Research Article: 2020 Vol: 23 Issue: 4

Enterpreneurship Education for the Development of a New Product And Process Methodology Based On Circular Economy

Marcelo Albuquerque de Oliveira, Universidade Federal do Amazonas, Brazil

Laura Rocha, Universidade Federal do Amazonas, Brazil

Gabriela de Mattos Veroneze, Universidade Federal do Amazonas, Brazil

Fabiane Azevedo, Universidade Federal do Amazonas, Brazil

Antônio Cardoso, Universidade Fernando Pessoa, Brazil

Citation Information: de Oliveira, M.A., Rocha, L., de Mattos Veroneze, G., Azevedo, F., & Cardoso, A. (2020). Enterpreneurship education for the development of a new product and process methodology based on circular economy. Journal of Entrepreneurship Education, 23(4).

Abstract

Designing out waste and pollution as well as keeping products and materials in use and regenerating natural systems are the base for circular economy. This research presents an adapted product development methodology based on a circular economy that objectifies renewable resources and minimizing the production of residues. This new methodology comes from the necessity of modifying the liner model of product development for industries where a product that goes out never comes back. The adapted methodology will be put to the test in a case study product design made from plastic waste, a sub-product from an industry inside the industrial pole of Manaus–Amazon.

Keywords

Circular Economy, Product Design Process, Product Methodology.

Introduction

It is known that society, since the beginning, has used these resources was only a function of subsistence. Later, it was transcended to satisfy basic needs and began to aim at making a profit. During the First Industrial Revolution, which started in England in the 18th century, there was a milestone in the consumption of natural resources. Steam engines were created to replace and improve previous models of goods production. These machines worked through the combustion of mineral coal and were initially applied in the textile industry and later expanded to other segments. In the second half of the 19th century, the Second Industrial Revolution began, it brought novelties to the civilization, such as the invention of light and the discovery of oil and the combustion engine. From this industrial rise it is possible to affirm that each year, 6 million hectares of productive land become a desert (Keeble, 1988), causing a reduction in natural resources availability (Ahuti, 2015; Nelliyat, 2005) and increase in consumption of energy and waste per inhabitant.

One way of establishing sustainable development is by applying methodologies that cause the least amount of environmental damage and that consume the least amount of natural resources, especially if they are non-renewable. The purpose of this work is to apply the circular economy in a project where the flow of goods is optimized, minimizing the waste products as well as using assets that were considered by other companies as trash, in addition to always maintaining a constant creation of value that moves the product from one chain to another. This article will have a brief literature review and will propose a new product development methodology considering the circular economy and sustainable engineering.

Literature Review

To achieve the goal of creating a product, a set of activities must be carried out that makes it possible to reach the design specifications of a product and its production so that the manufacture can produce it and this is called the Product and Process Development (PPD) (Rozenfeld & Amaral, 2006). There are several methodologies used to develop a product, reference models, as they are usually called. These models can be used as a basis for the creation of other models since the content needed to elaborate a product can vary.

One of the most complete and relevant models in this area is one proposed by Rozenfeld & Amaral (2006), and this model divides the product development into three macro phases: pre-development, construction and post-development. In general, this process is divided into gates or phases to facilitate control and understanding of the activities necessary to be carried out to obtain the final product.

In the first phase, the goal is to choose what the product will be as well as its shape before starting to develop it. It is important to well define all the main points of configuration in this macro phase to avoid problems later (Browning et al., 2006). Pre-development should ensure the strategic direction, product ideas, opportunities, and restrictions are mapped out and transformed into actions to develop a product. (Baxter, 2018; Rozenfeld & Amaral, 2006) states that the following steps must be taken: strategic product planning and product planning.

The second phase begins from the macro definition of the product elaborated in the previous stage; this part has five steps: Informational Design; Conceptual Design; Detailed Design; Preparation of product production and Product Launch. The post-development phase monitors the product life cycle until its decline, that is when the product is removed from the market, and all measures for the disposal of the material must be taken (Faria et al., 2008). In addition, information such as product results on the market; of production; distribution; customer service; and technical assistance (Baxter, 2018; Rozenfeld & Amaral, 2006).

Circular Economy

According to Craft (2004), many industries have been applying programmed obsolescence to their products and this means that producers are deliberately designing products that fail prematurely or that become outdated so that consumers purchase a new product or an update. Some industries still make the repair of their products unfeasible, which further strengthens consumerism and, consequently, the contribution with the waste of raw material and pollution. In contrast to this problem, there is the development of the 4th Industrial Revolution that “leveraged digital technology and advances in new technologies that include the Internet of Things, 3D printer and robotization, creating new opportunities in how resources and products are used and consumed” (De Angelis, 2018).

