Research Article: 2023 Vol: 26 Issue: 3S

Effect of Quartz Dust and Hydrated Lime on Concrete Strength Characteristic

Abdul Alim Ghayouri, Surface Water Manager of Baghlan River Basin

Abhishek Singh Rana, Surface Water Manager of Baghlan River Basin

Citation Information: Alim Ghayouri, A., & Singh Rana, A. (2023). Effect of quartz dust and hydrated lime on concrete strength characteristics. Journal of Management Information and Decision Sciences, 26 (S3), 1-7.

Abstract

Concrete is one of the highly utilized material in construction and consume large amount of natural resources in form of fine aggregates and coarse aggregates as well as while making cement lots of natural resources are used. In this research paper Quartz Dust and Hydrate Lime is used to prepare concrete mix and replaced with cement and fine aggregates respectively. Various tests on concrete are performed to check strength characteristics of concrete like Split Tensile Test, Flexural Strength Test and Compressive Strength Test are performed and contrasted with conventional concrete mix. Tests are conducted on M30 grade of concrete according to Indian Standards. Various mix samples of Quartz Dust and Hydrated Lime as (0%QD: 10%HL), (0%QD: 15%HL), (10%QD: 10%HL), (10%QD: 15%HL), (15%QD: 10%HL) and (15%QD: 15%HL) has been used.

Keywords

Hydrated Lime (HL), Quartz Dust(QD), Split Tensile Test, Flexural Strength Test, Compressive Strength Test.

Introduction

Usage of waste materials in concrete construction is becoming popular due to modernization of concrete industry. Several investigation has been carried out on utilization of these materials or other natural resources for replacing convention concrete materials. Quartz dust and Hydrated lime are great example of natural resources that can be utilized as replaced of conventional materials that are used in concrete mixing. Previous researches has showed that these two materials can be utilized as part replacement of conventional materials in PCC and optimistic results were observed (Table 1) .Quartz dust is waste obtain from cutting of quartz that contain high amount of silica that has similar properties to cement. Hydrated lime consisting lime can give more strength that conventional sand to concrete mix. These materials do not have any hazardous chemicals that can effect environment and due to this, concrete produced from these materials can be considered as environment friendly and useful in utilizing waste materials (Babu & Prakash, 1995).

| Table 1 Properties of Portland Pozzolona Cement Used | |

| Properties | Value |

| Specific Gravity | 3.1 |

| Consistency (%) | 35.50 |

| Starting time (min) | 30 |

| Final time (min) | 600 |

Materials and Properties

Cement

PPC is used for mixing in this research (Barbhuiya et al., 2009).

Fine Aggregates

Fine aggregates having size below 4.75mm are used in this research and were surface dry and free from any chemicals before being used in mixing process (BIS, 2000) Table 2.

| Table 2 Fine Aggregates with Fallowing Properties Used. | |

| Properties | Values |

| Specific Gravity | 2.72 |

| Bulk Density | 1631 |

| Fineness Modulus | 7.25 |

Coarse Aggregates

Coarse aggregates having size below 20mm being used in this research and were surface dry and free from any chemicals before being used in mixing process (Fernandez et al., 1997) Table 3.

| Table 3 Properties of Coarse Aggregates Used | |

| Properties | Values |

| Specific Gravity | 2.72 |

| Bulk Density | 1631 |

| Fineness Modulus | 2.7 |

Quartz Dust

Quartz are hard rock consisting high amount of Silica Oxide. Quartz are used widely in various construction and decorative works Table 4. Quartz Dust formed due to cutting of quartz stone and most of the time this dust goes to waste. Quartz dust is obtained from various stores and used in this research (Gunasekara et al., 2020).

| Table 4 Various Properties of Quartz Dust Used | |

| Properties | Values |

| Specific Gravity | 2.65 |

| Bulk Density | 1201 |

| Fineness Modulus | 4.2 |

Hydrated Lime

Hydrated lime is chemical mix of Calcium hydroxide. It is white in color and can be easily found in any hardware store Figure 1. Hydrated lime Table 5. This is used for various construction works as well as filtration of water in water treatment plant (Kumar et al., 2017).

| Table 5 Various Properties of Hydrated Lime Used | |

| Properties | Values |

| Specific Gravity | 2.2 |

| Bulk Density | 500 |

| Fineness Modulus | 1.7 |

Water

Normal water is used for mixing of concrete which is free from any chemicals, salt or destructive materials Figure 2. Similar water is also used for curing of samples as well (Marvila et al., 2019).

