Research Article: 2022 Vol: 28 Issue: 2S

Performance quality of cloud manufacturing and its effect on the digitally shifting organizations: An analytical and theoretical study

Namareq Latif Fenjan, Al-Turath University College

Jinan Hassan Sahib, Al-Turath University College

Citation Information: Fenjan, N.L., & Sahib, J.H. (2022). Performance quality of cloud manufacturing and its effect on the Digitally Shifting Organizations: An analytical and theoretical Study. Academy of Entrepreneurship Journal, 28(S2), 1-12.

Keywords

Performance Quality, Digitally Shifting Organizations, Traditional Manufacturing, Cloud Manufacturing, Digital Transformation

Abstract

The digital shifting is opening a way to move from the traditional manufacturing into the cloud manufacturing in order to exhibit the materials as a set of services that can be used on a specialized basis. As the presentation of such materials need a comparison of more information and maximizing the competition power for the industrial organizations and present the manufacturing services and containing the more complicated jobs, the thing that leads to the digital shifting and invent a business model resulting into a revolutionary change in the consumers’ predictions and their behaviors and this made a perturbation in several markets. Our project has focused on a main theoretical problem, and it branches to many questions: Is there any quality effect after using the cloud manufacturing on the digital organizations? As for the most crucial objective that the research seeks to achieve, which is to find the integrative relationship between the quality of cloud manufacturing performance and the organization’s ability to digitally transform. The research focused on the importance of depending on cloud manufacturing as a new production philosophy capable of changing the future perspective of the manufacturing industry by moving from traditional manufacturing platforms production-oriented to service-oriented manufacturing platforms. The research was based on a key assumption that((There is a theoretical correlation between the quality of cloud manufacturing performance and the organization’s digital transformation)), the research consists of two main variables, namely the independent variable represented by the quality of cloud manufacturing, which consists of several dimensions (service, time, cost, reliability) and the dependent variable is the transforming organizations Digitally and consist of several dimensions (political, process, individuals, stakeholders, infrastructure) The field of application of the research It is possible to apply the research to all organizations that seek digital transformation through cloud manufacturing.

Introduction

In this segment the research methodology will be clarified which addressed by the investigation issue and its inquiries, importance, targets. Besides, the primary speculation of this examination will likewise be disclosed to get somewhere inside in this subject which is significant in the cutting-edge administrational thinking.

Cloud fabricating is one of the cutting edge themes in administration thought, particularly in the field of assembling and keeping up the nature of items and their acknowledgment by clients in accordance with specialized turn of events and this will accomplish furnishing clients with different administrations for item customization, like mass assembling, limited scope creation and individual customization, by coordinating assembling resources and Effectively improve the overall manufacturing capacity of China's manufacturing industry by improving the allocation of resources within the manufacturing enterprise and between companies. And enhance cooperation between companies and shape the product service life cycle and thus helps to enhance demand and cooperation between companies. This will lead to improving the level of basic technology and the quality of service of institutions, maintaining sustainable development, improving quality, quantity and expiry time for service providers and meeting the required standards, especially when organizations turn to digitization and adopt the philosophy of digital transformation due to the development taking place in all technical fields. Therefore, our main problem lies in (Is there a possibility to measure the quality of cloud manufacturing performance in digitally transformed organizations).

Through the main problem that was addressed in the above paragraph, many theoretical questions emerged, namely:

1- Is there a possibility for digitally transformed organizations to maintain the services they provide?

2- Can digitally transformed organizations reduce labor costs and their products?

3- Can these organizations turn in the time specified for them without affecting their customers?

4- After the digital transformation, do these organizations maintain reliability in the direction of their work and the quality of their products?

This study aims to achieve several sub-goals, including:

1- Establishing a digital organizational structure capable of implementing the transformation process with high quality and in accordance with the policy prepared for that.

2- Focusing on the transformation process in terms of the work process through the use of digital technology in every work process within the organization under the same digital platform in the industrial sector and community service.

3- Creating and preparing the human resources department, including employees and executive managers. Through the development of digital intelligence individuals to prepare themselves to enter the digital and global labor market with a focus on the quality of cloud manufacturing in light of digital transformation.

4- Emphasis on stakeholders in accordance with the principle of cooperation by establishing partnerships with digital institutions to invest knowledge experiences in the field of digital technology.

