Research Article: 2022 Vol: 26 Issue: 2S

Health and Safety on Workplace between Augmented Reality and Regulator Compliance: Safety AR

Andrea Colantoni, University of Tuscia

Gianluca Egidi, University of Tuscia

Leonardo Bianchini, University of Tuscia

Valerio Di Stefano, University of Tuscia

Abstract

To introduce the Safety AR system, companies need specific related knowledge to the national transition programs Industry 4.0 which defines the guidelines on opportunities a support for the innovative development of Italian companies. Safety AR represents an interesting opportunity for all company sectors. Integrable perfectly to any production process, simple and intuitive, useful and innovative online with company objectives. Given the obligation of the employer to inform workers on the safety of workplaces Safety AR is born. Safety AR innovates communication related to safety pictograms according to the specific international indications of the ISO 7010: 2012 positioning the specific reasons for each individual pictogram, with the creation of ad hoc content in corporate logistics, such as preparatory to safety training courses, mandatory for every company. Furthermore Safety AR interconnected to Safety DB and web platform, makes it accessible to all workers, even without mobile devices, all updated information on the risks present in the company, with direct access to information from the workstations interactive totems positioned in the company.

Keywords

Workplace Safety Law, Augmented Reality, Signs, Industry 4.0

Introduction

Considering that in 2021 accidents at work increased significantly and in detail the fatal cases were 1,270 throughout Italy, 181 more than the 1,089 in 2019 (+ 16.6%). Faced with a reduction in deaths in transit by 30.1%, those occurring at work have in fact increased by more than a third (+ 34.9%). Important numbers that make us reflect on the importance of proper training and information on safety in the workplace. Ahmed, Irshad, Demirel, & Tumer. (2019).

A new world opens up before our eyes; a new experiential communicative opportunity will flank university (Arzhenovskiy 2017). Activities involving the entire academic community. Augmented Reality offers the possibility to view, in the real environment, cultural and informative multimedia contents useful for the knowledge of the multidisciplinary characteristics of the visit paths, active in the University. The INGRADI AR Augmented Reality Application will become a strategic, innovative and economic communication tool between all study disciplines present in the University. Augmented reality technology will offer an info point service active 24 hours a day, 7 days a week, placing multimedia contents in the real environment that report information of collective interest and that stimulate the user to get to know the places of the university, full of events and characters of great humanistic depth, a fundamental part of the medieval culture of Tuscia. All information will be available immediately, by framing the AR images, totems and markers with the camera of your smartphone, which will be activated with 3D animations and informative audio-videos.

These, which will be real info points, always active, positioned in every corner of historical and cultural interest, will make the tour itineraries a magical, memorable and useful experience for everyone.

Safety and Health on Workplaces by AR (Safety AR)

Safety AR is an innovative multifunctional tool, which identifies the real needs of every single production process with an interactive and functional approach. Safety AR is accessible thanks to one of the most innovative technologies of the moment, recognized by the national development plan among the enabling tools of industry 4.0 because it increases real-world interactions without replacing it. (Calafà, & Protopapa 2021). The approach experiential, its interactive capacity linked to the surrounding reality, increases the conceptual memorization by the end user because it relates the physical object and its digital content in the same environment in which it is located. The product service, the thematic area, the safety pictograms, the company equipment will be accompanied an info point active 24 hours a day 7 days a week, always accessible from the devices furniture supplied. In this way, companies will be able to create an asset in the economy, for example virtual hoc with targeted, specific and personalized content to facilitate workers the assimilation of experiential notions, contextualized in the working environment. Everyone operators interconnected with Safety AR will be able to transfer their objective skills, creating Augmented Reality content available to the entire business community. (Caputo, Greco, Fera, & Macchiaroli 2019).

Cooperation, creation and knowledge of business processes to verify data e monitor the quality and updating of work activities by cross-referencing data e statistics pursuing the maintenance of safety standards. The Safety AR system, with the help of Augmented Reality and a web platform for it dedicated, will make available the data processed in the company on digitized (Colantoni, Bianchini, Paris, Palma, Vincenti, & Gallucci, 2020).Marker cards, printed on Aluminum, on Totem, paper or adhesive ready to be positioned (Colantoni, Paris, Bianchini, Ferri, Marcantonio, & Palma 2021). In the workplace.

