Research Article: 2023 Vol: 26 Issue: 5

The influence of the corona-virus on the Tunisian supply chain and Transshipment problem

Elleuch Fadoi, Sfax University

Semi Boudabbous, Sfax University

Citation Information: Fadoi, F., & Boudabbous, S. (2023). The influence of the corona-virus on the tunisian supply chain and transshipment problem. Journal of Management Information and Decision Sciences, 26 (5),1-10.

Abstract

Background: This article aims to provide results of the impact of the Corona-Virus pandemic on the functioning of Tunisian companies. Based on a sample of these companies, the results showed a strong disruption of the various links in the supply chain following the generalized confinement of the population and the closure of borders.

Objectives: Overall, this study contributes both to the study of the effect of Corona-Virus on Supply Chain management and to the implications of the literature in this field and has important practical implications. Methods: We therefore sought to find out which links in the supply chain were the most impacted by applying ARENA modeling.

Results: The findings suggest that the analysis of the results makes it possible to detect the manifest existence of specific operating models.

Conclusions: The Lateral-Transshipment and Commodity Allocation problem in the context of the COVID-19 outbreak has many novel features. For this, we propose a new multi- objective optimization model for Lateral-Transshipment of emergent products in two steps. The objectives envisaged are the optimization of the quality of the transhipped product, the satisfaction of customer demand and the minimization of the overall cost including the shortage penalty.

Keywords

Supply Chains, ARENA-model, Corona-virus, Crisis Management and Crisis Logistics.

Introduction

The research works have already quoted a lot of the abrupt changes that the Corona-Virus pandemic has caused in all areas of human life.

The logistics and economic sectors have suffered major negative impacts almost without precedent. As described by the there exists (Gautam, 2020 & Sreekanth, 2020).

As the Corona-Virus pandemic has forced demand to drop and stores to close in major economies. Suppliers in producing countries have faced order cancellations and extended payment terms, forcing many to scale back operations or stop them altogether (Neoway, 2021).

With the Corona-Virus pandemic, an unprecedented global crisis throughout this century, there has been a serious interruption in the physical flows necessary for the daily life of individuals in the format known until then, impacting the entire production chain. and distribution. For this, the various social and economic sectors then began to experience problems (Hobbs, 2020).

The closure of several regions in China and the speed of the virus spreading globally, have disrupted supply chains and reduced business activities (Kumar & Mishra,2020 ; Sohrabi, et al.,2020). The interdependence of economies due to the globalization of trade has created critical dependencies. The COVID-19 pandemic has shaken certain certainties about the triumph of globalization presented by economic thought as a remedy for market imbalances and disparities in levels of development (Ma et al., 2019).

The COVID-19 pandemic has revealed the strategic importance of logistics in business value chains, but also its vulnerability. From the reduction of orders to the partial or total cessation of activities, almost all industries have suffered the consequences of the collapse in volumes transported (Missiroli, 2006; Posner, 2004).

Transshipment during the Corona-Virus is much more complicated. First of all, there are two distinct phases of product transshipment and allocation during the Corona-Virus. In the early stage of the epidemic, the movement of people in the affected areas was strictly controlled. This has resulted in a sharp decline in commercial product suppliers in the local area. In addition to the initial stock, the restocking of these products can only be done by lateral transshipment. Then the replenishment by lateral transshipment, the product stock can also be partially replenished by local collection.

The COVID-19 crisis challenges companies on their ability to anticipate new risks, in particular health hazards, in the definition of their Supply Chain strategy. The question also arises in terms of the resilience and ability of their supply chain to sustain or recover quickly in times of crisis. Finally, the overall performance of the company depends on the reliability and regularity of the supply chain, the challenge being to build new logistics strategies by providing them with the capacity for responsiveness and efficiency in a context characterized by uncertainty (Shaluf et al., 2003; Oparanma & Wechie, 2014).

This paper focuses on the impact of different modes of transshipment using two-stage on product quality, complete supply chain and distribution satisfaction during the Corona-Virus pandemic. This problem is formulated as a multi-objective optimization problem to optimize the Transshipment-allocation.

Mathematical Modeling

The global crisis following the Corona-Virus is a dynamic phenomenon that evolves over time and has common characteristics (Zhang et al., 2019).

• Uncertainty and complexity;

• Instant and very urgent decisions;

• The pressure of time and the duration of the situation

• Emergency plans overwhelmed by the scale of the situation

So to better control the management of this crisis, apply lateral Transshipment between the different Depots to reduce the impact of this disease on the economy and its stakeholders.

