Research Article: 2021 Vol: 25 Issue: 5S

Intelligent Systems in the Innovation Processes of Textile MSMEs A Systematic Literature Review

Ana Gutierrez, Universidad EAFIT

Jose Aguilar, Universidad de Los Andes, Universidad de Alcalá

Ana Ortega, Universidad EAFIT

Edwin Montoya, Universidad EAFIT

Abstract

Innovation has been considered a relevant factor for organizational performance that allows the creation and improvement of organizational competitive advantages, through the implementation of new ideas, products, concepts, services, and practices to increase productivity and market value. For organizations in the pursuit of innovation performance, the utilization of intelligent systems and artificial intelligence to guide the innovation process is a challenge. This presents a systematic literature review that analyses how intelligent systems have been used to improve the innovation capacities in Micro, Small & Medium Enterprises. The results show that even though there are relevant papers on the subject, there is not an established body of knowledge sufficient to ensure clear guidelines to improve the innovation process and performance based on intelligent systems. This paper exposes and discusses several challenges in this domain.

Keywords

Innovation Processes, Smart Innovation Capabilities, Intelligent Systems, Artificial Intelligence, Micro-Small and Medium Enterprises, Textile Industry

Introduction

Currently, it is difficult to think about moving forward and staying in the market without innovating. Regardless of the type of company, organizational advancement and development might be linked to its innovation activities and results (OECD, 2018). Micros, Small & Medium Enterprises (MSMEs), are some of the business sectors that need permanent innovation the most, to improve business results (Weldeslasie & Ahmed, 2019).

In general, innovation is considered a critical factor for companies´ survival and success due to the necessity to adapt faster and better to the changing needs of the environment. The reality is that MSMEs, due to their particular characteristics, in many cases obviate the implementation of a comprehensive plan of assets linked to innovation, technology management, and investment in research and development (Ferrer et al., 2015). Currently, the importance of innovation is increasingly evident as a consequence of rapid changes, which requires managers to explore and implement actions that allow them to tackle market´s needs, by designing and implementing adequate strategies in their companies (Sánchez, 2016). Organizational managers must recognize the importance of innovation and commit with the necessary internal changes, related to human capital development and creativity, at individual and group levels, being this a key factor for success (Flórez, 2019).

The innovation has been widely studied by the most successful companies worldwide, such as Apple, General Electric, Google, Honda, Microsoft, Facebook, and Sony, which have developed and applied different methods and solution strategies. For example, based on Artificial Intelligence (AI), some of these companies have managed to boost their growth and performance, by discovering how to develop effective innovation strategies. Innovation is becoming a survival necessity in business and organizations. This work is concentrated in the Innovation research area, mainly, on how through AI, we could help automate innovation processes.

This paper carries out a review of works that use AI and intelligent systems to improve innovation capabilities in the MSMEs in the textile industry. The main questions of the systematic literature review are: How can the processes of innovation in MSMEs be improved? What intelligent systems have been developed to improve the innovation capabilities of MSMEs? Also, How AI has been used in the textile industry?

Vagnani & Volpe (2017) reviewed different meta-analysis approaches based on Structural Equation Modelling (SEM) to determine the associations between the attributes of innovations, the managers´ behavioral preferences, and the organizations' innovation adoption decisions. Zhong, et al., (2017) reviewed 165 papers considering concepts such as intelligent manufacturing, IoT-enabled manufacturing, and cloud manufacturing. They have used the Google Scholar and Scopus databases. Their paper discussed critical technologies, such as the IoT, cloud computing, Big Data Analytics (BDA), Cyber-Physical Systems (CPSs), and Information and Communications Technology (ICT) in the context of smart manufacturing. This work is different from previous works because it focuses on how intelligent systems have been used to improve organizational innovation capabilities, understanding the innovation process as a series of steps to achieve innovation in MSMEs.

The contributions of this article are: (1) the identification of how intelligent systems and AI have been used in the innovation processes of MSMEs; particularly in the textile industry, (2) a proposal for an innovation process based on the different innovation models that exist, designed to work autonomously in each of its phases, and (3) the analysis of current challenges in the application of AI techniques to improve the innovation processes in the MSMEs.

This document is structured as follows: in the next section, the theoretical framework about innovation models is addressed. In the third section, the systematic literature review protocol is presented. Section fourth presents the literature review´s main results. The conclusions are presented in section five, outlining the limitations of the study, the contributions to theory and practice, and the recommendations for future research.

Conceptual Framework

The Innovation Models

Throughout history, different models have been developed to explain the process of innovation. The models that have been used the most are (Velasco et al., 2007; Nuchera, 2002; López, 2009): TRIZ, Design Thinking, and Lean Startup model. The following section is dedicated to explain the most used innovation models.

Triz Model

The knowledge management techniques provided by the Russian TRIZ methodology facilitate the development of systematic innovation at any level of an organization. Inventions range from a simple adaptation of something that already exists to an actual discovery that revolutionizes technology and science (level 1 to level 5 of inventiveness, according to the Altshuller classification) (Souchkov, 2010).

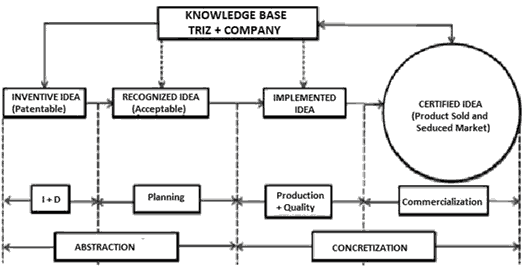

Figure 1 shows the TRIZ-based systematic innovation model, which response to the competitive business world´s modern needs. This model has been elaborated from two essential concepts: one of abstraction and the other of concretization.

In general, the conceptual model of Systematic Innovation with TRIZ covers two stages: abstraction and concretization. During the first stage, the idea is generated, and during the second stage, the idea is materialized in a product.

According to Souchkov (2010), the innovation process begins with a creative patentable idea and culminates when this idea is certified. The only way to certify an idea is the selling of a product based on this idea, which means that the primary indicator is the concretization. When concretization is achieved, the company´s knowledge base is evolving, and might become a source for future ideas.

In the first step, efforts are devoted to the research and development of an idea that must arise to solve any problem. The second step is the most complex, since the idea that has been generated must convince people responsible for approving or rejecting it. If the idea is accepted, it will be executed in the next stage, called concretization. The production and quality steps are crucial because a good idea could be poorly executed. Finally, the marketing step is essential, because a good product may not be sold due to wrong marketing. This last step is called “certified idea”, which is the culmination of the initial abstract idea because the consumer certifies the idea with its loyalty.

In this model, the innovation process is systematic, and therefore, it is possible to foresee it, plan it, organize it, transmit it, delegate it, accelerate it and induce it as it is already being seen (Souchkov, 2010). Organizations that have used TRIZ, have not only survived the demands of the new market conditions, but made spectacular progress in their competitiveness with a significant impact on their profits, the well-being of the company and society in general (Souchkov, 2010).

Design Thinking

Design thinking is a methodology useful in solving ill-defined or unknown complex problems

(Friis, 2020; Interaction Design Foundation, 2020) This approach has five stages (see Figure 2) running through a process that refines an idea until reaching a solution that meets the team's objectives. These steps are described below.

Empathize: The Design Thinking process begins with a deep understanding of the needs of the users involved in the solution, and their environment to generate solutions consistent with their realities.

