Research Article: 2023 Vol: 27 Issue: 2S

Role of IOT Technology for Financial Performance in Supply Chain Managers Response to New Normal

Kashmira Ganji, ICFAI Business School, IFHE University

Citation Information: Ganji, K. (2023). Role of iot technology for financial performance in supply chain managers response to new normal. Academy of Accounting and Financial Studies Journal, 27(S2), 1-10.

Abstract

This study aims to help managers better understand the crucial role of technology - the Internet of Things. The research proposes a viable method for Supply chain (SC) experts to successfully manage some of the organization's fundamental processes so that they may focus on more strategic work and become effective SCM business partners. This paper aims to help supply chain professionals understand IoT applications and its advantages in the Supply chain management (SCM) domain. A conceptual model was proposed in this study by integrating RBV and UTUAT/UTUAT2 theory to understand the importance of IoT adoption in SCM practices. The study finds SC professionals can leverage the various characteristics of IoT to match SC applications' expectations and thereby enhance performance. This paper elaborates on the ongoing efforts to restart the supply chain operations in the new normal situations. This study is limited to the conceptual framework, wherein future there is the scope of converting the propositions into a testable hypothesis.

Keywords

Internet of Things, SC Professionals, SCM Practices, Digitalization, Validation, Performance Management, Resilience, Data Protection and Surveillance.

Introduction

COVID-19 has caught the globe off guard, causing widespread confusion and anxiety for individuals. It is a shock to many enterprises and their working professionals worldwide, affecting countries, governments, organizations, and individuals (Papadopoulos et al., 2020). As the globe struggles to deal with uncertainty, supply chain (SC) professionals have constantly been developing their response to the crisis, assuring vendor management, inventory management, demand management, and risk management. Unexpected uncertainties, such as COVID-19, present not only obstacles but also opportunities. Organizations are under tremendous pressure to incorporate technology into all aspects of their operations to provide value to their customers. During the COVID-19 outbreak, marketplace vendors collaborated with many organizations to offer innovative technology-enabled solutions to organizations intended to facilitate them efficiently overcome the crisis.

There are four critical areas for every enterprise today. 1. Review of digital strategies in the new normal situations; 2. Reconstructing Supply chain; 3. Restructuring supply chain partnerships; 4. Investments in digital technologies (Capgemini, 2020). Technology has always been a game-changer, whether it is a printing press, Steam engine, right from those early inventions and technologies, to the technologies that have shaped the world over the centuries. Hence it is essential to give adequate attention to technologies because that has always resulted in improved quality of life for human beings and enabled to spur the economies. It has Supply chain managers play an essential role in industrial organizations, as it enhances the performance of supply chain (SC). Organizations have adopted technology during the last two decades primarily for purposes of agility, privacy, productivity, real-time processing, scalability, and, most crucially, cost reductions(Chatterjee et al., 2015; Thatcher & Oliver, 2001). In recent years, industries have witnessed many new technologies like robotic automation, Blockchain, 3D printing, Big Data analytics, and the Internet of things (IoT). Because of its process efficiency and automation capabilities, IoT applications are regarded as the most trending and essential advances among the technologies mentioned above. IoT is considered a significant breakthrough in recent times and will have considerable investments in the coming 3 to 5 years (IDC, 2020). IoT is one of the most exciting advancements that have the potential to change the way businesses function (Gartner, 2020). However, it is a less well-known technology due to popular misconceptions about the Internet of Things (Asemani et al., 2019; Pauli et al., 2021; Wessel et al., 2021).

The Internet of Things revolution will profoundly transform manufacturing, energy, agriculture, transportation, and other significant sectors of the economy during the next ten years, accounting for almost two-thirds of global GDP (WorldEconomicForum, 2021). According to statistics estimates, the worldwide IoT industry is anticipated to surpass USD 1250 billion by 2025, up from USD 690 billion in 2019, at a CAGR of 10.53 per cent between 2020 and 2025 (MI, 2020). With the importance of IoT technology, there are new and developing opportunities for businesses to reach customers and provide engaging solutions to customers and personnel. Within the firm, the supply chain management department is the most crucial beneficial department. This paper aims to help supply chain professionals understand IoT applications and its advantages in the Supply chain management (SCM) domain.

Research Questions

We aim to address a few crucial concerns about IoT in SCM.

