Research Article: 2021 Vol: 25 Issue: 4S

Supply Chain Management and Logistics Service Competency Influencing Logistics Performance of Palm Oil Entrepreneurs in Southern Thailand

Phutthiwat Waiyawuththanapoom, Suan Sunandha Rajabhat University

Preecha Wararatchai, Suan Sunandha Rajabhat University

Abstract

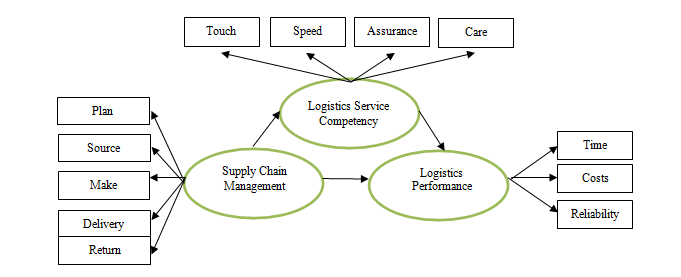

The palm oil industry in the country are suitable for implementing logistics and supply chain management systems in business administration since it is a highly competitive industry. This research, therefore, aims to study the levels of Supply Chain Management (SCM), Logistics Service Competency (LSC) and Logistics Performance (LP) of palm oil entrepreneurs in Southern Thailand, to study the direct effect of SCM on LSC and LP, and to study the indirect effect of SCM on LP. The sample was 300 palm oil entrepreneurs in Southern Thailand listed in the database of the Department of Internal Trade, Ministry of Commerce of Thailand, arisen from 20 times of the variables in the research model and stratified random sampling by area, divided into upper and lower southern regions. The research instrument was a questionnaire. The statistics used for data analysis were frequency, percentage, mean, standard deviation, confirmatory factor Analysis, and structural equation modelling. The results showed that the SCM, LSC, and LP were at a high level. In addition, SCM had a positive direct effect on LSC and LP and had a positive indirect effect on LP by the mediation effect of LSC. These findings can be guidelines for palm oil entrepreneurs to improve the business's logistics performance. Government agencies, besides, can use the research results to formulate a policy for helping palm oil entrepreneurs. Moreover, academicians and interested people can bring the findings to study and conduct additional research in the future.

Keywords

Logistics Performance, Logistics Service Competency, Palm Oil Entrepreneur, Supply Chain Management

Introduction

The major industries in the country are all suitable for implementing logistics and supply chain management systems in business administration, especially industries that use crude palm oil as raw materials because it is a highly competitive industry, the needs of customers are diverse, and the product has a short life cycle and is rapidly changing. It can be seen that the adoption of logistics and supply chain management systems in the industry will help operators to compete in the global market (Coyle et al., 2003) by mainly aiming to reduce inventory costs and create added value in every activity (Sorat, 2007).

The Supply Chain Management (SCM) of oil palm entrepreneurs, mostly in the southern Thailand, involves 4 main divisions: Fresh palm producers, yard, crude palm oil extraction plants, and refined palm oil refineries and industries that use crude palm oil as raw materials. The productivity of Thai palm oil, however, is less than those in Indonesia and Malaysia. This is because Thai farmers' logistics and supply chain management efficiency is lower in terms of the selection of oil palm cultivars, palm fruit maintenance, harvesting and storing of palm oil, and transportation cost management (Office of the National Economic and Social Development Council, 2020). For the improvement of Logistics Performance (LP) (Mert et al., 2011) and Logistics Service Competency (LSC) (Goldsby & Stank, 2000), it was found that SCM is an essential factor because it is a management system with a concept that focuses on the continuous coherence of all sections, whether they are alliances or suppliers, to achieve the interests of all parties (Paniangthong, 2005).

From the background and importance of the above problems, this made the researchers interested in studying the factors that can enhance the LSC and LP of the palm oil entrepreneurs in the southern Thailand as a guideline for improving the SCM of the palm oil. It is also beneficial to promote the ability to provide LSC of entrepreneurs involved in the palm oil industry and lead to increase LP of the palm oil entrepreneurs in the country.