Define: During this stage, the information collected during the previous phase is screened to keep what adds value.

Ideate: The Ideation stage aims to generate endless options with activities that favor expansive thinking.

Prototype: This stage turns the ideas into reality; for this, prototypes are built to make the ideas palpable, highlighting elements that must be improved or refined before reaching the result.

Test: This phase carries out tests of the prototypes, with the users involved in it. This phase is crucial and helps identify significant improvements, failures to solve, and possible shortcomings.

Lean Startup Model

The Lean Startup Method refers to a philosophy or methodology used when addressing the launch of new businesses and products (Ries, 2008). Generally, it is applied in the technological sector, although its use extends to companies in other areas (Llamas & Fernández, 2018). Lean Startup activities are: Validate, Create a Minimum Viable Product (MVP), Launch, Measure, and Learn.

Hypothesis Validation: validate the assumptions from which the idea is derived, which must be confirmed by the market and the client.

Creation of an MVP: generate a product with minimal characteristics that add value to the client.

Metrics: establish quantifiable elements to measure the expected performance with the new product.

Launch and Learn: the product is launched, and the learning obtained through iterations due to the utilization of the product will allow continuing improvements, and detecting necessary changes.

Proposed Model for the Innovation Process

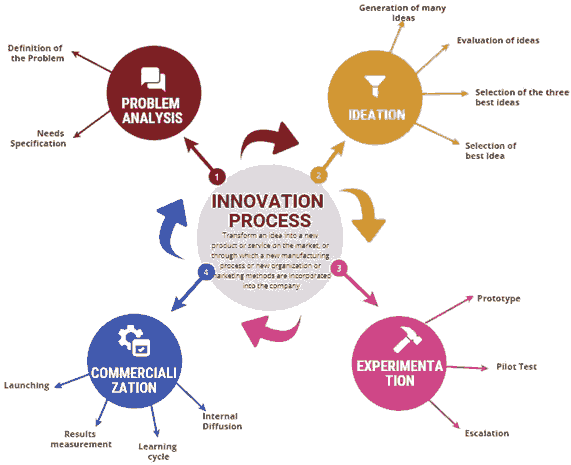

An innovation process is a structured strategy for ensuring that the innovation team idealizes an innovation and progresses on it until it is successfully implemented. This section explains a proposal of an Innovation process based on the different innovation models that exist (see Figure 2). In the proposed approach to the innovation process, four macro-processes are considered: Problem Analysis, Ideation, Experimentation, and Commercialization.

1. Problem Analysis: The problem must be identified and defined.

1.1 Definition of the problem: in this step, it must be indicated and defined what the problem is.

1.2 Needs Specification: it defines a list of requirements necessary to solve

2. Ideation: Different ways to solve the problem must be explored.

2.1 Generation of ideas: In this step, several ideas are generated. The amount here matters. The more, the better. It can use the technique of Brainstorming.

2.2 Ideas Evaluation: it is the process of comparing and contrasting ideas related to the new product, to select the most promising.

2.3 Selection of the three best ideas.

2.4 Choice of the best idea: The idea that best solves the problem.

3. Experimentation: A palpable version is generated, although not necessarily exact to the initially proposed product.

3.1 Prototype: It is the development of an initial product, which allows deciding if it is feasible.

3.2 Test: The main objective is to validate the creative process

3.3 Escalation: Means to transform a concept (prototype) in a commercial product

4. Commercialization: This is the process of launching new goods or services to the market.

4.1 Launching: it is oriented to publicize the innovation product and its results.

4.2 Results measurement: metrics to measure the results should be defined.

4.3 Learning cycle: The market will give feedback to know if the product must be changed, optimized, or persevere.

4.4 Internal Diffusion: it is the communication to internal clients and employees. The objective is the utilization of innovation as a positive reinforcement to motivate individuals within the organization.

Table 1 shows the relationship between the Innovation models explored and our proposed Innovation process. In general, each of the models contributed effectively to the phases and sub-processes of the proposed approach. The Lean Startup models and the Triz Model include all the macro-processes defined for the proposed model.

| Table 1 Mapping of Innovation Models in the Proposed Innovation |

|||

|---|---|---|---|

| Innovation Process/Model | TRIZ model | Design Thinking | Lean Startup |

| Problem Analysis | ✓ | ✓ | ✓ |

| Ideation | ✓ | ✓ | ✓ |

| Experimentation | ✓ | ✓ | ✓ |

| Commercialization | ✓ | ✓ | |

The differences between the proposed model and the other models are as follows:

Process

The differences between the proposed model and the other models are as follows:

• The Starting Point is Different: In the Lean Startup model, the process starts with an idea, which must be validated and can vary significantly before reaching the market. In Design Thinking, the starting point is a challenge (problem, need), not an idea. In our model, the starting point is the process of analyzing the problem, which begins with the definition of the problem and the specification of the needs of the identified problem.

• The Terminology is Different to Express Similar Concepts: For example, the Lean Startup model talks about MVP, the Design Thinking model talks about the prototype, while our model talks about the experimentation process with the prototype, testing pilot and escalation phases.

• The Number of Phases is Different for each Model: Particularly, the Lean Startup model has four phases, our innovation model also has four phases, but some of the phases in the Lean Startup model are included in our phases.

The main contributions of this approach are that each of the phases of the model is self- contained, autonomous, and can be self-managed. The characteristic of the phases described will allow the adequate definition of autonomous cycles of data analysis tasks (Sánchez et al., 2016) in future works. This model facilitates automatically to reach the goals of each phase by using the data from the innovation process and AI techniques for their analysis, as will be supported by the following literature review.

Description of the Protocol for the Systematic Literature Review

The first step to initiate the systematic review of the literature was to define the objective of the review, which was to establish the state of art in relation to intelligent systems that improve the innovation capacities in MSMEs. In the following steps, the procedure for the systematic literature review is described.

Research Question

The research questions defined around the objective of this systematic literature review are defined in Table 2. These questions are about the innovation processes in the MSMEs, the utilization of intelligent systems and AI for the innovation in the MSMEs, with a focus on the textile industry.

| Table 2 List of Search Questions |

|

|---|---|

| Question | Description |

| Q1 | How can the processes of innovation in MSMEs be improved? |

| Q2 | What intelligent systems have been developed to improve the innovation capabilities of MSMEs? |

| Q3 | How AI has been used in the textile industry? |

Inclusion and Exclusion Criteria

The inclusion criteria considered to apply filters in the article search are listed in Table 3.

| Table 3 List of Inclusion Criteria |

|

|---|---|

| Criteria | Description |

| IC-1 | Include publications with titles related to intelligent systems used in MSMEs, emphasizing their application in innovation processes |

| IC-2 | Include posts that contain keywords that matching those defined in the search string. |

| IC-3 | Include studies in two languages: English and Spanish |

| IC-4 | Include publications from the last five years |

The exclusion criteria that were defined for the systematic review of the literature are shown in Table 4.

| Table 4 List of Exclusion Criteria |

|

|---|---|

| Criteria | Description |

| EC-1 | Exclude publications that do not match the previous inclusion criteria. |

| EC-2 | Exclude all duplicate posts. |

| EC-3 | Non-digital publications (publications not available for review) |

The digital databases taken into account in the review to perform the search were ACM, WoS, Scopus, Google Scholar, IEEE Xplore, Science Direct, Wiley, Springer.

