Research Article: 2022 Vol: 25 Issue: 2S

The transition of traditional pottery-making into advanced ceramics in context to the Indian ceramic industry

Giriraj Kiradoo, Govt. Engineering College Bikaner

Dr.K.M.Ashifa, Istanbul Gelisim University

Anar Aliyev, Istanbul Gelisim University

Citation Information: Kiradoo, G., Ashifa, K.M., & Aliyev, A. (2022). The transition of traditional pottery-making into advanced ceramics in context to the indian ceramic industry. Journal of Management Information and Decision Sciences, 25(S2), 1-12.

Keywords

Advanced Ceramics, Ceramic, Indian Ceramic Industry, Sanitaryware, Ceramic Tiles, Synthetic Materials

Abstract

The unexpected evolution in the science and technology sector has transformed India's traditional pottery-making into advanced ceramic. Owing to the ceramic industry's market expansion, traditionally based pottery-making industries have now experienced rapid modern machinery growth. Pottery manufacturing has been one of the prestigious arts in the ancient history of India. During these days, pottery making process used for clay fired at low temperatures and open bonfires. They were generally based on hand made techniques and less decorated. A sudden upsurge in technology and industry has made development in the use of ceramic glazes that improved the popularity and practicality of ceramic usage. The present research report delivers information that government support for the housing sector and increasing demand for high-end products have influenced the Indian ceramic industry's significant development. In modern-day industrialization and globalization, India ranks third in its ceramic trading activities with a global industry growth rate of 11%. It demonstrates the achievement of the transition from traditional pottery-making to advanced ceramics. The research paper focuses on various aspects such as origin, history, development, innovation, technology up-gradation, research, and development of the ceramics industry with particular reference to India.

Citation Information

Kiradoo, G., Ashifa, K.M., & Aliyev, A. (2022). The transition of traditional pottery-making into advanced ceramics in context to the indian ceramic industry. Journal of Management Information and Decision Sciences, 25(S2), 1-12

Introduction

India's past has been industrially glorious. When the world was in a semi-cultured state, India was on the growth of commerce and manufacturing. Industries and handicrafts were the prime priority in ancient India's social life. India was famous for cotton textiles, precious metals, shipbuilding, gems, and carvings. Even 2000 years ago, India was an industrial-rich country. The bodies wrapped in Indian muslin in the pyramids of Egypt still witness to this fact. The historical iron pillar of Delhi is a living and vivid example of the antiquity and quality of our iron and steel industry. Since the Mauryan period, India's traditional trade was started by sea routes. At that time, clothing, carpeting, ivory, clay, and metal utensils, etc., were India's primary exports. Indian shipping was also in the advanced stage at that time. Bernier and Tavernier have mentioned and appreciated the Mughal art and commerce in their travel experiences.

During the celebrated Mughal emperor Akbar, Indian cotton and silk garments were exported to Persia and other Arab countries. In rural areas, industries were the heads of gold, silver, wood, jewellery, textile manufacturing, etc. In urban industries, the silk garments of Murshidabad, the muslin of Dhaka, the Shawl of Kashmir, the Jari Work on Sari of Banaras, and the ceramic industry of Murshidabad were incredibly famous.

India's industrial system began to be destroyed gradually after the arrival of the East India Company. The self-centred policy of the British proved to be disastrous for these industries. By the end of the eighteenth century, some industries became sick and were about to shut down. Furthermore, by the middle of the nineteenth century, their pride was eradicated. Nevertheless, the existence of our ancient industries still exists in one form or the other. Its importance in the Indian economy was acknowledged after independence, and revolutionary efforts were made to give them new life. Today's ceramic industry is a testimony to it.

The government's support in developing business activities and enhancing the use of technology has paved the way towards boosting India's ceramic industry. The change in demand in domestic and industrial sectors is a boon for India's advanced ceramic industry. In earlier days, ceramics were more about simple tiles and decorative pottery; Most decorative items were made of ceramics. Ceramic is a material crafted by subjecting a non-metallic material to high temperatures such as soil and subsequent cooling. The paper aims to explore the development of the Indian ceramic industry and evaluate and analyze the impact of modern technology and techniques on it. The report also highlights the technological progress prevailing in the industry, revenue, and employment opportunities. The SWOT matrix has also been developed to give a better perspective to the sector after technological advancement.