5- Focusing on infrastructure, which is concerned with the transformation process in terms of information technology systems in the organization through the arrangement of the digital ecosystem.

This investigation has a hypothetical and applied significance. In this examination, we will zero in on the hypothetical significance and work on the development of the cloud fabricating measure, with an accentuation on the nature of this framework, especially in digitally transformed organizations. The importance can be determined by the following:

1- Focusing on cloud manufacturing as a new production philosophy capable of changing the future perspective of the manufacturing industry by moving from traditional production-oriented manufacturing platforms to service-oriented manufacturing platforms.

2- Centrally fulfilling, organizing and controlling consumer demands as cloud manufacturing services through design innovation, cloud-based manufacturing and rapid product development at low cost through a social network and negotiation platform between service providers and consumers.

3- Cloud manufacturing supports the development of the quality of the product life cycle through decentralized sharing of information and comprehensive access to product design information that suits the consumer.

4- Promote resource sharing and rapid production of prototypes, reduce costs, reduce time to market, and improve service quality.

5- Cloud manufacturing contributes to revitalizing and accelerating organizations that want digital transformation.

6- Digitization has a major role in achieving the efficiency of cloud manufacturing performance, excellence and future predictability, and without it, organizations cannot expand and improve the quality of service provided to the customer.

Cloud Manufacturing

The Origin of the Cloud Manufacturing

An idea of cloud manufacturing was presented as another assistance situated assembling model that utilizations distributed computing innovation alongside the Internet of Things and modern manufacturing technologies to integrate manufacturing resources and capabilities to deliver reliable, affordable, on-demand manufacturing services for the entire manufacturing product lifecycle through intelligent integration of manufacturing resources and capabilities. Create a joint group from resources via the CM Cloud Manufacturing Platform (Mourad et al., 2020), which is a computing and service-oriented manufacturing model developed from existing advanced manufacturing models (such as ASP, AM, NM, Manufacturing Grid, and Enterprise Information Technologies under the support of cloud computing). Internet of things, virtualization and service, directed technologies, and advanced computing technologies (Lartigau et al., 2015).

Cloud Manufacturing (CM) is a service-oriented business model for sharing manufacturing capabilities and resources on a cloud platform (Barenji, 2021). Cloud manufacturing as a new manufacturing model is changing the outlook for the manufacturing industry by moving from traditional production-oriented manufacturing platforms to Service-oriented manufacturing platforms use cloud computing, Internet of Things (IoT) and information technologies to enable different organizations to collaborate despite spatial distances and disparate structures (Bouzary, 2020).

Adamson et al., (2017) defines cloud manufacturing as a network manufacturing mode in which locally and globally distributed manufacturing resources for the full product life cycle are provided by service providers to meet consumer demands and are centrally organized and controlled as cloud manufacturing services, while (Wu et al., 2017) refers to cloud-based design and manufacturing to a product awareness mode that can enhance knowledge, resource sharing, and rapid product development at low cost through a social network and negotiation platform between service providers and consumers, We conclude from the concepts developed by researchers that cloud manufacturing provides the following:

1- It depends on the rapid development of advanced technologies such as cloud computing, Internet of things and virtualization.

2- It enables centralized management of manufacturing resources and capabilities.

3- Focuses on on-demand service.

4- Provides intelligent, efficient and high quality services covering the entire product life cycle.

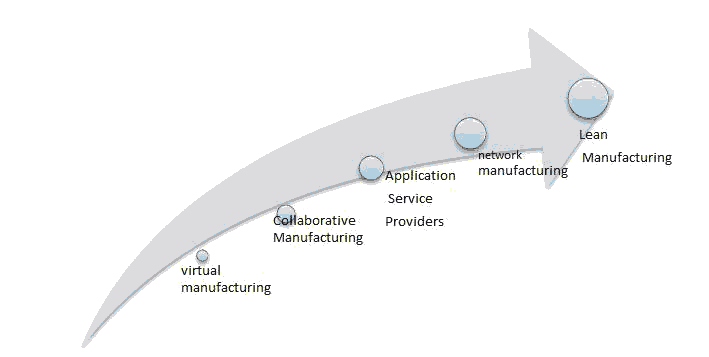

Since the last decade the exchange of information is strategically crucial to the development of companies as there is a growing need for global sharing of technology and knowledge since then significant efforts have been made in the direction of developing different frameworks and systems aimed at sharing and exchanging manufacturing information. The previous concept of cloud manufacturing was primarily networked manufacturing, where there is a large body of research in general that has staged its development in five main categories: Lean Manufacturing, Virtual Manufacturing, Application Service Providers, and Collaborative Manufacturing and network manufacturing, cloud manufacturing was introduced as a new paradigm that leverages manufacturing resources and shares capabilities for the entire product life cycle between manufacturing structures and enterprise systems Figure 1 shows the evolution of cloud manufacturing technologies to date (Mourad et al., 2020).

