Research Article: 2022 Vol: 28 Issue: 4S

The Impact of Green Supply Chain Management Practices on Business Performance of Extractive Industries in Jordan

Fatima Lahcen Yachou Ait Yassine, Irbid University College

Citation Information

Yassine, F.L.Y.A. (2022). The impact of green supply chain management practices on business performance of extractive industries in Jordan. Academy of Entrepreneurship Journal, 28(S4), 1-12.

Abstract

The study aimed at examining the impact of green supply chain management practices on business performance of extractive industries in Jordan. Data were gathered using an electronic questionnaire administered to a sample encompassed managers of purchasing, distribution, production functions of supply chain. The findings revealed that green manufacturing was in the first rank in terms of its impact on business performance, while green design and green distribution were in the second and third ranks. Reverse logistics had the lowest impact on business performance. On the other side, environmental collaboration and green purchasing had no significant effects on business performance.

Keywords

Green Supply Chain Management Practices, Business Performance, extractive industries, Jordan

Introduction

Interest in environmental issues including air pollution, solid waste management, exhaustion of the ozone layer as well as global warming received a noticeable importance from governments, societies and business organizations, (Jemai et al., 2020; Al- Quran et al., 2020). Industries in many countries form the structure of the economy, especially in developing countries, they are considered a source of pollution and environmental deterioration in them, because industries produce more emissions compared to other commercial activities, all in order to meet consumer needs and demands. Consequently, practices of green Supply Chain Management (SCM) gained extant importance due to its role in reducing the negative effects of the industrial processes and can enhance the competitive advantage of companies (Al-Hawary & Al-Jawazneh, 2011; Shahzad et al., 2020; Wang et al., 2020).

Environmental problems are becoming important to companies because stakeholders, including management, customers, competitors, NGOs, and employees, are increasingly demanding that companies address environmental and social sustainability in industrial and commercial operations (Carter & Easton, 2011; Ashraf et al., 2020). Companies’ abilities to reduce their environmental effects depend on their abilities to manage complex supplier relationships (Darnall et al., 2008; Le, 2020; Reche et al., 2020). One way to lessen the environmental effects of business organizations is through planning to manage green supply chains and control business activities from suppliers of raw materials to end customers and creating relationships that bind supply chain partners together (Linton et al., 2007; Micheli et al., 2020; Shahzad et al., 2020). Environmental Management (EM) focus has shifted to the supply chain level (Linton et al., 2007; Gao et al., 2020), which means that GSCM has emerged as a way to syndicate the elements of EM and GSCM (Srivastava, 2007; Yang et al., 2013; Pan et al., 2020), that is why companies incline to adopt GSCM practices. Companies also are apt to adopt GSCM practices due to external factors related to stakeholder pressure in addition to internal factors occasioning strategic processes of companies. On the positive side, GSCM practices enhance corporate image, rise efficiency and enrich innovation leadership (Testa & Iraldo, 2010; Banik et al., 2020; Shahzad et al., 2020; Wang et al., 2020).

Nowadays, business environment related risks become one of the most imperative challenges that face organizations. Such risks cannot be ignored in strategic planning in any organization, so that risk control represents an indicator that governs organizations’ abilities to adapt to the accelerating changes of the business environment, hence, organizations should find the best means to secure its continuity considering these changes based on their efforts in GSCM. Basically, the current study aims as investigating the impact of GSCM practices on business performance in extractive industries in Jordan.

Theoretical Framework and Hypotheses Development

GSCM Practices

Deeming EM as a strategic direction boosts organizational performance, companies, nowadays, seek to cultivate friendly environmental approaches within their supply chains (Diabat and Govindan, 2011; Shahzad et al., 2020; Wang et al., 2020). GSCM practices are an important way for companies to achieve their environmental goals (Micheli et al., 2020; Shahzad et al., 2020).

Companies may apply GSCM practices as provisions to meet the requirements that arise in complex supply chains, where GSCM practices join environmental concerns into products flow within organizational boundaries in order to improve efficiency and diminish environmental damage. These practices have become an accepted approach to managing industries (Kang & Hwang, 2017; Bhatia & Gangwani, 2021). Expressly, with the increase in environmental awareness in recent years, a consensus has been reached that the issues of GSCM and environmental pollution must be integrated through evaluating suppliers based on their environmental performance, developing environmentally friendly products and reducing carbon emissions associated with product transportation. The era of globalization has seen intense competition, rapid developments in technology and increased complexity of products, all of which create the need for continuous improvements in supply chain policies for companies. As a result, one of the many applications developed to meet this necessity is the concept and practices of green supply chain (Liu et al., 2020; Li et al., 2020).

Literature on GSCM contains a wide range of definitions of this concept (Ashraf et al., 2020; Le, 2020; Reche et al., 2020 Micheli et al., 2020; Shahzad et al., 2020). All authors agree that the GSCM includes coalescing environmental awareness with supply chain management. It was defined as an environmental innovation that integrates environmental issues into Supply Chain Management (SCM) (Seman & Arif, 2012; Li et al., 2020; Liu et al., 2020). GSCM started in the early 1990s when companies decided to go green with SCM due to the environmental impacts of production GSCM consists of recycling, reuse and replacement, as well as monitoring and improving the environmental performance. The concept also refers to the integration of certain practices such as product design, delivery, raw material selection, and waste management into the supply chain by considering environmental considerations (Srivastava, 2007).

