Research Article: 2021 Vol: 25 Issue: 3S

Bench Test of the Multi- Function Coconut Husk Processing Machine

Frederick Villa, Southern Luzon State University

Abstract

The goal was to improve and test competitiveness of micro-scale coconut enterprises, particularly in rural regions, by designing and fabricating a combined coconut husk decorticator, chipper, and compost mixer machine. A cold roll shaft and a single 6hp diesel engine generator were used to connect three distinct machines. The decorticator is used to make coir dust and coir fiber from coconut husk. Chips are made from coconut husk using the chipper. The compost mixer is used to combine coir dust with biodegradable wastes. These integrated machines were designed to increase the usage of coconut husks, which are often overlooked by farmers and industries. Farmers may earn more and become more competitive by constructing this integrated decorticator, chipper, and mixer. The output of using many machines at the same time was as follows: (1) In an hour, the Decorticator machine processed 293 pieces of coconut husks, yielding 52.67 kg of fiber and 123.00 kg of dust. (2) With a product output of 151 kg, the chipper machine processed an average of 274 pieces of coconut husks each hour. (3) In an hour, the mixer blended 6.08 sacks of coir dust and 6.08 biodegradable trash.

Keywords:

Bench Test, Coconut Husk Processing Machine, Farmers and Industries

Introduction

In today's world, many farmers face difficulty in giving nutrients to their crops due to the high cost of fertilizers on the market. Many new strategies are being introduced to assist these impoverished farmers with their productive costs. Scientists and innovators all around the world are hard at work developing new equipment and materials in order to create a masterpiece that will aid these impoverished farmers financially. Many Filipino innovators would most likely propose various approaches and ideas to improve agricultural and industrial stability in the Philippines. The exposure of coconut husk in this study will aid in the discovery of low-cost fertilizers, allowing farmers to reduce their crop-feeding costs. For almost 60 years, several elements of the coconut husk have been employed in industries.

This study details the results of a performance test of the Multi-Function Coconut Husk Processing Machine, which will benefit farmers, industries, businesses, and homes in their daily lives. People can make better use of their resources with the help of these machines. Supplemented with an adoption theory that would ensure the coconut husk processing machine's future viability and marketability.

Because they interact with minerals and cling onto calcium, coconut husk makes excellent growth medications. This coconut husk is also certain to provide a variety of benefits. Manganese is particularly abundant in coconuts, and it is necessary for bone health as well as the metabolism of carbohydrates, proteins, and cholesterol. They're also high in copper, which is found in large amounts in red blood cells.

For these reasons, the study's primary goal is to evaluate the performance of a multi-function coconut husk processing equipment that will benefit people all over the world.

Conceptual Literature

According to (Filippone, 2007), the English name coconut comes from the Spanish and Portuguese word coco, which means "monkey face," since the three round indentation markings or "eyes" present at the base of the coconut resemble a monkey's face (Figure 1).

by © 2007 Peggy Trowbridge Filippone

(http://homecooking.about.com/bio/Peggy-Trowbridge-filippone-137.htm)

Coconuts are the fruits of the coconut palm, which is botanically known as cocos nucifera (meaning "nut-bearing"). The fruit-bearing palms are native to Malaysia, Polynesia, and Southern Asia, but are now also common in South America, India, the Pacific Islands, Hawaii, and Florida.

The coconut fruit's water, flesh, sugar, and oil can all be used in cooking. It can also be used as a dish and a cup.

Natives burned the husk for fire, but today coir, a seed fibre extracted from the husk, is used to manufacture brushes, carpets, fishnets, and rope. Coconut oil is a saturated fat derived from dried coconut meat that is used in commercial frying, sweets, and margarines, as well as non-edible goods like soaps and cosmetics. Coconuts take up to a year to mature, although the trees can bloom up to thirteen times a year. Fruit is constantly forming, ensuring a consistent harvest all year. An average harvest from one tree is roughly 60 coconuts, with some trees delivering three times that much.

Coconut refers to the whole coconut palm, the seed, or the fruit, although it is never considered a botanical nut. The Portuguese and Spanish coined the term cocos, which means "grinning face," to refer to the three holes that mimic human facial characteristics.

