Research Article: 2021 Vol: 25 Issue: 1S

Sustainable Supply Chain's Effect on Competitive Performance, A Case Study In Al Basrah Oil Company

Mohammed Ghanim Ahmed, Halabja University

Alaa Abdulzahra Alag Aldhaher, University of Manouba

Baqer Talib Abdulkdhim, University of Sfax

Abdullah Mohammed Sadaa, Universiti Sains Malaysia

Keywords

Sustainable, Developments in Industrial, Businesses Invest, Economic Productivity

Abstract

A common belief remains that there is a substantial perception of environmental effect on the organization’s operations. Nevertheless, the relationship between sustainable performance and competitiveness has been relatively minimal in the study. This study explores the impact of adopting sustainability considering this hat on the Basrah-oil sector's competitive performance. An empirical relationship between the features of sustainable supply chains and organizations’ productivity is established in the report. The goal is to develop an analytical model of the supply chain's sustainable characteristics that enhance resource utilization, maximization of benefit and competitiveness in the oil industry. The Basrah-Oil company collected the data collected through questionnaire surveys and collected primary data on sustainability and its effect on organizational efficiency. The findings show that promoting energy savings, rising market share, and enhancing productivity are the most critical sustainability drivers. The results also show that, while the respondent organization’s sustainability strategies differed in nature, they were implemented thoroughly and effectively. Usually, the introduction of sustainability in the oil supply chain contributes to improved economic efficiency and environmental performance, which positively impacts the company's competitiveness. Managers, ecologists, government decision-makers and academics are of particular interest in these studies.

Introduction

In order to achieve sustainability, developments in industrial manufacturing systems, in the type and quantities of resources utilized, in waste management, emission prevention and the produce of products (Yaqoob et al., 2020) are concerned. This suggests that the directions that lead to environmental sustainability in each sector may be different, but the purpose of those directions remains consistent (Ng et al., 2019). Businesses invest multiple resources to establish long-term strategies in various fields, such as environmental and economic productivity. Introducing these techniques is a costly process. Nevertheless, it has relatively positive returns on investment (Stead & Stead, 2008). Even though a company's production operations and supply chain activities are essential for inherent benefits, some indications not providing production operations and a company's supply chain activities are acceptable (Alnoor, 2020; Alnoor et al., 2020; Hadi et al., 2018; Zangnaa et al., 2020).

Mohammed, et al., (2018) suggested that today's most significant obstacle is maintaining the supply chain's sustainability. Because of the implications of the global economic downturn, which contributes to companies reducing budgets and relegating investments in sustainable activities to the past, it is becoming more necessary to illustrate the sustainability case for business purposes. Many studies have examined potential benefits and roles of sustainability in enhancing operational performance in restricted scenarios and without regard to the oil industry (Golini et al., 2014), considering that this is an industry that is strongly connected with global energies and environmental concerns. This research demonstrates how to introduce more sustainable technologies in the supply chains of oil. This gives better control over the disposal of old merchandise, eliminates waste, and offers more efficient approaches to mitigate emissions. Concretely, by minimizing and disposing of old inventory and waste, industry activities are now less environmentally friendly and more expensive (Al-Abrrow et al., 2019; Jabbar et al., 2020; Sadaa et al., 2020).

Despite the various advantages that manufacturing operations and supply chain activities create, they are not sustainable at the current pace because they seem to be running out of steam. Besides, the major challenge in the supply chain is ensuring the sustainability of it today is due to when economies frequently in decline, companies are forced to cut expenses and invest in less sustainable activities (Golini et al., 2014).

There is an increased difficulty explaining the business justification for sustainable practices due to this cut in investments (Rueda et al., 2017). Many studies have discussed different aspects of sustainability within the oil and gas sector (as an industry that must be productive in the face of global energy and environmental issues): Oil and gas prices and related petroleum demand volatility, environmental conservation policies, and the direct and indirect the influence of gas and oil on the supply chain of gas and oil, among others. This research investigates the degree of incorporation of sustainability in the supply chain for gas and oil. It also provides a link between the features and competitiveness of the sustainable supply chain.

The study purpose is to investigate the effect of introducing the sustainability program on the oil supply chain's corporate competitiveness. Before this review, only a few studies focused on identical actor-based supply chains have been performed. These studies find lasting discrepancies in organizational competitiveness, with the resilience of supply chains to shifts in sustainability the main characteristic to test. The bulk of the recent e-cigarette research has concentrated on environmental conservation and greenhouse gas emission reductions. The focus of this study is on justifying the viability of an oil supply chain after market-driven changes.

Literature Review

Introduction

This section discusses supply chain management (SCM), sustainable supply chain management (SSCM) and competing priorities. Besides, analyses of supply chain management definitions (SCM). Furthermore, it explores the concepts of sustainability and addresses sustainable development. And it addresses competitive sustainability targets. Just as follows:

Management for the Supply Chain (SMC)

Some writers describe SCM as an operational term that requires the movement of materials and products (Xu et al., 2020). Others see it as a management philosophy, while others see it as a system of management (Ruiz-Benítez et al., 2018). The conceptions of these entities form their SCM definitions. Below are some of the principles for supply chain management.

SCM is a practice of incorporation mainly responsible for connecting critical business functions and business processes inside and across enterprises into a coherent and high-performance business model (Council of Supply Chain Management Professional (CSMP), 2001:14. SCM handles value-added upstream and downstream movements between suppliers, enterprises, resellers, final content consumers, final goods, and relevant details (Okeagu et al., 2020). SCM is a collection of operations intended to manage and coordinate transfer tasks from suppliers of raw materials to final consumers (Ruiz-Benítez et al., 2018). SCM is the 'degree to which a corporation cooperates effectively with its supply chain stakeholders and handles intra- and inter- organizational processes collaboratively to produce effective and efficient transfers of products and services, information, money and decisions to deliver maximum value to the customer' (Craighead et al., 2020).