GSCM is nowadays one of the emerging developments that companies try to implement. Khairani, Rajamanoharan & Thirumanickam (2012) pointed out that every company should undertake a standard shift regarding its environmental commitment in order to gain a competitive advantage in global markets where competitive advantage and environmental sustainability are believed to coexist. In emerging economies, GSCM practices are not highly imposed since there are only few companies that apply these practices due to a lack of concern for the environment (Geng, Mansouri & Aktas, 2017).

The main objective of GSCM practices is to ensure that companies consider environmental issues while making progress in their supply chains. Through this environmental awareness, GSCM practices aimed at eliminating environmentally hazardous processes from the supply chain, thus enhancing the companies’ environmental effectiveness and decreasing their risks. At the same time, it helps increase its profitability and market share (Seman & Arif, 2012; Li et al., 2020; Liu et al., 2020). The increasing significance of GSCM practices stems mainly from decreasing sources of raw materials and rising pollution.

GSCM practices emerged as a fundamental component of business value (Dadhich et al., 2015; Banik et al., 2020; Micheli et al., 2020). It represents a combination of viable practices in SCM upstream, including management of materials, design of products, manufacturing, distribution of products and management of product lifecycle. GSCM may leads to a decrease in profits, so the concept of GSCM means that all practices in the supply chain parts are responsible for reducing the environmental impacts associated with the operations of supply chain to guarantee more long-run profits (Ghobakhloo et al., 2013; Dadhich et al., 2015). Ghobakhloo et al., (2013) identified several practices of GSCM such as green design, green purchasing, green manufacturing, reverse logistics, Environmental cooperation with suppliers, and green distribution.

Green Purchasing

Green purchasing is a practice of using less dangerous activities or materials instead of using risky activities or materials. It is categorized as dual process consists of selecting and supplying green resources. This practice includes standards for supplies that can be handled in the management of green ingredients so that the supplies used in the product is easy to detached, adapted, or used in order to simplify existing operations (Hervani et al., 2005; Liu et al., 2020).

Green Design

Green design opens occasions to reduce any environmental influences inherent in creating first-hand products and production methods. Green product design encompasses two basic notions: explicitly, Environmentally Conscious Design (ECD) and lifecycle assessment (LCA) (Ghobakhloo et al., 2013). The later can be demarcated by its emphasis on the inquiry of the environmental problems of methods and products during its complete life cycle. Moreover, it minimizes the negative effects of the environment; therefore, companies use it to promote the expansion of their products (Gungor & Gupta, 1999; Buyle et al., 2013; Shahzad et al., 2020).

Green Manufacturing

Green manufacturing is a process comprises of three core stages: first, reducing the use of resources, decreasing waste and emissions. The goal of these processes is to shrink the consumption of indigenous materials and other assets with the aim of decreasing the entire quantity of waste in the processing phase by plummeting the use of energy and resources (Srivastava, 2007). Such a practice decreases the environmental consequences by choosing reprocessed goods to ease emissions, which is another vital feature of green manufacturing (Ghobakhloo et al., 2013; Le et al., 2020).

Reverse Logistics

Reverse logistics represents an important module of GSCM aims to collect, distribute and manage products until they are provided to customers. Reverse logistics services were used to deal with unsupplied products and guarantee returns (Sarkis, 2003; Reche et al., 2020). They include recycling, remanufacturing and reusing of resources. Recycling is well described as a technique for reprocessing waste materials into a new form different from the principal use of those materials. According to Ghobakhloo, et al., (2013), advantages of recycling embrace drawing out of basic ingredients, decreasing use of energy, and minimizing water and air pollution such as reusing packaging or shipping things. As well, products can be recycled once more for related purposes through reprocessing or, in other words, renewing and recurring used durable goods for use to increase product life, and originate further value from the original base of the product (Sarkis, 2003).

Environmental Cooperation with Suppliers

To attain well environmental performance in the industry, the company need to form an environmentally competitive supply chain containing of suppliers designated by the company according to a rigorous assessment of environmental capabilities and collaborate with them while communicating based on their understanding of environmental capabilities. Hart (1995) proposed a natural resource-based view, signifying that a firm's association with the natural environment is critical to firm's competitive advantage, which lays on capabilities that enable environmentally sustainable growth. Wong, et al., (2012) indicated that organizations’ growth depends on their capabilities to conserve natural resources. Moreover, collaboration and coordination between companies is an unrivaled asset, which provides the company with a competitive advantage (Wang, 2012).

Green Distribution

Green Marketing (GM) was regarded as promoting or advertising of goods, changing the processes of production, or using packaging that are balanced in line with environmental criteria (Cox, 2008; Le et al., 2020). GM wires a green way of life and reflects the association between the environment and products. Green distribution is an important constituent in managing green supply chains because of its potential to have a significant positive effect on the surroundings (Ghobakhloo et al., 2012).

