Research Article: 2022 Vol: 28 Issue: 1S

Teaching Factory Learning Model to Improve Student's Entrepreneurship Competencies

Anik Kusmintarti, Polytechnic State of Malang

Sidik Ismanu, Polytechnic State of Malang

Ayu Sulasari, Polytechnic State of Malang

Tri Yulistyawati Evelina, Polytechnic State of Malang

Citation Information: Kusmintarti, A., Ismanu, S., Sulasari, A., & Evelina, T.Y. (2022). Teaching factory learning model to improve student’s entrepreneurship competencies. Academy of Entrepreneurship Journal, 28(S1), 1-19.

Abstract

The purpose of this research is to develop an entrepreneurship learning model with the teaching factory method to improve students' entrepreneurship skills. This is a research and development study, conducted at Polinema Bakery. The research stages include: (1) exploring potential problems; (2) collecting information on the bakery business, (3) designing a teaching factory learning model; (4) Implementing the Teaching Factory Learning model. We used simulation method to implement the model. The results of the study stated that after following the Teaching Factory Learning, students achieved a number of entrepreneurship skills which include risk-taking behavior, be innovative, disciplined, confident to create and sell products, improve public speaking skills, gain knowledge about the real bakery business, improve decision making skills, financing, marketing, sales. In addition, be responsible, creative, consistent, and focus on goals despite many obstacles.

Keywords

Learning Model, Teaching Factory, Entrepreneurship Competencies.

Introduction

In March 2020, the President of Indonesia, Joko Widodo announced that the corona virus had entered Indonesia, and COVID 19 had become a pandemic. The Indonesian government seeks to inhibit the spread of the COVID-19 virus, among others, by conducting regional quarantine and Large-Scale Social Restrictions (PSSB). This condition has an impact on the economic activity in Indonesia. Most MSMEs and companies experience a decline in sales turnover and profits. As a result, the company took a policy to reduce the number of workers or laying off of employees. This causes the number of unemployed to increase and the number of jobs to decrease.

Small businesses are the driving force of the national economy and create new job opportunities (Hormozi, 2004), and entrepreneurship is recognized by all countries in the world. The increase in the number of entrepreneurs in a country is directly proportional to the level of prosperity of a country. David McClland suggests that a country tends to be prosperous in the future if it has a minimum number of entrepreneurs, 2% of the total population. This means that the more the number of entrepreneurs, the lower is the unemployment rate in a country, because entrepreneur can create job opportunities for the business owner as well as others. Therefore, the government gives full attention to increasing the number of entrepreneurs through fresh graduates from universities.

The National Entrepreneurship Movement serves as a forum for developing entrepreneurial mentality and increasing the number of entrepreneurs in Indonesia. This declaration is included in the Draft Law of the Republic of Indonesia, the National Entrepreneurship Article 21. The government, through the Ministry of Education and Culture provides supports for increasing the number of entrepreneurs by organizing entrepreneurship programs for students to encourage graduates to become interested in entrepreneurship.

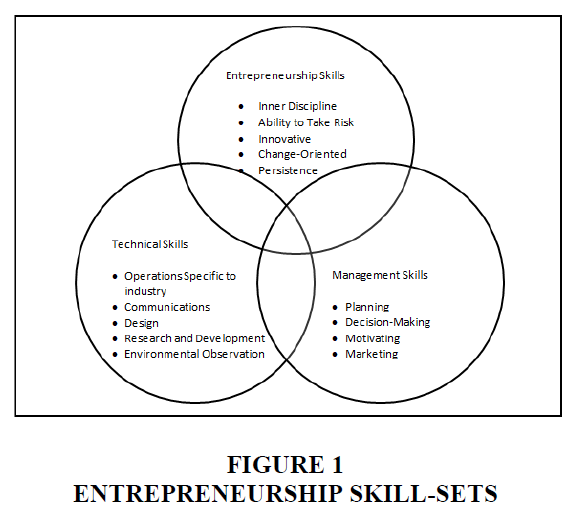

Entrepreneur is an alternative career choice for graduates. People who want to become entrepreneurs must have certain skills-set: entrepreneurship skills, technical skills and management skills. Entrepreneurship skills include: inner discipline, ability to take risk, be innovative, be change-oriented, and persistent. Technical skills include: industry specific operations, communications, design, research and development, and environmental observation. Management skills include: planning, decision-making, ability to motivate, marketing, finance, and selling (Cooney, 2012). The question arises, how is learning that can provide a number of entrepreneurship skills be designed?