1. Can IoT enhance digitalization in the supply chain?

2. Can IoT seamlessly connect all stakeholders such as supply chain professionals, vendors, and clients?

3. Does IoT help in determining the accuracy of SC operations and their automation and security?

4. Can IoT offer protection against data tampering or fraud prevention?

Literature Review

IOT Characteristics and Its Applications

Big data analytics, digitalization, interconnectivity, and remote monitoring have made significant advances across industries, improving every facet of modern society. And the Internet of Things is the driving force behind all of these advancements Table 1. IoT has revolutionized the digitalization of day-to-day human activities. Based on Gartner's Forecast database, we can expect that there will be approximately 20 billion devices connected to the internet by 2022. The more IoT devices that are linked, the more we will transform the way businesses operate and use resources. IoT has become a buzz across domains, attracting industry, academia, and practitioners (Medhi, 2019).

| Table 1 Summarizes The Application Of Iot Across Industries |

||

|---|---|---|

| Application Area | Description | References |

| Manufacturing | Enables smart factory, automated operations, allow automated recovery and shorten downtime in maintenance. The cross-enterprise framework leverages a decentralized (distributed) structure enabled by The internet of Things-based blockchain to achieve more excellent knowledge and service exchange in manufacturing networks. | (Li et al., 2018) |

| Agriculture | Information gathered from IoT devices about soil moisture, chemical applications, livestock health, and more allows farmers to track farm operations in real-time and make better-informed decisions on improving farm productivity and performing preventive maintenance. |

(Ummesalma et al., 2020) |

| Transportation | Excellent traceability and the capacity to inspect the entire journey of products across the supply chain, resulting in preventing fraud and counterfeiting across the supply chain; Routing Issues | (Speranza, 2018) |

| Energy Industry | Allows green energy use by utilizing intelligent metres to track data on both green and non-renewable energy use. | (Hossein Motlagh et al., 2020) |

| Healthcare and Clinical trials | Using IoT-based authorization workflows to provide transparency for patients and traceability for other stakeholders in health care. It removed complexity as a barrier for caregivers and patients by enabling healthcare services in hospitals, homes, offices, and travel. | (Javed et al., 2020; Rahmani et al., 2015) |

| Retail | Retailers can expand their businesses and increase their profits by enabling product identification and traceability, accurate daily inventory, shrinkage control, and dynamic price optimization. | (Serral et al., 2020) |

By linking all parties engaged on a single platform, IoT technology has the potential to disrupt sectors and enhance communication and efficiency within and outside of companies Table 2.

| Table 2 Provides The Summary Of Key Characteristics Of Iot |

|||

|---|---|---|---|

| IoT Characteristics | Definition/Description | Advantages in SCM | |

| Object (Input characteristics) | Addressability | Every physical thing has a unique identifying number. Once an item has been recognized, it may be enhanced with personalities and other information, allowing control over it. | Real-time and accurate insights. |

| Unique identity | Provide unique object identification across several locations | Transparency | |

| Mobility | Provide the object over different locations | More efficient regulations due to the ability to monitor activities from a distance | |

| System (Process characteristics) | Autonomy | Refers to systems that do not require direct human involvement to accomplish predefined tasks such as autonomous data collecting, autonomous behaviour, and reacting autonomously. | React more precisely even from remote locations |

| Context information | Refers to any kind of information that can be used to characterize the situation of an entity on a real-time basis (e.g., a person, an object, a place). | Real-time handling planning with regards to management and maintenance | |

| Heterogeneity | Several services were taking part in the system, which is expected to present very different capabilities from the computational and communication standpoints. | Broader applications due to linking multiple sources | |

| Interoperability | The ability of heterogeneous interface protocols to exchange information of different formats, structures for communication between devices. | Flexibility | |

| Security | To maintain data security, services, and the overall IoT system, several attributes must be assured, including confidentiality, integrity, authentication, authorization, non-repudiation, availability, and privacy. |

Fraud prevention | |

| Openness | This feature prevents the use of centralized authority. | Single source of truth | |

| Outcome (Output characteristics) | Identification | To track the materials, goods, or any equipment. | Tracking |

| Sensing | Sensors built into infrastructure for sensing the conditions, surveillance. | ||

| Actuation | It is remotely controlling of devices, even without Human instructions or control. | Faster operations, little cost. | |

Technology in SCM Practices

The impact of industrial 4.0 in Tu, (2018) highlight the need for digital supply chain practices indicating that the future of SCM depends on technology. Ben-Daya et al. (2019) explores the necessity of Technological practices in supply chain management. Companies must be highly flexible and establish high levels of risk mitigation capabilities and structural flexibility in order to survive, particularly in COVID 19 pandemic-like scenarios, which is feasible with the use of appropriate technological advancements. COVID-19 has compelled businesses to rethink their business strategy; thus, integrating SCM managers' processes with digital technology is critical. To align SC priorities with organizations goals, the SC department should integrate, rethink functional structures, and change the emphasis to more strategic tasks. Although several technologies exist, SC management must embrace IoT since it may greatly benefit the SC domain.