Business Performance

Performance measurement has been constantly growing by academics and practitioners due to the increasing criticism of financial measures for being short-term oriented, bearing in mind past performance, inconsistency with the present-day business environment, lacking predictive power focusing on physical assets, and enhancing job performance, being inappropriate at all levels in organizations. Thus, researchers are trying to find effective ways to measure performance. There is widespread interest in research related to the balanced scorecard, both in the development of its concept and its application in companies, government agencies, industrial and educational institutions, and this interest has reinforced the trend towards increasing use by organizations (Rumintjap, 2013; Wang et al., 2020).

The success of the company in its performance can be seen in terms of the achievements obtained. Every organization wants to know how it is performing, in addition to defining a strategy for the coming year. The company also uses performance as a form of accountability to stakeholders. The importance of knowing achievements encourages performance measurement (Al-Fitriyani, 2014; Banik et al., 2020). Performance measurement is a performance evaluation process that is conducted through setting standards and evaluating performance by comparing performance on the basis of established standards and feedback, whether by providing suggestions or inputs, and training to improve performance, So is reward as a form of recognition for good performance. A company can also improve performance by making performance measurement results a criterion for strategy formulation and the strategy is successfully implemented if the company is able to translate the strategy into a performance measurement system (Wibisono et al., 2011).

The Balanced Scorecard is characterized as not just a comprehensive system for measuring performance, but its function extended to transform strategic goals into coherent financial and non-financial measures, and it has now become an integrated management system that seeks to increase managerial harmony among employees and build organizational knowledge that helps improve capabilities to possess success factors in various fields and applying them to the organization's activity, as well as helping to focus on what must be done to increase performance progress and serve as an umbrella for diversification of the organization's programs, such as: quality, re-design and customer service (Bemard et al., 2007).

Balanced Scorecard has been defined as “a practical framework used as a basic approach that aims to improve current and future performance by studying a number of measures within four axes: the financial axis, the customer's axis, the internal operations axis, and the growth and learning axis (Kaplan & Norton, 1996). The Balanced Scorecard consists of four practices from the perspective of each of the customers, internal operations, the financial view, and the learning and growth view, and the study addresses them as follows:

Customer Perspective

Performance indicators used by some researchers from the customer perspective to improve service quality and customer satisfaction (Abu Qaaud et al., 2011; Shahzad et al., 2020; Al-Nady et al., 2016; Le, 2020; Alolayyan et al., 2018; Micheli et al., 2020; Alshurideh et al., 2017; Reche et al., 2020 ; Metabis & Al-Hawary, 2013; Ashraf et al., 2020; Altarifi et al., 2015; Al-Hawary & Alhajri , 2020; Fooladvand et al., 2015), loyalty (Al-Hawary & Al-Fassed, 2021) , competitive advantage (Pan et al., 2020; Al-Hawary & Al-Rasheedy, 2021) and innovation (Al-Hawary & Aldaihani, 2016; Li et al., 2020; Al-Hawary & Al-Syasneh, 2020) in line with customer expectations, improve timely delivery and maintain customer and market share. The value of customer satisfaction is also measured through a number of indicators according to this perspective, which are reliability, responsiveness, empathy, facilities, ensuring objectivity, and support facilities. Other indicators used according to this perspective are the involvement of customers in the company's activities.

Internal Process Perspective

This perspective deals with internal process. Metrics built on this standpoint permit managers to regulate how effective their business, and whether their products or services meet customer requirements. Those who are most familiar with these processes must carefully design these metrics. Two types of internal processes can be identified: those that focus on the core business; and operations support activities. Support processes are more repetitive and thus easier to evaluate using common metrics, though, the fluctuating nature of facilities administration since the institution of the balanced scorecard means that these two operations should be treated simultaneously (Pitt, 2008).

Learning and Growth Perspective

This outlook consists of employee training in addition to improvement of business culture connected to individuals through the knowledge aspect. People are the main resource for fast technological revolution; it has become essential for employees as an uninterrupted learning manner.

Financial Perspective

Kaplan and Norton emphasized the essential role of traditional financial statements inside the balanced scorecard system. Data must be true and obtainable when necessary. However, focusing on the financial statements alone results in a disturbed state with respect to other viewpoints. This is what the balanced scorecard system pursues to identify (Pitt, 2008).

GSCM Practices and Business Performance

Planning GSCM and controlling the business activities from raw material suppliers to end customers, and building relationships that ties partners of green supply chains together, provides a starting point for improving business performance and environmental sustainability (Linton et al., 2007). GSCM helps reducing the negative influence of industrial processes, and improve the competitive advantage of companies. GSCM practices improve the company's image, increase efficiency and enhance innovation leadership for managers. Therefore, corporate management adopts green supply chain management (Testa & Iraldo, 2010). A survey conducted by McKinsey (2014), 43% of respondents indicated that their companies seek to align green supply chain practices with their business goals. Previous studies confirm that well-designed environmental management in supply chains can create a competitive advantage that leads to improvement in business performance for the companies that adopt it (Shi et al., 2012). A study by Reuel, et al., (2018) originated that GSCM practices have an effect on company performance. Conducting an empirical study on the impact of GSCM, JIT and TQM on environmental sustainability, Green, et al., (2018) showed that JIT and TQM had direct and positive effects of GSCM practices, and that JIT and TQM methods and GSCM practices are complementary as they make a greater effect on environmental sustainability. Based on the literature above the study hypotheses can be formulated as follows:

H1: There is a statistically significant effect of to each other practices (green purchasing, green manufacturing, green design, reverse logistics, environmental cooperation with suppliers, green distribution) on business performance.