Sustainability

After its introduction, sustainability has been described in hundreds of different forms in numerous contexts and disciplines (Golini et al., 2014). The World Council on Environment and Growth (WCED) is the first sustainable term recognized internationally (Du Pisani, 2006:87). This identifies sustainability as 'development serving the needs of the present generation without the potential for future generations to fulfill their own needs' (WCDE, 1987, P. 8). This illustrates that choices now have corresponding effects for potential generations (Bell and Morse, 1999:54). Sustainability is a modern method of solving the current environmental crisis, meaning that progress does not degrade resources beyond the renewal level (WCED, 1987). Hyclick and Hockerts (2002) described corporate sustainability as 'meeting the requirements of a company's direct and indirect stakeholders (shareholders, staff, consumers, pressure group and communities), without losing its capacity to meet the needs of potential stakeholders as well as' (P. 131).

The point is not what sustainability implies, but what it means to take care of (Dresner, 2008). That does not mean that if a description is questionable, it has no significance at all. When a language community agrees on what they say, terms make sense (Jacob, 1991). As it depends on fiscal, environmental, and social aspects, there are several sustainability concepts, and each can provide its studies (Brown et al., 1997). Sustainability may also have many interpretations, as it is closely connected.

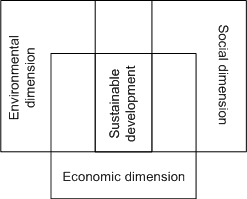

Triple Bottom Line (TBL or 3 BL) of Sustainability

Triple Bottom Line (TBL) is often referred to as foundations of sustainability, components of sustainability and components of sustainability, 3Es (Economic, Environmental and Equity) sustainability and 3Ps' sustainability (Profits, Earth and People). TBL originated in the 1990s at the Earth Summit in Rio de Janeiro in 1992 and proposed 27 concepts (Gopalakrishnan et al., 2012). The triple bottom line indicates that the economic, environmental and social bottom line of sustainability is equivalent to the focus of the company's operations (AL‐Abrrow et al., 2020). Financial, environmental, and social bottom lines are tied together in a complex cause and effect structure. Because progress does not result in depleting land, the habitat will not be maintained as growth leads to environmental harm (Dyllick & Hockers, 2002:77). Thus, an objective (sustainability) is important for the convergence of environmental policy and development strategies (WCED, 1987:45).

Three environmental concerns need to be integrated into supply chains (Linton et al., 2007:11). In this vertical integration, businesses are relying on other organizations for a large part of their income. The triple bottom line is still fractured (Gopalakrishnan et al., 2012:17). Due to decentralized 3BL, environmental effects are increasing due to procurement decisions, inventory processes, shipping, accumulation of waste, substantial deforestation, depletion of resources and greenhouse emissions, contributing to climate change and global warming (Markley and Davis, 2007:15). Re-designing products and services, aligning fundamental business values and rendering production environmentally sustainable, incorporates environmental programmers that assist in changing energy, recycling, efficient waste management and complying with government regulations (Yusuf et al., 2012:18).

Sustainable Supply Chains

However, several meanings have been recorded in the recent phenomenon of sustainable supply chain management, including.

According to MacDonald's (2004), the sustainable supply chain is one that realises development by understanding the social, economic, and environmental implications of its policies and actions; and that supply chains must also care to protect the environment from the adverse effects of their policies and efforts while generating financial gains and attending to the needs of stakeholders (Jennings & Zandbergen, 2005). Similarly, sustainable supply management in the systematic alignment of key inter-organizational business processes to enhance the individual company's long-term economic success and supply chains is a strategic, consistent integration and achievement of the social, environmental, and economic objectives of an organization (Carter & Rogers, 2008).

The sustainable supply chain inventory handles, information, and capital flows by translating fiscal, financial, and social priorities into customer and stakeholder needs accounts (Seuring & Muller, 2008). To create a truly sustainable supply chain, the specific measures required require management, intending to achieve a truly sustainable supply chain (Pagell & Wu, 2009).

The sustainable supply chain refers to all forward processes in the chain, such as resource sourcing, manufacture, and delivery, as well as reverse processes for the storage and disposal of returned used or discarded items and or parts of items, to ensure a socio-economic and ecologically viable recovery (Bloemhof & Nunen, 2005:17; Huang, Yan & Qiu, 2009:22). Sustainable supply chain management is the coordination and synchronization of commercial, environmental, and social activities throughout the supply chain to improve the physical, environmental and social efficacy of businesses in the supply chain (Kaynak & Montiel, 2010:18). It also identified sustainability objectives through the procurement and supply phase, combining social, economic, and environmental elements (Walker & Jones, 2012).

Sustainable Supply Chain Management (SSCM)

Sustainable Supply Chain Management (SSCM) expands SCM's reach to environmental and social challenges and aims to discuss all sustainability dimensions in the supply chain's design and optimization (Seuring & Müller, 2008a; Bai & Sarkis, 2010; Gold et al., 2010:112). The introduction of ethical supply chain operations is relatively recent but has been growing for more than a decade, and the concept is being applied globally (Kleindorfer et al., 2005; Seuring et al., 2008; Seuring & Muller, 2008b; Pagell & Wu, 2009; Vermeulen & Seuring, 2009; Buyukozkan & Cifci, 2010; Kuik et al, 2011; Gopalakrishnan et al., 2012). Sustainable supply chain management is also a method of introducing sustainability in the organization, with existing methods having certain drawbacks in detailing those (Haake & Seuring, 2009). The emphasis on supply chains is a step towards sustainable adoption when the supply chain communicates with the product from initial raw material production to retail distribution. Sustainability must also involve issues and flows outside the supply chain management center: Commodity development, by-products of output, product usage results, an extension of product existence, end-of-life product and processes of end-of-life recovery (Linton et al., 2007). It is important to address the organizational consequences of different methods and how businesses should implement sustainability into their supply chains (Linton et al., 2007).