Cloud Manufacturing Importance

Cloud manufacturing covers a wide range of fields including applications in sheet forming and processing, polymer industry, semiconductor manufacturing industry, WEEE, large equipment manufacturing industry, thermoforming process control, vendor selection and order customization in the locomotive manufacturing industry, complex custom product modification and Online intelligent process monitoring in manufacturing as well as broad applications in additive manufacturing and robotics (Bouzary, 2020).

Cloud manufacturing supports product lifecycle development by engaging networks, decentralized information sharing, and comprehensive access to product design information, thus promoting collaboration in design technologies, it can also promote resource sharing, rapid prototyping and cost reduction, reduce time to market, and improve service, and enhancing user experience (Mourad et al., 2020)

(Wan et al, 2020) puts three points that explain the importance of cloud manufacturing for companies of different sizes:

1. Provide customers with a variety of product customization services, such as mass manufacturing, small-scale production and personalized customization, by integrating manufacturing resources and effectively improving the overall manufacturing capacity of China's manufacturing industry by improving resource allocation within the manufacturing enterprise and between companies.

2. Strengthening cooperation between companies and forming the product service life cycle industry chain and thus helps to enhance the demand and cooperation between companies. Through long-term cooperation or demand in conjunction with product production, logistics, waste recycling and other endeavors with the continuous development of the platform.

3. Improving the level of basic technology and service quality of enterprises, maintaining sustainable development, improving quality, quantity and expiry time for service providers and meeting the required standards, and has a significant impact on the conformity of the follow-up service of enterprises through continuous improvement of its core technology in an environment characterized by the development of many manufacturing enterprises.

The Components of Cloud Manufacturing System

The original CM task is first created from a description model and then a graph-based semantic similarity algorithm is implemented to match tasks and services and dynamic modeling of manufacturing equipment capacity where the knowledge structure can be updated in real time and a kind of manufacturing resource information method is added to virtualize the resources in CM (Bouzary, 2020), CM's system architecture includes the traditional resource tier, virtual resource tier, and global service tier. and application layer coupled with a cloud management engine that deploys semantic web technologies to allow bi-directional transmission between different cloud modes, encouraging users to switch between different clouds at the macro level and controlling licensing of manufacturing resource sharing at the micro level, and takes into account factors such as manufacturing capabilities and business strategy Work and security concerns and from the following four layers:

1. Create public cloud manufacturing tasks

2. Semantic feature space for public cloud manufacturing task

3. Sub-semantic description of the cloud manufacturing task

4. Semantic model applications to the cloud manufacturing task (Mourad et al., 2020).

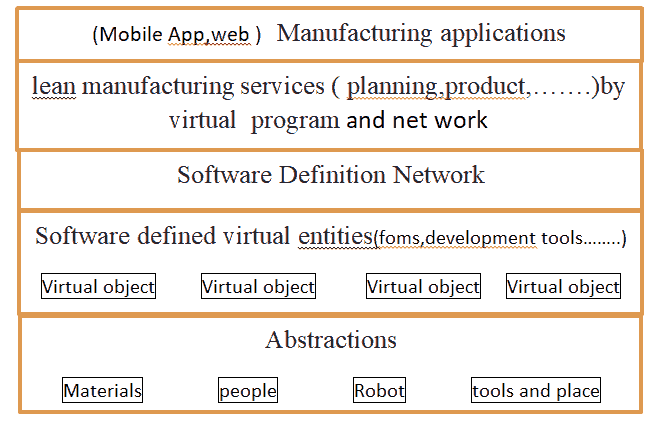

(Yang et al., 2020) proposed a software-defined cloud manufacturing framework, which can greatly improve the resiliency and agility of a cloud manufacturing system. The framework consists of six layers:

Abstractions: The abstraction layer manages the resource of atomic devices with basic programmable functions.