Research Model

as shows in Figure 1.

Methodology

Population and Sample Selection

The major aim of the study was to look at the impact of GSCM practices on Business Performance (BP) of extractive industries in Jordan. Data were gathered via email through self-reported questionnaires distributed to a purposive sample of managers in purchasing, distribution, production and supply chain. In total, 186 questionnaires were received containing 19 inacceptable questionnaires. Hence, the final sample is restricted to 167 questionnaires.

Measures

The questionnaire made up of two sections along with a section regarding control variables. Control variables considered as categorical measures were composed of gender, age, educational level, and experience. The two main sections were dealt with a five-point Likert scale (1= strongly disagree, 5= strongly agree). The first section covered 33 items used to measure GSCM based on (Dadhich et al., 2015; Ghobakhloo et al., 2013). These items were circulated into dimensions as follows: green design (six items), green purchasing (six items), green manufacturing (five items), green distribution (five items), reverse logistics (six items), and environmental collaboration (five items). the second section incorporated eight items developed to measure BP (Abu Qaaud et al., 2011; Ashraf et al., 2020; Le, 2020; Reche et al., 2020 Micheli et al., 2020; Shahzad et al., 2020 Alolayyan et al., 2018; Alshurideh et al., 2017; Altarifi et al., 2015; Al-Hawary & Alhajri , 2020).

Findings

Measurement Model

Structural Equation Modeling (SEM) was carried out using IBM AMOS. V.24 to test hypotheses. SEM is a contemporary statistical technique for estimating the relationship between variables (Wang & Rhemtulla, 2021). Reliability and validity were tested using confirmatory factor analysis (CFA). Table 1 sum up the results of convergent and discriminant validity as well as reliability.

| Table 1 Results Of Validity And Reliability Tests |

|||||||

|---|---|---|---|---|---|---|---|

| Constructs | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1-GDE | 0.733 | ||||||

| 2-GPU | 0.623 | 0.744 | |||||

| 3-GMA | 0.594 | 0.583 | 0.727 | ||||

| 4-GDI | 0.558 | 0.645 | 0.662 | 0.765 | |||

| 5-RLO | 0.617 | 0.597 | 0.615 | 0.568 | 0.740 | ||

| 6-ECO | 0.583 | 0.588 | 0.590 | 0.664 | 0.682 | 0.754 | |

| 7-BP | 0.711 | 0.698 | 0.706 | 0.718 | 0.715 | 0.695 | 0.761 |

| VIF | 1.977 | 2.972 | 2.085 | 1.439 | 1.227 | 2.468 | --- |

| Loadings range | 0.688-0.794 | 0.624-0.818 | 0.672-0.766 | 0.704-0.806 | 0.652-0.825 | 0.681-0.834 | 0.644-0.839 |

| AVE | 0.537 | 0.554 | 0.529 | 0.585 | 0.548 | 0.568 | 0.579 |

| MSV | 0.485 | 0.502 | 0.455 | 0.492 | 0.510 | 0.513 | 0.522 |

| Internal consistency | 0.872 | 0.879 | 0.847 | 0.871 | 0.876 | 0.862 | 0.914 |

| Composite reliability | 0.874 | 0.881 | 0.848 | 0.875 | 0.879 | 0.867 | 0.916 |

Table 1 shows that the values of factor loading were within the domain (0.624-0.839), these values are greater than the minimum cut-off value (Al-Lozi et al., 2018; Sung et al., 2019). Average Variance Extracted (AVE) is used indicator to assess convergent validity that must be above 0.50 (Howard, 2018). The results indicate that the AVEs were bigger than 0.50 for all constructs, thus the measurement model has an appropriate convergent validity. Rimkeviciene, et al., (2017) suggested the comparison approach to test the discriminant validity in covariance-based SEM. This approach is based on matching the values of Maximum-Shared Variance (MSV) with AVE values, as well as comparing the square roots of AVE values (√AVE) with the association between the structures. The results illustrate that MSV values were slighter than AVE values and that the square roots of the AVEs were higher than the correlation values among the rest of the constructs. Therefore, the measurement model used is characterized by discriminative validity. The internal consistency measured through Cronbach's Alpha coefficient (α) and composite reliability. The results listed in Table 1 demonstrated that values of alpha coefficient and composite reliability were greater than 0.70, which is the lowest limit for judging measurement reliability (de Leeuw et al., 2019).