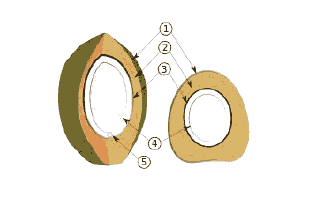

The exocarp/epicarp (1), mesocarp (2), endocarp (3), endosperm (4), and embryo (5) layers of the coconut have intimidating names (5). as shows in Figure 2.

The layers of a common coconut are depicted in the diagram above. The coconut husk is made up of the exocarp (1) and mesocarp (2). The exocarp (outermost layer) of coconuts marketed in non-tropical nation is frequently removed. The mesocarp is made up of coir fibers, which have a variety of traditional and commercial applications. Once the coconut has been de husked, layers 3, 4, and 5 are left. Once the husk is removed, the outermost shell (3) has three germination pores (stoma) or eyes that are clearly visible on its outside surface.

The palm tree (Cocos nucifera) grows up to 30 meters (98 feet) tall, with pinnate leaves that are 4–6 meters (13–20 feet) long and pinnae that are 60–90 cm long; old leaves fall away neatly, leaving the stem smooth. Coconuts are divided into two categories: tall and dwarf coconuts. A tall coconut palm tree on fertile terrain can produce up to 75 fruits each year, although most of the time it produces less than 30, owing to poor cultural practices.

Coconut Industry

According to the United States Library of Congress, after Indonesia, the Philippines is the world's second largest producer of coconut products. It produced 11.8 million tons in 1989. Coconut goods, coconut oil, copra (dry coconut), and desiccated coconut made up about 6.7 percent of Philippine exports in the same year. Coconut trees were grown on around 25% of cultivated land, and it is estimated that between 25% and 33% of the population was at least somewhat dependent on coconuts for their livelihood. Coconut production was formerly concentrated in Luzon's Southern Tagalog and Bicol areas, as well as the Eastern Visayas. Western Mindanao and Southern Mindanao were key coconut-growing regions in the 1980s.

The average coconut farm in the early 1990s was a medium-sized unit of fewer than four hectares. Instead of entering into tenancy agreements, absentee owners would hire local peasants to pick coconuts. On a piece-rate basis, the villagers were compensated. Those working in the coconut sector were less educated and older than the ordinary rural worker, and they earned lower-than-average wages. The United States Library of Congress (http://countrysides.us/Philippines/63.htm) is the source of this information.

Objectives of the Study

1) How does the multi-function coconut husk processing machine perform in terms of:

a) Coir fiber and dust are created.

b) Biodegradable garbage and coconut dust

c) Chips made from coconut husk

Methodology

Project/Research Design

This study included developmental research as well as experimental research methods. The machines' prediction abilities were determined using an experimental procedure that included a number of tests.

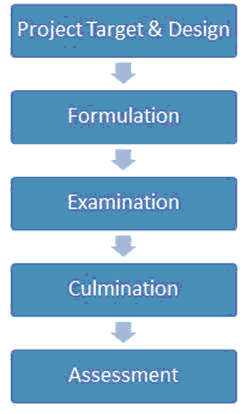

Project Development

The project's progress is depicted in the diagram above. It all began with a project plan and the creation of a series of interconnected coconut husk processing equipment. Following the completion of the plan, the fabricator assisted the researcher in fabricating the machines based on the design. The researcher then carried out tests to see if the machines were working as expected based on the design. Corrections were made to the machines before they were finalized, taking into account the results of the test for the adjustment of the machines with parts and fixes. The machines have been finalized based on the corrections and changes made as a result of the tests. The newly conceived and constructed machines were put to the test in order to determine their acceptance. as shows in Figure 3.

Results and Discussions

Test Result

Individually and simultaneously, the machines were put to the test. It was discovered that during the first test of the machine's operation using a 5Hp AC Induction Motor, the machines ran effectively for the first five minutes, but that after that, the operation did not work properly because the energy supply was insufficient, resulting in intermittent power and poor coconut husk processing. As a result, the researcher chose to switch the motor from an AC-powered 5 horsepower induction motor to a 6 horsepower diesel engine generator. The operation was subsequently brought back to normal as a result of this change and adjustment, yielding the following results (Table 1):

| Table 1 Performance Test of Mini-Decorticator Machine |

||||

|---|---|---|---|---|

| Description | Trial 1 | Trial 2 | Trial 3 | Average |

| Per hour, the number of coconut husks processed (pieces) | 300.00 | 295.00 | 290.00 | 295.00 |