Gates: The gate (integrated computing units or standalone computers) supports the integration of atomic devices in cyberspace and acts as bridges for bidirectional interactions.

Software Defined Virtual Entities: providing different functionality for user tasks through virtualization and creating different mapping relationships between hardware resources in cyberspace (one-to-one, one-to-many, many-to-many, one-to-many).

Software Definition Network: Meet the requirements of manufacturing applications, and increase the resilience of networks by clearly separating the basic network functions of redirection (data plane) from the network configuration (control plane).

Manufacturing Services: The service layer focuses on how to create composite manufacturing services based on simple services that are recorded and published. In a higher layer to connect them to complex manufacturing tasks

Manufacturing Applications: Implementation of the control logic in the work network of the application in the program units and the control loop (control-analysis-planning-implementation), and as in Figure (2) below:

The Challenges of the Cloud Manufacturing

Collective efforts must be made by the communities of ICT, robotics, automation and manufacturing to make cloud manufacturing a standard in the intelligent connected world. (Yang et al., 2020) shows the challenges in front of this matter, including:

1. Standards and Interoperability: Cloud software manufacturing requires a common standard as the basis for networking and the integration and virtualization of manufacturing assets or objects in cyberspace and many heterogeneous resources, for interoperability, manufacturing resources must be able to collaborate with each other some on the physical and informational levels.

2. Simulation, Verification, Verification and Dependence: Simulation based on digital dual models is an efficient approach, physical objects and dual digital units interact mutually, and other challenges include the development of online models without interruptions in physical systems according to the dynamic environment, the wide participation of users in decision-making activities.

3. Collaborative Data Processing and Big Data Analytics: Data is generated at different levels and stages of manufacturing environments such as quality control, energy consumption, machine conditions, and functional progression. Aggregating data vertically and horizontally across manufacturing systems is challenging, data purification and aggregation near peripheral devices can lead to reduce the amount of data transmission in the network, but the challenge is to avoid information loss in the process.

4. Security and Privacy: Privacy and security are critical in a future highly open and connected world. Cyber-attacks can cause serious problems to entire manufacturing systems, by hacking into virtual entities and networks or introducing malicious code into cyberspace.

And (Mourad et al., 2020) set a number of challenges. These include:

1. Unclear principles to protect end user investment.

2. Difficulty in communication between departments in the organization and between stakeholders in the supply chain

3. Limited collaboration and interaction between business partners within cloud manufacturing networks.

4. Lack of framework for providing cloud manufacturing service.

5. Difficulty in deploying material resources, such as machines and screens.

6. Limitations allowing stakeholders to access necessary manufacturing information as per their requirements, enabling integration of heterogeneous manufacturing resources along the product lifecycle.

The Dimensions of Cloud Manufacturing

CM provides many services with similar functions but differs in QoS values such as availability and response time and preferences such as price and degree of trust, service providers and consumers are looking for an effective methodology for selecting partners in the cloud platform where several techniques are available to select the preferred and most suitable services in different contexts and some agreed Researchers focus on basic dimensions such as time, price, reliability, service or maintainability (Barenji, 2021), and we include a table with the most important dimensions addressed by researchers: as shows in Table 1.

| Table 1 Dimensions of Cloud Manufacturing Quality |

|||||

|---|---|---|---|---|---|

| Researcher and year | time | Cost or price | Authenticity | availability | service |

| Liu et al. (2013) | v | v | v | ||

| Cheng et al. (2014) | v | v | |||

| Huang et al.(2014) | v | v | v | ||

| Lartigau et al. (2015) | v | v | v | v | v |

| Cao et al. (2015) | v | v | v | v | |

| Xu et al. (2016) | v | v | v | v | |

| Yao (2017) & Zhou | v | v | v | v | |

| Que et al. (2018) | v | v | v | ||

| (Barenji, 2021) | v | v | v | v | v |

Service

Cloud manufacturing allows cloud users to deliver or acquire manufacturing tasks on a service or maintainability basis. The cloud manufacturing approach seeks to overcome some of the drawbacks of earlier approaches to network manufacturing, such as the lack of stable manufacturing resource transactions in large-scale manufacturing processes, or the presence of insufficient interfaces for tools Mediums or APIs for deploying manufacturing resources to the heterogeneous network representation, lack of flexibility and agility among the manufacturer (Mourad et al., 2020).