Structural Model

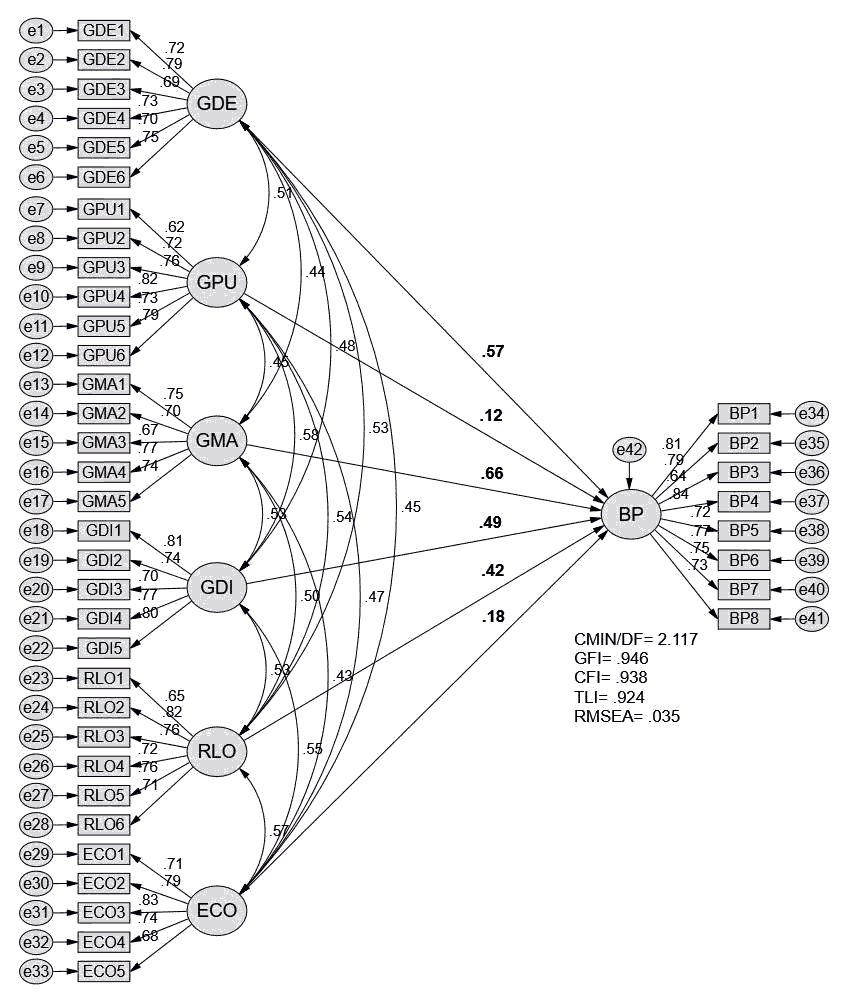

The structural model illustrated no multicollinearity issue among predictor constructs because variance inflation factor (VIF) values are below the threshold of 5, as shown in Table 1 (Hair et al., 2017).This result is supported by the values of model fit indices shown in figure 2.

The results in Figure 1 specified that the chi-square to degrees of freedom (CMIN/DF) was 2.117, which is less than three, the upper limit of this indicator. The values of the goodness of fit index (GFI), the comparative fit index (CFI), and the Tucker-Lewis index (TLI) were upper than the minimum accepted threshold of 0.90. Moreover, the result of root mean square error of approximation (RMSEA) was 0.035; this value is a reasonable error of approximation because it is less than the higher limit of 0.08. So, the structural model used in this study was recognized as a fit model for predicting the DEP and generalization of its result (Ahmad et al., 2016; Shi et al., 2019). To verify the results of testing the study hypotheses, SEM was used, the results of which are recorded in Table 2.

| Table 2 Hypotheses Testing |

|||||

|---|---|---|---|---|---|

| Relations | Beta | t value | p value | ||

| GDE | a | BP | 0.574*** | 21.06 | 0.000 |

| GPU | a | BP | 0.116 | 9.26 | 0.118 |

| GMA | a | BP | 0.662*** | 23.47 | 0.000 |

| GDI | a | BP | 0.490** | 17.79 | 0.006 |

| RLO | a | BP | 0.418* | 14.22 | 0.03 |

| ECO | a | BP | 0.183 | 10.54 | 0.08 |

Note: GDE: green design, GPU: green purchasing, GMA: green manufacturing, GDI: green distribution, RLO: reverse logistics, ECO: environmental collaboration, BP: business performance, * p<0.05, ** p<0.01, *** p<0.001.

On the basis of the results in Table 2, the highest impact was for green manufacturing (β =0.662, t =23.47, p =0.000), followed by green design (β =0.574, t =21.06, p =0.000), then green distribution (β =0.490, t =17.79, p =0.006), and finally the lowest impact was for reverse logistics (β =0.418, t =14.22 p =0.03). However, the results indicated that environmental collaboration (β =0.183, t =10.54, p =0.08) and green purchasing (β =0.116, t =9.26, p =0.118 had no impact on business performance.