Research Questions

The research question that has been set for the report is:

• How has the Indian ceramic industry evolved from handmade pottery work to advanced ceramics?

• How has technology created an impact on the development of advanced ceramics in traditional ways?

• What advancements have been made in advance and technical ceramics in the present era?

Objectives of the Study

• To analyze traditional pottery transition to the advanced ceramic industry.

• To identify the history of potter making and the sudden innovation in the ceramic industry.

• To assess developments in the field of the ceramic industry over time.

Research Methodology

Apart from several books, the current research analyses research papers and reviews to conduct secondary research to gain potential research questions. The use of thematic analysis in this research will enhance the in-depth knowledge of the subject. Qualitative analysis based on academic literature published over the past few years has been done to explore the origins, history, development, development origin, history, development and development of new technology, modern ceramic products, and the future's ceramic industry.

Discussion

Theme 1: History and Development of Ceramics

It would not be too hyperbolic to write that ceramics' history and development are causally linked to a civilized man's history and development. Stones, clay, sand, mineral resources, and gravel pebbles, etc., are common resources whose importance is often reflected in human development. The stone-age man was a migratory organism that made food, made his clothes, and developed shelters. This actor of ancient times effectively used wood and stone. They often lived in caves, which nature had made by ripping stones. A stone that was added to his hand was the first hammer of the human being. The stone was cut and made scathing, and the human being invented an axe for the first time by connecting it with one end of the wooden stick. Thus, with patience and confidence with stone tools and weapons, the human being was scintillating from the Paleolithic to the Neolithic.

During the same time, some pottery was shaped from clay by some unknown artists. As a result, a faraway man from water and food resources now came closer and began to live permanently. Instead of the animal leather, he started making food with pottery wares in a civilized manner. Thus, stones and clay were the ubiquitous resources until man first used copper and other metals.

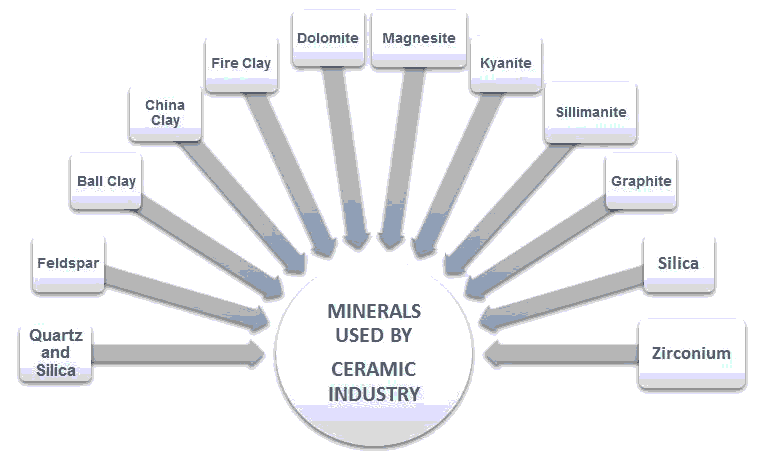

When the hungry man insisted on his brain, he discovered agricultural art. As a result, human beings began to cultivate, and in the meantime, there was an introduction to different types of clays. Gradually, based on his experience power, he understood how many types of clays are available, the places where the clays are found, and what works are likely to be used. as shows in Figure 1.

The clay's pottery work was first developed by the Neolithic man, a wealthy art established in ancient civilizations like Babylonia, Egypt, China, and India. China wares, also known as semi-translucent porcelain, have been made in China for thousands of years. In many parts of the world, such as in the Far East, pottery is a handicraft business in many parts of the United States and India. In modern industrial units, they are being produced at a considerable level, and the skilled workers' demand is continuously increasing.

On the development path, the man managed the important but essential responsibility of housing construction and development. With the clay's knowledge, human beings planned to build houses and discovered the golden world of bricks. For those who lacked wood, clay bricks proved to be an essential and first resource. The homes constructed from raw bricks or the sun-soaked bricks are produced simultaneously from invention to the present. By adding his essentiality to the experience gained from the brick making process, human beings focused on tiles production and were also successful.