Learning is the process of teaching students in a defined way to achieve learning objectives. According to Law Number 20 of 2003, concerning the National Education System, learning is defined as a process of interaction between students and educators and learning resources in a learning environment. Furthermore, Komalasari (2013) defines learning as a system or process of teaching students or learners that is planned or designed, implemented and evaluated systematically, so that learners can achieve learning goals effectively and efficiently.

The achievement of entrepreneurship learning objectives is determined by the accuracy of the selection of learning methods. If the goal of entrepreneurship education is to equip a person with entrepreneurship skills that can be applied directly, the best way is to provide education and training that allows a person to be directly involved in the entrepreneurial process. This includes training involving industry. On the other hand, if the goal of entrepreneurship education is to prepare a person to act as an entrepreneur, the most effective way is to facilitate experimentation by trying entrepreneurship in a controlled environment, for example, through business simulations or role playing (Ahmad, Baharun & Rahman, 2004). In this study, the purpose of entrepreneurship learning is to equip students with a number of entrepreneurship skills-set, namely: Entrepreneurship skills, Technical skills and Management skills. Teaching factory as a learning concept has to be in a real atmosphere, so that it can bridge the competency gap between industrial needs and school knowledge (Kuswantoro, 2014).

Based on the description above, the purpose of this study is to develop an entrepreneurship learning model with the teaching factory method to improve students' entrepreneurship competencies.

Entrepreneurship Skills

Entrepreneurship is a discipline, like any other discipline that can be studied (Drucker, 1985). Currently, being an entrepreneur is an alternative career choice for some college graduates. Reality shows that some students operate a business while studying. Even though they do run a business, everyone’s level of entrepreneurship competencies is different (Lichtenstein & Lyons, 2001). As mentioned before, everyone who wants to become an entrepreneur must have entrepreneurship skills-set: Entrepreneurship skills, Technical skills, and Management skills (Cooney, 2012). Figure 1 describes the entrepreneurship skills-set.

Kutzhanova, Lyons, and Lichtenstein (2009), researchers in entrepreneurial development systems, identified four main dimensions of skills:

1. Technical Skills, which are those skills necessary to produce the business product or service;

2. Managerial Skills, which are essential to the day-to-day management and administration of the company;

3. Entrepreneurial Skills, which involve recognizing economic opportunities and acting effectively on them;

4. Personal Maturity Skills, include self-awareness, accountability, emotional skills, and creative skills.

Based on the above explanation, to become a successful entrepreneur, one must have all the above four skills.

Teaching Factory Concept

Teaching factory is a means of student learning to gain competence in accordance with the real situation in the industry. The teaching factory concept is a combination of realistic learning and work environment and creates relevant learning experiences (Nanyang Polytechnic, 2018). Learning using the teaching factory concept was born because (1) routine learning is not sufficient, (2) students benefit from direct practical experience, and (3) team-based learning experiences (students, lecturers and industry participation) enrich the educational process and provide tangible benefits for all parties (Lamancusa et al., 2008). In this case, industry as a partner supports the idea, lecturers as educators, and students as learners carry out intellectual recognition through the concept of the learning factory.