| Produced Coconut Fiber Volume (Kilogram) | 54.00 | 52.00 | 51.00 | 52.33 |

| Coconut Dust Production Volume | 126.00 | 123.00 | 121.00 | 123.33 |

| One (1) hour of diesel usage (Liter) | 0.75 | 0.73 | 0.70 | 0.73 |

According to the Table 2 above, 295 pieces of coconut husks are processed in an hour. The average amount of fiber produced by the indicated coconut husk is 52.33 kilograms, whereas the average amount of coconut dust produced is 123.33 kilos. The average amount of fuel utilized per hour of operation is 0.73 liters. This simply proves that the coconut husk is made up of roughly 30% fibers and 70% dust.

| Table 2 Performance Test of Mini-Mixer Machine |

||||

|---|---|---|---|---|

| Description | Trial 1 | Trial 2 | Trial 3 | Average |

| Coconut Dust Volume Processed for One (1) Hour (common rice sack) | 6.00 | 7.00 | 6.50 | 6.50 |

| One (1) hours’ worth of biodegradable waste processed (common rice sack) | 6.00 | 7.00 | 6.50 | 6.50 |

| One (1) hour of diesel usage (Liter) | 0.76 | 0.74 | 0.71 | 0.74 |

The average coconut dust processed in one hour is 6.50, which is the same as the wastes because both materials were treated at the same time. The average amount of diesel consumed in an hour is 1.22 lit. as shows in Table 3.

| Table 3 Performance Test of Mini-Chipper Machine |

||||

|---|---|---|---|---|

| Description | Trial 1 | Trial 2 | Trial 3 | Average |

| The number of coconut husks that were processed during one hour (pieces) | 280 | 285 | 283 | 282.7 |

| For one (1) hour, the volume of coconut chips produced was (Kilogram) | 154 | 157 | 156 | 155.67 |

| Diesel Used for One (1) Hour (Liter) | 0.74 | 0.73 | 0.7 | 0.72 |

Table 3 above shows that the average coconut husk processed into chips is 282.70 while the volume of coconut chips produced has an average of 155.67 kilogram. The diesel used for an hour is 0.72 liters.

The Table 4 above shows that when the machines are used simultaneously, the average number of coconut husks processed each hour is 293 pieces. The average amount of fiber produced by the given coconut husk is 52.67 kilograms, whereas the average amount of coconut dust produced is 123 kilos. The average amount of fuel utilized per hour of operation is 0.83 liters.

| Table 4 Performance Test of the Machines |

||||

|---|---|---|---|---|

| Mini-Decorticator | Trial 1 | Trial 2 | Trial 3 | Average |

| The number of coconut husks that were processed during one hour (pieces) | 295 | 291 | 293 | 293 |

| Coconut Fiber Production Volume (Kilogram) | 53 | 51 | 54 | 52.67 |

| Produced Coconut Dust Volume (Kilogram) | 124 | 122 | 123 | 123 |

| For one (1) hour, diesel was used (Liter) | 0.85 | 0.8 | 0.83 | 0.83 |

Because both materials were processed at the same time, the mini-mixer had an average coconut dust processed within one hour of 6.08, as shown in the table above. The average amount of diesel consumed in an hour is 0.83 liters. as shows in Table 5.

| Table 5 Performance Test of the Machines (Simultaneous Used) |

||||

|---|---|---|---|---|

| Mini-Mixer | Trial 1 | Trial 2 | Trial 3 | Average |

| Volume of Coconut Dust Processed for One (1) Hour (common rice sack) | 5.5 | 6.5 | 6.25 | 6.08 |

| Volume of Biodegradable Waste Processed for One (1) Hour (common rice sack) | 5.5 | 6.5 | 6.25 | 6.08 |

| Diesel Used for One (1) Hour (Liter) | 0.85 | 0.8 | 0.83 | 0.83 |

The Table 6 above shows that during simultaneous usage of the machine, the mini-chipper processed an average of 274 coconut husks into chips, with an average volume of 151 kg of coconut chips generated. An hour's worth of diesel is 0.83 liters. The production of the processed coconut husks is affected by the simultaneous use of the machine, according to the statistics above. It could be due to the machine's increased load, particularly the generator. This is akin to a person operating a machine that is connected to a generator. This also indicates that the amount of diesel consumed was the same for all three machines because they all used the same source of energy, a 6-hp generator.