The ancient vestiges prove that when human beings started systematically living in society by forming groups, they had to face different problems. The significant issues were sewage evacuation, cleanliness of household latrines and bathrooms and irrigation and water management etc. Gradually, these problems became so severe that human beings had no other option but to get rid of them. The human being invented the cleaning management system based on intellectual force. The cleanliness management system gave rise to today's developed sanitaryware industry. The situation today is that these comforts have become so advanced that they are beyond the imagination of a normal human being.

With the discovery of electricity, the field of ceramics became more elaborate. Electrical insulators and power plants were developed to prevent unnecessary electrical damage, no obstruction in the electricity supply, and avoid any significant potential accidents. As a result of the industrial revolution, there was a flood of industries all over the world. Iron steel industries and many other industries were developed in which the construction of furnaces for generating high temperature was essential. High-temperature products were invented to manufacture furnaces and to keep the temperature created. In this long run of development, humans also discovered many other necessary products, including plaster of Paris, clay products, crockery, asbestos pipes, granite tiles, crushed stones, hydrated lime etc.

Thus, it can be said that clay and ceramics have been an essential part of our civilization and culture from the very beginning. Although the information about the form of ceramic religious objects is available 24000 years ago, the work of the presently wide-spread pottery has been found in 6400 BC when our ancestors built permanent residence on the riverbanks and established the agricultural economy. The fire was invented in 3500 BC to improve the strength of the potter's the wheel and clay-made objects. The rural potters are still working in the same manner, and the vessels made of terracotta clay and the novelty vessels are still an essential part of their subsistence. A senior member of modern ceramics Prof. According to Kingery, ceramics have been developed in this order: as shows in Table 1.

| Table 1 Timeline Of Ceramic Development |

|

|---|---|

| Renaissance Maiolica | 1485 |

| European Hard Porcelain | 1708 |

| Ceramic Factory Manufacture | 1750 |

| Basic Steel Refractories | 1879 |

| Electrical Ceramics | 1876-1910 |

| Synthetic Ceramics | World war II |

| High-Performance Fine Ceramic | 1962 |

Human civilization and human needs also change and increase and strive to feed their stomachs and meet their family and society's needs today. The industrial sector is expanding to meet various essentials, and there is a tremendous spread of ultra-modern amenities. Because of this growing pleasure, new industries have started setting up satisfying the consumers and earning profit by producing them according to their needs. In Rigveda, it is prayed to make us an executive person, renounce laziness, and earn massive wealth through proper means.

Thus, the destination of the ceramic development journey started with human civilization is not yet close. Today, traditional ceramic products are being made with innovative technology, while the discussion of advanced ceramics among entrepreneurs is at a climax. as shows in Table 2.

| Table 2 Scope Of Ceramics Products |

||

|---|---|---|

| S.No. | Name of Field | Name of Product |

| 1 | Sanitation System Products | Sanitaryware |

| Salt Glazed Sewer Pipe | ||

| RCC Spun Pipe | ||

| 2 | Refractories Products | Fire Clay Bricks & Blocks |

| Graphite Crucibles | ||

| Silicon Carbide Crucibles | ||

| Furnace insulation Bricks | ||

| 3 | Clay Products | Ceramic Candles |

| Flooring tiles Clay | ||

| Chemical Porcelainware | ||

| 4 | Ground Minerals | Quartz & Silica |

| Feldspar | ||

| Ball Clay | ||

| China Clay | ||

| Fire Clay | ||

| Dolomite | ||

| Magnesite | ||

| Kyanite | ||

| Sillimanite | ||

| Graphite | ||

| Silica | ||

| Zirconium | ||

| 5 | Plaster of Paris Products | Plaster Boards |

| Plaster of Peris Powder | ||

| 6 | Electrical Wate Products | Insulators |

| Resistors | ||

| 7 | Table Wares Products | Crockery |

| 8 | Decorative Products | Flowerpots |

| Idol | ||

| Show Piece | ||

| 9 | Others | Cement Tiles |

| Bricks | ||

| Granite Tiles | ||

| Crushed Stone | ||

| Hydrogen Lime | ||

| Asbestos pipe | ||

Theme 2: The Evidence of Ceramics From the Ancient Records

There is a long history of pottery making and the precipitous surge in demand caused by innovation and advanced technology. Many archaeological undertakings have uncovered that Egyptians used blue tiles and blocks to design their homes and other building structures around the 4th century BC. Beautifully coated ceramic blocks in Mesopotamia were additionally a distinctive sight. These blue blocks in some ancient places can be explored. (Thomas et al., 2018)