Search Chains

For the definition of the search chains (see Table 5), the keywords are:

• Linked to AI: “data analytics”, “artificial intelligence”, “data analysis”,

• Linked to the organizations “MSMEs”, “textile industry”, “Smart MSMEs”,

• Linked to innovative processes: “Innovation Ecosystem”, “innovation strategies”, “innovation processes” Quality criteria.

| Table 5 Search Strings Per Research Question |

||

|---|---|---|

| Question | Description | Search string |

| Q1 | How can be improved the processes of innovation in MSMEs? | (“smart innovation capabilities” OR “innovation processes” OR “Ecosystem innovation”) AND (“micro small and medium business” OR SME OR MSME) |

| Q2 | What intelligent systems/models have been developed that improve the innovation capabilities of MSMEs? | (“intelligent system” OR “intelligent model” OR “Artificial Intelligence” OR “data analysis” or “data analytic”) AND (“innovation capabilities” OR “innovation processes” OR “innovation processes in MSMEs” “Ecosystem innovation” OR “innovation processes in SMEs”) |

| Q3 | How has AI been used in the textile industry? | (“intelligent system” OR “intelligent model” OR “Artificial Intelligence” OR “data analysis” or “data analytic”) AND “textile industry” |

Search Strategy

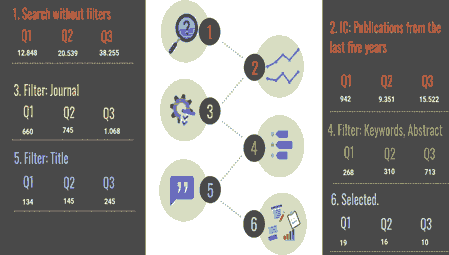

For the development of the protocol, preliminary searches were conducted aimed to identify existing systematic literature reviews and assess the volume of potentially relevant studies. To obtain the final list of publications to analyze, several combinations of search keywords for each research question were used. According to the searches carried out, new keywords were added. The process of selection of articles was carried out using the search chains defined for each research question, and applying the exclusion and inclusion criteria, according to the following steps:

Step 1:Search Without Filters: it defines the total number of articles for each search question, without taking into account any type of inclusion or exclusion criteria

Step 2:Publications from the Last Five Years: the temporality inclusion criterion was applied, and articles with a publication date that was within the last five years were taken into account.

Step 3:Type of Paper: this filter excludes papers that are not in Journals or conferences.

Step 4:Keywords and Abstract: this filter is applied because the search chains must be contained in the keywords and the article´s summary.

Step 5:Title: this filter is applied because the search chains must be contained in the article´s title.

Step 6:Final Selection: this step selects the articles from the previous step, which match the search questions.

Figure 3 shows the flow chart of the selection process, and finally, 44 articles were suitable for proceeding with the analysis.

Preliminary Results

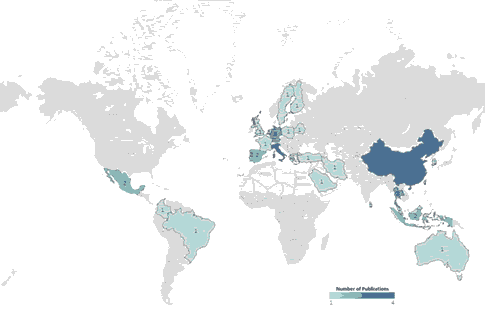

Figure 4 shows the distribution of the production of selected scientific papers per country. Overall, China and Italy are the countries with the most papers with 9%. Also, Germany and Thailand seem to have a solid tradition to study topics related to innovation capability in small businesses with 7%. According to the World Innovation Index 2019, the innovation in China is evident in numerous spheres; the country maintains first place in patents by origin, industrial designs and trademarks by origin, net exports of high technology, and exports of creative products. Thus, China is firmly installed in the group of leading innovative nations. In Italy´s case, the investment on research and development reaches only 1.38 percent of GDP (Gross Domestic Product), a number that despite its growth in recent years remains low. However, Italy occupies the eighth place in the world in scientific publications (second in our domain), an issue that has been discussed by Mauro Battocchi, ambassador of Italy in Chile (Siebert, 2020): “The academic world is working well to create science and research, and we see it in publications; Companies are doing a good job, and after all Italy is well-positioned to face new challenges, but the biggest issue is technology transfer. If we can combine successful scientific production with the strength of the Italian company, Italy will be even stronger”. This situation is similar in Germany, the leader in industry 4.0, and in Thailand, where the nation has experienced massive economic growth for the past years, based on its innovation performance.

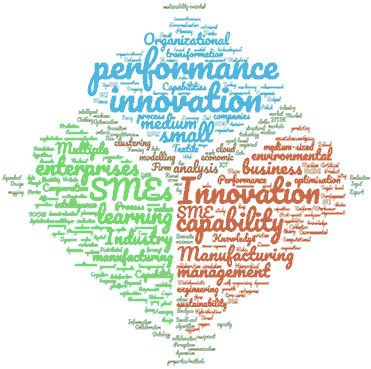

In figure 5, the word cloud of all the articles selected to perform the review is presented. Those words with the highest repetition number correspond to: innovation process (19), innovation (15), innovation capability (18), micro small and medium business (7), IA Textile (11). These words were considered in our search string within the protocol.

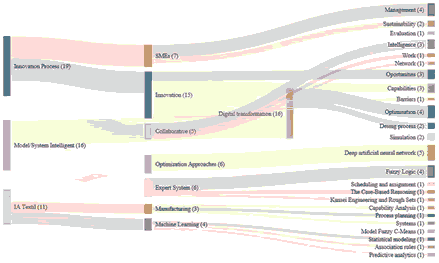

The most frequent keywords have been used to generate a Sankey diagram (see Figure 6), which helps visualize the technologies, methods or processes considered in the reviewed papers.

According to Figure 6, medium and small companies try to evaluate and improve their processes by implementing strategies in the context of management and sustainability. Thanks to the development of innovation in those organizations, they have identified the barriers, but they have also defined opportunities and capabilities through collaborative work, in a network based on digital transformation. Finally, the articles showed how AI has been applied in the textile industry (e.g., optimization, simulation) through different techniques (e.g., deep learning and fuzzy logic).

Analysis of the Papers

Improvement of the Processes of Innovation in MSMEs

Young & Seong (2016) investigated ways to maximize firm performance according to design Innovation management and market dynamics. They defined a multi-agent simulation approach to understand the MSMEs´ performance, considering each MSME as an agent and observing their innovation activities. They concluded that the level of firm diversity influences the performance of MSMEs’ innovative activities. They designed an Agent-Based Innovation Simulator to experiment based on the following assumptions: (1) every MSME attempts to execute innovative activities to accomplish its work efficiently; (2) each MSME prefers to work with those partners (MSMEs) in a similar category; (3) a single MSME tends to be divided into a number of subgroups; and (4) diversity in how MSMEs influences the firm’s decision to collaborate with others in order to complete their work effectively.