Price or Cost

Increasing competition in the market (particularly in countries offering lower wages) is motivating manufacturing enterprises to investigate and adopt new models of manufacturing and business and to transform long-term supply chains into broader manufacturing networks in the short term in order to reduce costs (Barenji, 2021), The price or cost consists of (the cost of the manufacturing resource service + the cost of preparation): includes all the costs inherent in the implementation of the service and the preparations and modifications associated with it. Price is a function of the implicit supplier and manufacturing demand (input and output) and is predetermined by the relevant service provider. To reach the optimal solution, the price must be reduced and can it is calculated from the maximum price that the applicant is willing to invest independently of the currency (Lartigau et al., 2015).

Time

The ability of a supplier's service to handle unforeseen circumstances, such as late delivery or simply its ability to interoperate. Maintainability is expressed as the percentage calculated from the number of unexpected conflicts and the number of times these conflicts were successfully addressed (Lartigau et al., 2015) The trend is towards industries where capabilities are accessible and employable from anywhere in the world and in Any time to collect and integrate huge and valuable capabilities from different disciplines and different manufacturers to consumers, the capabilities are independent Large, geographically dispersed, and heterogeneous in terms of: Operating environment, culture, social capital, and goals Where time is an important deciding factor in cloud manufacturing (Barenji, 2021), time consists of (manufacturing resource service execution lead + setup time): Duration refers MfgT indicates service execution duration and preparation time. Duration is a function of equipment accuracy and quality as features of demand and is important to reduce and evaluate from the required deadline (Lartigau et al., 2015).

Reliability

Many businesses want to use their resources effectively and efficiently, and share some capabilities with others, and some consumers use these capabilities without investing in facilities and technology. ICT infrastructure plays a key role in enabling through sharing/sharing of information, secure communications and coordination (Barenji, 2021); the reliability of the service of a resource depends mainly on the global reliability of the associated service provider. But the specification of the order and the use of a particular resource can also have an impact on the final reliability. Reliability is expressed as a percentage and is evaluated with the minimum level of reliability acceptable to the applicant (Lartigau et al., 2015).

Digital Shifting

The Concept of Digital Shifting

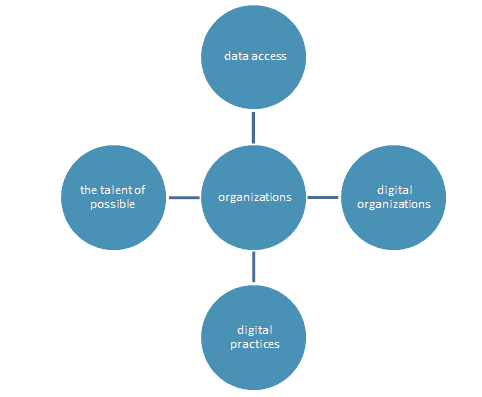

The practice of building digital organizations on the basis of new information technologies is taking its first steps; this practice is called digitization, that truly digitization can provide important competitive advantages. Under these circumstances, many leaders seek to experiment with these new technologies, and digital organizations are defined as organizations that gain experience using technologies; To understand the competitive advantages that can provided for their business; to determine the trends and magnitude of their business transformation; To assess the risks of their business related to this transformation and change the management methods and tools used by the company and conditions for their application under the new conditions and update the ideas of the professional community about management, as well as search for new ideas and update the existing methods and tools of management , and a digital organization is one in which the most volatile complementary assets are computer capital assets (Ananyin et al., 2018). The researchers (Obukhova et al., 2020) defined the digital process as the digital duality of a physical institution that was formed as a result of its digital transformation, and the researchers (Patel et al., 2018) defined it as a strong combination of people, technology and organizational capacity that fits perfectly with the environment economic and social today. A digital organization is resilient and has people and teams who work with technology and collaborate to make process improvements, develop new solutions, and rely less on hierarchy in a digital organization. It has an actor-oriented architecture based on continuous learning and adaptation. as shows in Figure 3.