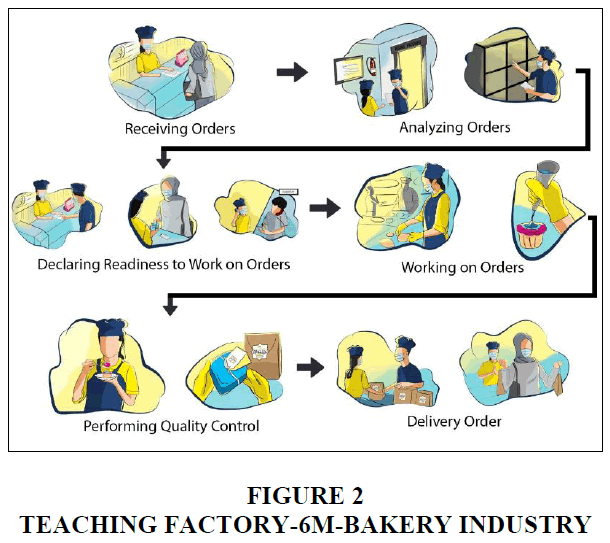

The Indonesian German Institute defines teaching factory as a learning concept in a real setting, so that it can bridge the competency gap between industrial needs and school knowledge. The same definition was put forward by Kuswantoro (2014). Teaching factory is a learning concept in a real situation to bridge the competency gap between the knowledge provided by the school and the needs of the industry. Based on these definitions, Teaching Factory Learning can be interpreted as learning that provides services or products based on procedures and standards that have been set in the industrial world and applied according to the situation in the industry; Nurtanto et al. (2017) define Teaching factory as a combination of competency-based and production-based learning approaches, where the practical learning process is carried out resembling the practical processes carried out in the real world of work by holding production or service activities in the school environment. Furthermore, Martawijaya (2015) suggests that the Teaching Factory-6M Learning model in one work cycle consists of six steps, namely: receiving customers, analyzing orders, stating readiness to work on orders, working on orders, carrying out quality control, and submitting orders.

Previous Research Studies on Teaching Factory Learning

The results of previous studies stated that the 6-step teaching factory model, effectively increased students' productive competence (Martawijaya, 2011). Another researcher, Risdiana, Hidayat, and Suherman (2014) stated that the ability of students' hard skills in carrying out light service orders and carrying out quality control increased after participating in 6-Step Teaching Factory Learning; Amar, Hidayat, and Suherman (2015) stated that students' achievement motivation increased after following the TF-6M learning model. The characteristics of someone who has high achievement motivation include: (1) having a high responsibility for his duties; (2) setting challenging, difficult and realistic goals; (3) having hope of success; (4) working hard to achieve success; (5) not thinking about failure; and (6) trying to get the best results; Martawijaya (2012) states that the TF-6M model can improve student competencies, namely soft skills, hard skills, motivation, sense of responsibility and work ethic; Risnawan (2019) stated that the application of teaching factory management enables the provision to enter the industry, and the output is well absorbed by the industrial world.

Based on theoretical studies and previous research studies, it can be concluded that the implementation of the Teaching Factory model can improve a number of student skills, namely technical skills, managerial skills, entrepreneurial skills, and life skills.

Research Method

Research and development is carried out at the State Polytechnic of Malang, especially at the Polinema Bakery. The Polinema bakery is small business. The research stages include: (1) exploring potential problems; (2) digging up information about the bakery business, (3) designing a Teaching Factory Learning model; (4) implementing the Teaching Factory Learning model. Implementation is done by simulating Teaching Factory learning.

Results

The number of students who are in entrepreneur is one of the performance indicators for the Director of the Malang State Polytechnic. The researcher’s questions include. What type of skills should students have in order to become an entrepreneur?, What learning models can provide entrepreneurial skills? To answer these questions, an industrial survey was conducted in the Polinema Bakery so as to investigate the bakery business process, starting from consumers placing orders until sending the orders to consumers.

The description of the bakery industry process is grouped into the following stages: (A) receiving bakery orders; (B) analyzing bakery orders; (C) declaring readiness to work on bakery orders; (D) working on bakery orders; (E) performing bakery quality testing; (F) submitting bakery orders. The details of each stage is explained as follows.

Receiving Bakery Orders

Consumers meet the cashier to place an order for bakery, at the same time, the cashier invites consumers to view the bakery catalog and collect the order form. The bakery catalog contains various product variants offered to consumers. Next, the consumer selects the product and fills out the order form. The procedure for receiving bakery orders from consumers is as follows:

1 Consumers meet the cashier to order a bakery item.

2 The cashier invites consumers to pick up the bakery catalog and order form.

3 The cashier writes the order on the duplicate order form. The original order form is given to the production team, and the duplicate is archived.