Digital supply chain

It is not always possible to handle all operations from a centralized authority. And with COVID like situations resulted in the shutdown of companies or SC managers to work from home. These unanticipated situations created hassles and, thereby, poor performance. The business's downturn in retailing and operation, since most finished items move through the SC sector to end customers, has also impacted the manufacturing industry, particularly non-essential commodities. A recent survey by PwC found that trade activities in the country experience a loss of about 900 billion dollars due to COVID 19 (PwC, 2020). Hence to mitigate the impact of COVID 19 on business activities, supply chain industries must employ innovative measures in digitalization. IoT devices give real-time data on location, speed, and other parameters like temperature for supply chain activities. Much of this information would be difficult or impractical to obtain manually. Professionals are more prepared to reduce interruption, anticipate more precise expected arrival times, and maintain open contact with customers and other stakeholders (Thomas, 2021).Though IoT devices are transforming supply chain management (SCM) basics, the technology will have the most significant influence in digital edge situations.

Proposition 1: Interoperability, heterogeneity, Identification, and sensing features of IoT will positively influence SCM professionals for undertaking Digitalization in SC.

Validation

The asset tracking ability of RFID and GPS sensors are Internet of Things-enabled devices that can monitor items "from flooring to store" (Thomas, 2021). It is observed that IoT has tremendous capabilities like supply chain visibility, adaptability and agility to cope with several SC professionals challenges (Ellis et al., 2015). IoT sensors give more accurate inventory than humans can. Companies can more accurately control stock levels because information on the delivery of raw - materials to production lines, or produced commodities in warehousing, is provided in real-time. The IoT's Scheduled Maintenance capability can be well utilized to manage periodic and predictive maintenance for industry, resulting in less downtime and cost savings(Shen et al., 2020).

Proposition 2: Object characteristics like addressability, unique identity and mobility features of IoT will positively influence its adoption by SCM professionals in data validation by providing real-time analytics, transparency and more efficient regulations.

Performance management

The increase in product monitoring and traceability is a significant potential benefit firm may get from using IoT. Other possible advantages include improved inventory management and control, increased levels of interconnectedness among internal core business processes. The most essential data point for logistics experts is knowing where a cargo is at any given time. For cold chain operations, IoT devices give real-time data on location, speed, and other parameters like as temperature. Much of this information would be difficult or impractical to obtain manually. Professionals are more prepared to reduce interruption, anticipate more precise expected arrival times, and maintain open contact with customers and other stakeholders (Thomas, 2021).

Proposition 3: Openness, Autonomy, Real time context information features of IoT will positively influence its adoption by SCM professionals for comprehensive, systematic and transparent performance management.

Resilient operations

A study by Ivanov & Dolgui (2020) indicates that it is important for supply chains to make reactive decisions during shocks like COVID 19. And resilience operations can be made possible with digital supply chains. The COVID outbreak increased the pressure on supply chain operations to be more robust, resilient and flexible, resulting in a surge of investment in digital systems powered by IoT data (Haddud et al., 2017). As we prepare for a post-pandemic era, companies’ increased know-how and awareness of solutions like RAIN RFID, IoT will play a key role in evolving the industry’s approach to solving supply chain issues from reactive to proactive, setting them up for future success, says Jill West, Vice President of Strategic Communications at Imping (Thomas, 2021).

Proposition 4: Autonomy, Actuation, Openness features of IoT will positively influence its adoption by SCM professionals for undergoing resilient supply chain operations.

Data protection and surveillance

With the implementation of the General Data Protection Regulation (GDPR) on May 25,2018, the need for data security has assumed significance in the European context (GDPR, 2018) as non-compliance by the organization might attract penalties. GDPR protects and empowers the European citizens data privacy and reshapes the way organization across the region approach data privacy. The nature of the IoT is such that data sharing taking place will be published using technology. With the permissioned IoT hub, the access is restricted; thus, only the trusted parties are provided access.