The visualization of process data or information content will be activated framing, with the camera of the enabled mobile devices, the markers inserted on paths guide pre-established or in particular business areas of common use to enrich of multimedia content for the corporate work environment. For example, consult a maintenance sheet, or view a 3D graph containing data or audio video explaining the information and terms of the requested service will no longer be a problem. (Gualtieri, Palomba, Merati, Rauch, & Vidoni 2020).

Safety AR will manage all AR content from a web platform that will process the data updating the databases in the cloud. (Hietanen, Pieters, Lanz, Latokartano, & Kamarainen, 2020).

Materials and Methods

Based on the great work done by the international community for the prevention of accidents in the workplace and on the analysis of global statistical data, fits Safety AR the preliminary information notice to refer to the mandatory training courses for all workers. Thanks to its operational versatility, it allows you to create a system in the company personalized information and management aimed at raising awareness among workers on the issue of business security through the display of specific multimedia content e customized for areas and risk levels to be addressed. Safety AR allows access to data and their management with the use of innovative Augmented Reality technology. As can be seen from the ISO 7010: 2012 standard reported above, the experts from all over the world are united in the search for a useful solution for the safety of the workers in carrying out the activities, in consideration of world statistics still worrying. Safety AR provides the tools for the employer to create a good useful for safeguarding the health of workers by placing information content on all safety pictograms in the company, with audio video and 3D animations created by the workers themselves, as a prerequisite for subsequent refresher corse on corporate security.

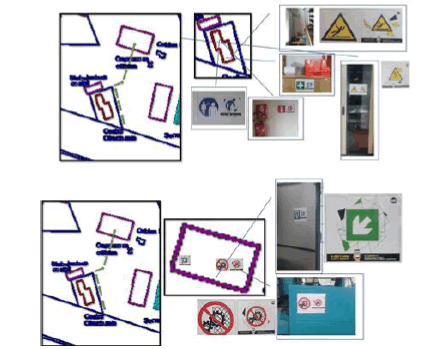

The system is intredatd with several instruments as us below (Figure 1 & Figure 2).

Each safety pictogram allows access to information content through the touch of 4 virtual function keys.

Results and Discussion

Idea is create the experimental path with several safety signs interconnected with the device to AR visualization and improve the knowledge’s on the safety management.

The potential of the system account is the possibility of adapting it to the most varied contests, updating it remotely and composing it (Lim, Zheng, & Chen 2020). According to business needs.

In fact, it does not have a single field of application: it can be used in simpler companies (such as supermarkets) to more complex companies with greater specific risks (oil company) allowing reality to attribute a specific and concrete meaning to the signal, attributed in based on the activities carried out in the company. In fact, one of the most important gaps foreseen by the legislation on safety at work in force is the too generality and abstractness of the meaning of the signs and pictograms: a gap that with the AR system (Rauch, Linder, & Dallasega 2019). would be filled and overcome. In the figure 3, we can see the path with allocated the signs:

AR technology applied to the workplace safety sector allows the worker to be informed and trained correctly, monitoring, as already mentioned, the views and training hours through a system connected to the network. Furthermore, the augmented reality system integrated with workplace safety allows the Head of the Prevention and Protection Service (Stern, & Becker 2020). to carefully monitor the basic training hours (4 hours according to Legislative Decree 81/200) for each operator.

Therefore, alongside an integrated system that significantly improves the information and training of workers, there is a control system (Sun, Zheng, Gong, Garcia-Paredes, & Ordieres-Mere 2020). That facilitates the tasks of the RSPP, allowing it to carry out its tasks in a shorter time and more effectively.

Conclusions

The AR is more than just a tool for driving for safety and health workplace innovations aspects; it is also useful for motivating workers, encouraging interactive learning, and developing critical thinking and decision-making skills. While AR can help boost the learning process, with augmented reality will create (Wöll, & Sulíková 2022). Significantly better returns on innovation. (Zidek, Pitel, Adamek, Lazorik, & Hosovsky 2020).

The AR model can also obtain a direct consequence of the greater training of the worker, a drastic reduction of accidents and deaths in the workplace by making the worker directly to verify the risks and potential dangers. (Mamychev, & Miroshnichenko 2022).