Order Analysis

The procedure for analyzing consumer orders is as follows:

1 The cashier gives the customer order form to the production team.

2 The production team analyzes customer orders and decide whether to accept or reject the order. The analysis is carried out on the availability of raw materials, direct labor, and the need for overtime hours. The team will then fill out the production readiness form.

Analysis of raw material availability

The production team checks the availability of raw materials needed to produce consumer orders. Are the raw materials sufficient? If the raw materials are sufficient, the production team puts a check on the box, next to the readiness of the raw materials on the production readiness form. However, if the raw materials are insufficient, then the production department fills out the raw material order form. The form is made in duplicate. The original is filed and 2 copies are given to the cashier.

Analysis of direct labor availability

The production team calculates the amount of direct labor needed to work on the consumer product orders. If there are sufficient direct workers, the production team checks the readiness of direct workers on the production readiness form. However, if it is not sufficient, then the production department fills out a direct labor request form. The form is made in duplicate, original is filed and 2 copies are given to the cashier.

Analysis of the need for overtime hours

The production team calculates direct labor hours. Are overtime hours needed? If there is no need for overtime hours, then the production team puts a check next to ‘Do not require overtime hours’ on the production readiness form. However, if overtime hours are needed, then the production department fills out a form requiring overtime hours. The form is made in duplicate, original is filed and 2 copies are given to the cashier.

Readiness to work on orders

At this stage, the cashier receives confirmation that the production manager is ready to work on the order. Confirmation of ‘Readiness to work on orders’ is indicated on the production readiness form, which is then endorsed by the production manager. The cashier then informs the consumer that the order is received and the customer makes the payment. Then, the cashier contacts the supplier to place an order for raw materials.

Documents and forms are used when stating readiness to work on orders, namely: product order forms, production readiness forms, order payment receipts, and receipts for purchasing raw materials. The personnel involved in this stage are cashiers, consumers and suppliers. The procedure for stating readiness to work on an order is as follows:

1. Based on the confirmation from the production team (form signed by the production manages), customer orders are executed, the cashier provides information to consumers that the order is confirmed.

2. Consumers pay a deposit, as required, based on the agreement made by both parties, namely the cashier and the consumer.

3. The cashier accepts payments from consumers and gives a receipt to the consumer as a proof of payment.

4. The cashier purchases raw materials from the suppliers, gets a payment receipt from the supplier for the materials purchased.

5. The cashier looks for additional direct labor, if needed.

6. The cashier calculates the number of hours needed for the job and then decides if additional hours of overtime work is required.

7. The cashier informs the production team that the raw materials are ready, the workforce is ready, and the additional working hours have been calculated and approved.

Working on orders

The production team produces consumer-ordered products. Documents and forms used at this stage are: recipe books, bakery production flowcharts, and order forms. The people involved are the production team. The procedure for working on an order is as follows:

1. Production team prepares production equipment to start working on customer orders.

2. The production team weighs the raw materials according to the bakery order.

3. Production team prepares the dough.

4. After making the dough, they proceed with the initial fermentation.

5. Next, the production team makes dough balls according to the weight of the bakery product that is made.

6. The production team will then fill and shape the dough.

7. The next step is to do the topping.

8. Once the topping is made, they will proceed with baking.

9. When the baked item is ready, then it has to be cooled.

Quality Control

The quality testing comes after the bakery item passes through the cooling stage. If it passes the quality test, then it is ready to be packaged. The documents needed during this stage are: order form, quality testing flowchart, and quality testing form. The people involved are the production team.

The quality testing procedure is as follows:

1 The production team conducts quality testing, including: taste, bakery texture, and appearance of the bread.

2 If the quality of the bakery is in accordance with the standards required, then the results are recorded on the quality test form and quality record book. But if the quality is not up to standard, then the bakery item is sorted.

3 The next procedure is to package the item and box it.

Delivery the order

The cashier receives confirmation from the production team that the order has been completed and is ready to be handed over to the customer. Documents needed are: order forms, product delivery flowcharts, and sales notes. The people involved are the production team and the cashier. The procedure for delivering products to consumers is as follows:

1. The cashier receives confirmation from the production team that the ordered product is complete.

2. The cashier hands over the ordered product to the consumer.

3. Consumers receive the product and make the payment.

4. The cashier receives payment and makes 2 copies of sales notes. One is given to the consumer and the other is archived. They are then recorded on the sales report.