Proposition 5: Enhanced security and actuation features of IoT will positively influence its adoption by SCM professionals in Data protection and surveillance from cyber-attacks.

Proposed Conceptual Framework

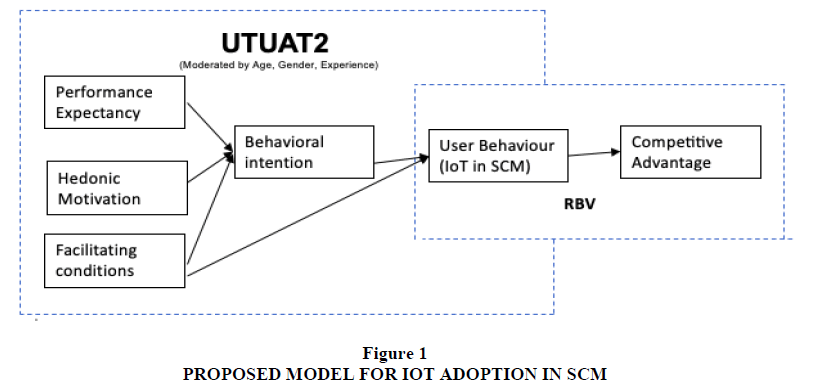

The Internet of Things is still in its early phases of development, and most companies have yet to realize its full potential. Several researchers contributed significantly to the development of technology acceptance models in the literature. Based on the literature's observations and contributions regarding the problems faced by SCM managers, the unified theory of acceptance (UTAUT) and also its extension UTAUT2 are appropriate in explaining IoT adoption in the SCM (Venkatesh et al., 2003; Venkatesh et al., 2012). While the UTAUT/UTAUT2 model describes adoption, i.e. user behaviour intentions and eventual technology usage, a viable model needs adjustment in the case of new and emerging technologies. We have included the resource-based view (RBV) in the suggested conceptual model for a more profound comprehension, i.e. motivation and adoption.

RBV supplements UTAUT/UTAUT2 by describing how IoT enables businesses to better leverage their internal resources and skills to create a competitive edge. RBV proposes that companies make rational decisions influenced by their internal operational economic situation (Oliver et al., 1997). An organization is defined by RBV as a collection of resources. They are the valuable, scarce, imperfectly unique, and non-substitutable resources that generate institutional competitive advantages (Barney, 1991). Figure 1 summarizes the proposed conceptual model.

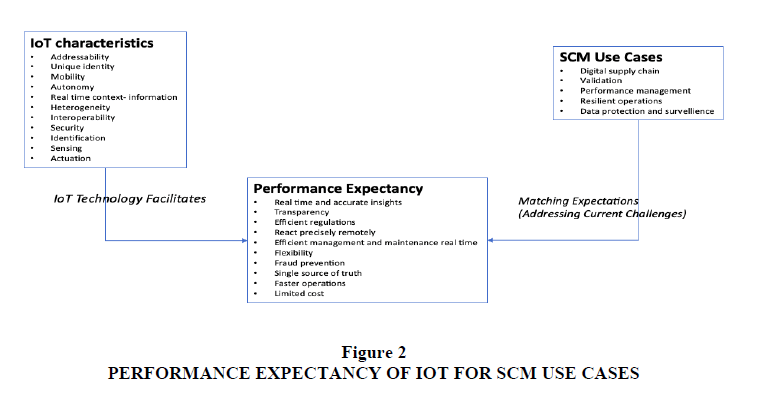

In this performance expectancy of IoT, addressing the current SCM challenges is the key construct. The finer elements of the performance expectancy are summarized in Figure 2.

As noticed in the literature, multiple business domains are actively exploring the IoT. Considering the executives' novelty-seeking tendency and competitive pressures in the digital era, retained the "Hedonic motivation" construct of the UTAUT2 framework. This construct becomes vital as multiple parties involved in the network need to relish and continue in the IoT SC network. The IoT features has compatibility, control over the system map to the "Facilitating Conditions" of the UTAUT2 framework and hence retained. Open source development, enhancements in Logistics and transportation and entrepreneurial business opportunities related to IoT hub also facilitate its adoption. Considering the early stages of the IoT, limited scope/evidence of the current study, few other constructs (i.e. effort expectancy, social influence, price value, habit) of the UTAUT2 framework were not included.