Sustainable supply chain management is when modern brand goods reach past the traditional point of consumption in the first-order supply chain. This point of consumption is then related to the end of origin in the second-order supply chain, namely the second-hand goods market. From birth in the first-order supply chains, the second-order supply chains should be considered by corporate guidelines. Most items on the market are no longer made entirely from non-renewable materials but are produced from renewable and recycled energy sources (Svensson, 2007).

The partnership between suppliers and target companies is the core feature of a supply chain that deploys sustainability. Organizational efficiency, beneficial environmental benefits, resource reductions, adaptability to ever-changing demands, technology advances, energy recycling and mitigation of carbon emissions will result in a secure procurement relationship (Simpson & Power, 2005). A practical, sustainable supply chain will safeguard critical quality control processes, quality management of manufacturers, environmental management practices green supply management and management of customer relations, human resource sustainability, and business code of ethics and expanded code of conduct (Kaynak & Montiel, 2010). Such factors related to successful company practices include product returns; reduction of sources; recycling; product replacement; content reuse; waste disposal; refurbishment; repair; and re- manufacturing (Stock, 1998:11). The common denominator is that both need a holistic approach beyond the narrow point of origin and final limits of supply chain descriptions in the literature (Svensson, 2007, pp. 263). Initially,' eco supply chain',' green packaging' and 'sanitary goods' centred on enhancing the manufacturer's brand to minimize environmental impacts (Chaabane, 2011:18).

Sustainable supply chain Indices

Sustainability metrics may be divided generally into three economic indicators, environmental indicators, and social indicators. There are several indicators of composites (Alhamdi et al., 2019; Alnoor et al., 2018; Hadi et al., 2019; Abbas et al., 2020).

Indicators of Economic

Economic measurements are those which show differences in the financial capacity of the studied method. Regarding its owners, economic metrics financially classify all facets of business operations; show the organization’s financial system, financial legitimacy, and other economic interaction components (GRI, 2002).

There are economic pattern indicators calculated using two approaches: the evaluation of discount rates for resource depreciation and the average production factor (TFP). The definition of discount rates in sustainability was first initiated by Barbier (1989), Pearce, et al. (1990). Discount prices are based on the definition of intergenerational resources or more on the narrow non-renewable capital term of its predecessor (Meadows et al. (1972). Those economic metrics include:

Indicators of Environmental

Manufacturing firms utilize these measures to analyze the level of mineral production and the degradation of the ecosystem. Ecological metrics describe the impacts of corporate processes on living and non-living animals, such as ecosystems, soil, water, and assistance (Crabtree & Bayfield, 1998; Azapagic, 2003; Labuschagne, 2004; Martins et al., 2007; Delai & Takahashi, 2011). In the early 1970s, after the US Council on Environmental Quality (CEQ) formation, environmental indicators became common (Rogers et al., 2008).

The method used for assessing environmental measures is the calculation of resource depletion discount rates. An ecological and economic pattern indicator can be used to estimate discount rates for resource depletion and emissions (Abdulaali et al., 2019). In this situation, the factor is not monetary amounts, but total units (e.g., tons of parts per million). Likewise, this technique is primarily used for the systemic exploitation of resources and long-term waste, such as gas emissions or global warming. These physical equations are also used as a basis for economic valuation, often to extrapolate industrial growth capacity and constraints. More value should be added to biological measures; monetary metrics should be used as a replacement. The following descriptions of environmental indicators include:

Indicators of Social

The purpose of social indicators is to transform facets of intergenerational capital into meaningful numbers or, at least, operationalized terms (Singh et al., 2012). The overall organizational relationships with staff, vendors, contractors and consumers were formed in the social impact index (Azapagic, 2003; Delai & Takahashi, 2011). Approaches to the quantification and operationalization of social variables should be carefully confined to those components that quantitative or analytical approaches and methods can substantially define (Hardin, 1991). The most direct equity quantification includes calculating capital distribution (Ness et al., 2007; Singh et al., 2012).

It seems that such a numerical concept could have some limitations that need to be taken into account. This is because it is focused on a static interpretation of circumstances and social and cultural conventions and pretends that individuals are not valid. People differ in their capacity, how they use and respect their wealth, and are conscious of social justice (Delai & Takahashi, 2011). Some standard social metrics in literature include.

Competitive Performance & Competitive Advantage

The Competitive Performance or Competitive Advantage Definitions

The economic benefit generated by organizations is a competitive success or competitive advantage (Helfat, 2007:18). Competitiveness is an organizational condition of superior efficiency when a firm competes successfully either on pricing or by offering a premium for differentiation. It evolves out of the admiration of the customer of what a corporation makes. It aims to create a successful and sustainable role against the factors that define market competitiveness (Porter, 1985:66). Besides, value is determined by the degree of satisfaction that a customer subjectively releases. It can be accomplished by manufacturing creativity, productivity, and efficiency, leading to lower costs or better quality. Competitiveness could be better protected by setting a position early that would be difficult for rivals to emulate. It can be calculated by both financial metrics and the perceived profit of customers. Many studies have discussed competitive advantages; a resource-based perspective (routine-based view) and a market-based idea are included.