Crisis management strategies emphasize the ability to anticipate potential risks. This preparation or pre-crisis phase involves a preventive policy to minimize probable shortages, with emphasis on the duration of supply, the quantity transported between warehouses and the quantity distributed. Crisis management strategies emphasize the ability to anticipate potential risks. This preparation or pre-crisis phase involves a preventive policy to minimize the probable damage (Evans & Elphick, 2005).

Supply Chain and Crisis Management

Generally, the global crisis occurs more frequently and becomes increasingly severe (Weisæth et al., 2002). It occurs in supply chains and represents real threats for all companies regardless of their size, Coombs (1999) sees that the crisis offers opportunities and the possibility of starting to develop new crisis management models such as the application of transshipment to adapt to strategies to overcome them. However, in a logistics chain, the crisis becomes more severe when the activities of one or more links in this chain lead to a major disruption of the normal circulation of goods (Desoutter & Lavissiere, 2018; Jeong et al., 2020).

Conceptual Model

The COVID-19 pandemic has affected supply chains globally (Alharthi& Khalifa, 2019). It was a challenge for the resilience of supply chains at the global level. The destabilizing effect of the crisis has prompted some researchers Lynch (2009); Torrado & Barbosa-Póvoa (2022) to rethink new logistics solutions.

The Corona-Virus pandemic has affected supply chains on a global scale. The destabilizing effect of the crisis has prompted some researchers (Serdarasan, 2013). To rethink new logistics solutions and, for example, the application of transshipment - lateral (Wang & Ma, 2015; Asadpour et al., 2022).

The Actions of Companies in the Face of the crisis can be grouped into three Groups:

• Companies better prepared to react to the probability of the crisis: which have forged strong links with their external environments (suppliers, customers). They have put in place a system capable of ensuring risk management to anticipate the repercussions of the crisis (Sarkis, 2020).

• Others who anticipated the likelihood of a crisis and prepared to mitigate its impact, so they put in place proactive management strategies to ensure business continuity. They have put in place management strategies and for example Transshipment-preventive and planning to avoid stock-outs and overstocking.

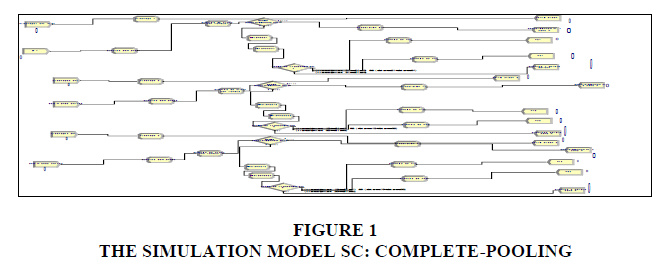

• In addition companies unable to react to the impact of the Covid-19 pandemic, which are dependent on a geographical area or a main supplier for their strategic supply. For this, their supply chains are not resilient enough to cope with different types of internal or external disruptions. They do not have an inventory and production management or planning system that would allow them to anticipate stock shortages and optimize resources. The model can be represented by the simulation modeling software which is the ARENA model, as shown in Figure 1.

Formulation of the Problem

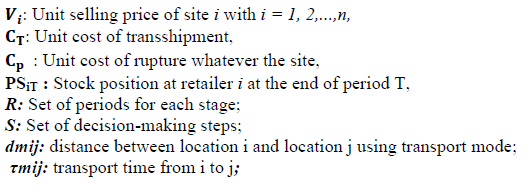

Notations:

But, Before Applying Transshipment, it is Necessary to Study the Following Steps:

• Control the inventory level of each storage depot;

• Observe the customer demand of each retailer;

• If the retailer at the same level has excess stock and can fill the break from the other site, this will require the application of transshipment;

• The transshipment will be applied at a very low cost compared to that of an emergency order from the central warehouse;

• Any unfulfilled request after the application of the transshipment will be lost;

• Determine the stock position after the demand has been satisfied by transshipment.

Objective Function

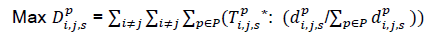

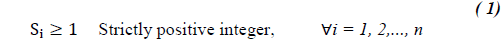

The objective is to improve the Average Global Profit of the distribution system over a finite time horizon R, composed of T periods. It includes the selling price, the unit cost of transshipment and the cost of rupture (Ma et al., 2019).

The mathematical formulation of the objective function, for the first "Complete-Pooling" transshipment policy, then takes the form of equation (1).