The Importance of Digital Shifting

The different ways in which digital technology is viewed in creating value has profound resonance in achieving economic gains, process improvements and brand name enhancements that connect customers closely to the company, that physical products and digital resources, such as the Internet of Things, drive organizations to digital transformation beyond Organizational Boundaries to External Innovation Networks (Saarikko et al, 2020), the benefits of digitization are significant for creating efficiencies and operational excellence and predictability, without digitization companies cannot expand and customize services. Ensures disciplined and standardized business operations and provides the accuracy and security of essential transactions Makes data accessible and reliable Benefits of successful digital transformation include revenue growth and margins, lasting customer loyalty and the ability to attract top talent (and thus continue to grow) Successful companies in the digital economy will be digital (to provide value to customers) and digitize (to provide scale and efficiency), although companies are still struggling with digitization, what it means and how to do it is now well established (Ross, 2019).

Verhoef, et al., (2021) identifies three factors driving the need for digital transformation: First, since the advent of the World Wide Web a growing number of accompanying technologies (for example, broadband Internet, smartphones, Web 2.0, SEO, cloud computing, online payment systems, cryptocurrencies) have forced companies to digitally transform their businesses, and It affects the company's cost structure by replacing more expensive humans while providing service with the help of robots and through the use of artificial intelligence and blockchain.

Secondly, due to new digital technologies, the competition is changing dramatically. In retail, technologies have disrupted the competition landscape, shifting sales to relatively young digital companies. The competition has not only become more global, but has also intensified as large, information-rich companies have started.

Third, consumer behavior is changing in response to the digital revolution Market figures show that consumers are shifting their purchases to online stores Consumers are becoming more connected, informed, empowered and active as digital technologies allow consumers to participate in creating value by designing and personalizing products, and helping other customers by sharing reviews products.

Stages of Digital Transformation of the Organization

How are organizations progressing to become digital? The journey towards becoming a digital organization can be described through four main stages:

1. Trying–Characteristics of organizations at this stage are inflexibility and inability to achieve results.

2. Getting Started-Organizations begin to develop digital capabilities by investing in new knowledge and relationships.

3. Participation–Organizations have diverse digital capabilities, and develop collaboration across the organization.

4. Self-enhancement-These organizations are very flexible, able to quickly conduct reorganization and/or self-regulation.

Proactive leadership and investment are key factors that determine a company's ability to go digital. The four main factors are:

- The digital mindset first

- Digital practices

- Potential talents

- Access to data and collaboration too

The first step in building a digital mindset is to explain the benefits of digital transformation to key stakeholders. The next stage for the leader is to be a role model for the employees, then provide monetary and non-monetary rewards to encourage digital change As shown in Figure (3), talent begins Enabled by developing digital skills, the first step is to identify future skill requirements made by HR and IT teams, then analyze the gap between the desired and current skills of employees, the next step is to overcome the gap, followed by developing the necessary digital skills monitoring system which is metadata analysis, and use Social media, mobile devices (Konti? & Vidicki, 2018).

Dimensions of the Digital Transformation Process for Organization

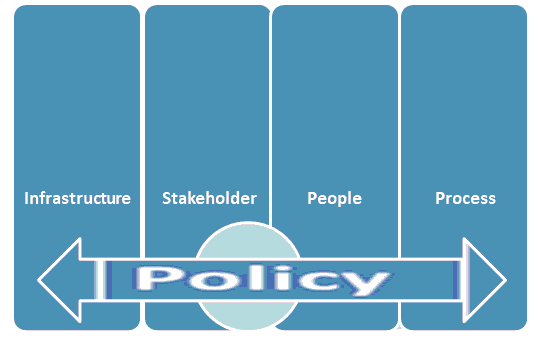

The process of transforming from a physical organization to a high-performance digital organization effectively, as the process includes the following:

1. Policy: It is the process of transformation in terms of governance and management through the creation of a digital organizational structure for the C-Suite (the president or CEO) within the framework of the implementation of the digital strategy.

2. Process: It is the process of transformation in terms of the work process through the use of digital technology in every work process within the organization under the same digital platform. There is the development of policies and procedures in line with digital technology and management of the information system systematically. Including the search for technology and innovation that can be used in the industrial sector and community service.

3. People: is the process of transformation in terms of human resource management, including employees and executives. Through the development of digital intelligence individuals to prepare themselves to enter the digital and global labor market, develop managers and workers with digital competencies. In addition to developing digital leadership for executives.

4. Stakeholder: In terms of cooperation with companies and communities. By creating partnerships with digital institutions to recruit students to practice experiences or to provide digital support from them. And the application of digital technology in academic and professional services to society and society.