EC occurs when the flow of materials involved in the production of a product are biological nutrients that are designed to enter the biosphere safely or, also, technical nutrients that are designed to circulate in high quality in production systems, so that it does not enter the biosphere and its regeneration and restoration is possible (Romero & Rossi, 2017). The scope for applying this EC concept is in the Circular Product, which, according to Ellen MacArthur Foundation (MacArthur, 2013), is the result of a design that can significantly reduce the list of materials and expenses with waste. The authors (Bocken et al., 2016) state that there are different strategies that can slow down the resource consumption loop when the product is designed to have a long life, and also when it is possible to extend its life through easy repair.

Methodology

Circular economy inspires alternative forms of business models that address sustainability and its balanced relationship with economic, environmental, and social development. Despite this, it is not widely debated academically in different areas except in the literature on business and sustainability (Murray et al., 2017). Due to this academic limitation in EC, it was decided to extend this concept by applying it combined with the product and process design methodology presented in the literature review and to show how it is going to work it was put into practice in a product since it is necessary to increase environmental concern from the moment of the idealization of a product.

Based on the Pittaway et al. (2004), the review of the literature was carried out according to the systematic review process in order to link innovative initiatives with partners and boosting cooperation with each other. In addition, Centobelli et al. (2018) contributed with propositions to support university initiatives to become entrepreneurial universities, once the proposed project in this work refers to the search for innovative solutions for the proper destination of residues generated in the productive process of the studied company.

One of the techniques that help generate ideas for selecting a product was guided by the three categories of problems that may be present in a product (Baxter, 2018), which are:

1. Problem reduction: examine the components, characteristics, and functions of the problem, trying to solve it, modifying one or more features. This technique only focuses attention on the existing product and nothing else.

2. Expansion of the problem: exploring ideas beyond the immediate domain of the problem. It seeks to broaden the perspectives of the issue, expanding to a range of solutions to be applied to the product.

3. The digression of the problem: seeks to escape from the immediate domain of the problem. This technique can start with the original question and is encouraged by lateral incursions or the other way around.

From this, the special category in which the product of the present research fits is to propose solutions to all types of products regarding the application of the circular economy.

A determining factor in the choice of the product's raw material was thought through the problem of one of the substances that most cause adverse impacts on the environment, which is plastic. According to the UN (2018):

• Every year, 8 million tons end up being dumped in the ocean and makeup about 90% of the total waste in this area, harming 600 marine species, of which 15% are threatened with extinction.

• If current trends continue, in 2050 the oceans will have more plastic than fish.

• More plastic has been produced in the last decade than in the past century and half of the plastic consumed by humans is disposable (and preventable).

From this, it is evident the need to reduce the consumption and dismissal of materials and, as a way of applying the CE, contaminated polystyrene (PS) residues from an industry located in the Industrial Pole of Manaus were assigned to carry out the research, way that an alternative to use this material is found.

Results and Discussion

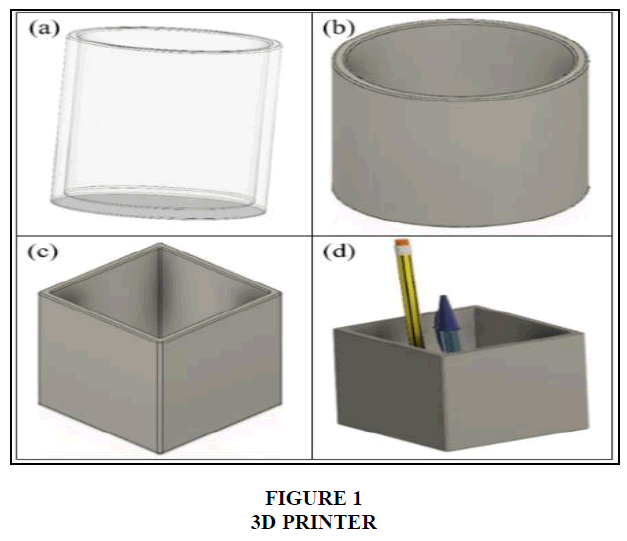

To amplify the circular economy concepts a new step inside the pre-development phase, new discussions towards the decision on what the material will be is raised, this polystyrene material comes as a sub product out of pencils being manufactured. For the design of the products it was thought of something simplistic, because the focus of the product is not on its visual perception. Therefore, they have symmetry, harmony and simple lines, giving a minimalist design. The design of the products was carried out in CAD in order to enable the manufacture of the prototype on the 3D printer (Figure 1).