An example of the hallways and Babylon's door is one such place where coated blocks are a tremendous hit among visitors and art enthusiasts. The Ishtar door, considered one of the seven unique wonders of the old world, was built in the fifth century BC. The sculpture is adorned as a foundation with a dark-coated blue with mythical snakes, bullocks, and lions (Mohansandari and Kalavani, 2017). One can explore the first reference of ceramic-based products in India in the age of the Neolithic Age. These were handmade ceramic products; However, the foot wheels were used later. The Chalcolithic era and the primary metal age are different from unmistakable societies in various pieces of our country, especially the Ahar culture in south-eastern Rajasthan, Malwa culture in western MP, Jorge culture in west Maharashtra, and much further. The Vedic era saw the painted grey ware (PGW) culture (Abinaya, 2019). As a result, it is seen as a pre-iron period of PGW. Then, later, the Vedic sites are the iron period of PGW. This ceramic is an Iron Age stone found in the Ganga's plain and the Ghaggar - Hakara Valley, which is permanent from about 1200 BC-600 BC. The area of Mathura in up was the largest PGW site (Shendur et al., 2020).

Stone monuments indicate the developed sites of giant (super) stones (lith) culture between the third century BC to the first century AD. This culture is mainly known for its vast stone graves. This age in the south is described using iron. The relevance and cynicism of ceramics have become huge in the Shunga, Kushan and Gupta periods. The coated ceramic period began in the twelfth century AD when Turkic Muslim rulers supported potters from Persia, Central Asia and elsewhere to comfortably achieve current northern India (Lefrancq et al., 2019). Holding a critical position in the public eye, the stoneware in traditional pottery was based on making seals, pots and compartments using a wheel, generally practical in its use, and putting them on fire in a rectangular 'stove' in deep and red tones.

After some time, India's direct small dirtiness method includes ceramic, coated ceramics, ceramic products and unglazed papier-mache products. The best ceramics in India are accepted to be of unglazed classification. In different places, they have methods, plans, colours, surfaces, styles, and wraps. For example, Kangra is known for its dark products of ceramics, Jhajjars for thin-necked 'Surahis', and the utensils and figures of Kutch animals and other creatures (Uurankar et al., 2018).

Theme 3: Technological Advancement in the Ceramic Industry

The man had shaped and used the everyday materials he finds in his immediate environment to make instruments, utensils, arms, garments, and lodgings to acquire and set up food better and experience more quickly in natural conditions the initial steps and for a considerable number of years. The hands' arrival with the erect position's advancement encouraged him in such constructional endeavours and simultaneously added to the development of intellectual capacity that leads him logically to the assembling of an ever-increasing number of muddled antiquities. In this long human transformative course, the "innovation" is first restricted distinctly in the forming, anyway detailed, of existing regular materials (Kalemtas, 2019). The creation of new materials is a moderately ongoing turn of events and started at around 11,000 years before present with the disclosure of pyro-technology, which was first applied, on the production of lime and gypsum mortars (Kingery et al., 1988).

Nonetheless, the excellent second in the innovative advancement in the principal clay production around 9,000 years before present in the Near East and somewhat prior in the Far East (Rice 1987). The growth is mainly due to the factors of:

• Involvement with pyro technology for consuming limestone at temperatures over 800 o C and

• Participation with little crude dirt. It oversaw in this manner to create unexpectedly on earth another material, the ceramics products (Choudhary et al., 2018).

Theme 4: Vistas of Advanced Ceramic in India

Advanced ceramics are a new generation of high-performance materials based on inorganic materials found in abundance on the ground level. Good strength, lightweight, dimensional stability, chemical inactivity and maintaining most of the above properties at elevated temperatures are noteworthy features. Their electrical and optical quality are adapted so that they can provide high performance. Advanced ceramics covers very vast areas of innovative developed materials whose non-modest use of properties has highlighted many new possibilities. Unlike traditional ceramics, advanced ceramics are processed in clean conditions with pure materials like alumina, zirconia, silicon nitride, silicon carbide, boron carbide, boron nitride, etc. In advanced ceramics, the high-quality powder is shaped by controlled or functional conditions to produce materials with exceptional properties. These materials have many abilities such as tolerating high temperatures, unique strength, hardness, combating decay, optical and electronic properties, etc.