On the other side, have centred on building dynamic skills that can contribute to strategic gains. This research addressed the Resource-Based View (RBV), Market-Based View (MBV) and organizational capabilities/competitive priorities. This research uses a resource-based viewpoint as it focuses on the implementation of sustainability in the Basra-oil company, which requires sufficient capital for sustainability implementation. Competitive priorities also refer to competitive dimensions and 'competitive abilities' (Hendry, 2010). Competitive objectives are an essential part of internal contingency with corporate capacities (Peng et al., 2011:65). Competitive marks are priorities and targets that guide market management (Koufteros et al., 2002:75). For profitable businesses, these are key growth drivers that impact earnings (Snaddon, 1996). Therefore, they are critical for competition and growth, formation, contest, and competitiveness management (Gunasekaran & McGaughey, 2002:22). Effective programs and action plans are implemented to meet these targets, including improvements in the production policy decision-making method, such as capacity, infrastructure, vertical alignment, quality control, human resource management, production strategy and reporting processes and production monitoring processes (Hallgren et al., 2010, p. 513).

In an operational strategy, the cumulative approach to the achievement of enhanced skills is concerned. Therefore, various scholars viewed the incremental model differently, with a similar simple structural function of successive progression (Hallgren et al., 2010). For example, cost, quality, Speed, and Flexibility (Boyer & Lewis, 2002). Others characterise them as Innovation, Dependability, Customisation, & Relationship Management (Miller & Roth, 1994; Christiansen et al., 2003: Corbett & Van-Wassenhove, 1993; Frohlich & Dixon, 2001). They were implemented in order of delivery, pace and essential design capability by Hill (2000). According to Gunasekaran & McGaughey (2002), expense, speed, reliability, consistency, and usability are competitive measurements. Slack (1991) states that speed, durability, performance, and resilience lead directly and indirectly to low-cost manufacturing.

The first series was similarly presented by an empirical finding from North America and Japan: quality and distribution, followed by cost and flexibility (Nakane, 1986; Ferdows et al., 1986; DE Meyer et al., 1989). A few years later, they were discovered in reverse order by Ferdows & DE Meyer (1990), versatility, expense, distribution and quality. Quality, reliability, versatility, flexibility, agility and finally, effectiveness are the sequence for building sustainable supply chain capabilities (Vokurka et al., 2002).

Although quality and on-time delivery are essential for all manufacturing companies, some companies emphasize cost efficiency and versatility (market competition). In contrast, others emphasise flexibility by low cost-efficiency focus (when competing on differentiation and a wide product range with high-profit margins). There is a debate on additional parts, however (Christiansen et al., 2003). For instance, to better understand the competitive landscape facing businesses, Miller & Roth (1994) added a framework on service-related variables. Furthermore, Hendry (2010) added customization and order repeats. The focus is on how strategic goals direct decisions on leadership practices, technology, production processes and capacity (Peng et al., 2011). Study on operations management utilizes cumulative approaches to strategic goals (Hallgren et al., 2010).

Cost: A low-cost position encourages businesses to employ competitive prices and a high sales volume; companies may realise considerable benefits resulting in a cost-profit compared to rivals (Hart & Ahuja, 1994). Companies target a role in an attractive market by defensible expense or distinction and hold their competitors off-balance through strategic acquisitions, pricing tactics and signals (Day, 1994).

Speed: Speed is the company's ability to produce fast orders, execute delivery commitments and reduce production lead times (Boyer and Lewis, 2002). Rate offers accurate and prompt information to businesses about inventory orders and requirements. Shorten the lead times between companies by eliminating time compression difficulties. Synchronizes of lead times and capacities between the supply chain layers or levels further work will flow in a synchronized way up and down the chain (Peng et al., 2011:12). Increasing speed ensures that the material spends less time in inventory, minimizing the expense of direct material and overhead storage (Richardson & Snaddon, 2011:36).

Flexibility: Flexibility is the company's willingness to adjust tactics reasonably rapidly with minimum capital from low-cost suppliers to fast product growth (Hayes & Pisano, 1994:19). It is an adaptive solution to environmental uncertainty; it is used by businesses to respond efficiently and successfully to a vibrant market (Vickery et al., 1999:56). Flexibility is the manufacturers' ability to make fast design and volume adjustments, adapt capability rapidly, have a wide range of product features and varieties, product mix and changeover (Slack, 1991:76). Moving from one commodity to another causes no loss of production (Richardson & Snaddon, 2011:12).

Quality: Quality can fulfill the customer's specified and implicit expectations or customer satisfaction and loyalty (International Organization for Standardization, 2000, cited in Gryna, 2001). Others see it as conforming to the specifications (Crosby, 1996:54). Quality is multi-dimensional and can be viewed in numerous ways: eight quality components are recognized by Garvin (1988): efficiency, characteristics, reliability, perceived quality, conformity, longevity, serviceability and aesthetics. Quality has internal and external dimensions (Juran & Godfrey, 1999). Quality capabilities are the basis for another cost (efficiency), delivery (responsiveness) and flexibility capabilities. Quality eliminates rework, scrap, and waste (Richardson & Snaddon, 2011). An observational finding indicates that, regardless of the capacity to create high-quality service at a fair price, consumers renew contracts with an organization (Perunovic' et al., 2012).

Similarly, quality preparation begins with the consumers and their needs being discovered and goods developed that lead to those needs (Eneizan et al., 2019). Identification of a procurement approach is the primary goal of the quality planning process. For quality preparation, monitoring, and improvement; confidence between supply chain members is also essential (Donovan & Maresca, 1999:54).