| Table 6 Performance Test of the Machines (Simultaneous Used) |

||||

|---|---|---|---|---|

| Mini-Chipper | Trial 1 | Trial 2 | Trial 3 | Average |

| The number of coconut husks that were processed during one hour (pieces) | 275 | 273 | 274 | 274 |

| For one (1) hour, the volume of coconut chips produced was (Kilogram) | 152 | 150 | 151 | 151 |

| For one (1) hour, diesel was used (Liter) | 0.85 | 0.8 | 0.83 | 0.83 |

Conclusions

1) The mini-decorticator can separate fiber and dust from the husk, the mini-mixer can combine coconut dust and biodegradable wastes, and the mini-chipper can cut and chip the coconut husk, according to test results.

2) The multi-function coconut husk processing machine may be built with locally sourced components and materials and requires the use of standard tools, machinery, and equipment.

3) The constructed machinery decorated or separated the fiber and dust from the husk, mixed the coconut dust and biodegradable trash, and cut or chipped the coconut husk very well.

Recommendations

1) Farmers should not concentrate just on the sale of coconuts; they should also evaluate the value of the coconut husk, which could help them make more money.

2) A researcher or even a farmer should be encouraged to utilize this type of multi-function coconut husk processing machine in their backyard or on their farm in order to optimize profits and apply the best technique of using natural compost for the plants.

3) Changes to the machine's design could be explored for larger sizes and maximum utilization or production.

4) More research should be done and included to improve the situation The machines' features and efficiency.

References

- Akaranta, O. (1996). “Wood finishes from modified coconut coir dust extract”. Pigmail and Resin Technology, 25(1), 11-15.

- Black, P.H., & Adams, E.O. (2006). Machine design. New York: Macmillan Co.Faires, V.M. (2002). Design of machine elements. New York: Mackmillan Co.

- Gosse link, R.J.A., Van der Putten, J.C., Van der Kolk, J.E.G., Dam, V., & Eugels, B.K. (2000). Vegetable fibre based geotextiles with adjusted durability. IECA annual conference, Palm Springs, USA.

- Hughes, A.U., & Bil, D. (2013). Electric motors and drives, fundamental types and Application, (4th Edition). Oxford, United Kingdom: Elsievier Limited.

- Naveen, H., James, S.J., & Stephen, W.N. (2008). Vitro suppresion of soilborne plant pathogens by coir. Department of Plant Pathology, University of Nebroska, NE68583. 2008-11-19, URL: http://www.agrococo.com/Pathogen-Suppression.pdf. Accessed: 2009 – 08 - 17.

- Hellstrom, L. (2010). On the wood chipping process-A study on basic mechanism in order to optimize chip properties for pulping. Sweden: Kopieringen Mittuniversitetet.

- Mathur, P.N., Muralidharan, K., Porthasathy, V.A., Batugal, P., & Bonnot, F. (2008). Data analysis manual for coconut researchers ISBN 978-92-9043-736-9

- Miller, R., & Miller, M.R. (2008). Industrial electricity and motor control. New York Mc Graw Hill.

- Ranganna, B.B., Ramakumar, V.M., & Said, P.P. (2011). Development and performance of nutmeg decorticator. The Mysore Journal of Agricultural Sciences, 4, 764-768.

- Salaverria, L.B. (2012), Coconut husk touted as next big PH export. Philippine Daily Inquirer. Retrieved December 27, 2014 from http://business.inquirer.net/65553/coconut-husks-touted-as-next-big-ph_export.

- Sarian, Z. (2010). New Coconut fields high. The Manila Bulletin, 11.

- Shansen, F., Yan, Z., & Zhaoyu, M. (2015). The design of coconuts automatic decorticator based on the PLC. Journal of Agriculturel Mechanization Research, 2.

- Spotts, M.F., & Shoup, T.E. (2000). Design of Machine Elements, (7th Edition). Upper Saddle River, New Jersey: Prentice Hall.

- Kijikar, S. ( 1991). “Handbook: Coconut husk as a potting medium”. ASEAN-Canada Forest Tree Seed Center Project, 3612-77-1.