The advanced ceramic materials can be valuable superconductors. The field of advanced ceramics is growing surprisingly, including cutting tools, dyeing, valves, seals, molecular fuels, tiles used in spacecraft and missiles, pollution control equipment, gas and humidity measuring instruments, thermal folding coverings, medical equipment, dentures, artificial heart valves, bones joint, optical and electronic devices, and mechanical engines, etc. Thus, advance ceramics have emerged as the key to craft science.

Advanced ceramic products' performance depends on the raw materials, converting raw materials into powders and how the final product is produced, mainly depending on raw materials. The powder made because of raw materials, and various processes must have high chemical purity and excellent particles of a specific size. Natural and traditional raw materials contain intrinsic impurities, which adversely affect the quality of the final product. The primary defect in the natural and conventional raw material is cracked in finished goods, the large size of the particles, the gap between the particles, the lack of early aggregation of particles and the unwanted shapes, which leads to a decline in the mechanical and electrical properties.

Given these defects, the requirement of synthetic materials for advanced ceramics has been made authentic. Some processing techniques have been developed to achieve synthetic raw material, including solution techniques, vapour phase techniques, Salt decomposition techniques, carbothermal reduction techniques, self-propagating high-temperature synthetic techniques and reaction formed synthesis techniques.

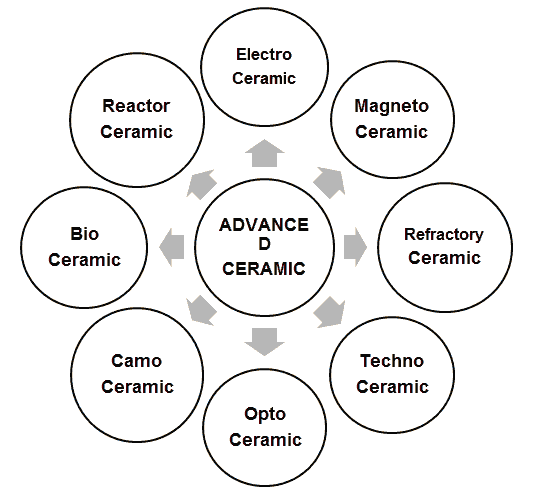

In advanced ceramics, thousands of high quality small and large products are produced, resulting in an extensive area. But the various products to be produced can be functional classing according to the nature of their original actions. The advanced ceramics are classified into electro-ceramics, magneto ceramic, refractory ceramic, techno ceramic, Opto ceramic, camo ceramic, bio-ceramic, and reactor ceramic. Reactor ceramic covers the production of molecular energy and molecular fuel. Package substrate, capacitors, piezo-electrics, thermistor and varistors are essential products of Electro Ceramics. The Bio- Ceramic include bones of various joints of the human body, artificial teeth, ear bone restoration, artificial heart valves, etc. Engines manufactured through advanced ceramics are forty per cent less loaded and more than thirty per cent fuel savers compared to other engines, which are essential products of Techno Ceramics. The Refractory Ceramics include large casting furnaces and high-temperature tolerance blocks products in factories. Camo ceramics include spacecraft and missile tiles, pollution control devices, etc. Other products like the sharp lens are the toxic products of Opto Ceramics (Giriraj, 2003).as shows in Figure 2.

CERMAT2 has been revolutionizing the field of ceramics. CERMAT2 was finished in October 2017, yet work has been proceeding from that point forward. One of the venture targets included preparing another age of youthful scientists in cutting-edge nonlinear solid mechanics and mathematical usage with clay creation applications. A portion of these scientists has just made an effective beginning with expanding and spreading the CERMAT2 strategies across ceramics' business (Rackstraw, 2019).