Innovation: Innovation opportunities occur both within businesses (process, product and service innovation) and within companies (co-innovation). Since businesses do not work in isolation, the potential for co-innovation is provided through collaborations between firms. Co-innovation occurs when stakeholders have a common goal, complementary systems and procedures, prospects for mutual gain and cooperation, and faith and engagement are present (Bonney et al., 2007:98). Innovativeness can make sustainable companies. Different rivals have perfected numerous skills and may deliver better quality, more efficient service or more creative goods, and to compensate the competitors, a parity company can lower the costs. (Pagell & Wu, 2009:65).

Dependability: The focus of reliability should conform to the business's delivery requirements from the supplier to the consumer. To satisfy delivery conditions, processes and procedures for preparing ahead for suppliers and consumers, efficient control of the internal business and supplier capacity and synchronization between companies is essential (Slack, 1991). More excellent reliability will lower overhead costs by chasing late delivery and rescheduling production (Richardson & Snaddon, 2011).

Customization: In recent years, customization has gained a lot of attention; mass customization and related supply chain build-to-order will improve productivity (Gunasekaran and Ngai, 2005). Increased customization of supply chains that have traditionally manufactured uniform goods has evolved due to a growing demand for consumers to receive a degree of individualism in either the products they receive or how they are distributed to them (Hendry, 2010).

Relationship Management: Dimensions such as engagement, coordination, interdependence, confidence, involvement, communication/information, and knowledge exchange have been defined in relationship management (Mohr & Spekman, 1994; Lee & Kim, 1999; Lee, 2001).

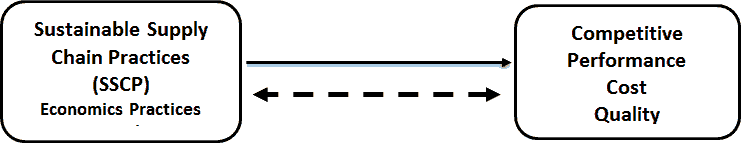

Theoretical Research Model

Research Hypothesis

H1 There is a significant correlation relationship between sustainable supply chain practices and Competitive performance.

Sub hypothesis:

H2 There is a significant effect of sustainable supply chain practices on cost advantage.

H3 There is a significant effect of sustainable supply chain practices on quality advantage.

H4 There is a significant effect of sustainable supply chain practices on Speed advantage

H5 There is a significant effect of sustainable supply chain practices flexibility advantage.

H6 There is a significant effect of sustainable supply chain practices on innovation advantage.

Research Methods

This study introduced the quantitative analysis approach. Via a questionnaire survey, data was collected from the Basrah-Oil company in Iraq. The questionnaire was as pilot-tested and using the pilot study results. The questionnaire was reviewed. The reviewed questionnaire was then validated by Alpha Cronbach and used to conduct a general survey of research organizations from the oil supply chain. In our research organization, the questionnaire was administered for sampling through direct interviews. For this study, the questionnaire was adopted because it is easy and accurate to assist. The questionnaire also has the advantage and many respondents, of reaching very busy executives during short periods. This study's target respondents were the managers of all corporate research divisions; they are individuals with the broadest company knowledge and experience to discuss all aspects of the survey. Furthermore, sustainability implementation is seen as a managerial responsibility that only managers are best positioned to account for their companies' performance (Ahmed et al., 2021). The data obtained were analysed using the Social Science Statistical Package program (SPSS).

Statistical Results And Discussion

Statistical results

The survey responses (SPSS® version 21) for windows were entered to conduct a statistical review of the administered questionnaire's data. The analysis tool SPSS allows the frequency means and standard deviation of the data obtained from the sample to be computed. It also allows for thorough statistical analyses such as data similarity analysis between the different classifications of the research theme for association checking or discrepancies between the reacting organizations to the report.

Descriptive and Distribution Statistics of Research Variables

An alternative normality approach is a calculation of descriptive and distribution statistics. It is carried out to follow the 'assumptions' created by individual evaluations. Checking of hypotheses involves gathering descriptive statistics of the study variables chosen. The set of ratings, mean, standard deviation, skewness, and kurtosis are informative statistics. Skewness value gives an indicator of distribution symmetry and kurtosis provides details regarding the distribution's 'pawedness'; Skewness and kurtosis value of '0' is produced if the distribution is entirely regular (an unusual phenomenon in social sciences) (Pallant, 2010:13).

Table (1) indicates that most of the variables favour skewness and kurtosis, with some negative skewness and kurtosis values. This does not generally mean a scale challenge but represents the calculated construct's inherent essence (Pallant, 2010). Skewness will not cause a significant difference in the study if the sample is comparatively high. Kurtosis will contribute to underestimating the variance, but this probability is often reduced (Tabachnick & Fidell, 2007). Table (1) states that it is possible to consider the distribution as natural. From the normality study performed in Figure 5.1, it can be inferred that the data collection follows the usual distribution condition that the sample is taken from a normally distributed population.

| Table 1 Descriptive and Distribution of Research Variables |

|||||||

|---|---|---|---|---|---|---|---|

| Research Variables | Min | Max | Mean | Std. Dev. | Skew | Kurtosis | |

| Environmental Sustainability | Environmentally Friendly Production Process | 1 | 5 | 3.96 | 0.606 | 1.008 | 0.153 |

| Wastes Reduction Wastes | 1 | 5 | 3.81 | 0.546 | -0.094 | -0.013 | |

| Emission Free Production | 1 | 5 | 3.87 | 0.561 | 0.276 | 0.516 | |

| Uses Renewable Resources | 1 | 5 | 3.04 | 0.643 | 0.797 | 0.288 | |

| Reuses Scraped Materials | 1 | 5 | 3.85 | 0.573 | -0.001 | -0.089 | |

| Social Sustainability | Openness Culture | 1 | 5 | 3.83 | 0.656 | 1.165 | 0.668 |