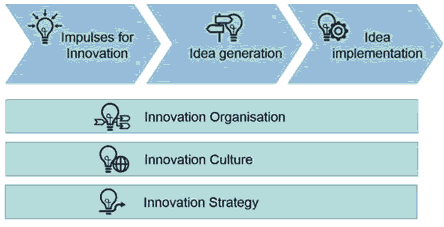

Niewöhner et al. [13] identified challenges to which companies must respond as part of their innovation management to obtain a holistic picture of all innovation management activities; they have defined a total of six fields of action that must be taken into account in connection with innovations (see Figure 7).

• Impulses for Innovations: it comprises all activities that ensure the fundamental knowledge generated, from which ideas can be developed

• Idea Generation: it is about generating innovative ideas. Based on the knowledge of the domain, concrete ideas are generated

• Idea Implementation: it involves the successive concretization of an innovative idea

• Innovation Organization: the central question in the field of innovation is what must be the structural conditions to carry out innovation projects successfully.

• Innovation Culture: a successful innovation process is not only based on knowledge and experience, but requires an appropriate environment in which innovative ideas can grow.

• Innovation Strategy: the innovation strategy is necessary to ensure that innovation activities are not without purpose.

Oleśków, et al., (2017) analyzed the innovativeness levels in companies and industries of various sizes of the entire world, and concluded that the innovativeness of companies is at low to moderate level. Additionally, they proposed an open space platform, where organizations can evaluate their innovation competencies, which allow cross-sectorial and cross-border cooperation. Finally, they proposed roadmaps about projects and organizations, to help industrial development and generate new industrial value chains.

Bagheri, et al., (2019) examined 116 SMEs from eight sectors that showcase high innovative activity within the UK, and offered new insights into internationalization´s role in their international performance. The fundamental question in this study was why and how technological innovation determines the international firm’s performance. Technological innovation plays a crucial role in achieving this competitiveness and increasing firm performance. The model predicts that internationalization can improve firm performance, whereas technological innovation has a mediating role.

Rifat et al. (2015) described how the smaller firms´ coexistence with larger companies, in recent years, helped remove innovation limitations and achieved the required performance in global competition. Moreover, vertical and horizontal cooperation with customers, providers, and other participants, play a significant role in small and medium organizations´ innovation processes. On the other hand, Rahab (2015) analyzed the relationship between innovativeness and market orientation. They concluded that there is a positive influence of the market orientation on innovativeness, such that the firms’ innovativeness level increase when they pay attention to the market orientation.

The research of Rifat, et al., (2016) provided new evidence on the effects of KMC (Knowledge Management Capabilities) on innovation performance in the emerging market of Turkey, where fast information and knowledge integration, along with the application, are crucial for firms to adapt to a dynamic environment. In this research, the authors developed a questionnaire for the largest 1000 firms in Turkey from different sectors. The questionnaire consisted of 41 questions: 12 questions to measure the performance effects of KMC, five questions for ED (Environment Dynamism), four questions for innovation performance, 11 questions for LC (Learning Capability), five questions to control the effects of industry structure factors, one question for the stage of industry’s life cycle, two questions for demographic aspects (age and size), and the last question to categorize the primary business activity of the firms. Findings highlight the importance of KMC and LC, and the critical role of knowledge management in innovation performance.

Xing, et al., (2019) explored the relationship between GOI (Green Organizational Identity) and CEP (Corporate Environmental Performance) in a moderated meditation model, which includes SER (Sustainability Exploration Innovation), SEI (Sustainability Exploitation Innovation), and GER (Government Environmental Regulation). Using SEM and a bootstrap method based on data sets from 380 Chinese companies, they conclude the moderating role of GER, and the indirect effect of GOI on CEP via SER and SEI, revealing the driving effect of GER on innovation and performance.

Xin & Sun (2016) carry out an empirical study to explore if innovation offsets the corporation loss caused by environmental regulation and to improve corporation competitiveness. They analyze Chinese pollution-intensive corporations during 2007–2012, and the results showed that the implementation of flexible control policies had achieved initial success and environmental regulations had significant positive effects on the corporation's innovation.

Maletič, et al., (2015) addressed the gap of sustainability-oriented innovation practices, which result in significantly improved products, services, processes and management systems. The study analyzed the effects on the performance dimensions (i.e., economic performance, quality performance, innovation performance, environmental performance and social performance), considering manufacturing and service industries across five countries: Germany, Poland, Serbia, Slovenia and Spain. The regression analysis results demonstrated that sustainability- oriented innovation practices are positively related to overall organizational performance. From a practical perspective, the study explained how organizations can embed sustainability aspects in their innovation processes with the aim to improve their overall performance.

In their study, Conesa, et al., (2016) assessed the relationship of economic sustainability with organizational innovation and firm performance in a single integrated model, by using SEM in a dataset of 552 Spanish firms. The authors proposed a model of the relationship between the three dimensions of sustainability: CSR activities (social and environmental sustainability), innovation performance and firm performance (economic sustainability) in Spanish SMEs. The results supported a partial mediation effect of innovation performance on the relationship between CSR and firm performance, explaining how CSR is an important driver mechanism for companies to be more innovative, efficient and effective.

Pittawat & Alisara (2017) aimed to help improve the innovation of Thai SMEs in food manufacturing. They analyze the triple helix model of innovation that describes the interactions between government, academia, and industry, to promote economic and social development, by considering 87 responses of a questionnaire regarding SME collaboration. The majority of the samples were fruit and vegetable processing manufacturers, followed by meat and fish/aquatic animal manufacturers. Multiple regressions was applied to quantify the relationship between the identified factors, and findings showed that SME collaboration with the industrial sector was at the highest level when compared with the university and government sectors, respectively. Also, the results indicate that SME collaboration with the industry sector had a positive effect in the innovation of Thai food manufacturing SMEs, and the government sector also has a positive influence.

Apanasovich, et al., (2016) analyzed the most effective innovation modes in the context of post-Soviet Transition Economies (PSTE), specifically in Belarus. In the study, the study considered two dependent variables: product innovation and organizational innovation. By applying two regression models, one for the product innovation output (ProdIO), and the other for organizational innovation output (OrgIO), results demonstrated that there is a positive correlation between innovation modes and product innovation.

The purpose of the paper of Castela, et al., (2018) was to propose an innovative management methodology to evaluate innovation capability in SMEs, through the combined use of cognitive mapping and the Analytic Hierarchy Process (AHP). They create a non-parametric method for the evaluation of SME innovation capabilities. The proposed approach is useful to evaluate SME innovation capability because the collective cognitive map helps to structure well the problem.

De Martino & Magnotti (2018) analyzed the innovation capacity of agrifood MSMEs in the Campania region, through a theoretical framework that addresses the influence of some external and internal resources on the development of innovation activities. These variables are about the local socio-economic external context of firms, the internal resources (investment in R&D, number, competencies and revenues of employees, etc.), as well as the collaborative relationships with externals partner (research organizations, suppliers, etc.). The article remarked the significant role of public funding in boosting the innovation capacity of agrifood MSMEs; this is a critical element for developing collaborative innovation, which at the regional level has to be performed by public decision-makers, both as a promoter or initiator of innovation networks. The implementation and the creation of innovation networks, such as the case of the technological districts, or the development of research projects can generate and favor the circulation of knowledge; thus, increasing the innovation capacity of agrifood MSMEs.