U/C

With

And

Note that the degree of satisfaction can be weighted by the level of urgency  the actual rate of demand satisfaction

the actual rate of demand satisfaction  and the proportion of demand for each product by the customer is:

and the proportion of demand for each product by the customer is:

Analysis of the Results

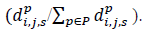

We recall that the structure of the network considered in this paper is composed of a distribution center and multi-retailers, which are faced with random requests which follow a Normal law of the μ mean and the standard deviation σ . These requests are independent and identically distributed (i.i.d).We then assume that :

We solved our problem via the simulation approach by successively testing the effect of "Complete-Pooling” transshipment policies on the Average Global Profit and Average Global Desservice Rate. But for a number of retailers greater than two, it is necessary to choose the recipient and the recipient of the quantity transferred laterally between sites at the same level. This leads to a first study which focuses on choosing the best transshipment strategy in terms of economic profitability.

To select the best strategy, we considered the following performance measures for evaluating the contribution of the transshipment:

• The number of supply orders (without-transshipment),

• The number of orders fulfilled through transshipment,

• The quantity of transshipment transferred from a storage site which is in an overstock position to that of the same echelon which faces a rupture,

• The quantity of unsatisfied order at a retailer (quantity lost),

The sample is made up (N = 97) of companies which are different according to the type of work sector.

The upper limits of the transshipment volumes of products originating from the central depot and which will be distributed between the retailers are indicated in the Table 1. Daily product needs in nearby depots are given based on historical data.

| Table 1 Determination Of Different Measures Of The Initial Level Of Replenishment |

|

|---|---|

| k | |

| 2 | 355 |

| 3 | 327 |

| 4 | 420 |

| 5 | 575 |

| 6 | 655 |

| 7 | 753 |

| 8 | 825 |

| 9 | 998 |

| 10 | 1062 |

Activity level

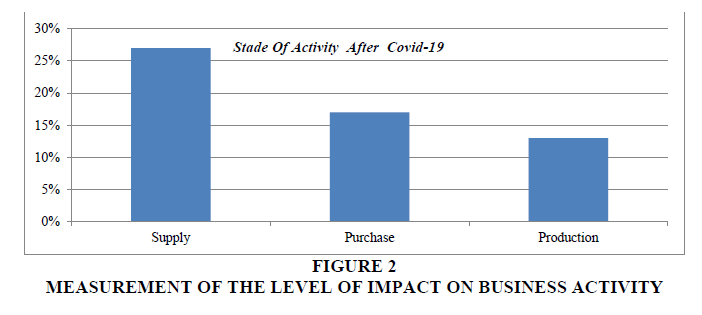

After a survey of 97 Tunisian companies, the sampling result will be presented in Figure 2 which targets to measure the level of the impact of COVID-19 on business activity in Tunisia.

The consequences of COVID-19 have proven to be heavy on the national economy. The results of our study show that 77% of companies experienced an economic downturn after confinement. With 55% of them judging this decline moderate or severe Figure 2.

While, only 22% of these companies recorded an increase in activity (example: the pharmaceutical industry, medical and mass distribution).

Logistics

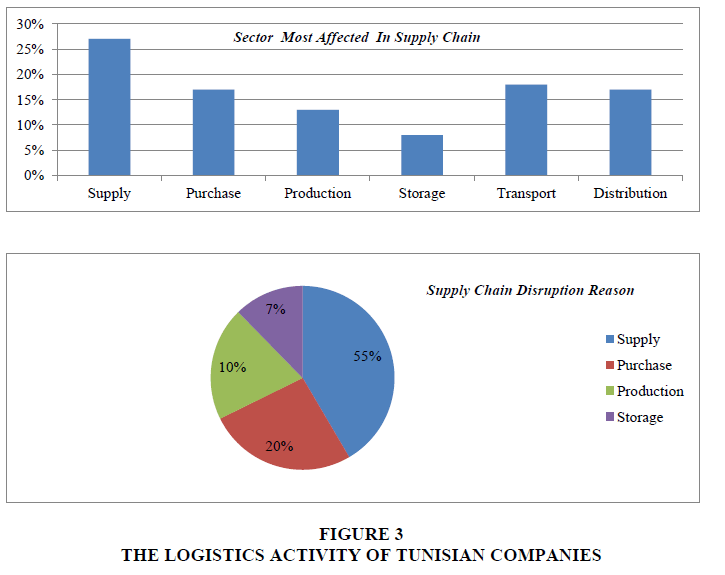

The impact of Corona-Virus on logistics is also very significant. Several countries have since faced a health crisis, causing enormous damage, particularly in Tunisia where the Covid-19 virus is growing with frustrating frequency.