Literature Review

Logistics Performance

Logistics Performance (LP) refers to the performance in planning and controlling the flow of raw materials and products, including the distribution of products to the market until the consumer, by which the organization or production process is appropriate and cost-effective. Therefore, LP covers the measurement of sourcing raw materials, packing, loading and unloading, the delivery-receiving process, organizing various transportation infrastructures, including road systems, rail systems, ports, airports, customs and warehouses, etc. The Logistic Performance Index (LPI) was established by the World Bank. In the context of Thailand, Industrial Logistics Performance Index (ILPI) was determined by Department of Primary Industries and Mines (2020) to be used as a benchmark to measure the LP of entrepreneurs in the same industry as well as other 24 industries and 88 sub-sectors to promote the improvement and development of the organization towards logistics standards and be able to enhance customer Service and reduce total logistics costs by measuring operational efficiency using ILPI assessment, comprising 9 logistics activities, 3 dimensions, and 27 indicators. The study, therefore, divides LP into 3 dimensions: cost, time, and reliability (Hausman et al., 2012).

Supply Chain Management

Council of Supply Chain Management Professionals (2013) defines Supply Chain Management (SCM) that are related to logistics that SCM is the view of logistics from external organization by incorporating customers and suppliers. SCM is the connection of planning-oriented activities, coordination and control of raw materials, and parts and goods from the supplier to the customer by focusing on the flow of two components, namely raw materials and information (Pintuma et al., 2020). SCM, furthermore, is an operation that extends from the internal level to the cooperation among the organizations in relation to manufacturers from upstream, midstream and downstream or from the purchasing department until the product is distributed to the end consumers (Phrapratanporn et al., 2019). In other words, SCM is a method of integrating various departments from supplier, manufacturers, warehouses, and stores together effectively to ensure that production and distribution of goods are carried out correctly in terms of right quantities, right place, and right time, with the goal of minimizing the cost of the entire system and responsiveness to the level of service that customers require (Sorat, 2007; Aunyawong et al., 2020). In the study, SCM comprises 4 dimensions: Plan, Source, Make, Delivery, and Return (Hammel et al., 2002; Akintoye et al., 2000).

Logistics Service Competency

Logistics Service Competency (LSC) refers to the ability of individuals from raw material manufacturers, processing factories, wholesalers, retailers, until the consumer to carry out the main activities, comprising transportation, inventory services, purchase orders, information services and related financial activities as well as supporting activities, consisting of warehouse management, product care, purchasing, packaging, and customer demand management. In addition to the activities that are directly related, such a process will require infrastructure which includes transport network, communication, information, and finance, including supporting factors such as relevant regulations. Furthermore, the scope is covered by the public and private sectors as well as local, national and global levels to create customer satisfaction by effective management. Past studies on LSC found that researches related to supply chain management describes the indicators of the service process in these 4 areas: Touch, Speed, Assurance, and care (Hammel et al., 2002; Chandra & Kumar, 2000; Gunasekaran, 2004; Zeng & Rosseti, 2003).

Hypothesis Development

Developing logistics performance of small and medium enterprises must focus on the internal factors of the organization containing understanding the division of labor, service quality, total costs, selection of qualified suppliers, partnerships with supply chain members, relationships with supply chain networks, and developing business Opportunities (Chen et al., 2019). In addition, supply chain management with a focus on internal integration will lead to production flexibility (Thaiprayoon et al., 2019). This will help business organizations improve logistics performance, especially in terms of cost reduction and delivery speed (Khalaf & Mohadem, 2019) Besides, supply chain management with the integration of internal and external data and joint decision making positively affects the logistics performance of container carriers (Lai et al., 2020).

Hypothesis 1: Supply chain management has a positive direct effect on logistics performance.

Supply chain management will result in better customer perception of the organization in logistics services and customer satisfaction in the B2B businesses (Gaudenzi et al., 2020). By allowing customers to participate, the business organization can develop effective logistics services (Yu et al., 2018). Moreover, supply chain management that aims to build relationships between partners in the supply chain will create customer satisfaction with the company's logistics services (Doganay & Ergun, 2017).

Hypothesis 2: Supply chain management has a positive direct effect on logistics service competency.