Implications

In this paper, we develop a conceptual model to understand the importance of IoT adoption in SCM practices. By leveraging the literature support, this study made three important contributions to the research in this domain.

First, although, IoT has been considered to be implemented in several domains and functions, it has received less attention and full-fledged implementation in Supply chain domain. Therefore, this paper assumes significance, given the enormous potential of IoT for Supply chain professionals.

Secondly, theoretical perspective, this study integrates RBV and UTAUT/UTAUT2 by explaining how IoT adoption helps organizations use their internal resources and capabilities to gain a competitive advantage.

Thirdly, considering the challenges faced by SCM during this COVID scenario, and changes to be incorporated in the new normal post COVID scenario, especially in countries like India, needs professionals support. This study tries to examine how technologies like IoT can help SC professionals to cope up with such challenges and enhance their smooth operations with IoT adoption.

Conclusion and Future Scope

Solutions get more sophisticated and superior as technology advances and companies compete. Over the next decade, IoT technology will continue to drive transformation in a number of industries. Businesses that grasp the possibilities of IoT will indeed be better positioned to take advantage in the coming years. Responding to the impact of COVID-19 on the supply chain sector, players across the value chain have implemented effective methods aimed at maintaining production and ultimate customer delivery. Some of the creative approaches include the use of IoT technology to monitor and accept consumer orders, strategic collaborations between manufacturers, middlemen, and delivery firms, innovative inventory management to minimize stock-outs, and so on. The majority of these strategies have shown to be beneficial and should be continued in the future.

COVID 19 has provided an unparalleled opportunity for current and upcoming SCM leaders to navigate through difficulties and play a pivotal role in strengthening the relation with stakeholders, business leaders, clients and others. For today’s supply chain domain, it is important to accelerate the digitalization processes and with IoT seeming to be the most promising solution of SC professionals for entire SC practices. Future research has scope to extend this conceptual model and empirically test the research propositions.

References

Asemani, M., Abdollahei, F., & Jabbari, F. (2019). Understanding IoT platforms: towards a comprehensive definition and main characteristic description. 2019 5th International Conference on Web Research (ICWR).

Indexed at, Google Scholar, Cross Ref

Barney, J. (1991). Firm resources and sustained competitive advantage. Journal of Management, 17(1), 99-120.

Indexed at, Google Scholar, Cross Ref

Ben-Daya, M., Hassini, E., & Bahroun, Z. (2019). Internet of things and supply chain management: a literature review. International Journal of Production Research, 57(15-16), 4719-4742.

Indexed at, Google Scholar, Cross Ref

Capgemini. (2020). Fast forward Rethinking supply chain resilience for a post - COVID 19 world.

Chatterjee, S., Moody, G., Lowry, P.B., Chakraborty, S., & Hardin, A. (2015). Strategic relevance of organizational virtues enabled by information technology in organizational innovation. Journal of Management Information Systems, 32(3), 158-196.

Indexed at, Google Scholar, Cross Ref

Ellis, S., Morris, H.D., & Santagate, J. (2015). IoT-enabled analytic applications revolutionize supply chain planning and execution. International Data Corporation (IDC) White Paper, 13.

Gartner. (2020). Internet of things: Unlocking True Digital Business Potential.

GDPR, E. (2018). Frequently asked questions about the incoming GDPR. In.

Haddud, A., DeSouza, A., Khare, A., & Lee, H. (2017). Examining potential benefits and challenges associated with the Internet of Things integration in supply chains. Journal of Manufacturing Technology Management.

Indexed at, Google Scholar, Cross Ref

Hossein Motlagh, N., Mohammadrezaei, M., Hunt, J., & Zakeri, B. (2020). Internet of Things (IoT) and the energy sector. Energies, 13(2), 494.

Indexed at, Google Scholar, Cross Ref

IDC, M.A.T. (2020). IoT, Platforms and Analytics: 3 Driving Forces for Logistics BPO Services.

Ivanov, D., & Dolgui, A. (2020). A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control, 1-14.

Indexed at, Google Scholar, Cross Ref

Javed, A.R., Sarwar, M.U., Beg, M.O., Asim, M., Baker, T., & Tawfik, H. (2020). A collaborative healthcare framework for shared healthcare plan with ambient intelligence. Human-centric Computing and Information Sciences, 10(1), 1-21.