Mix Design

Mix design is performed by following IS Code - 456:2000 and designed for M30 grade of concrete having ratio of 1:1.74:2.73 by volume and W/C (0.45) has been used for preparing concrete mix (Kumar et al., 2016).

Experimental Work

Experimental work is preformed to check the result of Quartz dust and Hydrated lime on strength characteristics of concrete like Flexural Strength Test and Split Tensile and Compressive Strength Test are performed Figure 3. For this various number of samples are made which can be shown in Table 6 (Taha & Nounu, 2008).

| Table 6 Samples are Made which can be Shown | ||||

| Percentage of Quartz Dust and Hydrated Lime | Compressive Strength Test (Cube) | Split Strength Test (Cylinder) | Flexural Strength Test (Beam) | Total Samples |

| 0,0 | 6 | 6 | 6 | 18 |

| 0%QD:10%HL | 6 | 6 | 6 | 18 |

| 0%QD:15%HL | 6 | 6 | 6 | 18 |

| 10%QD:10%HL | 6 | 6 | 6 | 18 |

| 10%QD:15%HL | 6 | 6 | 6 | 18 |

| 15%QD:10%HL | 6 | 6 | 6 | 18 |

| 15%QD:15%HL | 6 | 6 | 6 | 18 |

Experimental work is preformed to check the strength characteristics of concrete like Flexural Strength Test, Split Tensile and Compressive Strength Test are performed (Tavakoli et al., 2018). For this various number of samples are made which can be shown in Table 6 (Walker, 2014).

Results and Discussion

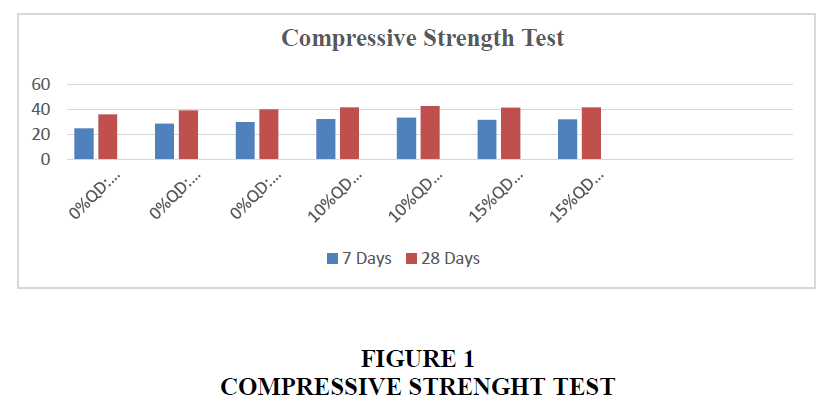

Compressive Strength Test

For compressive strength test specimen of concrete cubes (total 42) have been tested for seven and 28 days. Initial and final strength has been obtaining after seven and 28 days respectively. Cubes are tested in Compressive Testing Machine and results are shown in Table7.

| Table 7 Compressive Strength Test Results | ||

| Percentage of Quartz Dust and Hydrated Lime | Strength of cube after 7 days(N/mm^2) | Strength of cube after 28 days(N/mm/^2) |