5. Consumers gets a receipt as proof of payment.

The next research step is to design the Entrepreneurship Learning Model with the Teaching Factory Method. The bakery industry business process begins with the consumer placing an order for the product to the cashier. Then the production team analyzes the order to find out whether it is accepted or rejected. If accepted, the production team informs the cashier to deliver the item to consumers. Furthermore, the production team prepares orders, continues to carry out quality control, and finally submits orders to consumers. The design drawing of the entrepreneurship learning with the Teaching Factory-6M Learning model is shown in Figure 2.

To find out the results of teaching factory learning, the implementation was carried out using the simulation method. A total of 10 students were involved in the simulation, having the following roles: one person as a consumer; one person as cashier, seven people in production, one person in delivery. After students take part in learning with the teaching factory method at the bakery polynema, students are asked to answer the following questions: (1) What skills did you acquire after participating in the entrepreneurship learning with the teaching factory method? (2) What benefits did you gain after participating in entrepreneurship learning with the teaching factory method? ; (3) In the future, do you think you would like to be an entrepreneur?

Students' answers to these questions are as follows:

Student #1

After I took part in learning with the teaching factory model, I gained a lot of knowledge and skills. I was motivated to stay involved and learn how to make the right business proposal. So, I also learned a lot about how to start a business, properly based on theory and practice. In addition, my ability to create and innovate increased.

Student #2

After I took part in learning with the factory teaching model, I acquired the skills to innovate, learn new things, survive in any kind of situation. I feel more responsible and willing to take risks. In the future, I want to develop the business that is currently in running.

Student #3

I am currently building a business in the culinary field. I hope that the products sold can be useful for the community, and can create jobs for the surrounding community. The skills that I have acquired after participating in entrepreneurship learning with the factory teaching method are, skills in processing the production of goods that are sold. Besides that, I am more disciplined and wiser in making decisions, an improvement that is needed when I go into the field and see firsthand that the product can be useful. In addition, I improved my skills in producing goods and marketing, skills that are needed to support the product that is being marketed.

Student #4

In the future I want to be an entrepreneur, because, apart from the fact it suits my personality, I hope that I will also be able to provide employment and thus reduce unemployment. After participating in entrepreneurship learning with the factory teaching method, I have developed new skills and learned to be innovative. These can help me improve the quality of products in general. In addition, I noticed an overall improvement, especially in the management area, which is a very risky and necessary skill for every entrepreneur. In addition, good organization can improve the quality of management of an entrepreneur who expects to be able to achieve the set targets.

Student #5

Yes, in the future I will be an entrepreneur. As a young person who witness the growing condition of the human population, I can understand that the need for jobs is also increasing. With entrepreneurship, I can create jobs for myself and others. Along with the growth in economy, entrepreneurship can reduce unemployment and also improve people's lives. After taking entrepreneurship lessons with the teaching factory method, I understand what the current state of the industry is like and thus make it easier for us to innovate.

Student #6

I have been an entrepreneur for the past 4 years. After taking entrepreneurship lessons with the factory teaching method, I have improved my creativity and innovation skills. My entrepreneurial spirit has also improved. I feel more resilient and focused on my goals even though there are many obstacles and problems that arise in terms of the activities/businesses. In addition, my sense of efficiency (measurement of quality standards, time and cost) is also better, considering that I am in the tutoring service industry.

Student #7

Yes, in the future I will be an entrepreneur. By participating in entrepreneurship learning with the teaching factory method, my skills including creative digital/content creation, design, coding have improved. I am also better at product marketing strategy.

Student #8

Yes, in the future I will be an entrepreneur. Entrepreneurship learning with the teaching factory method increased my entrepreneurial spirit. I learned about commitment and consistency, taking responsibility, managing time, applying the knowledge gained in lectures. Besides that, entrepreneurial nature of my character certainly got better after completing teaching factory learning course, especially in terms of time management, taking responsibility, financial management and public speaking. By participating in the course, I have become more confident in terms of facing the industrial world in the future.