Discussion and Conclusion

The results disclosed that there is an impact of GSCM practices on business performance, this result is consistent with Linton, et al., (2007), who assured that planning of GSCM and controlling the business activities of suppliers and customers, creating a relationship that links supply chain partners together provides a starting point for improving business performance and environmental sustainability. Shi, et al., (2012) confirm that well-designed environmental management in supply chains can create a competitive advantage that leads to upgrading business performance for the companies that adopt it. Reuel, et al., (2018) found that GSCM practices have an impact on the performance of the company.

The results indicated that the current companies apply GSCM practices in terms of green purchasing, green manufacturing, green design, logistics reverse, environmental cooperation with suppliers, and green distribution. These companies design their product by choosing reusable materials as they are less harmful to the environment, encourage designing products that are easy to repair, reducing waste related to packaging, and providing design specifications to suppliers so that they include these specifications into their environmental considerations of the purchased resources. Moreover, organizations cooperate with suppliers to achieve the environmental goals, selecting suppliers according to environmental standards, and focus their product design and the the manufacturing process on reducing energy consumption and natural resources. Further, organizations reduce noise pollution to a minimum level, replacing hazardous materials in manufacturing and use emission filters.

The surveyed organizations focused on obligating suppliers to provide manufacturing requirements to companies in accordance with their environmental policies in order to reduce the negative impact on the environment, use of environmentally friendly packaging materials, and use of reusable containers in the provision of logistics services. In fact, these practices contribute to enhancing business performance of these companies in terms of four aspects, i.e., financial, internal process, customers, learning and growth.

References

Abbad, J., & Al-Hawary, S.I. (2011). Measuring banking service quality in Jordan: A case study of Arab Bank.Abhath Al-Yarmouk, 27(3), 2179?2196.

Abu Qaaud, F., Al-Shoura, M., & Al-Hawary, S. I. . (2011). The Impact of the Service Marketing Mix in the Service Quality of Health Services from the Viewpoint of Patients in Government Hospitals in Amman " A Field study ". Abhath Al-Yarmouk, 27(1B), 417?441.

Ahmad, S., Zulkurnain, N., &Khairushalimi, F. (2016). Assessing the Validity and Reliability of a Measurement Model in Structural Equation Modeling (SEM).British Journal of Mathematics & Computer Science, 15(3), 1?8.

Al- Quran, A.Z., Alhalalmeh, M.I., Eldahamsheh, M.M., Mohammad, A.A., Hijjawi, G.S., Almomani, H.M., & Al-Hawary, S.I. (2020). Determinants of the Green Purchase Intention in Jordan: The Moderating Effect of Environmental Concern. J Sup. Chain. Mgt Vol, 9(5), 366-371.

Al-Hawajreh, K., AL-Zeaud, H., Al-Hawary, S.I. ., & Mohammad, A.A. (2011). The Influence of Top Management Support and Commitment on Total Quality Management Indicators from Managers and Heads of Departments Viewpoint: A Case Study of Sahab Industrial City". Jordan Journal of Business Administration, 7(4), 557?576.

Al-Hawary, S.I. & Al-Fassed, K.J. (2021). The impact of social media marketing on building brand loyalty through customer engagement in Jordan. International Journal of Business Innovation and Research. In Press.

Al-Hawary, S.I., & Aldaihani, F.M. (2016). Customer relationship management and innovation capabilities of Kuwait airways. International Journal of Academic Research in Economics and Management Sciences, 5(4), 201?226. Al-Hawary, S.I.S., & Alhajri, T.M.S. (2020). Effect of electronic customer relationship management on customers' electronic satisfaction of communication companies in Kuwait.Calitatea, 21(175), 97-102.

Al-Hawary, S.I.S., & Al-Rasheedy, H.H. (2021). The effect of strategic learning for human resources on dynamic capabilities of airlines companies in Kuwait.International Journal of Business Information Systems, 37(4), 421-441.

Al-Hawary, S.I., & Al-Syasneh, M.S. (2020). Impact of dynamic strategic capabilities on strategic entrepreneurship in presence of outsourcing of five stars hotels in Jordan.Business: Theory and Practice, 21(2), 578-587.

Al-Lozi, M.S., Almomani, R.Z.Q., & Al-Hawary, S.I.S. (2018). Talent management strategies as a critical success factor for effectiveness of human resources information systems in commercial banks working in Jordan.Global Journal of Management and Business Research: A Administration and Management, 18(1), 30?43.

Al-Nady, B.A., Al-Hawary, S.I., & Alolayyan, M. (2016). The role of time, communication, and cost management on project management success: An empirical study on sample of construction projects customers in Makkah City, Kingdom of Saudi Arabia.International Journal of Services and Operations Management, 23(1), 76?112.

Alolayyan, M., Al-Hawary, S.I., Mohammad, A.A., & Al-Nady, B.A. (2018). Banking service quality provided by commercial banks and customer satisfaction. A structural equation modelling approaches.International Journal of Productivity and Quality Management, 24(4), 543?565.

Alshurideh, M., Al-Hawary, S.I., Batayneh, A.M., Mohammad, A., & Al-Kurdi, B. (2017). The impact of Islamic banks? service quality perception on Jordanian Customers Loyalty.Journal of Management Research, 9(2), 139?159.