Logistics performance can be improved through logistics service competency which is a mediator on the effect of service culture on logistics performance (Luu, 2019). By focusing on human resource management based logistics competency, the firms achieve their goals (Jhawar et al., 2016). Furthermore, the development of service values and the ability to provide logistics services by taking into account the interests of customers as the main priority over the interests of the establishment will result in organizational logistics performance (Chao & Shih, 2016).

Hypothesis 3: Logistics service competency positively mediates the effect of supply chain management on logistics performance.

Research Methodology

Population and Sample

The population was 1,551 palm oil entrepreneurs in Thailand (Department of Internal Trade, 2020). The sample consisted of 300 palm oil entrepreneurs in Thailand, calculated from the sample size calculation according to the condition for using statistical analysis of the Structural Equation Modeling (SEM) was that the sample size was not less than 20 times the variables in the model because it makes the variables have a more normal distribution (Angsuchot et al., 2009; Hair et al., 2010). From the research conceptual framework, there were 3 latent variables and 12 observed variables, totaling 15 variables. Therefore, a sample of not less than or equal to 300 samples (15 x 20) was required for the data to be distributed as most commonly based on the principle of structural equation analysis for greater research reliability. The sampling was done by stratified sampling by area because the populations in the subgroups had the same business characteristics (Vanichbancha, 2010). The Demographic information of sample was shown in Table 1.

| Table 1 Demographic Information of Sample |

||

|---|---|---|

| Personal Information | (n=300) | Percentage |

| 1. Gender | ||

| Male | 161 | 53.7 |

| Female | 139 | 46.3 |

| 2. Age | ||

| Less than 30 years | 120 | 40 |

| 31 - 40 years | 138 | 46 |

| More than 40 years | 42 | 14 |

| 3. Marital Status | ||

| Married | 153 | 51 |

| Single | 147 | 49 |

| 4. Educational Level | ||

| Bachelor or Lower | 154 | 51.3 |

| Higher than Bachelor | 146 | 48.7 |

| 5. Business Type | ||

| SMEs | 204 | 68 |

| Partnership | 94 | 31.3 |

| Company Limited | 2 | 0.7 |

| 6. Source of Capitals | ||

| Self-Capital | 198 | 66 |

| Loan Capital | 102 | 34 |

| 6.1 Self-Capital | ||

| Less than 1 million Baht | 59 | 29.8 |

| 1 - 5 million Baht | 123 | 62.1 |

| More than 5 million Baht | 16 | 8.1 |

| 6.2 Loan Capital | ||

| Less than 1 million Baht | 70 | 68.6 |

| 1 - 5 million Baht | 20 | 19.6 |

| More than 5 million Baht | 12 | 11.8 |

| 7. Business Experience | ||

| Less than 1 year | 48 | 16 |

| 1 - 5 years | 140 | 46.7 |

| More than 5 years | 112 | 37.3 |

| 8. Authorized capital | ||

| Less than 1 million Baht | 86 | 28.7 |

| 1 - 5 million Baht | 158 | 52.7 |

| More than 5 million Baht | 56 | 18.6 |

| 9. Annual Revenues | ||

| Less than 1 million Baht | 28 | 9.3 |

| 1 - 5 million Baht | 142 | 47.3 |

| More than 5 million Baht | 130 | 43.4 |

Research Instrument

A questionnaire was an instrument used to collect data. The instrument accuracy was checked for validity and reliability. The validity consisted of content validity using IOC >0.5(Petchrot & Chamniprasat, 2004) and construct validity using Confirmatory Factor Analysis (CFA), while the reliability was checked for Cronbachs’ alpha coefficient >0.8 Cronbach (1990). For data interpretation, the researchers set the mean score range for interpreting to demonstrate the difference in the data by using 5-level Likert scale to interpret the meaning of the average score. The criteria for determining the weight of the assessment used a formula recommended by Best and Kahn (2006).