For this, we have summarized in Figure 3 the sectors most affected by COVID-19 in the Tunisian supply chain.

Crisis Management

As a result of Covid-19, many businesses are impacted by reduced consumer demand and economic downturn, transportation restrictions and supply chain disruptions. So they must take into account the preparation tools against the Covid-19 pandemic which can be proactive and/or reactive. Faced with supply disruptions, companies favored the diversification of suppliers and the search for substitute products. Suppliers have also asked to extend payment terms due to the drop in activity.

Disruptions are therefore observed in all links of the supply chain. Possible reactive solutions to minimize supply disruption are remote delivery. But in our research work we combined it with the use of Lateral Transshipment.

The COVID-19 crisis has highlighted the important role digital technologies can play in running businesses Table 2.

| Table 2 Determination Of The Effect Of Applying Lateral Transshipment Between Retailers On Overall Average Profit |

||

|---|---|---|

| K | Without –Transshipment | With–Transshipment |

| 2 | 75670 | 80626 |

| 3 | 133770 | 162904 |

| 4 | 155521 | 170978 |

| 5 | 143871 | 152975 |

| 6 | 127177 | 135233 |

| 7 | 112483 | 128157 |

| 8 | 105790 | 113230 |

| 9 | 99097 | 107200 |

| 10 | 98403 | 102256 |

Table 2 presents the different values of Average Global Profit for these companies located at the same level. Initially, we evaluated by simulation and using the ARENA software these results without the transshipment application. Then, we study the possibility of an existing cooperation between different retailers, and we seek to evaluate the performance of transshipment between warehouses on the improvement of the economic profitability of the whole centralized system Table 3.

| Table 3 Determination Of The Average Global Desservice Rate |

||

|---|---|---|

| k | Wuthout-transshipment | Complete-Pooling |

| 2 | 0.77 | 0.56 |

| 3 | 0.86 | 0.681 |

| 4 | 0.85 | 0.676 |

| 5 | 1.3 | 0.996 |

| 6 | 1.492 | 0.957 |

| 7 | 1.366 | 1.152 |

| 8 | 1.957 | 1.39 |

| 9 | 1.952 | 1.597 |

| 10 | 1.997 | 1.775 |

To calculate these values, we apply the formula (2) which designates the Average Global Disservice Rate.

Limitations

To our knowledge, this is the first effort to document the psychological impacts of the Covid-19 pandemic on a representative sample of Tunisian companies via a survey method. However, several limitations should be noted.

First, the main limitation of this study is that the sample size for our interview survey was relatively small compared to typical survey-only studies; however, the survey interview approach allows for the capture of additional specifics and detail, and therefore complements the survey-based approaches of previous studies focused on mental health students during this pandemic.

Second, this suggests that qualitative type research is needed studied not only to gain a deep understanding of the mechanisms, but also to understand the consequences of observed inequalities in order to complement the conclusions of the current quantitative approach.

Finally, the transshipment method applied is Corrective-Lateral Transshipment only. While, the preventive approach can be applied and also there is another limitation which emphasize the type of Transshipment-Lateral which can between complete-pooling and partial-pooling.

These different limits are an idea for a new research work on Transshipment cooperated with Covid-19.

Conclusion

In this article we propose a Lateral Transshipment of products in the context of the COVID-19 epidemic. In the first stage, the inventory of the central warehouses concerned can only be replenished from a period R of 28 days. In view of this scenario, an optimization model was constructed to reflect the reasonable arrangement of the external transshipment product by maximizing the transshipment product quality, and the level of customer satisfaction by minimizing the cost of the system which contains the cost of the penalty in order to reduce the shortage. COVID-19 is an exceptional event that has had a major impact on the global economic supply chain.

The complexity of supply chains weakens the development of commercial transactions. This context offers, on another level, a multitude of opportunities for new structures and new business models.

References

Alharthi, M.N.A.N., & Khalifa, G.S. (2019). Business continuity management and crisis leadership: an approach to re-engineer crisis performance within Abu Dhabi Governmental entities.International Journal on Emerging Technologies,10(2), 32-40.

Asadpour, M., Olsen, T.L., & Boyer, O. (2022). An updated review on blood supply chain quantitative models: A disaster perspective.Transportation Research Part E: Logistics and Transportation Review,158, 102583.