Altarifi, S., Al-Hawary, S.I.S., & Al Sakkal, M.E.E. (2015). Determinants of e-shopping and its effect on consumer purchasing decision in Jordan.International Journal of Business and Social Science, 6(1), 81?92.

Ashraf, S., Ahmed, T., Saleem, S., & Aslam, Z. (2020). Diverging mysterious in green supply chain management. J. Comput. Sci. Technol, 13(1), 22-28.

Banik, A., Taqi, H.M.M., Ali, S.M., Ahmed, S., Garshasbi, M., & Kabir, G. (2020). Critical success factors for implementing green supply chain management in the electronics industry: an emerging economy case.International Journal of Logistics Research and Applications, 1-28.

Bernard, W., Lan, G., Wei, L., and Dan, Y. (2007). Reducing conflict in balanced scorecard evaluations.Accounting, Organizations and Society, 32(4-5), 363-377.

Bhatia, M.S., & Gangwani, K.K. (2021). Green supply chain management: Scientometric review and analysis of empirical research.Journal of cleaner production, 284, 124722.

Carter, R., & Easton, L. (2011). Sustainable supply chain management: evolution and future directions.International Journal of Physical Distribution & Logistics Management, 41(1), 46?62.

Dadhich, P., Genovese, A., Kumar, N., & Acquaye, A. (2015). Developing sustainable supply chains in the UK construction industry: A case study.International Journal of Production Economics, 164, 271-284.

Darnall, N., Jolley, J., & Handfield, R. (2008). Environmental management systems and green supply chain management: Complements for sustainability?Business Strategy and the Environment, 17(1), 30?45.

de Leeuw, E., Hox, J., Silber, H., Struminskaya, B., & Vis, C. (2019). Development of an international survey attitude scale: Measurement equivalence, reliability, and predictive validity. Measurement Instruments for the Social Sciences, 1(1), 9.

Diabat, A., & Govindan, K. (2011). An analysis of the drivers affecting the implementation of green supply chain management.Resources, Conservation and Recycling, 55(6), 659-667.

Gao, J., Xiao, Z., Wei, H., & Zhou, G. (2020). Dual-channel green supply chain management with eco-label policy: A perspective of two types of green products.Computers & Industrial Engineering, 146, 106613.

Geng, R., Mansouri, A., & Aktas, E. (2017). The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies.International Journal of Production Economics, 183, 245?258.

Ghobakhloo, M., Tang, S.H., Zulkifli, N., & Ariffin, M. (2013). An integrated framework of green supply chain management implementation.International Journal of Innovation, Management and Technology, 4(1), 86.

Hair, J.F., Babin, B.J., & Krey, N. (2017). Covariance-based structural equation modeling in the journal of advertising: Review and Recommendations.Journal of Advertising, 46(1), 163?177.

Hart, S.L. (1995). A Natural-Resource-Based View of the Firm. Manag. Rev., 20, 986?1014.

Howard, M.C. (2018). The convergent validity and nomological net of two methods to measure retroactive influences.Psychology of Consciousness: Theory, Research, and Practice, 5(3), 324?337.

Jemai, J., Do Chung, B., & Sarkar, B. (2020). Environmental effect for a complex green supply-chain management to control waste: A sustainable approach.Journal of Cleaner Production, 277, 122919.

Kang, M.J., & Hwang, J. (2017). Interactions among Inter-organizational Measures for Green Supply Chain Management.Procedia Manufacturing, 8, 691-698.

Kaplan, S., & Norton, P. (1996). Balanced Scorecard: Measures that Drive Performance. Harvard Business Review, 71-79.

Khaireddin, M., Mohammad, I.E., Sahem, A., & Abu, A.N. (2015). Just-in-time manufacturing practices and strategic performance: An empirical study applied on Jordanian pharmaceutical industries. International Journal of Statistics and Systems, 10(2).

Le, T. (2020). The effect of green supply chain management practices on sustainability performance in Vietnamese construction materials manufacturing enterprises.Uncertain Supply Chain Management, 8(1), 43-54.

Li, G., Li, L., Choi, T.M., & Sethi, S.P. (2020). Green supply chain management in Chinese firms: Innovative measures and the moderating role of quick response technology.Journal of Operations Management, 66(7-8), 958-988.

Linton, D., Klassen, R., & Jayaraman, V. (2007). Sustainable supply chains: An introduction.Journal of Operations Management, 25(6), 1075?1082.

Liu, J., Hu, H., Tong, X., & Zhu, Q. (2020). Behavioral and technical perspectives of green supply chain management practices: Empirical evidence from an emerging market.Transportation Research Part E: Logistics and Transportation Review, 140, 102013.

Liu, S., Eweje, G., He, Q., & Lin, Z. (2020). Turning motivation into action: A strategic orientation model for green supply chain management.Business Strategy and the Environment, 29(7), 2908-2918.