Data Analysis

First, demographic characteristics survey and the level of variables in the research were

analyzed using descriptive statistics, including percentage, mean, standard deviation, Skewness, and Kurtosis to measure the normal distribution of data in the analysis of SEM. Second, discriminant validity was tested based on Maximum Shared Variance (MSV)<Average Variance Extracted (AVE) and Average Squared Shared Variance (ASV)<AVE; Also, the latent variable's AVE should be greater than the squared correlation between the latent variable and all other variables. In addition, the convergent validity was tested taking into account that the composite reliability value must be greater than 0.7 and AVE > 0.5 (Fornell & Larcker, 1981). Third, CFA was used to check the construct validity of the questionnaire. Forth, direct and indirect effects between latent variables used path analysis to examine the research hypotheses. Fifth, SEM used six indicators (c2, c2 2/df, GFI, AGFI, RMR and RMSEA) to test the model fit based on hypothesis and empirical data with the criteria as proposed by Diamantopoulos & Siguaw (2000).

Research Results

Testing Results of Measurement Model

The results showed that the observed variables averaged between 4.00 – 4.45, which was at a high level and had a standard deviation between 0.69 and 0.83, by considering the skewness with values between -3 and +3 and kurtosis of<8 indicating a normal distribution (Kline, 2005). The factor loadings of all variables were positive and significantly different from zero at the 0.001 level. The variable with the most factor loading was Return (SCM_5) with a factor loading of 0.989 and the variable with the least factor loading was Make (SCM_3) with a factor loading of 0.664. In addition, R2 was from 0.441 to .0978, as shown in Table 2.

| Table 2 Testing Results of Measurement Model |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Variable | x̄ | S.D. | Remark | Sk | Ku | β | S.E. | t | R2 |

| SCM | 3.69 | 0.09 | High | - | - | - | - | - | - |

| Plan (SCM_1) | 3.67 | 0.69 | High | -0.674 | 0.664 | 0.794 | 0.053 | 16.618*** | 0.631 |

| Source (SCM_2) | 3.76 | 0.74 | High | -0.525 | 0.467 | 0.902 | <- -> | <- -> | 0.814 |

| Make (SCM_3) | 3.60 | 0.83 | High | -0.683 | 0.659 | 0.664 | 0.047 | 13.418*** | 0.441 |

| Delivery (SCM_4) | 3.82 | 0.74 | High | -0.477 | 0.247 | 0.765 | 0.052 | 14.887*** | 0.585 |

| Return (SCM_5) | 3.61 | 0.75 | High | -0.460 | 0.740 | 0.989 | 0.049 | 17.910*** | 0.978 |

| LSC | 3.59 | 0.08 | High | - | - | - | - | - | - |

| Touch (LSC_1) | 3.67 | 0.78 | High | -0.442 | 0.479 | 0.841 | 0.042 | 21.923*** | 0.768 |

| Speed (LSC_2) | 3.56 | 0.75 | High | -0.545 | 0.968 | 0.906 | <- -> | <- -> | 0.808 |

| Assurance (LSC_3) | 3.53 | 0.81 | High | -0.578 | 0.533 | 0.836 | 0.041 | 21.256*** | 0.746 |

| Care (LSC_4) | 3.60 | 0.80 | High | -0.379 | 0.086 | 0.881 | 0.055 | 15.295*** | 0.475 |

| LP | 3.63 | 0.06 | High | - | - | - | - | - | - |

| Time (LP_1) | 3.57 | 0.78 | High | -0.400 | 0.478 | 0.906 | 0.061 | 20.1888*** | 0.821 |

| Cost (LP_2) | 3.76 | 0.77 | High | -0.454 | 0.431 | 0.810 | 0.049 | 20.386*** | 0.656 |

| Reliability (LP_3) | 3.55 | 0.82 | High | -0.580 | 0.621 | 0.958 | <- -> | <- -> | 0.973 |

| Note: S.D.=Standard Deviation, Sk=Skewness, Ku=Kurtosis, β=Standardized Regression Weight, S.E.=Standard Error,*** p-value<0.001 | |||||||||