Kritsadee, et al., (2017) tested a model of factors affecting the innovativeness of SMEs using SEM. Data about innovativeness were collected using questionnaires that were mailed to 283 entrepreneurs. The proposed model determined that learning orientation and proactiveness had direct effects on innovativeness. The results are a guideline to build innovativeness in enterprises. The analysis addressed product, process, as well as organizational and marketing innovation, and the contribution of them to the organization's results, e.g., market share, environmental sustainability, profit, etc.

Based on a survey from Korean SMEs in the manufacturing sector, Kim, et al., (2018) established that innovation capability is a fundamental aspect of firm performance, and the organizational rigidity and insufficient resources are barriers. Finally, they concluded that top management leadership and external networking impact innovation capability. Guo, et al., (2019) divided enterprises´ external knowledge acquisition into external technical knowledge acquisition and external market knowledge acquisition, and examine this theoretical framework with the environmental innovation as a mediator. They used a sample of 416 Chinese SMEs, and the results revealed that high levels of technical and market knowledge acquisition are related to SMEs’ performance the positive impact of technical knowledge acquisition is mainly embodied through economic performance; while market knowledge acquisition´s positive impact is mainly embodied through environmental performance. Meanwhile, environmental performance plays a mediating role between environmental innovation and economic performance; and environmental innovation plays a mediating role between external knowledge acquisition and enterprise performance.

Guzman, et al., (2018) investigated the effects that innovation capabilities have on the business performance of 308 SMEs within the context of Aguascalientes, Mexico. The results showed a positive effect on Mexican SMEs´ performance of the innovation in products, processes, marketing and management have. Thus, this paper studied the relationship between innovation capabilities and business performance, and defined some of the innovative aspects to consider in order formulating innovation strategies.

Table 6 describes the domains in the innovation process context where the previous works were applied (e.g., for the management of innovation processes or to analyze the innovation capability).

| Table 6 Domain in the Innovation Processes where the Previous Works have been Applied |

|

|---|---|

| Domain | Meaning |

| Innovation management | In the context of idea generation, Idea implementation, organizational Innovation, and Innovation culture |

| Innovation in the SMEs | It is related to product, process, marketing, or organization |

| Sustainability Impact in the innovation processes | Improvement in economic performance, quality performance, innovation performance, environmental performance, and social performance |

| Method to evaluate the Innovation capacity | Multivariate statistical methods; forecasting methods, Uncertain linguistic variables, fuzzy logic |

Intelligent Systems to Improve the Innovation Capabilities of MSMEs

Giulia (2016) proposed an innovation management system to analyze the data and classify the possible changes in the production process to allow new products. They propose changes in the components or in the production operations. Gasparetto, et al., (2018) proposed a framework in which an Intelligent Work piece Carrier (IWC) is introduced in a traditional production line for a flexible organizational model. This work integrates the knowledge of production steps in the IWC to allow decision making about the process execution. They develop a first prototype to verify the effectiveness of the proposed framework and the results showed that the IWC is a necessary component for flexible production systems.

Cluster manufacturing has been used in the world to improve competitiveness via sharing resources and profits. Suthep & Chiwapon (2019) presented a model for performance evaluation of the bus body cluster manufacturing in Thailand. Fuzzy logic is used to determine the efficiency of each factory according to five dimensions: Reliability, Flexibility, Source, Capacity, and Quality, providing a cost optimization for each situation.

Singh, et al., (2016) proposed a fuzzy rule-based expert system for manufacturing performance assessment in SMEs. The sixteen used metrics were categorized as four economic, five environmental and three social measures. They propose to gather the inputs in terms of linguistic variables in the decision-making process of manufacturing SMEs. The fuzzy rule-based expert system elicits all the aspects of the organization based on the triple-bottom-line framework. On the other hand, Bilal, et al., (2019) propose a system to evaluate the product development process. The system helps decision-making in large enterprises manufacturing, or a group of SMEs, by using explicit knowledge of formal decision events. It stores and reuses the events and experiences related to different activities of the industrial production process, (e.g., product design, manufacturing, and product inspection).

Applications using Artificial Neural Networks (ANN) have been also revised. For example, Silva, et al., (2019) compared the performance of several ML techniques like ANN, Support Vector Machines and Support Vector Regression (SVM-SVR) machines. They demonstrated the importance of considering external factors, such as macroeconomic and microeconomic indicators, like the prices of related products that affect the level of sales in an organization. Zygiaris (2017) conceptualized an information extraction mechanism for semi-structured data, based on web semantic ontologies, in order to introduce an initial stage of the innovation intelligence chain. They use an ontological framework related to innovation chain intelligence, in order to extract the information, and represent and update the knowledge.

Also, innovation capability is a key factor s for surviving in a hyper-competitive situation. The study of Allawi (2018) described the influence of knowledge sharing in innovation capability. The study used a hybrid (qualitative and quantitative) approach for an effect-causal analysis. The factual analysis was conducted based on a survey of 145 employees in a telecommunication company in Indonesia. They concluded that knowledge sharing has a positive influence on creativity, as well as creativity has a positive influence on innovation capability.

The digital transformation is forcing organizations to go towards data-driven business models. Ossi, et al., (2019) presented a conceptual framework to explain the innovation capabilities based on big data and business models. Using the design science research method approach, the authors built the framework based on the existing literature and applied it in three firms.

Adamides & Karacapilidis (2020) proposed an ICT support framework focused on the micro- foundations of dynamic capabilities: “opening” mental models, and development of social capital through collaboration and knowledge management; while the aim of Álvarez-Castañón (2019) was to analyze the dimensions of the Open Innovation (OI) and the technological and innovation capabilities of SMEs in a traditional manufacturing industry. A regression analysis was conducted in a sample of 33 SMEs in Guanajuato, Mexico.

Table 7 describes how IA techniques have been used in the innovation processes in previous works.

| Table 7 Some Intelligent Systems in the Context of Innovation Processes |

|

|---|---|

| IA method | Objective |

| Fuzzy logic | To optimize the efficiency of each company considering five dimensions, which are capacity, quality, reliability, source, and flexibility Expert system based on the characteristics of SMEs |

| Artificial Neural Networks | For product sales forecasting with high rotation |

| Semantic Web ontologies | For information extraction and knowledge representation from the production chain |

The AI in the Textile Industry

The textile industry has developed expert systems applications to increase production, improve quality and reduce costs (Weldeslasie & Ahmed, 2019). The analysis of textile designs or structures, includes the use of mathematical models like the Finite Element Method (FEM), which has facilitated the prediction of the behavior of that textile structure under mechanical loads (Arjmandi et al., 2017). Finally, the Case-Based Reasoning (CBR) method proposed by Bullon, et al., (2017) complemented those previous´ methods results.

The paper of Santiago-Santiago, et al., (2017) presented an interactive design support system for fashion designers when designing workwear or corporate wear clothes. This system is fed by a semantic database that describes the relations between function and clothes in a specific context of use. This application contains relevant information for clothes designers and producers, alerting them with user’s clothes preferences for a particular task.

On the other hand, Shih-Wen proposed a predicting model to identify color trends (Shih-Wen et al., 2016). The method, based on fuzzy c-means, was used to separate the collected color data, and the minimum mean-square error was then used to determine the color clusters. In order to verify the quality of the system, four datasets of Pantone from spring 2014 to fall 2015 were taken as samples, and the color for spring 2016 was predicted and compared with that of Pantone spring 2016. The work of Vinod & Poonkuzhali (2018) focused on sales forecasting using trend analysis of garment industries based on the e-commerce data collected from the Coimbatore region, a region in India of cotton production with a high density of textile industries. Time series analysis is performed, and the forecasting about sales trends is derived from the data.