5. Infrastructure: is the process of transformation in terms of information technology systems in the organization through the arrangement of the digital ecosystem. Develop high speed internet system, cloud computing and data center that can access data all the time as well as cyber security system. Including the uses of IoT systems for business and management processes. (Rujira, et al., 2020: 835-836).

as shows in Figure 4.

Figure 4: Components of the Transformation Process Towards a Digital Organization

Source: Rujira, Nilsook & Wannapiroon (2020).

Conclusions and Recommendations

Conclusion

After presenting the topic theoretically in the foregoing, considering the topic of cloud manufacturing as one of the modern topics that need theoretical knowledge, and they were singled out within the field of digitally transformed organizations.

1- It turns out that there is a growing research interest in the issue of cloud manufacturing, which needs in-depth theoretical research.

2- It became clear that there is a growing interest in how to achieve quality in the cloud manufacturing process, especially in organizations that seek digital transformation.

3- Identifying the components of cloud manufacturing, which consists of six layers, namely (- abstractions-portals:-software-defined virtual entities-software identification network:-manufacturing services:-manufacturing applications)

4- Knowing the most important determinants of cloud manufacturing and its difficulties, which are (standards and interoperability,

5- Simulation, Verification, Verification and Certification, Collaborative Data Processing and Big Data Analytics, Security and Privacy)

6- Addressing the dimensions of quality that can be applied with the cloud manufacturing philosophy

7- Knowing the stages of transformation of the digitally transformed organization ((trying, starting, participating, self-enhancing))

8- The importance of clarifying the main dimensions of the digitally transforming organizations.

Recommendations

1- Focusing on cloud manufacturing and its applicability in industrial organizations.

2- Focusing on how to invest technology and digital transformation in products and maintain the quality of products.

3- We recommend the application of cloud manufacturing in industrial organizations because of its impact on reducing costs and keeping pace with digital development.'

4- Focus on applying the dimensions of cloud manufacturing quality to enhance trust among these organizations and customers.

5- Increasing the identification of the most important determinants of the application of cloud manufacturing in order to reduce the failures that accompany the process of applying this manufacturing, which is reflected on the quality

6- Focusing on the most important dimensions of the digitally transformed organizations, especially (political, practical, individuals, stakeholders, infrastructure).

7- Urging organizations to implement such systems that are able to be technologically compatible with digital development.

8- Focusing on the process of digital transformation, and this transformation is inevitable because the next and current world is the digital world and will produce new generations of development and industrial technology.

References

Adamson, G., Wang, L., Holm, M., & Moore, P. (2017). Cloud manufacturing-A critical review of recent development and future trends.International Journal of Computer Integrated Manufacturing, 30(4–5), 347-380.

Crossref , Google scholar , Indexed at

Ananyin, V.I., Zimin, K.V., Lugachev, M.I., Gimranov, R.D., &Skripkin, K.G. (2018). Digital organization: Transformation into the new reality.Business informatics, 2(44), 45-54.

Crossref , Google scholar , Indexed at

Barenji, R.V. (2021). A block chain technology based trust system for cloud manufacturing.Journal of Intelligent Manufacturing, 1-15.

Crossref , Google scholar , Indexed at

Bouzary, H. (2020). Integrated service matching and composition for cloud manufacturing platforms (Doctoral dissertation). Texas: The University of Texas at San Antonio.

Cao, Y., Wang, S., Kang, L., & Gao, Y. (2016). A Tqcs-based service selection and scheduling strategy in cloud manufacturing.International Journal of Advanced Manufacturing Technology, 82, 1-4.

Crossref , Google scholar , Indexed at

Changcheng, W., Hualin, Z., Liang, G., Xun, X., Ray Y.Z., & Fu, Y. (2020). Cloud manufacturing in China: a review.International Journal of Computer Integrated Manufacturing, 1-25.

Crossref , Google scholar , Indexed at

Cheng, Z., Zhan, D., Zhao, X., & Wan, H. (2014). Multitask oriented virtual resource integration and optimal scheduling in cloud manufacturing.Journal of Applied Mathematics, 1-9.

Crossref , Google scholar , Indexed at

Huang, B., Li, C., & Tao, F. (2014). A chaos control optimal algorithm for qos-based service composition selection in cloud manufacturing system. Enterprise Information Systems, 8(4), 445-463.