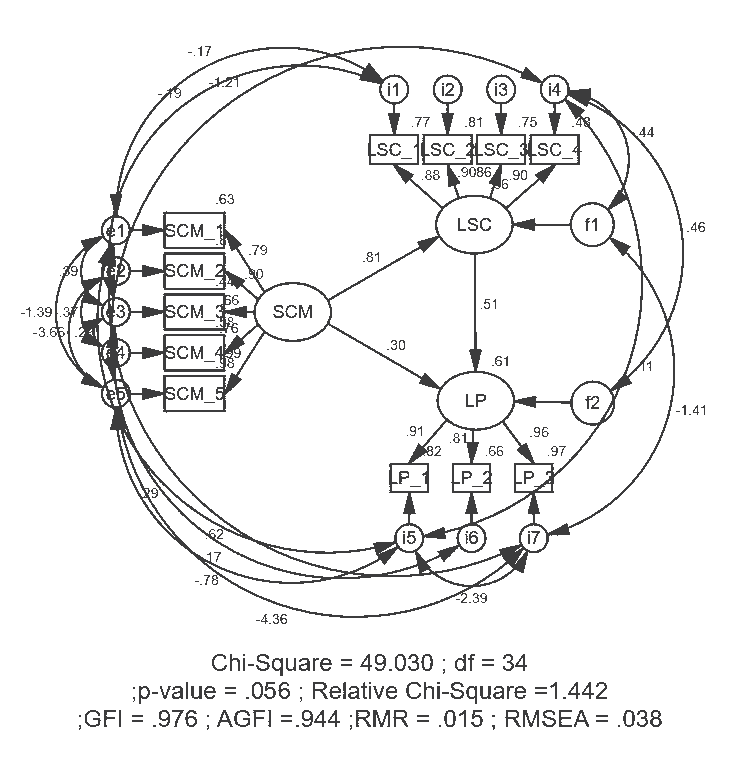

Path Analysis Results

The results of checking the structural validity of the model by analyzing the structural equation revealed that the model was consistent with the empirical data since it depicted that Chi-Square (CMIN)=49.030, df=34, p-value=0.056, Relative Chi-Square=1.442, GFI =0.976, AGFI=.944, RMR=0.015, RMSEA=0.038, so it indicated that the model had construct validity. As a result, H1-H3 was accepted with statistical significance at the 0.001 level, by which SCM had a positive direct effect on LP, with the effect size of .302 (S.E.=0.087; t-value=3.861), SCM had a direct effect on LSC, with the effect size of 813, SCM had a positive indirect effect on LP, with a LSC mediation effect size of .418 (S.E.=0.057; t-value=15.618), Moreover, SCM predicted SSCP by 66.2 percent and LP by 60.7%, as shown in Figure 2 and Table 3.

| Table 3 Testing Results |

||||||||

|---|---|---|---|---|---|---|---|---|

| H | IndependentVariable | Mediating Variable | DependentVariable | β | p-value | S.E. | t-value(C.R.) | R2 |

| H1 | SCM | - | LP | 0.302 | 0.000 | 0.087 | 3.861 | 0.662 |

| H2 | SCM | - | LSC | 0.813 | 0.000 | 0.057 | 15.618 | 0.607 |

| H3 | SCM | LSC | LP | 0.418 | 0.000 | - | - | - |

| Note: β=Standardized Regression Weight | ||||||||

Conclusion and Discussion

The findings depict that supply chain management, logistics service competency, and logistics performance of palm oil entrepreneurs in the southern Thailand is at a high level. This is consistent with Wang (2018); Huang, et al., (2021); Kaupa & Naude (2021); Khan, et al., (2021); Lambert (2017). In addition, first, supply chain management has a positive direct influence on logistics performance, consistent with Chen, et al., (2019); Khalaf & Mohadem (2019), and Lai, et al., (2020). Second, supply chain management has a positive direct effect on logistics service competency, in line with Gaudenzi, et al., (2020); Yu, et al., (2018); Doganay & Ergun (2017). Third, logistics service competency positively mediates the effect of supply chain management on logistics performance, in relation to Luu (2019); Jhawar, et al., (2016); Chao & Shih (2016).

For academic recommendations, government by the Office of Small and Medium Enterprises Promotion (OSMEP) and the Thai Logistics and Production Society (TLAPS), as well as educational institutions offering courses in logistics and supply chain management should jointly organize training and seminars to educate oil palm entrepreneurs on the development of supply chain management, whether it is in terms of plan, source, make, delivery, and return, because when palm oil entrepreneurs have more knowledge of supply chain management, it will surely make entrepreneurs have the ability to provide more logistics services competency, in terms of welcoming customers, speed of service, and caring, and increase logistics performance. For policy recommendations, government organizations and the private sectors should jointly support the development of oil palm business entrepreneurs to have quality in their operations and provide advices in terms of supply chain management, upgrading logistics service competencies, and including improving logistics performance. The government, moreover, should co-invest with palm oil entrepreneurs who need capital assistance and cooperate among various private sectors to help small and medium enterprises, including promoting the stable country's economy.