Zimmerling, et al., (2019) investigated the utilization of Machine Learning (ML) techniques in the textile context, using variable geometries to obtain physically accurate predictions of images from the textile industry, recognizing distinct geometric features in a textile piece using ML- algorithms. They analyzed the algorithm’s learning capacity vis-a-vis geometry variations. This work used fabric forming for approach validation, which is applied to other material classes (for example, stitched non-crimp fabrics).

The purpose of Klement, et al., (2017) was to develop a tool to solve scheduling problems in a textile company, in order to assign the resources through time. To do so, they use a hybridization between a metaheuristic and a list algorithm. The metaheuristic can be used in any problem, and the list algorithm is very specific to the studied problem.

Optimizing the parameters of the manufacturing process requires an intensive search for resources in a high-dimensional parameter space. Pfrommer, et al., (2018) proposed a substitute-based optimization as a simplified model to guide the search for optimized parameter combinations, where the substitute model was iteratively improved with new observations to find optimized parameter settings. They applied substitute-based optimization in a composite textile draping process. In addition, a deep neural artificial model was trained to predict the cutting angle of more than 24,000 textile elements. Finally, Packianather, et al., (2017) proposed data mining techniques applied to a manufacturing SME, like the ant colony model that has been largely used to solve combinatorial optimization problems (Aguilar, 2001) or the artificial immune systems to solve detection problems (Araujo et al., 2003).

Murphy, et al., (2019) investigated the use of ML technologies for order flow time estimation in dynamic job shops, using a discrete event simulation framework for modeling manufacturing operations. Data was generated via simulation, a series of experiments were conducted, and the proposed approach´s performance was compared with conventional methods. In this paper, five ML models were tested: ANNs, gradient boosting, and regression trees with the ensemble and boosting concepts. Complex dynamic shop behaviors, such as rework, machine downtime, machine setup time, and machine repair time were considered. A series of simulation runs are then conducted with varying dispatching rules, such as FCFS (First Come First Served), SPT (Shortest Processing time first), EDD (Earliest Due Date first), to collect data for training, validating and testing of the ML models.

Aiming at the current requirements of the manufacturing execution system of SMEs, and with the development of enterprise in cloud manufacturing, Zhou, et al. (2019) proposed a manufacturing cloud platform application research for SMEs based on micro-service architecture. In this research, they used micro-service architecture to implement a platform- based business system, which solves very well the scalability problems of business applications and catches user requirements.

Table 8 shows the different AI methods used in the context of the textile industry. In general, different ML techniques have been used, but other techniques also. Besides, there are different types of applications of those methods (e.g., to support the design process, to improve the manufacturing process).

| Table 8 AI Methods Used in the Textile Industry |

||

|---|---|---|

| AI technique | Manufacturing processes in the textile industry | Ref |

| Expert System | An expert system for production. | Bullon et al., 2007 |

| An expert system for clothing design processes | Santiago-Santiago et al., 2015 | |

| Machine Learning | An intelligent system for fashion color prediction | Shih-Wen et al., 2016 |

| A forecasting market trends approach to determine | ||

| the sales of garments | Vinod & Poonkuzhali, 2019 | |

| Textile formability assessment | Packianather, et al., 2017 | |

| Estimation of the order flowtime | Zimmerling, et al., 2019 | |

| Optimization | Solving scheduling problems | Packianather, et al., 2017 |

| Approaches | Parameters optimization of a manufacturing process | Zimmerling, et al., 2019 |

Discussion

Improvement of the Innovation Processes in MSMEs

The Triple Helix concept has been discussed in the development of dynamics of knowledge based on innovation systems (Pittawat & Alisara, 2017). Recent studies have explored the relationship between SMEs and this concept to drive innovation performance. One challenge is to explore the Triple Helix, and even the Quadruple Helix concept (Carayannis & Campbell, 2009) (which includes the civil society as a participant) to the fashion sector, taking into account the benefits that MSMEs would have in terms of collaboration, resource access knowledge transfer and innovation skills, which could be applied in the innovation processes of MSMEs. Also, the creation of industrial value chains contributes to regional smart specialization strategies by capitalizing on complementary competencies, which positively impacts the innovation performance of MSMEs (Oleśków et al., 2017).

MSMEs should be open to learn new things via different activities, such as market surveys, observation and listening of customer comments and innovation related training. These activities allow increasing the knowledge to develop new creative ideas, meeting the customer demands. One challenge is to automate the process of generating creative ideas with the sources of knowledge already available in the market and the organization.

Future research should help the design, development and implementation of frameworks and systems to help organizations, especially MSMEs, in their innovation processes, as MSMEs engaged in more innovation processes present better overall international performance and competitive advantages (Bagheri et al., 2019). As seen in the literature review, intelligent systems and AI might help the innovation process; therefore a challenge for future research and development is to work on computational frameworks to support the innovation processes of the MSMEs.

On the other hand, organizations might consider sustainability aspects in their innovation processes, not only for corporate responsibility, but for the positive impact on their overall performance. One research opportunity then is to examine the factors that drive the sustainability-oriented innovation practices in organizations, especially in MSMEs. Thus, it is necessary to better explore the variables that moderate the relationship between sustainability- oriented innovation practices and organizational performance, understanding the importance of differential innovation attributes and organizational characteristics.

Intelligent Systems to Improve the Innovation Capabilities of MSMEs

Knowledge creation and management have proven to be very important for the innovation process, and they require the use of analytical tools and benefit from the use of intelligent systems and (AI Zygiaris, 2017). It is a managerial challenge to implement systems that allow refining the innovation process with the use of data analysis tools, to offer the possibility of improving the innovation capabilities of MSMEs.

MSMEs are a constant source of data valuable for innovation, concerning products, processes, management and marketing, but in many cases, they do not have systems that allow them to manage this information efficiently. One managerial challenge is to build data repositories with an adequate data analysis framework that exploits these sources of data to help in the decision- making process.

The use of IA techniques allows automating activities like decision-making, problem-solving, and learning. A challenge is to use them in the context of MSMEs, to transform these organizations towards data-driven business models. Finally, it would be valuable for theoretical and practical considerations, to evaluate the innovation capability of SMEs using automatic tools based on IA techniques like fuzzy cognitive maps (Aguilar, 2013) or multiagent systems (Aguilar et al., 2005).

The AI in the Textile Industry

As indicated by the literature review, the textile industry might use expert systems applications for product innovation, business expansion and user requirement, and to increase production, improve quality and reduce costs. Also, personalization is a challenge for the textile industry, and IA can be used to determine new products or characteristics, based on the profile of the clients (Reza et al., 2018).

The demand for personalized products makes necessary flexible production solutions that can deal with the problems of changing environments (Torn & Vaneker, 2019). Future research should help the identification and definition of smart environments for decision making that increase productivity without the need for the human component, in order to do the production processes more autonomous, personalized and efficient. Another challenge is the creation of an intelligent agent for the textile industry, which can learn innovative strategies and share them with other members of the organization.

The textile industry generates huge amounts of data as a result of thousands of transactions and processes that are carried out daily in all points of the value chain (Constantinescu et al., 2015). The challenge is how to intelligently manage all that volume of information that is being generated, using a smart data warehouse based on the Big Data and Data Analysis paradigms, in order to use this data to make better-informed decisions (e.g., in the operational and marketing areas) (Sivalogathasan, 2016; Pedron et al., 2018).