Indexed at, Google Scholar, Cross Ref

Li, Z., Wang, W.M., Liu, G., Liu, L., He, J., & Huang, G.Q. (2018). Toward open manufacturing: A cross-enterprises knowledge and services exchange framework based on blockchain and edge computing. Industrial Management & Data Systems.

Indexed at, Google Scholar, Cross Ref

Medhi, D.P.K. (2019). Is Academic Research in Industry 4.0 and IoT Aligned to the Industrial Needs-A Text Analytic Approach. Available at SSRN 3450480.

Indexed at, Google Scholar, Cross Ref

MI. (2020). INTERNET OF THINGS (IOT) MARKET - GROWTH, TRENDS, COVID-19 IMPACT, AND FORECASTS (2021 - 2026).

Oliver, R.L., Rust, R.T., & Varki, S. (1997). Customer delight: foundations, findings, and managerial insight. Journal of Retailing, 73(3), 311-336.

Indexed at, Google Scholar, Cross Ref

Papadopoulos, T., Baltas, K.N., & Balta, M.E. (2020). The use of digital technologies by small and medium enterprises during COVID-19: Implications for theory and practice. International Journal of Information Management, 55, 102192.

Indexed at, Google Scholar, Cross Ref

Pauli, T., Fielt, E., & Matzner, M. (2021). Digital Industrial Platforms. Business & Information Systems Engineering, 63(2), 181-190.

Indexed at, Google Scholar, Cross Ref

PwC. (2020). www.pwc.com/ng/COVID-19.

Rahmani, A.M., Thanigaivelan, N.K., Gia, T.N., Granados, J., Negash, B., Liljeberg, P., & Tenhunen, H. (2015). Smart e-health gateway: Bringing intelligence to internet-of-things based ubiquitous healthcare systems. 2015 12th Annual IEEE Consumer Communications and Networking Conference (CCNC).

Serral, E., Vander Stede, C., & Hasi?, F. (2020). Leveraging IoT in Retail Industry: A Maturity Model. 2020 IEEE 22nd Conference on Business Informatics (CBI).

Indexed at, Google Scholar, Cross Ref

Shen, W., Yang, C., & Gao, L. (2020). Address business crisis caused by COVID-19 with collaborative intelligent manufacturing technologies. IET Collaborative Intelligent Manufacturing, 2(2), 96-99.

Indexed at, Google Scholar, Cross Ref

Speranza, M.G. (2018). Trends in transportation and logistics. European Journal of Operational Research, 264(3), 830-836.

Indexed at, Google Scholar, Cross Ref

Thatcher, M.E., & Oliver, J.R. (2001). The impact of technology investments on a firm’s production efficiency, product quality, and productivity. Journal of Management Information Systems, 18(2), 17-45.

Indexed at, Google Scholar, Cross Ref

Thomas, R. (2021). IoT: The Eyes and Ears of the Supply Chain.

Tu, M. (2018). An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management: A mixed research approach. The International Journal of Logistics Management.

Indexed at, Google Scholar, Cross Ref

Ummesalma, M., Subbaiah, R., & Narasegouda, S. (2020). A Decade Survey on Internet of Things in Agriculture. In Internet of Things (IoT) (pp. 351-370). Springer.

Indexed at, Google Scholar, Cross Ref

Venkatesh, V., Morris, M. G., Davis, G. B., & Davis, F. D. (2003). User acceptance of information technology: Toward a unified view. MIS quarterly, 425-478.

Indexed at, Google Scholar, Cross Ref

Venkatesh, V., Thong, J. Y., & Xu, X. (2012). Consumer acceptance and use of information technology: extending the unified theory of acceptance and use of technology. MIS quarterly, 157-178.

Indexed at, Google Scholar, Cross Ref

Wessel, L., Baiyere, A., Ologeanu-Taddei, R., Cha, J., & Blegind-Jensen, T. (2021). Unpacking the difference between digital transformation and IT-enabled organizational transformation. Journal of the Association for Information Systems, 22(1), 102-129.

Indexed at, Google Scholar, Cross Ref

WorldEconomicForum. (2021). Industrial internet of things: Unleashing the potential of connected products and services.

Received: 03-Dec-2022, Manuscript No. AAFSJ-22-12960; Editor assigned: 05-Dec-2022, PreQC No. AAFSJ-22-12960(PQ); Reviewed: 19-Dec-2022, QC No. AAFSJ-22-12960; Revised: 22-Dec-2022, Manuscript No. AAFSJ-22-12960(R); Published: 29-Dec-2022