Indexed at, Google Scholar, Cross Ref

Coombs, W.T. (1999). Information and compassion in crisis responses: A test of their effects.Journal of public relations research,11(2), 125-142.

Indexed at, Google Scholar, Cross Ref

Desoutter, M., & Lavissiere, A. (2018). Handling Supply Chain Crises when everything has been done to avoid them. InSupply Chain Forum: An International Journal, 19, 3, 219-232.

Indexed at, Google Scholar, Cross Ref

Evans, N., & Elphick, S. (2005). Models of crisis management: An evaluation of their value for strategic planning in the international travel industry.International journal of tourism research,7(3), 135-150.

Gautam, S. (2020). COVID-19: air pollution remains low as people stay at home.Air Quality, Atmosphere & Health,13, 853-857.

Hobbs, J.E. (2020). Food supply chains during the COVID?19 pandemic.Canadian Journal of Agricultural Economics/Revue canadienne d'agroeconomie,68(2), 171-176.

Indexed at, Google Scholar, Cross Ref

Jeong, K., Cha, J., & Kim, Y. (2020). Scrm awareness in the shipbuilding and marine equipment market: empirical evidence from South Korea, China, and Singapore.Sustainability,12(12), 5115.

Indexed at, Google Scholar, Cross Ref

Kumar, R., & Mishra, R.S. (2020). COVID-19 global pandemic: impact on management of supply chain.International Journal of Emerging Technology and Advanced Engineering,10(4), 132-139.

Indexed at, Google Scholar, Cross Ref

Lynch, G. S. (2009).Single point of failure. Wiley

Ma, Z.J., Wang, K.M., & Dai, Y. (2019). An emergency blood allocation approach considering blood group compatibility in disaster relief operations.International Journal of Disaster Risk Science,10, 74-88.

Missiroli, A. (2006). Disasters past and present: new challenges for the EU.European Integration,28(5), 423-436.

Indexed at, Google Scholar, Cross Ref

Neoway. (2021). https://blog.neoway.com.br/cadeia-de-suprimentos

Oparanma, A.O., & Wechie, I. (2014). Crisis management processes to ensure effective and continuous performance.Journal of Business and Management,16(8), 01-04.

Posner, R.A. (2004).Catastrophe: risk and response. Oxford University Press.

Sarkis, J. (2020). Supply chain sustainability: learning from the COVID-19 pandemic.International Journal of Operations & Production Management,41(1), 63-73.

Indexed at, Google Scholar, Cross Ref

Serdarasan, S. (2013). A review of supply chain complexity drivers.Computers & Industrial Engineering,66(3), 533-540.

Shaluf, I.M., Ahmadun, F.L.R., & Mat Said, A. (2003). A review of disaster and crisis.Disaster Prevention and Management: An International Journal,12(1), 24-32.

Sohrabi, C., Alsafi, Z., O'neill, N., Khan, M., Kerwan, A., Al-Jabir, A., ... & Agha, R. (2020). World Health Organization declares global emergency: A review of the 2019 novel coronavirus (COVID-19).International journal of surgery,76, 71-76.

Sreekanth, C.R. (2020). Supply DIsruption due to Covid-19.Industrial Engineering Journal,13(5).

Torrado, A., & Barbosa-Póvoa, A. (2022). Towards an optimized and sustainable blood supply chain network under uncertainty: a literature review.Cleaner Logistics and Supply Chain,3, 100028.

Indexed at, Google Scholar, Cross Ref

Wang, K.M., & Ma, Z.J. (2015). Age-based policy for blood transshipment during blood shortage.Transportation Research Part E: Logistics and Transportation Review,80, 166-183.

Weisæth, L., Knudsen Jr, Ø., & Tønnessen, A. (2002). Technological disasters, crisis management and leadership stress.Journal of Hazardous Materials,93(1), 33-45.

Zhang, X., Liu, X., Song, X., & Zheng, M. (2019). Stochastic location-allocation modelling for emergency mobile blood collection.IFAC-PapersOnLine,52(13), 1114-1119.

Received: 27-Jun-2023, Manuscript No. JMIDS-23-13814; Editor assigned: 30-Jun-2023, Pre QC No. JMIDS-23-13814(PQ); Reviewed: 15-Jul-2023, QC No. JMIDS-23-13814; Revised: 21-Jul-2023, Manuscript No. JMIDS-23-13814(R); Published: 31-Jul-2023