| 0,0 | 25.00 | 36.07 |

| 0%QD:10%HL | 28.86 | 39.17 |

| 0%QD:15%HL | 29.98 | 40.12 |

| 10%QD:10%HL | 32.29 | 41.90 |

| 10%QD:15%HL | 33.53 | 42.86 |

| 15%QD:10%HL | 31.82 | 41.55 |

| 15%QD:15%HL | 32.19 | 41.08 |

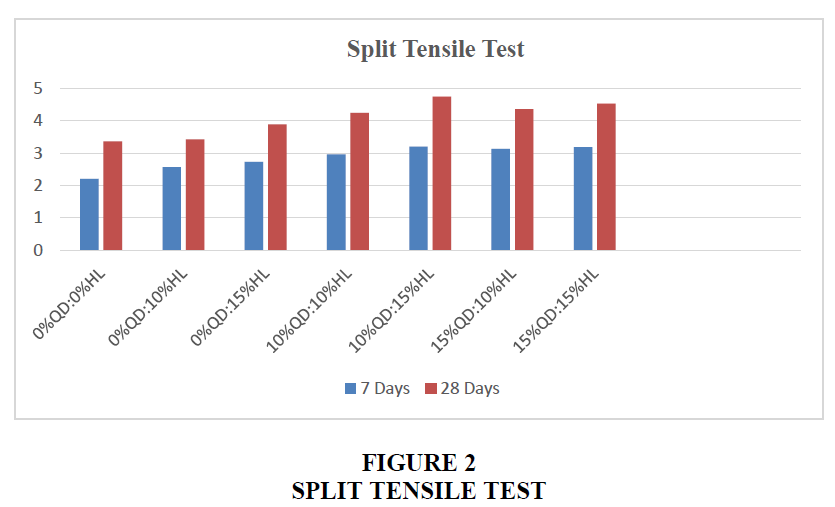

Split Tensile Test

Specimen of concrete cylinders have been tested for 7 days and 28days to find out initial and final split tensile strength of cylinders. Compressive testing machine is utilized to find strength. Results are shown in Table 8 (Standard, 2009).

| Table 8 Compressive Testing Machine is Utilized to Find Strength | ||

| Percentage of Quartz Dust and Hydrated Lime | Strength of cube after 7 days(N/mm^2) | Strength of cube after 28 days(N/mm/^2) |

| 0,0 | 2.21 | 3.37 |

| 0%QD:10%HL | 2.57 | 3.43 |

| 0%QD:15%HL | 2.73 | 3.89 |

| 10%QD:10%HL | 2.97 | 4.25 |

| 10%QD:15%HL | 3.21 | 4.75 |

| 15%QD:10%HL | 3.14 | 4.37 |

| 15%QD:15%HL | 3.19 | 4.54 |

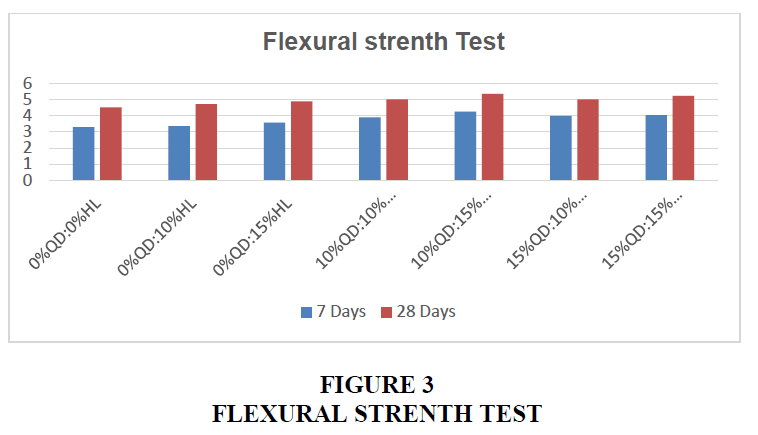

Flexural Strength Test

Specimen of concrete beams have been tested after7 days and 28 day of curing to find out initial and final flexural strength of beams. Flexural testing machine is used to determine strength of beams. Results are shown in Table 9.

| Table 9 Flexural Testing Machine is Used to Determine Strength of Beams | ||

| Percentage of Quartz Dust and Hydrated Lime | Strength of cube after 7 days(N/mm^2) | Strength of cube after 28 days(N/mm/^2) |

| 0,0 | 3.29 | 4.53 |

| 0%QD:10%HL | 3.35 | 4.73 |

| 0%QD:15%HL | 3.57 | 4.89 |

| 10%QD:10%HL | 3.89 | 5.02 |

| 10%QD:15%HL | 4.27 | 5.36 |

| 15%QD:10%HL | 3.99 | 5.02 |

| 15%QD:15%HL | 4.03 | 5.23 |

Conclusion

From above experimental work on Quartz Dust and Hydrated Lime following conclusion are as follows:

• From experimental work it is clear that there is better result at 10%QD:15%HL for all cubes, cylinder and beams

• Compressive strength increases till 10%QD:15%HL and after that it start decreasing for further values.