McKinsey & Company (2014). Sustainability?s strategic worth: McKinsey Global Survey results. http://www.mckinsey.com/insights/sustainability/sustainabilitys strategic worth Mckinsey global survey results, ret.

Metabis, A., & Al-Hawary, S.I. (2013). The Impact of Internal Marketing Practices on Services Quality of Commercial Banks in Jordan. International Journal of Services and Operations Management, 15(3), 313?337.

Micheli, G.J., Cagno, E., Mustillo, G., & Trianni, A. (2020). Green supply chain management drivers, practices and performance: A comprehensive study on the moderators.Journal of Cleaner Production, 259, 121024.

Pan, X., Pan, X., Song, M., & Guo, R. (2020). The influence of green supply chain management on manufacturing enterprise performance: moderating effect of collaborative communication.Production Planning & Control, 31(2-3), 245-258.

Pitt, M., & Tucker, M. (2008). Performance measurement in facilities management: Driving innovation?Property Management, 26(4), 241-254.

Reche, A.Y.U., Junior, O.C., Estorilio, C.C.A., & Rudek, M. (2020). Integrated product development process and green supply chain management: Contributions, limitations and applications.Journal of Cleaner Production, 249, 119429.

Reuel, B., Aguilar, E., Borromeo, M., Pereja, S., & Junnell, E. (2018). How green supply chain management affects the company?s performance? Presented at the DLSU Research Congress 2018 De La Salle University, Manila, Philippines June 20 to 22, 2018.

Rimkeviciene, J., Hawgood, J., O?Gorman, J., & De Leo, D. (2017). Construct validity of the acquired capability for suicide scale: Factor structure, convergent and discriminant validity.Journal of Psychopathology and Behavioral Assessment, 39(2), 291?302.

Rumintjap, M.L. (2013). Implementation of balanced scorecard as a benchmark of performance measurement in RSUD Noongan.Journal of EMBA, 1(3), 841-850.

Crossref, GoogleScholar, Indexed at

Sarkis, J. (2003). A strategic framework for green supply chain management.Journal of Cleaner Production, 11, 397-409.

Sekaran, U., & Bougie, R. (2016). Research methods for business: A skill-building approach (Seventh edition).

Seman, A., Zakuan, N., Jusoh, A., & Arif, M. (2012). Green supply chain management: A review and research direction.International Journal of Managing Value and Supply Chains, 3(1), 1-18.

Shahzad, F., Du, J., Khan, I., Shahbaz, M., Murad, M., & Khan, M.A.S. (2020). Untangling the influence of organizational compatibility on green supply chain management efforts to boost organizational performance through information technology capabilities.Journal of cleaner production, 266, 122029.

Shi, D., Lee, T., &Maydeu-Olivares, A. (2019). Understanding the Model Size Effect on SEM Fit Indices.Educational and Psychological Measurement, 79(2), 310?334.

Shi, G., Koh, C., Baldwin, J., & Cucchiella, F. (2012). Natural resource based green supply chain management. Supply Chain Management: An International Journal, 17(1), 54?67.

Srivastava, K. (2007). Green supply-chain management: A state-of-the-art literature review.International Journal of Management Reviews, 9(1), 53?80.

Sung, K.-S., Yi, Y.G., & Shin, H.-I. (2019). Reliability and validity of knee extensor strength measurements using a portable dynamometer anchoring system in a supine position.BMC Musculoskeletal Disorders, 20(1), 1?8.

Testa, F., & Iraldo, F. (2010). Shadows and lights of GSCM (Green Supply Chain Management): determinants and effects of these practices based on a multi-national study.Journal of Cleaner Production, 18(10?11), 953?962.

Wang, C., Zhang, Q., & Zhang, W. (2020). Corporate social responsibility, Green supply chain management and firm performance: The moderating role of big-data analytics capability.Research in Transportation Business & Management, 37, 100557.

Wang, Y.A., &Rhemtulla, M. (2021). Power analysis for parameter estimation in structural equation modeling: A discussion and tutorial.Advances in Methods and Practices in Psychological Science, 4(1), 1?17.

Wibisono, E., Mardiono, L., & Wijaya, P.S. (2011). Integration of analytics model and performance dashboard in performance measurement using balanced scorecard. Proceedings of the 6th National Industrial Engineering Conference; 2011 Oct 20; Surabaya, Indonesia. Surabaya: NIEC6. 76-83.

Wong, C.W., Lai, K.-H., Shang, K.-C., Lu, C.-S., & Leung, T. (2012). Green operations and the moderating role of environmental management capability of suppliers on manufacturing firm performance.International Journal of Production Economics, 140, 283?294.

Yang, S., Lu, S., Haider, J., & Marlow, B. (2013). The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in Taiwan.Transportation Research Part E: Logistics and Transportation Review, 55, 55?73.

Received: 24-Dec-2021, Manuscript No. AEJ-21-10646; Editor assigned: 26-Dec-2021, PreQC No. AEJ-21-10646(PQ); Reviewed: 07-Jan-2022, QC No. AEJ-21-10646; Revised: 17-Jan-2022, Manuscript No. AEJ-21-10646(R); Published: 24-Jan-2022