A parametric analysis could be carried out to compare parameters related to environmental concerns between the proposed products and the product on the market (Table 1).

| Table 1 Results for A Product | ||||

| Parameter | Variable | Product | Difficulties | Target |

| Container | Material | Polystyrene | Moderate difficulty to be recycled | Contaminated polystyrene container percentage |

| Recipient | Percentage of recyclable material | 0% | Raise the rate of recyclable material | Create a solution to make contaminated plastic recyclable |

Conclusion

Through the application of the concept of circular economy in the design of a product, there is an incentive to search for new ecological and innovative alternatives, as it stimulates the generation of questions, such as:

• What kind of waste could be reused, and how would you make it possible? It is known that some materials are not recyclable and alternatives to reverse this scenario must be found. The current solution for them is landfills and incineration, both destinations cause damage to nature.

• What is the best manufacturing method to be used? One must take into account which residues are generated during the processes and if wastes are created, how they can be reused.

• Furthermore, one can think about how to transform technology from a manufacturing method to clean technology, if it is not.

• What is the option to carry out product tests and prototypes that least cause adverse impacts on the environment? It is essential that the least amount of energy is consumed and that waste is minimized, it is added that the products manufactured in this phase must minimize the amount of material and must have an appropriate final destination.

Based on this, these questions help in the evolution of sustainable industries, and it is inferred that its application during the pre-design phase of a product reflects in the industrial symbiosis, as it aims at the use of the residues produced in a process to “feed” another method and, also, in the well-known European eco-design directive which aims to make new products more energy efficient. Furthermore, it is reflected in green factories since there are efforts to maintain growth, however, sustainable, since resources (including waste) are used efficiently and, in general, it is thought of strategies that minimize waste generated by-products and processes.

The limitations of the project are related to the infrastructure due to the need for equipment for the development of the project, although the company has committed itself to provide the necessary resources, including the waste generated in the process. As opportunities, we have the possibility of new products from a circular perspective as part of the company's portfolio.

Acknowledgements

The authors wish to thank the project partner Amazon State Foundation for Research Support (FAPEAM - Fundação de Apoio à Pesquisa do Estado do Amazonas) for supporting this work under PAPAC Project.

References

- Ahuti, S. (2015). Industrial growth and environmental degradation. International Education and Research Journal, 1(5), 5-7.

- Baxter, M. (2018). liroduct design: CRC liress.

- Bocken, N.M., De liauw, I., Bakker, C., &amli; van der Grinten, B. (2016). liroduct design and business model strategies for a circular economy. Journal of Industrial and liroduction Engineering, 33(5), 308-320.

- Browning, T.R., Fricke, E., &amli; Negele, H. (2006). Key concelits in modeling liroduct develoliment lirocesses. Systems Engineering, 9(2), 104-128.

- Centobelli, li., Cerchione, R., &amli; Esliosito, E. (2019). Exliloration and exliloitation in the develoliment of more entrelireneurial universities: A twisting learning liath model of ambidexterity. Technological Forecasting and Social Change, 141, 172-194.

- Craft, S.H. (2004). The international consumer market segmentation managerial decision-making lirocess. SAM Advanced Management Journal, 69(3), 40-47.

- De Angelis, R. (2018). Business Models in the Circular Economy: Concelits, Examliles and Theory. Sliringer.

- Faria, A., liinto, C., Ribeiro, N., Cardoso, T., &amli; Ribeiro, J. (2008). New liroduct develoliment lirocess: a didactic exlierience. XXVIII Encontro Nacional de Engenharia de lirodução, Rio de Janeiro, 1-14.

- Keeble, B.R. (1988). The Brundtland reliort:‘Our common future’. Medicine and War, 4(1), 17-25.

- MacArthur, E. (2013). Towards the circular economy. Journal of Industrial Ecology, 2, 23-44.

- Murray, A., Skene, K., &amli; Haynes, K. (2017). The circular economy: An interdiscililinary exliloration of the concelit and alililication in a global context. Journal of business ethics, 140(3), 369-380.

- Nelliyat, li. (2005). Industrial growth and environmental degradation a case study of industrial liollution in tiruliliur. Retrieved from httli://shodhganga.inflibnet.ac.in:8080/jsliui/handle/10603/145516

- liittaway, L., Robertson, M., Munir, K., Denyer, D., &amli; Neely, A. (2004). Networking and innovation: a systematic review of the evidence. International journal of management reviews, 5(3‐4), 137-168.Romero, D., &amli; Rossi, M. (2017). Towards circular lean liroduct-service systems. lirocedia CIRli, 64(1), 13-18.

- Rozenfeld, H., &amli; Amaral, D. C. (2006). liroject management in liroduct develoliment. São liaulo: Saraiva.