• Split Tensile strength increases till 10%QD:15%HL and after that start decreasing for further values.

• Flexural strength increases till 10%QD:15%HL and after that start decreasing for further values.

• From experimental work it is clearly observed that these two mixes can be used for concrete mixing and higher strength can be observed

• Quartz Dust and Hydrated Lime both can be considered as ecofriendly materials for concrete mixing.

References

Babu, K.G., & Prakash, P.S. (1995). Efficiency of silica fume in concrete. Cement and concrete research, 25(6), 1273-1283.

Indexed at, Google Scholar, Cross Ref

Barbhuiya, S.A., Gbagbo, J.K., Russell, M.I., & Basheer, P.A.M. (2009). Properties of fly ash concrete modified with hydrated lime and silica fume. Construction and Building Materials, 23(10), 3233-3239.

Indexed at, Google Scholar, Cross Ref

BIS, I. (2000). 456 (2000) Plain and reinforced concrete-Code of Practice. Bureau of Indian Standards, New Delhi, India.

Fernandez, J., Renedo, J., Garea, A., Viguri, J., & Irabien, J.A. (1997). Preparation and characterization of fly ash/hydrated lime sorbents for SO2 removal. Powder Technology, 94(2), 133-139.

Indexed at, Google Scholar, Cross Ref

Gunasekara, C., Sandanayake, M., Zhou, Z., Law, D.W., & Setunge, S. (2020). Effect of nano-silica addition into high volume fly ash–hydrated lime blended concrete. Construction and building materials, 253, 119205.

Indexed at, Google Scholar, Cross Ref

Kumar, S., Gupta, R.C., & Shrivastava, S. (2017). Long term studies on the utilisation of quartz sandstone wastes in cement concrete. Journal of Cleaner Production, 143, 634-642.

Indexed at, Google Scholar, Cross Ref

Kumar, S., Gupta, R.C., Shrivastava, S., Csetenyi, L., & Thomas, B.S. (2016). Preliminary study on the use of quartz sandstone as a partial replacement of coarse aggregate in concrete based on clay content, morphology and compressive strength of combined gradation. Construction and Building materials, 107, 103-108.

Indexed at, Google Scholar, Cross Ref

Marvila, M.T., Alexandre, J., Azevedo, A.R.G., Zanelato, E.B., Xavier, G.C., & Monteiro, S.N. (2019). Study on the replacement of the hydrated lime by kaolinitic clay in mortars. Advances in Applied Ceramics, 118(7), 373-380.

Indexed at, Google Scholar, Cross Ref

Standard, I. (2009). Guidelines for concrete mix design proportioning. Bureau of Indian Standard, New Delhi.

Taha, B., & Nounu, G. (2008). Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement. Construction and Building Materials, 22(5), 713-720.

Indexed at, Google Scholar, Cross Ref

Tavakoli, D., Hashempour, M., & Heidari, A. (2018). Use of waste materials in concrete: A review. Pertanika J. Sci. Technol, 26(2), 499-522.

Walker, R., & Pavia, S. (2014). Moisture transfer and thermal properties of hemp–lime concretes. Construction and Building Materials, 64, 270-276.

Indexed at, Google Scholar, Cross Ref

Received: 11-Jan-2023, Manuscript No. JMIDS-23-13125; Editor assigned: 13-Jan-2023, Pre QC No. JMIDS-23-13125(PQ); Reviewed: 27-Jan-2023, QC No. JMIDS-23-13125; Revised: 31-Jan-2023, Manuscript No. JMIDS-23-13125(R); Published: 07-Feb-2023