Furthermore, it would allow greater protection for the employer as it would be, at least in part, exempted from civil and criminal liability deriving from accidents.

References

Ahmed, S., Irshad, L., Demirel, O., & Tumer, I. (2019). Comparison of virtual reality and digital human modeling for proactive ergonomics design and performance assessment during an emergency situation. Digital human modeling and applications in health, safety. Ergonomics and Risk Management, 1–19.

Arzhenovskiy, A.G. (2017). Methods of determination of power and fuel-economic rates of machine and tractor units. Agricultural Machinery and Technologies, 6, 36-40.

Calafà, L., & Protopapa, V. (2021). Migrants’ health and interdisciplinary logics. Lavoro e Diritto, 35(2), 105–129.

Caputo, F., Greco, A., Fera, M., & Macchiaroli, R. (2019). Digital twins to enhance the integration of ergonomics in the workplace design. International journal of industrial ergonomics, 71, 20–31

Crossref, GoogleScholar, Indexed at

Colantoni, A., Bianchini, L., Paris, E., Palma, A., Vincenti, B., ... & Gallucci, F. (2020). Different pellet mixtures obtained from spent coffee grounds: energetic characterization. 28th European Biomass Conference and Exhibition, 3.

Colantoni, A., Paris, E., Bianchini, L., Ferri, S., Marcantonio, V., ... & Palma, A. (2021). Spent coffee ground characterization, Pillarization test and emissions assessment in the combustion process. Scientific Reports, 1–14.

Gualtieri, L., Palomba, I., Merati, F., Rauch, E., & Vidoni, R. (2020). Design of human-centered collaborative assembly workstations for the improvement of operators’ physical ergonomics and production efficiency: A case study. Sustainability, 12(3606), 89–111.

Crossref, GoogleScholar, Indexed at

Hietanen, A.R., Pieters, R., Lanz, M., Latokartano, J., & Kamarainen, J.K. (2020). AR-based interaction for human-robot collaborative manufacturing. Robotics and Computer-Integrated Manufacturing, 63, 1–9.

Crossref, GoogleScholar, Indexed at

Lim, K.Y.H., Zheng, P., & Chen, C.A. (2020). State-of-art survey of digital twin: techniques, engineering product lifecycle management and business innovation perspectives. Journal of intelligent manufacturing, 31, 1313–1337.

Rauch, E., Linder, C., & Dallasega, P. (2019). Anthropocentric perspective of production before and within Industry 4.0.Computers & Industrial Engineering,139, 1–15

Crossref, GoogleScholar, Indexed at

Stern, H., & Becker, T. (2020). Concept and evaluation of a method for the integration of human factors into human-oriented work design in cyber-physical production systems. Sustainability, 11(4508), 233–265.

Crossref, GoogleScholar, Indexed at

Sun, Sh., Zheng, X., Gong, B., Garcia-Paredes, J., & Ordieres-Mere, J. (2020). Healthy operator 4.0: A human cyber-physical system architecture for smart workplaces. Sensors, 20, 1–21.

Crossref, GoogleScholar, Indexed at

Wöll, V., & Sulíková, R. (2022). How to prevent unsafe behavior of employees? Explanatory models of insecure behavior at the workplace and prevention methods. In Studies in Systems, Decision and Control, 377.

Zidek, K., Pitel, J., Adamek, M., Lazorik, P., & Hosovsky, A. (2020). Digital twin of experimental smart manufacturing assembly system for industry 4.0 concept. Sustainability, 12,3658, 39–54.

Crossref, GoogleScholar, Indexed at

Mamychev, A.Y., & Miroshnichenko, O.I. (2022). A typology of risks and threats associated with the digital transformation of economic and legal systems. In Smart Innovation, Systems and Technologies, 254.

Received: 21-Nov-2021, Manuscript No. ije-21-9664; Editor assigned: 30-Nov-2021, PreQC No. ije-21-9664 (PQ); Reviewed: 05-Dec-2021, QC No. ije-21-9664; Revised: 11-Dec-2021, Manuscript No. ije-21-9664 (R); Published: 04-Jan-2022