| Fair And Equitable Practices | 1 | 4 | 3.93 | 0.625 | 0.275 | 0.444 | |

| Health And Safety | 1 | 4 | 3.89 | 0.526 | 0.253 | 2.331 | |

| Employment Opportunities | 1 | 4 | 3.9 | 0.6 | 0.292 | 0.842 | |

| Ethical Business & Transparency | 1 | 3 | 3.82 | 0.557 | -0.049 | -0.054 | |

| Economical Sustainability | Profit Growth | 1 | 5 | 3.24 | 0.797 | 0.463 | 0.989 |

| Inventory Reduction | 1 | 5 | 3.97 | 1.078 | 0.01 | -0.4 | |

| Market Share Growth | 1 | 5 | 3.02 | 1.273 | -0.034 | -0.955 | |

| Efficient Supplier | 1 | 5 | 2.81 | 1.234 | 0.072 | -0.704 | |

| Value Added Maximization | 1 | 5 | 3.19 | 1.036 | 1.15 | 1.126 | |

| Speed | 1 | 5 | 3.53 | 0.92 | 0.097 | -0.178 | |

| Cost | 1 | 4 | 3.31 | 0.86 | 0.211 | -0.551 | |

| Competitive Performance | Flexibility | 1 | 5 | 3.37 | 0.88 | 0.418 | 0.282 |

| Quality | 1 | 5 | 3.53 | 0.92 | 0.097 | -0.178 | |

| Innovation | 1 | 4 | 3.31 | 0.86 | 0.211 | -0.551 | |

Correlation Analysis

| Table 2 Correlation Of Sustainable Supply Chain Dimensions And Competitive Performance Dimensions. *: Correlation Is Significant At .05 Levels (2-Tailed). **: Correlation Is Significant At .01 Levels (2-Tailed). |

|||||

|---|---|---|---|---|---|

| Variables | Speed | Quality | Flexibility | Cost | Innovation |

| Environmental Sustainability | -.196* | .257** | .255* | -.222* | .234* |

| -0.042 | -0.007 | -0.055 | -0.021 | -0.015 | |

| Social Sustainability | -.255** | .234* | 0.119 | 0.226* | 0.311** |

| -0.008 | -0.015 | -0.066 | -0.0311 | -0.009 | |

| Economic Sustainability | 0.242 | 0.246** | 0.213* | .280** | 0.321 |

| -0.086 | -0.018 | -0.055 | -0.003 | -0.077 | |

The association of environmental mitigation strategies and the following competitive variable is seen in Table (2): Expense, efficiency, versatility and pace reducing emissions, waste and prices by manufacturing environmentally conscious goods. Preventing emissions will contribute to substantial reductions that can minimize manufacturing costs compared to rivals. Reducing costs may contribute to efficiency increases at lower retail rates. Low market rates contribute to better sales churn (the lower the prices, the higher the volume (demanded or sold). Higher revenue churn contributes to higher net profit, as its market share often rises due to sales turnover increases.

Significant associations between environmental sustainability and competition are also seen in the Table (2). This validates the literature that environmental sustainability practices contribute to increased Research and Development (R&D), contributing to a spike in creativity. The secret to creativity is sustainability. Sustainability is a mechanism of transformation of clear action strategies that improve the system's infrastructure and creativity.

The important link between new economic sustainability and the following competitive priorities is demonstrated in Table (2): Expense, efficiency, versatility, and pace. Financial benefits, such as cost reductions may promote the usage of emerging technology. There is a clear connection between environmental understanding and the competitiveness of a business.

Table (2) also reveals that economic sustainability is strongly associated with the following strategic objectives: Expense, efficiency, versatility, and pace for competitors. via material usage control, recycling, and environmentally conscious packaging schemes make market enterprises gain savings and productivity. The environmental advantages are accomplished by refining the distribution systems, both in terms of packaging and transport. Reuse of packaging lowers consumption of raw materials and minimizes manufacturing cycles. For the same cause, landfill packaging would be limited. Besides, until recycled, other issues linked to the handling of waste are eliminated. Due to the contamination of detergent residuals, conventional packaging poses problems with the process; however, the unsafe disposal of packaging with potential dispersion of the internal residual detergent is reduced.

Table (2) also reveals a strong connection between social sustainability and the following competitive goals: Expense, efficiency, pace, and versatility. The relationship may be defined as the Basra-oil business was interested in analyzing its success in the general atmosphere for social sustainability. This also illustrates that social sustainability in all research company operations contributes to more job prospects and increases protection. What is being measured is the pace at which the industrial manufacturing process minimizes environmental damage. Therefore, it is anticipated that businesses will announce the results of their sustainability appraisal to demonstrate how their sustainability efforts increase the climate's efficiency.

The Chi-square statistical test was performed to verify the study variables' associations and assess if there is a meaningful differential between sustainability characteristics and strategic targets. Table 4.40 illustrates that sustainability and corporate competitiveness have predictive importance. That's no big gap at 0.000 between environmental practices and corporate productivity. Therefore, the incorporation of sustainability in businesses has beneficial implications on the accomplishment of strategic targets.

| Table3 Chi-Square Statistics Of The Impacts Of Sustainability On Competitive Objectives |

||||

|---|---|---|---|---|

| Variables | N | Chi-Squared (X) | Df | P-Value |

| Speed | 30 | 66.702 | 16 | 0 |

| Quality | 30 | 40.872 | 12 | 0 |

| Flexibility | 30 | 61.834 | 16 | 0 |

| Cost | 30 | 81.288 | 12 | 0 |

| Innovation | 30 | 39.848 | 12 | 0 |

Table 3 demonstrates a connection between the introduction of sustainability and a company's productivity. That is, the introduction of sustainability could contribute to strategic targets being achieved. The cumulative effect of the introduction of sustainability in Basra-oil on the business's productivity in question is growing. Besides, suppose the study topic is reaffirmed as a theory. In that case, the alternative hypothesis will be agreed at a 5 percent level of validity (p≤0.05) that sustainability influences competitive efficiency.