Several years later, when it was anticipated to develop new material for ceramics, the dire need for new material was felt—a high possible effect on creation cost, rates of rejects, and in general industry maintainability. CERMAT2 focuses on an effective method that ensures the pottery business move away from its conventional approaches to receive a more level-headed and logical methodology. Given cutting-edge nonlinear mechanical demonstrating, this methodology includes a numerical constitutive displaying of artistic materials, exploratory examination, characterization, and mathematical recreation with the limited component strategy (Ziemann et al., 2017). The streamlining plan using Virtual Prototyping – under which the project is approved in silico utilizing PC supported designing programming without using an actual model.

Prior Tiles were significantly utilized as beautiful items, yet now, as tiles are changing, customer inclinations are developing complex. Presently tiles are practically just as stylishly progressed. Today, we have tiles that spend significant time in different viewpoints, for example, slip-obstruction for washrooms and pool territories. Against bacterial properties for outside, particularly in moist districts and scratch-safe properties appropriate for high traffic regions (Hu et al., 2019). These properties of tiles make them a need without settling on the visual attraction offered by them.

Theme 5: Increase in Use of Innovative Ceramic Products

As increasingly tiling alternatives and plans become accessible, tiles are not merely kept to the Kitchen and Bathroom territories. However, they are favoured in non-ordinary regions like front rooms, rooms, eateries, shopping centres, and workplaces (Dias et al., 2017). Alongside the floor tiles, the most recent fury is divider tiles picked by clients to enhance their dividers and exterior cladding, supplanting paints, which were the only choice accessible prior. Tiles are impervious to stains and earth, cleaned with a moist mop, wipe, or regular family cleaners. Consequently, these are favoured in the living regions, on dividers, floor, or veneers. For instance, the most recent contributions from Somany Ceramics, Glosstra tiles are divider tiles with additional sheen and have polished surfaces, which enlighten a dull room and upgrade the style remainder of the living territory (Sitdikov et al., 2017). Attributable to the mechanical progressions and inventiveness in plans, there are bounty decisions accessible in tiles for insides and outsides of homes, lodging halls, retail sources, formal gatherings, etc. Globally and in India, as the arrangements become bigger, particularly ground surface, vitrified tiles are the solitary choice. These are accessible in plenty of plans and designs and are utilized for floors of fluctuated home-grown and mechanical structures. For example, with the properties, reflexive surface, stain opposition, soil obstruction, clean and low upkeep, these tiles are ideal for the said customers. Development in the vitrified fragment will rise (Haddar et al., 2018).

Theme 6: The Future of the Ceramic Industry

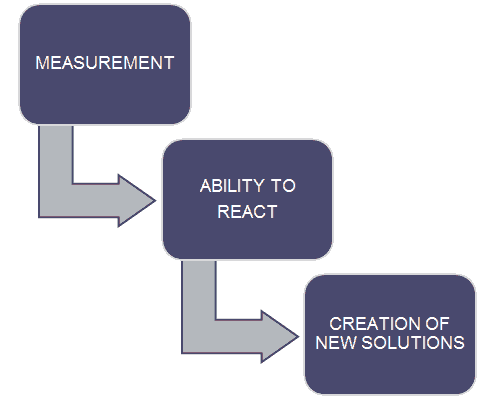

Disruption in the digital expressions in the customary ceramics materials industry drives the market's extension for the most creative and imaginative ceramic product makers. For example, patterns of cutting-edge plans (self-washing and self-adjusting), manageable artistic tiles, or energy-productive pottery are now blasting. Pottery organizations have put resources into innovations, so their methods of creation and production cycles can stay up with the market's business requirements (Ruys, 2018). The movement from conventional assembling to computerized producing is just the initial step. However, this was sufficient without an activity plan that coordinates every one of the zones of the organization and incorporates three principal fields: figure 3.

Research suggests that the execution of cutting-edge advanced printing has the best effect on tile classification. As indicated by Dal-Tile's Thorn-Brooks, automatic printing has changed the business in recent years, and makers are presently ready to create considerably more complex items that better address the client's issues. The advancement of printing innovation has prompted makers to have the option to make novel examples, plans and dynamic tones on individual tiles, like common materials, which they are repeating with unbelievably high levels of credibility (Peng and Chen, 2018).