Acknowledgement

The corresponding author is Phutthiwat Waiyawuththanapoom from College of Logistics and Supply Chain, Suan Sunandha Rajabhat University, Thailand. The corresponding author’s e-mail is phutthiwat.wa@ssru.ac.th.

References

- Akintoye, A., McIntosh, G., Fitzgerald, E. (2000). A survey of supply chain collaboration and management in the UK construction industry. European Journal of Purchasing and Supply Management, 6, 159-168.

- Angsuchot, S., Vijittavanich, S., & Gulipinyopanuvat, R. (2009). Analytical statistics for social science research and behavioral sciences: Techniques for using LISREL Program, (3rd edition). Bangkok: Mission Media. (in Thai)

- Aunyawong, W., Wararatchai, P., & Hotrawaisaya, C. (2020). The influence of supply chain integration on supply chain performance of auto-parts manufacturers in Thailand: A mediation approach. International Journal of Supply Chain Management, 9(3), 578-590.

- Best, J.W., & Kahn, J.V. (2006) Research in Education, (10th Edition). Pearson Education Inc., Cape Town.

- Chao, M., & Shih, C.T. (2016). Customer service-focused HRM systems and firm performance: Evidence from the service industry in Taiwan. The International Journal of Human Resource Management, 29(19), 2804-2826.

- Chandra, C., & Kumar, S. (2000). Supply chain management in theory and practices: A passing fad or a fundamental change? Industrial Management and Data Systems, 100(3), 100-113.

- Chen, I.S.N., Fung, P.K.O., & Yuen, S.S.M. (2019). Dynamic capabilities of logistics service providers: Antecedents and performance implications. Asia Pacific Journal of Marketing and Logistics, 31(4), 1058-1075.

- Cochran, W.G. (1977). Sampling techniques, (3rd Edition). New York: John Wiley and Sons Inc.

- Council of Supply Chain Management Professionals. (2013). Supply chain management terms and glossary. Illinois: CSCMP.

- Coyle, J.J., Bardi, E.J., & Langley, J.C. (2003). The management of business logistics: A supply chain perspective, (7th Edition). South-Western, Mason: Ohio.

- Cronbach, L.J. (1990). Essentials of psychological testing, (5th edition). New York: Harper Collins.

- Department of Internal Trade. (2020). Palm oil entrepreneur list. Bangkok: Ministry of Commerce.

- Department of Primary Industries and Mines. (2020). Logistics and supply chain performance indices. Bangkok: Ministry of Industry.

- Diamantopoulos, A., & Siguaw, J.A. (2000). Introducing LISREL, Sage Publications.

- Doganay, A., & Ergun, S. (2017). The effect of supply chain collaboration on supply chain performance. Journal of Management, Marketing and Logistics, 4(1), 30-39.

- Fornell, C., & Larcker, D.F. (1981). Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research, 18(1), 39–50.

- Gaudenzi, B., Confente, I., & Russo, I. (2020). Logistics service quality and customer satisfaction in B2B relationships: A qualitative comparative analysis approach. The TQM Journal, 33(1), 125-140.

- Gunnasekaran, A., Patel, C., & Mcgaughey, R. (2004). A framework for supply chain performance measurement. International Journal of Production Economics, 87(3), 333-347.

- Hair, J.F., Black, W.C., Babin, B.J., & Anderson, R.E. (2010). Multivariate data analysis, (7th Edition). Prentice Hall, Upper Saddle River, New Jersey.

- Hammel, T., Phelps, T., & Kuettner, D. (2002). The re-engineering of HewlettPackard's CD-RW supply chain. Supply Chain Management: An International Journal, 7(3), 113-118.

