber recycling using surface reclaiming techniques together with high temperature compression molding, that indicated that they can be used to produce floor rubber tiles. This method can also be used in other rubber products (Aree, 2013).

Environmentally Friendly Products

Consumers have become more receptive towards environmentally friendly products and services. These products have expanded from a niche market to a wider market, with product innovation creating a more positive image for the brand. Innovation is especially important in terms of customer perception. Consumers who trust the brand will tell their friends about the product, this is especially true with eco-friendly products (Ottman, 2011). Green product development has two important objectives: (1) improving the quality of the environment and (2) satisfying consumers. Therefore, it is necessary to focus on the value that is provided to consumers, consumer empathizing, including reliably providing true, transparent, and proven information (Ottman, 2006). Moreover, consumers do not expect perfection from the product, but do expect the products to be truly environmentally friendly and clearly communicate to consumers their purpose with concise, clear, easy to understand (Barber, 2012). Consumers have started to pay more attention to the environment, but it has been found that consumers in different age brackets show different interest in environmentally friendly products. Some researchers have found that younger generations are more interested in the environment. Meanwhile, other researchers see that older people show both more concern and interest in the environment (Kotler, 2016).

Innovative eco-friendly products with the goal of reducing pollution, saving resources, and improving the environment, as well as the ability to adapting to changing global norms and values, will give businesses a competitive advantage (Qiu et al., 2020). The market positioning of environmental products will create more benefits for the business, such as generating marginal profits (by reducing waste and supplies), creating opportunities to access new markets, adding value to products, increasing competitive advantage, and reducing toxic risk. These products will also increase consumers’ positive attitudes towards brand image, confidence and satisfaction and create greater willingness to buy environmental products, which is essentially what sets the product apart from its alternatives in the market (Chen, 2010; Norazah Mohd, 2016).

New Product Development

The process of developing new products consists of 6 stages: idea generation, idea screening, business analysis, product development, market testing, and commercialization. It allows organizations to offer new products that satisfy consumers better than the original products, while also finding ways to reduce costs or investments that could be wasted on the failure of new product introductions (Etzel, 2007). The new product development process starts from concept design then turned into a real product prototype. This is systematically done to increase the speed in which the product is introduced to market. Reduce risk and increase the success ratio of new products. Organize work and focus on the efficient use of resources. The new product development process can be measured and verified by any process (Cooper, 1990). In addition, the most important part of sustainable product development is that at every stage of the process, it is necessary to take into account the triple bottom line (Fung, Chan, Choi & Liu, 2021). Including product designs that focus on production waste or by-product and choosing raw materials that have minimal environmental impact. In other words, reducing landfill waste by reusing, recovering, recycling, redesigning, reducing, and remanufacturing (Gupta, 2015; Howarth, 2006).

Figure 2 shows the proposed conceptual framework for future studies that will be conducted via a mixed method in 4 phases. The first phase is a new product development process for prototypes of recycled sneakers from footwear industrial waste. Classify and measure the quantity of unused items or all waste incurred from the operation of the shoe factory, including raw material waste and waste incurred in the production process. Then, analyze the chemical properties of the above waste items and assess the feasibility. Identify and select raw materials that can be used for effective and efficient recycling. Next, laboratory testing will be conducted, followed by quality testing by Department of Science Service of Thailand. The final phase concerns the consumer; a quantitative study of consumers’ attitudes and consumer acceptance of recycled sneakers from footwear industrial waste will be explored. For a large population of 56.6 million people (Thai citizens, age 8 – 74 years old), the sample size for the confidence interval of +/- 5% is 400 (Cochran, 1963). Thus, the data will be gathered through an online questionnaire with 400 respondents or more. Primary data collection and statistical investigation methods are used to test the hypothesis. The future study will reveal the relationship between demographic, attitude, price sensitivity, purchase intention, and product acceptance. Frequency analysis, descriptive statistics, inferential analysis, t-test, one-way ANOVA, post hoc analysis and multiple linear regression analysis will be conducted and interpreted with SPSS programs. Commercialization and Marketing plans will be developed based on the survey results to meet the needs of customers and to identify the right communication channels.

Conclusion

The results of further studies of this framework will provide a prototype for shoes whose raw materials make use of industrial waste (reclaimed rubber soles and rerolled canvas) can reduce costs by more than 50%. This process can also reduce industrial waste that is turned into energy by burning, or that becomes landfill waste, both of which adversely affect the environment. It has not been found that current shoe manufacturers use such methods in production. In addition, the model has proposed a study of consumer attitude and acceptance towards environmentally friendly products in order to plan marketing to meet the needs of targeted customers for commercialization. The framework for the development of recycled sneakers from footwear industrial waste will benefit several industries including footwear, apparel, bag, and other rubber products that aim to move close to achieving the Sustainable Development Goals.

References

- Aree, P. (2013). Crumb rubber recycling using surface reclaiming techique togerther with high temperature compression molding. Thailand: Prince of Songkla University.

- Barber, N.A. (2012). Profiling the potential “Green” hotel guest: Who are they and what do they want? Journal of Hospitality & Tourism Research, 38(3), 361-387.

- BLab. (2021). A global community of leaders. Retrieved from https://bcorporation.net/.

- Bonvoisin, J., Stark, R., & Seliger, G. (2017). Field of research in sustainable manufacturing.

- Cai, Y.J., & Choi, T.M. (2020). A United Nations sustainable development goals perspective for sustainable textile and apparel supply chain management. Transportation Research Part E: Logistics and Transportation Review, 141, 102010.

- Cheah, L., Ciceri, N.D., Olivetti, E., Matsumura, S., Forterre, D., ... & Kirchain, R. (2013). Manufacturing focused emissions reductions in footwear production. Journal of Cleaner Production, 44, 18-29.