Conclusion

This study's fundamental aim is to identify the Impact of Sustainable Supply Chain on Competitive Performance in the Basrah oil company. Additionally, the research proposed to justify competitive performance through sustainability implementation. Three attributes of the sustainable supply chain were discussed in this research. The aim is to investigate the impacts of sustainability implementation on corporate competitiveness of Basrah-oil supply chain. The sustainable supply chain has three components that include an economic, environmental and social component.

The results include the following:

• The outcome indicates that the Basrah oil business utilizes fiscal, environmental, and social metrics to measure and report its success in terms of sustainability.

• The results further demonstrate that the adoption of sustainability strengthens competitive targets.

• The study of associations indicates a significant statistical association between qualities of sustainability and strategic goals.

• The coefficient of regression indicates a substantial positive impact of sustainability on strategic goals.

• Similarly, the chi-square figures indicate that sustainability at a substantial 5 percent range (P<0.05) affects strategic goals. Taken together, the association measure, the regression analysis test, and the chi-square figures also show that the introduction of sustainability significantly impairs the accomplishment of strategic goals.

• The finding also shows that sustainability is an essential technique for achieving corporate resilience and indicates that the Basrah-oil corporation is no anomaly in this situation.

Recommendation

1. The Basrah-Oil business's top management must exploit their expertise and understanding of sustainability and its effect on competitive results.

2. The organization must strengthen the awareness of workers regarding the ways of achieving sustainability in everyday life.

3. Enhance sustainability by robust training and development initiatives for all organisation employees, especially the top, middle and executive managers.

4. The Basrah-Oil business's top management must promote and award all creative practices that increase sustainability across all supply chain operations.

5. To meet its strategic goals, Basrah-Oil must consider all facets of a reliable supply chain.

6. To increase the Basrah-Oil group's sustainability, top management must show a high dedication to environmental activities and behavior in the supply chain.

References

- Abbas, S., Hadi, A.A., Abdullah, H.O., Alnoor, A., … & Khaw, K.W. (2021). Encountering Covid-19 and perceived stress and the role of a health climate among medical workers. Current Psychology, 1-14.

- Abdulaali, A.R., Alnoor, A., & Eneizan, B. (2019). A multi-level study of influence financial knowledge management small and medium enterprises. Polish Journal of Management Studies, 19(1), 21-31.

- Abdullah, H., Ismail, I., Alnoor, A., & Yaqoub, E. (2021). Effect of perceived support on employee's voice behaviour through the work engagement: A moderator role of locus of control. International Journal of Process Management and Benchmarking, 11(1), 60-79.

- Ahmed, M.G., Ganesan, Y., Hashim, F., & Sadaa, A.M. (2021). The effect of chairman tenure on governance and earnings management: A case study in iraq. Journal of Asian Finance, Economics and Business, 8(3), 1-18.

- lhamdi, M., Alnoor, A., Eneizan, B., Abdulla, M., & Abdulaali, A.R. (2019). Determinants of the production system time (jit) on reduce waste: Case study in a salsal water company. International Journal of Academic

Research in Business and Social Sciences, 9(7), 17-32. - Alnoor, A. (2020). Human capital dimensions and firm performance, mediating role of knowledge management. International Journal of Business Excellence, 20(2), 149-168.

- Alnoor, A.M., Al‐Abrrow, H., Abdullah, H., & Abbas, S. (2020). The impact of self‐efficacy on employees' ability to accept new technology in an Iraqi university. Global Business and Organizational Excellence, 39(2), 41- 50.

- Al-Abrrow, H., Alnoor, A., & Abbas, S. (2019). The effect of organizational resilience and CEO’s narcissism on project success: Organizational risk as mediating variable. Organization Management Journal, 16(1), 1-13.

- Alnoor, A., Eneizan, B., Makhamreh, H.Z., & Rahoma, I.A. (2018). The effect of reverse logistics on sustainable manufacturing. International Journal of Academic Research in Accounting, Finance and Management Sciences, 9(1), 71-79.

- Bonney, L., Clark, R., Collins, R., & Fearne, A. (2007). From serendipity to sustainable competitive advantage: Insights from houston's farm and their journey of co-innovation. Supply Chain Management: An International Journal, 12 (6): 395-399.

- Boyer, K.K., & Lewis, M.W. (2002). Competitive priorities: Investigating the need for trade-offs in operations strategy. Production and Operations Management, 11(1): 9–20.

- Craighead, C.W., Ketchen, D.J., & Darby, J.L. (2020). Pandemics and supply chain management research: Toward a theoretical toolbox. Decision Sciences, 51(4), 838–866.

- Delai, I. and Takahashi, S. (2011). Sustainability Measurement System: A Reference Model Proposal. Social Responsibility Journal, 7 (3): 438-471.

- Eneizan, B., Mohammed, A.G., Alnoor, A., Alabboodi, A.S., & Enaizan, O. (2019). Customer acceptance of mobile marketing in Jordan: An extended UTAUT2 model with trust and risk factors. International Journal of Engineering Business Management, 11.

- Flynn, B.B., Sakakibara, S., Schroeder, R.G., Bates, K.A. & Flynn, E.J. (1990). Empirical Research Methods in Operations Management. Journal of Operations Management, 9(2), 250-284.

- Goodland, R. (1995). The concept of environmental sustainability. Annual Review Ecological System, 26 (1995), 1- 24.

- Golini, R., Longoni, A., & Cagliano, R,. (2014). Developing sustainability in global manufacturing networks: The role of site competence on sustainability performance. International Journal of Production Economics, 147, 448-459.