The possibilities for the utilization of AI are varied and wide, but if AI technology is included in the industry, then experts in this field will be needed, and collaboration with the scientific sector will be crucial. Also, the quadruple helix model will be necessary, especially, the collaboration of the academy with experts from companies in the same field. Also, refinement collaboration between companies will be crucial, as the more information we have the more effective and secure the developed models will be. AI will move the technological innovation systems.

Crossed Challenges

According to the systematic literature review performed, there are no studies related to features engineering that allow the analysis of the variables required in the innovation processes of MSMEs. A feature engineering work will allow identifying the most relevant variables that describe and influence the innovation processes. Also, future research should focus on exploring and defining the most appropriate AI technologies so that the MSMEs improve their innovation processes.

In the globalization context, it is important to consider the influence that the international markets have on MSMEs to improve their innovation strategies. Future research should address the incorporation of data analysis techniques in the innovation process, to gain knowledge about international markets and their needs.

The results of the previous studies demonstrate the importance of knowledge management within organizations and its impact on the innovation process and innovation performance, consequently, it is necessary to create tools for optimal knowledge management, particularly the use of analytical tools to support decision-making during the innovation process is a big challenge, in theoretical and practical terms.

Acknowledgement

The authors thank Ministry of Science, Technology and Innovation and Universidad EAFIT for Bicentennial Scholarships that helped support this work.

References

- Ferrer, L.E., González, K.P., & Mendoza, L.M. (2015). Innovation as a key factor to improve the competitiveness of SMEs in the Department of the Atlantic, Colombia. Free Opinion, 16, 21-36.

- Sánchez, O.M., Cervantes, A.V., & Peralta, M.P. (2016). Management of innovation in small and medium-sized companies in Barranquilla-Colombia. Journal of Social Sciences, XXII(2), 79-84.

- Flórez, N.L. (2019). Innovation as management strategies for SMEs. Master Thesis, Nueva Granada Military University, Colombia.

- Vagnani G., & Volpe L. (2017). Innovation attributes and managers' decisions about the adoption of innovations in organizations: A meta-analytical review. International Journal of Innovation Studies, 1(2), 107-133.

- Zhong, R.Y., Xu, X., Klotz, E., & Newman, S.T. (2017). Intelligent manufacturing in the context of industry 4.0. Review Engineering, 3(5), 616–630.

- Velasco, E., Zamanillo, I., & GurutzeIntxaurburu C. (2007). Evolution of the models on the innovation process: From the linear model to the innovation systems. In XX Annual Congress of AEDEM, 2.

- Nuchera, A., León, G., & Pavón J. (2002). The management of innovation and technology in organizations. Editorial Pyramid. Madrid.

- López, O., Blanco, M., & Guerra, S. (2009). Evolution of innovation management models. Negative Innings, 5(2), 251-264.

- Souchkov, V. (2010). TRIZ and systematic business model innovation. In Global ETRIA Conference TRIZ Future 2010.

- Friis, R., & Siang, Y. (2020). 5 stages in the design thinking process.

- Llamas F.J., Fernández, J.C. (2018). The Lean Startup methodology: development and application for entrepreneurship. Revista EAN, 84, 79-95.

- Young, W., & Seong, W. (2016). Market dynamics and innovation management on performance in SMEs: Multi-agent simulation approach. Procedia Computer Science, 91, 707- 714.

- Niewöhner, N., Asmar, L., Wortmann, F., Röltgen, D., Kühn A., & Dumitrescu, R. (2019). Design fields of agile innovation management in small and medium sized enterprises. Procedia CIRP, 84, 826-831.

- Oleśków, J., Stachowiak, A., Batz, A., & Fertsch, F. (2017). The level of innovation in SMEs, the determinants of innovation and their contribution to development of value chains. Procedia Manufacturing, 11, 2203-2210.

- Bagheri, M., Mitchelmore, S., Bamiatzi, V., & Nikolopoulos, K. (2019). Internationalization orientation in SMEs: The mediating role of technological innovation. Journal of International Management, 25(1), 121-139.

- Kamalian, A., Rashki, M, Hemmat, Z, & Jolfaie, S. (2015) Cooperation networks and innovation performance of Small and Medium-Sized Enterprises (SMEs). International Journal of Management, Accounting and Economics, 2, 233-243.

- Rahab, S. (2015). Innovativeness model of small and medium enterprises based on market orientation and learning orientation: Testing moderating effect of business operation mode. Procedia Economics and Finance, 4, 97-109.

- Rifat, K., Meltem, Y., & Gultekin, A. (2016). Is the relationship between innovation performance and knowledge management contingent on environmental dynamism and learning capability? Evidence from a turbulent market, Business Research, 2.

- Xing, X., Wang, J., & Tou, L. (2019). The relationship between green organization identity and corporate environmental performance: The mediating role of sustainability exploration and exploitation innovation. International Journal of Environmental Research and Public Health Public Health, 16, 6.

- Xin, Z., & Sun, B. (2016). The influence of Chinese environmental regulation on corporation innovation and competitiveness. Journal of Cleaner Production, 112, 1528-1536.

- Maletič, M., Maletič, D., Dahlgaard, J., Dahlgaard-Park, S., & Gomiscek, B. (2015). Effect of sustainability-oriented innovation practices on the overall organizational performance: An empirical examination. Total Quality Management & Business Excellence.

- Conesa, I., Soto-Acosta, P., & Palacios, M. (2016). Corporate social responsibility and its effect on innovation and firm performance: An empirical research in SMEs. Journal of Cleaner Production.

- Pittawat, U., & Alisara, J. (2017). Enhancing the innovation of small and medium enterprises in food manufacturing through Triple Helix Agents. Kasetsart Journal of Social Sciences.

- Apanasovich, N., Alcalde, H., & Parrilli, M. (2016). The impact of business innovation modes on SME innovation performance in post-Soviet transition economies: The case of Belarus. Technovation, 57–58, 30-40

- Castela, B., Ferreira, F., Ferreira, J., & Marques, C. (2018). Assessing the innovation capability of small- and medium-sized enterprises using a non-parametric and integrative approach. Management Decision, 56(6), 1365-1383

- De Martino, M., & Magnotti, F. (2018). The innovation capacity of small food firms in Italy. European Journal of Innovation Management, 21(3), 362-383.

- Kritsadee, P., Sanguan, L., & Somnuk, A. (2017). Factor affecting innovativeness of small and medium enterprises in the five southern border provinces. Kasetsart Journal of Social Sciences, 38(3), 204-211.

- Kim, M., Park, J., & Paik, J. (2018). Factors influencing innovation capability of small and medium- sized enterprises in Korean manufacturing sector: facilitators, barriers and moderators. International Journal of Technology Management, 76(3-4).

- Guo, Y., Wang, L., Wang, M., & Zhang, X. (2019). The mediating role of environmental innovation on knowledge acquisition and corporate performance relationship—A study of SMEs in China. Sustainability, 11.

- Guzman, G., Garza-Reyes, J., Pinzón-Castro, S., & Kumar, V. (2018). Innovation capabilities and performance: Are they truly linked in SMEs? International Journal of Innovation Science.