Chen, Y.S. (2010). The drivers of green brand equity: Green brand image, green satisfaction and green trust. Journal of Business Ethics, 93(2), 307-319. - Chrobot, P., Faist, M., Gustavus, L., Martin, A., Stamm, A., Zah, R., & Zollinger, M. (2018). Measuring fashion: Environmental impact of the global apparel and footwear industries study. Retrieved from https://quantis-intl.com/wp-content/uploads/2018/03/measuringfashion_globalimpactstudy_full-report_quantis_cwf_2018a.pdf.

- Chunhasawasdikul. (2014). Rubber world.

- Cochran, W.G. (1963). Sampling techniques (2nd Edition). Wiley.

- Cooper, R. (1990). Stage-gate systems: A new tool for managing new products. Business Horizons, 33, 44-54.

- Ellen Mac Arthur Foundation. (2013). Towards the circular economy: Economic and business rationale for an accelerated transition. Retrieved from https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf.

- Etzel, M.J., Walker, B.J., & Stanton, W.J. (2007). Marketing (14th Edition). McGraw-Hill/Irwin.

- Euromonitor. (2018). Footwear in Thailand - Analysis, Country Report. Retrieved from https://www.euromonitor.com/footwear-in-thailand/report.

- Franco-García, M.L., Carpio-Aguilar, J.C., & Bressers, H. (2019). Towards zero waste: Circular economy boost, waste to resources. Springer International Publishing.

- Fung, Y.N., Chan, H.L., Choi, T.M., & Liu, R. (2021). Sustainable product development processes in fashion: Supply chains structures and classifications. International Journal of Production Economics, 231.

- Geissdoerfer, M., Savaget, P., Bocken, N.M.P., & Hultink, E.J. (2017). The circular economy – A new sustainability paradigm? Journal of Cleaner Production, 143, 757-768.

- Giannetti, B.F., Agostinho, F., Eras, J.J.C., Yang, Z., & Almeida, C.M.V.B. (2020). Cleaner production for achieving the sustainable development goals. Journal of Cleaner Production, 271, 122127.

- Gupta, D.S., Dangayach, G., & Singh, A. (2015). Key determinants of sustainable product design and manufacturing. Procedia CIRP, 26.

- Halstenberg, F., Steingrímsson, J.G., & Stark, R. (2017). Material reutilization cycles across industries and production lines.

- Hengstmann. (2010). Waste Management in Footwear. AFIRM RSL Seminar, AFIRM group, Hong Kong.

- Howarth, G., & Hadfield, M. (2006). A sustainable product design model. Materials & Design, 27(10), 1128-1133.

- Kotler, P., & Keller, K.L. (2016). Marketing management (Fifth edition). Pearson.

- Lopes de Sousa Jabbour, A.B., Ndubisi, N.O., & Roman Pais Seles, B.M. (2020). Sustainable development in Asian manufacturing SMEs: Progress and directions. International Journal of Production Economics, 225, 107567.

- Nithi-Uthai, N., Saelim, E., Tohair, P., Raksapram, J., Tohsan, A., & Parkaree, W. (2007). Utilization of crumb rubber. Thailand: Prince of Songkla University.

- Nithi-Uthai, P. (1989). Chemicals for Rubber. Prince of Songkla University.

- Norazah Mohd, S. (2016). Green product purchase intention: Impact of green brands, attitude, and knowledge. British Food Journal, 118(12), 2893-2910.

- Ottman, J., Stafford, E., & Hartman, C. (2006). Avoiding green marketing Myopia: Ways to improve consumer appeal for environmentally preferable products. Environment, 48, 22-36.

- Ottman, J.A. (2011). The new rules of green marketing: Strategies, tools and inspiration for sustainable branding. Sheffield, England: Routledge.

- Qiu, L., Jie, X., Wang, Y., & Zhao, M. (2020). Green product innovation, green dynamic capability, and competitive advantage: Evidence from Chinese manufacturing enterprises. Corporate Social Responsibility and Environmental Management, 27(1), 146-165.

- S&PGlobal (1999). The S&P global corporate sustainability assessment. Retrieved from https://www.spglobal.com/esg/csa/csa-resources/about-csa.

- Sachs, J. (2015). The age of sustainable development: Columbia University Press.

- Skiltere, D., & Bormane, S. (2018). Integrated marketing communication as a business management tool in the context of sustainable development. De Gruyter Open Access, 1, 115-123.

- Staikos, T., & Rahimifard, S. (2007). Post-consumer waste management issues in the footwear industry. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 221(2), 363-368.

- Tang, C.S., & Zhou, S. (2012). Research advances in environmentally and socially sustainable operations. European Journal of Operational Research, 223(3), 585-594.

- Van Rensburg, M.L., Nkomo, S.P.L., & Mkhize, N.M. (2020). Life cycle and end-of-life management options in the footwear industry: A review. Waste Management & Research: The Journal for a Sustainable Circular Economy, 38(6), 599-613.

- World Bank (2020). Global economic prospects. Washington, DC. Retrieved from https://www.worldbank.org/en/publication/global-economic-prospects.

- WorldFootwear (2020). World Footwear 2020 Yearbook. Retrieved from https://www.worldfootwear.com/.

- Zhang, Z., Wei, X., Wu, H., Wang, Q., Zheng, W., & Tang, X. (2018). The present situation of the old shoes recycling and the existing old shoes treatment method. IOP Conference Series: Materials Science and Engineering, 382, 032055.

- ZWIA. (2015). Zero waste international alliance. Retrieved from http://zwia.org/aboutus/.