Student #9

Yes, in the future I will be an entrepreneur. After taking entrepreneurship lessons with the factory teaching method, I am more confident in creating and selling products and taking risks.

Student #10

Yes, because with entrepreneurship I can develop relationships, understand market strategies and especially get passive income outside of my main job. After participating in entrepreneurship learning with the factory teaching method, my perceptions have changed,. Now I understand market share and market interest better, especially in the technopreuner field.

Based on the results of the interview, it can be concluded that after participating in learning with the 6-step teaching factory method, students' entrepreneurship skills increased, although the types of skills acquired were different. These skills include: students feel that they have gained knowledge regarding the real bakery business; gained experience in managing a business, are able to make a good business plan, they are confident with creating and selling products; they have better marketing skills, financial management ability, they are better able to see market opportunities and market interests, wiser in decision making, have developed a sense of creativity and innovation, understand the sense of efficiency, dare to take risks, also developed a sense of responsibility, discipline, public speaking, and networking.

Conclusion

The results of the study stated that students had a number of entrepreneurship skills after participating in entrepreneurship learning with the 6-step teaching factory method, namely: (1) receiving bakery orders; (2) analyzing bakery orders; (3) showing a readiness to work on bakery orders; (4) performing bakery quality testing; (5) submitting bakery orders. Students have developed entrepreneurial skills (dare to take risks, innovate, and be disciplined); technical skills (dare to create and sell products, public speaking, gain knowledge about the real bakery business); Management skills (decision making, finance, marketing, sales), and personal maturity skills (responsible, creative, consistent, and focused on goals despite many obstacles). The students' entrepreneurship competencies can grouped into three groups: entrepreneurship skills, technical skills, and management skills.

The findings of this study strengthened the results of previous studies which stated that students' productive competencies increased after following the 6-step teaching factory model. Likewise, the ability of students' hard skills, i.e. carrying out light service orders and carrying out quality control, has increased after participating in the 6-Step Teaching Factory learning. Stated that the six-step teaching factory is effective in increasing students' productive competence. suggests that the TF-6M model can improve student competencies, including: soft skills, hard skills, motivation, sense of responsibility and work ethic.

References

Ahmad, F., Baharun, R., & Rahman, S.H.A. (2004). Interest in entrepreneurship: an exploratory study on engineering and technical students in entrepreneurship education and choosing entrepreneurship as a career. RMC project: Vot 71790. Faculty of Management and Human Resource Development Universiti Teknologi Malaysia.

Amar, A.F., Hidayat, D., & Suherman, A. (2015). Application of the 6-step teaching factory learning model (tf-6m model) to increase student achievement motivation in vocational high schools. Journal of Mechanical Engineering Education, 2(2), 189-198.

Cooney, T.M. (2012). Entrepreneurship Skills for Growth-Orientated Business. Dublin Institute of Technology. Report for the Workshop on “Skills Development for SMEs and Entrepreneurship”. OECD. LEED. Copenhagen.

Hormozi, A.M. (2004). Becoming an entrepreneur: How to start a small business. International Journal of Management, 21(3).

Komalasari, K. (2013). Pembelajaran Kontekstul: Konsep dan Aplikasi. Bandung : PT Refika Adiatama

Kuswantoro, A. (2014). Teaching Factory Rencana dan Nilai Entrepeneurship. Graha Ilmu: Semarang.

Martawijaya, D.H. (2015). Model TF-6M: Model Pembelajaran Teaching Factory 6M. Edisi 2

Nanyang Polytechnic. (2018). Teaching factory concept. https://www.nyp.edu.sg/schools/seg/innovative-teaching-and-learning.html. Accessed on 02 Aug 2021.

Nurtanto, M., Ramdani, S.D., & Nurhaji, S. (2017). Development of teaching factory models in vocational schools. Proceedings of the National Seminar on Education FKIP UNTIRTA, 447-454.

Risdiana, T., Hidayat, D., & Suherman, A. (2014). Improving students' hardskills through the implementation of the 6-step teaching factory learning model. Journal of Mechanical Engineering Education, 1(1), 154-161.

Risnawan. (2019). Teaching factory management in efforts to develop learning quality in vocational high schools. Educational Management Media, 2(1).