- Hausman, W.H., Lee, H.L., & Subramanian, U. (2012). The impact of logistics performance on trade. Production and Operations Management, 22(2), 236-252.

- Huang, Y.C., Borazon, E.Q., & Liu, J.M. (2021). Antecedents and consequences of green supply chain management in Taiwan's electric and electronic industry. Journal of Manufacturing Technology Management.

- Jhawar, A., Garg, S.K., & Khera, S.N. (2016). Modelling and evaluation of investment strategies in human resources for logistics improvement. International Journal of Simulation and Process Modelling, 11(1), 36-50.

- Kaupa, F., & Naude, M.J. (2021). Critical success factors in the supply chain management of essential medicines in the public health-care system in Malawi. Journal of Global Operations and Strategic Sourcing.

- Khalaf, M.A., & Mokadem, M.Y.E. (2019). The relationship between internal integration and manufacturing flexibility in the Egyptian industry. International Journal of Quality and Service Sciences, 11(1), 16-33.

- Khan, M.I., Haleem, A., & Khan, S. (2021). Examining the link between Halal supply chain management and sustainability. International Journal of Productivity and Performance Management.

- Kline, R.B. (2005). Principles and practice of structural equation modeling, (2nd edition). New York: Guilford.

- Lai, P.L., Su, D.T., Tai, H.H., & Yang, C.C. (2020). The impact of collaborative decision-making on logistics service performance for container shipping services. Maritime Business Review, 5(2), 175-191.

- Lambert, D.M. (2017). The supply chain management and logistics controversy. Brewer, A.M., Button, K.J. and Hensher, D.A. (Ed.) Handbook of Logistics and Supply-Chain Management, (2nd Edition), Emerald Group Publishing Limited, Bingley, 99-126.

- Luu, T. (2019). Promoting logistics performance in Vietnam-based manufacturing firms: The role of service-oriented high-performance work systems and mediation mechanisms. International Journal of Physical Distribution & Logistics Management, 49(1), 52-74.

- Richey, M., & Chen. (2011). Logistics service orientation: An integrated strategy to build logistics service competency. Journal of Transportation Management, Spring/Summer, 27-47.

- Office of the National Economic and Social Development Council. (2020). Supply chain management of palm oil industry. Bangkok: NESDC

- Petchrot, L., & Chamniprasat, A. (2004). Research methodology. Bangkok: Phim Dee Printing Co., Ltd (In Thai)

- Phrapratanporn, B., Wararatchai, P., Aunyawong, W., & Rashid, N. (2019). Enhancing supply chain performance of SMEs in Thailand using the integrated personnel development model. International Journal of Supply Chain Management, 8(5), 176-186.

- Pintuma, S., Khaengkhan, M., Waiyawuththanapoom, P., & Aunyawong, W. (2020). Moderating effect of information sharing on the relationship of supply chain management capabilities and business performance: A study of the food industry. International Journal of Supply Chain Management, 9(2), 341-351.

- Sorat, T. (2007). Applications of logistics and supply chains. Bangkok: V-Serve Logistics.

- Thaiprayoon, K., Sawasdee, A., & Jermsittiparsert, K. (2019). Supply Chain Management in Smart Cities: Ensuring Sustainability through Flexibility in Thailand. International Journal of Supply Chain Management, 8(5), 780-791.

- Vanichbuncha, K. (2010). The principle of statistics, (12th edition). Bangkok: Thummasarn.

- Wang, M. (2018). Impacts of supply chain uncertainty and risk on the logistics performance. Asia Pacific Journal of Marketing and Logistics, 30(3), 689-704.

- Widodo, K.H. (2014). Sustainable supply chain based scenarios for optimizing trade-off between Indonesian furniture and crude-palm-oil industries. Operations and Supply Chain Management: An International Journal, 3(3), 176-185.

- Yu, K., Luo, B.N., Feng, X., & Liu, J. (2018). Supply chain information integration, flexibility, and operational performance: An archival search and content analysis. The International Journal of Logistics Management, 29(1), 340-364.

- Zeng, A.Z., & Rossetti, C. (2003). Developing a framework for evaluating the logistics costs in global sourcing processes: An Implementation and Insights. International Journal of Physical Distribution & Logistics Management, 33(9), 785-803.