Crossref , Google scholar , Indexed at

Kontic, L., & Vidicki, Ð. (2018). Strategy for digital organization: Testing a measurement tool for digital transformation.Strategic Management, 23(1), 29-35.

Crossref , Google scholar , Indexed at

Lartigau, J., Xu, X., Nie, L., & Zhan, D. (2015). Cloud manufacturing service composition based on QOS with geo-perspective transportation using an improved artificial bee colony optimisation algorithm.International Journal of Production Research, 53(14), 4380-4404.

Crossref , Google scholar , Indexed at

Liu, W., Liu, B., Sun, D., Li, Y., & Ma, G. (2013). Study on multi- task oriented services composition and optimisation with the “Multi-composition for each task” pattern in cloud manufacturing systems.” International Journal of Computer Integrated Manufacturing, 26(8), 786-805.

Mourad, M.H., Nassehi, A., Schaefer, D., & Newman, S.T. (2020). Assessment of interoperability in cloud manufacturing.Robotics and Computer-Integrated Manufacturing, 61.

Crossref , Google scholar , Indexed at

Obukhova, A., Merzlyakova, E., Ershova, I., & Karakulina, K. . (2020). Introduction of digital technologies in the enterprise. In E3S Web of Conferences, 159, 04004.

Crossref , Google scholar , Indexed at

Patel, A., Kalita, P.C., & Asthana, S. (2018). Design for future: Strategic management and design innovation framework for digital organizations. DS 91: Proceedings of Nord Design 2018, Linköping, Sweden.

Que, Y., Zhong, W., Chen, H., Chen, X., & Ji, X. (2018). Improved adaptive immune genetic algorithm for optimal qos-aware service composition selection in cloud manufacturing.International Journal of Advanced Manufacturing Technology, 96(9–12), 4455-4465.

Crossref , Google scholar , Indexed at

Ross , J. (2019). Don't confuse digital with digitization: Who wins in a digital world? Cambridge, Massachusetts London, England.

Rujira, T., Nilsook, P., & Wannapiroon, P. (2020). Synthesis of vocational education college transformation process toward high-performance digital organization.International Journal of Information and Education Technology, 10(11), 832-837.

Crossref , Google scholar , Indexed at

Saarikko, T., Westergren, U.H., & Blomquist, T. (2020). Digital transformation: Five recommendations for the digitally conscious firm.Business Horizons, 63(6), 825-839.

Crossref , Google scholar , Indexed at

Verhoef, P.C., Broekhuizen, T., Bart, Y., Bhattacharya, A., Dong, J.Q., Fabian, N., & Haenlein, M. (2021). Digital transformation: A multidisciplinary reflection and research agenda. Journal of Business Research, 122, 889-901.

Vial, G. (2019). Understanding digital transformation: A review and a research agenda.The Journal of Strategic Information Systems, 28(2), 118e144

Crossref , Google scholar , Indexed at

Xu, W., Tian, S., Liu, Q., Xie, Y., Zhou, Z., & Pham, D.T. (2016). An improved discrete bees algorithm for correlation-aware service aggregation optimization in cloud manufacturing.International Journal of Advanced Manufacturing Technology, 84(1–4), 17-28.

Crossref , Google scholar , Indexed at

Yang, C., Lan, S., Wang, L., Shen, W., & Huang, G.G. (2020). Big data driven edge-cloud collaboration architecture for cloud manufacturing: a software defined perspective.IEEE Access, 8, 45938-45950.

Crossref , Google scholar , Indexed at

Zhou, J., & Yao, X. (2017). Multi-population parallel self-adaptive differential artificial bee colony algorithm with application in large-scale service composition for cloud manufacturing.Applied Soft Computing, 56, 379-397.

Crossref , Google scholar , Indexed at

Zhou, L., Zhang, L., Zhao, C., Laili, Y., & Xu, L. (2018). Diverse task scheduling for individualized requirements in cloud manufacturing.Enterprise Information Systems, 12(3), 300-318.

Crossref , Google scholar , Indexed at

Received: 28-Dec-2021, Manuscript No. AEJ-21-8969; Editor assigned: 30-Dec-2021, PreQC No. AEJ-21-8969(PQ); Reviewed: 10-Jan-2022, QC No. AEJ-21-8969; Revised: 21-Jan-2022, Manuscript No. AEJ-21-8969(R); Published: 28-Jan-2022