- Giulia, B. (2016). A support system to manage product and process changes in manufacturing. IFAC-Papers Online, 49(12), 1080-1085.

- Gasparetto, W., Egger, G., Giusti, A., Rauch, E., Riedl, M, & Matt, D. (2018) Intelligent workpiece carrier for distributed data collection and control in manufacturing environments. Procedia Manufacturing, 24, 190-195.

- Suthep, B., & Chiwapon, N. (2019). A fuzzy logic combined with lp model for performance evaluation to distribute purchase orders in cluster manufacturing. Procedia Manufacturing, 30, 19-25.

- Singh, S., Udoncy, E., & Musa, S. (2016). Development of sustainable manufacturing performance evaluation expert system for small and medium enterprises. Procedia CIRP, 40, 608-613.

- Bilal, M., Sanin, C., & Szczerbicki, E. (2019). Smart Virtual Product Development (SVPD) to enhance product manufacturing in industry 4.0. Procedia Computer Science, 159, 2232-2239.

- Reza, H., Ray, Z., & Xun, W. (2018). A survey study on industry 4.0 for New Zealand manufacturing. Procedia Manufacturing, 26, 49-57.

- Torn, I., & Vaneker, T. (2019). Mass personalization with industry 4.0 by SMEs: A concept for collaborative networks. Procedia Manufacturing, 28, 135-141.

- Silva, J., Mojica Herazo, J., Rojas, R., Pineda, R., Morgado, R., & Varela, N. (2019). Early warning method for the commodity prices based on artificial neural networks: SMEs case. Procedia Computer Science, 151, 1243-1248.

- Constantinescu, C., Francalanza, E., & Matarazzo, D. (2015). Towards knowledge capturing and innovative human-system interface in an open-source factory modelling and simulation environment. Procedia CIRP, 33, 23-28.

- Zygiaris, S. (2017). Innovation Chain Intelligence (ICI). International Journal of Management Technology, 4(2), 13-21.

- Sivalogathasan, V. (2016). How to improve innovation capability? : The role of intellectual capital and organizational motivation of manufacturing firms in Sri Lanka. Journal of Business Management.

- Aulawi, H. (2018). Improving innovation capability trough creativity and knowledge sharing behavior. IOP Conference Series: Materials Science and Engineering, 434.

- Pedron, C., Picoto, W., Colaco, M., & Araújo, C. (2018). CRM system: The role of dynamic capabilities in creating innovation capability. Brazilian Business Review, 15, 494-511.

- Ossi, Y., Jukka, S., Porras, J., & Vesa, H. (2019). Innovation capabilities as a mediator between big data and business model. Journal of Enterprise Transformation.

- Adamides, E., & Karacapilidis, N. (2020). Information technology for supporting the development and maintenance of open innovation capabilities. Journal of Innovation & Knowledge, 5(1), 29-38.

- Álvarez-Castañón, L., López-Lira, A., & Estrada-Domínguez, J. (2019). Open innovation as evolutionary path to increase SMEs’ capabilities. Revista Espacios, 40, 20.

- Bullon, J., González, A., Hernández, A., & Queiruga, A. (2017). Manufacturing processes in the textile industry. expert systems for fabrics production. Advances in Distributed Computing And Artificial Intelligence Journal, 6, 41-50.

- Santiago-Santiago, K., Laureano-Cruces, A., Antuñano-Barranco, A., Domínguez-Perez, O., & Sarmiento-Bustos, O. (2015). An expert system to improve the functioning of the clothing industry. International Journal of Clothing Science and Technology, 27, 1.

- Shih-Wen, H., Chu-Hsuan, L., Rong-Qi, C. (2016). An intelligent system for fashion colour prediction based on fuzzy C-means and gray theory. Color Research & Application, 42, 2.

- Vinod, S., & Poonkuzhali, S. (2018). Improvising the sales of garments by forecasting market trends using data mining techniques. International Journal of Pure and Applied Mathematics, 119(7), 797-805.

- Sánchez, M., Aguilar, J., Cordero, J., Valdiviezo-Díaz, P., Barba-Guamán ,L., & Chamba-Eras, L. (2016). Cloud computing in smart educational environments: Application in learning analytics as service. New Advances in Information Systems and Technologies. Advances in Intelligent Systems and Computing, 444, 993-1002.

- Aguilar, J. (2013). Different dynamic causal relationship approaches for cognitive maps. Applied Soft Computing , 13, 271-282.

- Aguilar, J., Cerrada, M., Mousalli, G., Rivas, F., & Hidrobo, F. (2005). A multiagent model for intelligent distributed control systems. Lecture Notes in Computer Science, 3681, 191-197.

- Aguilar ,J. (2001). A general ant colony model to solve combinatorial optimization problems. Revista Colombiana de Computación, 2, 7-18.

- Aguilar, J., Salazar, C., Velasco, H., Monsalve-Pulido, J., & Montoya, E. (2020). Comparison and evaluation of different methods for the feature extraction from educational contents. Computation, 8.

- Araujo, M., Aguilar, J., & Aponte, H. (2003). Fault detection system in gas lift well based on artificial immune system. In Proceedings International Joint Conference on Neural Networks, 3, 1673-1677.

- Packianather, M., Davies, A., Harraden, S., Soman, S., & White, J. (2017). Data mining techniques applied to a manufacturing SME. Procedia CIRP, 62, 123–128.

- Zimmerling, C., Dörr, D., Henning, F., & Kärger, L. (2019). A machine learning assisted approach for textile formability assessment and design improvement of composite components. Composites Part A: Applied Science and Manufacturing, 124.

- Klement, N., Silva, C., & Gibaru, O. (2017). Solving a discrete lot sizing and scheduling problem with unrelated parallel machines and sequence dependent setup using a generic decision support tool. In Proceedings IFIP International Conference Advances in Production Management Systems, 513, 459–466.

- Pfrommer, J., Zimmerling, C., Liu, J, Kärger, L., Henning, F., & Beyere, J. (2018). Optimisation of manufacturing process parameters using deep neural networks as surrogate models. Procedia CIRP, 72, 426-431.

- Murphy, R., Newell, A., Hargaden, V., & Papakostas, N. (2019). Machine learning technologies for order flowtime estimation in manufacturing systems. Procedia CIRP, 81, 701-706.

- Zhou, Y., Wang, M., Chen, R., Wang, Y., & Wang, J. (2019). Research on application of SME manufacturing cloud platform based on micro service architecture. Procedia CIRP, 83, 596-600.

- Weldeslasie, D., & Ahmed, D. (2019). The application of expert systems in manufacturing sector. International Journal of Innovative Technology and Exploring Engineering, 9(1), 4744-4749.

- Arjmandi, M., Ramezani, M., Giordano, M., & Schmid, S. (2017). Finite element modelling of sliding wear in three-dimensional woven textiles. Tribology International, 115, 452-460.

- Siebert, F. (2019). Research, development and innovation: The challenges of Chile and Italy amid the current technological irruption.

- Interaction Design Foundation. (N.D). Literature topics design thinking. What is design thinking?

- Ries, E. (2008). The lean startup method. Deusto, Barcelona.

- Carayannis, E.G., & Campbell, D.F. (2009). Mode 3 and Quadruple Helix: Toward a 21st century fractal innovation ecosystem. International journal of technology management, 46(3-4), 201-234.