- Hadi, A. A., Alnoor, A., & Abdullah, H. O. (2018). Socio-technical approach, decision-making environment, and sustainable performance: Role of ERP systems. Interdisciplinary Journal of Information, Knowledge, and Management, 13, 397-415.

- Hadi, A. A., Alnoor, A., Ismail, E., Eneizan, B., & Makhamreh, H. Z. (2019). Psychological contract and organizational misbehavior: Exploring the moderating and mediating effects of organizational health and psychological contract breach in Iraqi oil tanks company. Cogent Business & Management, 6(1), 1683123.

- Hayes, R.H., & Pisano, G.P. (1994). Beyond world class: The manufacturing strategy. Harvard Business Review, 72, 11-20.

- Helfat, C.E., Finkelstein, S., Mitchell, W., Peteraf, M.A.,..& Winter, S.G. (2007) Dynamic Capabilities: Understanding Strategic Change in Organizations, Malden, MA: Blackwell.

- Hendry, L.C. (2010). Product Customization: An Empirical Study of Competitive Advantage and Repeat Business.

- International Journal of Production Research, 48(13): 3845–3865.

- Jabbar, A.K., Almayyahi, A.R. A., Ali, I.M., & Alnoor, A. (2020). Mitigating uncertainty in the boardroom: analysis to financial reporting for financial risk COVID-19. The Journal of Asian Finance, Economics, and Business, 7(12), 233-243.

- Kotzab, H., Teller, C., Grant, D. B., and Sparks, L., (2011). Antecedents for the adoption and execution of supply chain management. Supply Chain Management, an International Journal, 16(4): 231-245.

- Kotler, P., & Armstrong, G. (2008). Principles of Marketing, Twelfth edition, New Delhi, India: Prentice Hall Inc. Krajnc, D. & Glavic, P. (2003). Indicators of Sustainable Production. Clean Technology Environmental Policy, 5, 279-288.

- Mohammed, M.D., Talab, H.R., & Ali, O.S. (2018). Economic diversification and government sustainable supply chain governance: An empirical approach on government expenditure of Iraq. International Journal of Supply Chain Management, 7(6), 566–577.

- Newell, G., (2009). The Significance of Sustainability Best Practice in Retail Property. Journal of Retail and Leisure Property, 8(4): 259-271.

- Ng, T.W.H., Yam, K.C., & Aguinis, H. (2019). Employee perceptions of corporate social responsibility: Effects on pride, embeddedness, and turnover. Personnel Psychology, 72(1), 107–137.

- Pagell, M., & Wu, Z., (2009). Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of 10 Exemplars. Journal of Supply Chain Management, 45(2): 37–56.

- Porter, M.E. & Van Delinder, C. (1995). Towards a New Conception of the Environmental Competitiveness Relationship. Journal of Economics Perspectives, 9, 97-118.

- Richeson, L.L., Charles, W., & Starner, J.W. (1995). The Effects of Communication on the Linkages between Manufacturers and Suppliers in a Just-in-Time Environment. International Journal of Purchasing and Material Management, 31(1): 10-23.

- Rueda, X., Garrett, R.D., & Lambin, E.F. (2017). Corporate investments in supply chain sustainability: Selecting instruments in the agri-food industry. Journal of Cleaner Production, 142, 2480–2492.

- Ruiz-Benítez, R., López, C., & Real, J.C. (2018). The lean and resilient management of the supply chain and its impact on performance. International Journal of Production Economics, 203, 190–202.

- Sadaa, A.M., Ganesan, Y., & Ahmed, M.G., (2020). The effect of earnings quality and bank continuity: the moderating role of ownership structure and CSR. Journal of Sustainable Finance and Investment, 1–21.

- Shrivastava, P. (2010). Pedagogy of Passion for Sustainability. Academy of Management Learning and Education, 9 (3), 443-455.

- Slack, N., Chambers, A., Johnson, R. &Betts, A., (2006). Operations and Process Management Principles and Practice for Strategic Impacts, Cape Town: Prentice Hall.

- Stadtler, H. (2000). Improved Rolling Schedules for the Dynamic Single-level Lot-sizing Problem. Management Sciences, 48(2): 318-326.

- Stead, J.G., & Stead, W.E. (2008). Sustainable strategic management: an evolutionary perspective. International Journal of Sustainable Strategic Management, 1(1), 62.

- Stead, W.E., & Stead, J.G. (1995). An Empirical Investigation of Sustainability strategy Implementation in Industrial Organizations. Research in Corporate Social performance and Policy, 1(1995): 43-66.

- Svensson, G., (2007). Aspects of Sustainable Supply Chain Management (SSCM): Conceptual Framework and Empirical Example. Supply Chain Management: An International Journal, 12(4): 262-266.

- Tabachnick, B.G., & fidell, L.S. (2007). Using Multivariate Statistics, 5th edition, Boston; Pearson Education.

- Xu, X., Lee, S. Do, Kim, H.S., & You, S.S. (2020). Management and optimisation of chaotic supply chain system using adaptive sliding mode control algorithm. International Journal of Production Research, 1–17.

- Yaqoob, F.A., Mohammed, I. S., & Abdameer, W. (2020). Harmonize the pillars of corporate governance to achieve sustainability through earning quality In Iraqi banks Listed in the Iraq Stock Exchange. International Journal of Innovation, Creativity and Change, 14(10), 874–898.

- Zangnaa, M.G., Riyadh, H.A., Alfaiza, S.A., & Dananjoyo, R. (2020). The examination of consumer’s perceptions of perceived benefits towards the intention to continue seeking the online advertising. International Journal of Advanced Science and Technology, 29(8), 126–139.