More explicitly, Noah Chitty, Crossville's head of specialized administrations, said carrying this innovation into the tile business has permitted makers to configure tiles in Photoshop utilizing visual artisans' aptitudes to make and repeat looks. Presently, the company can take common stone or wood, or pretty much anything, put it on a flatbed scanner, take the following picture, and reproduce it in exceptionally superior quality onto the outside of porcelain or a fired tile (Growth of ceramic industry, 2020).

New advancements have affected the surface plans of tiles and the shapes and sizes of those entering the market. These advances permit makers to make everything from mosaics in hexagons to rectangular shapes and even enormous configuration porcelain pieces. Innovation in ceramics has allowed the industry vendors to go greater, thicker, and slenderer with their designs. They are making more significant size arrangements and more slender profile thicknesses than was not observed in the historical period.

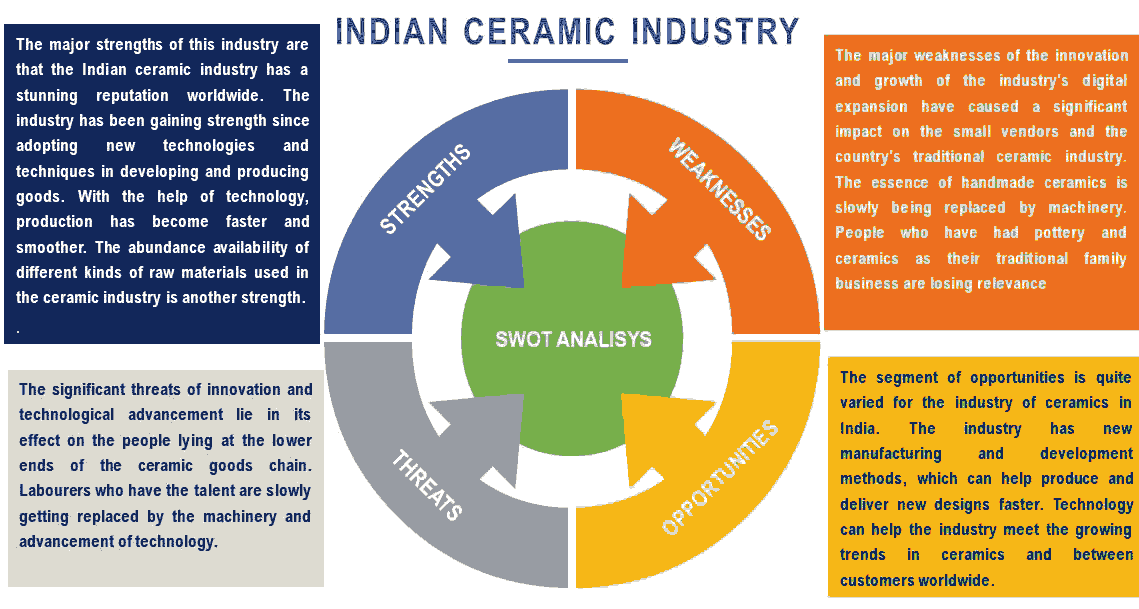

Huge configuration tiles keep on acquiring ubiquity both in the private and business plan. The progressions in size have helped the class with advancing from 24 x 48-inch boards to 5 x 10-foot porcelain boards. In any case, it is not just about the size. Thicknesses are likewise assuming a significant job. Meagre tile is an advancement acquiring footing that presents an exciting chance for the commercial centre. as shows in Figure 4.

Strengths

The major strengths of this industry are that the Indian ceramic industry has a stunning reputation worldwide. The industry has been gaining strength since adopting new technologies and techniques in developing and producing goods. With the help of technology, production has become faster and smoother. The abundance availability of different kinds of raw materials used in the ceramic industry is another strength.

Weaknesses

The major weaknesses of the innovation and growth of the industry's digital expansion have caused a significant impact on the small vendors and the country's traditional ceramic industry. The essence of handmade ceramics is slowly being replaced by machinery. People who have had pottery and ceramics as their traditional family business are losing relevance (Transition from traditional pottery-making to ceramics, 2020).

Opportunities

The segment of opportunities is quite varied for the industry of ceramics in India. The industry has new manufacturing and development methods, which can help produce and deliver new designs faster. Technology can help the industry meet the growing trends in ceramics and between customers worldwide.

Threats

The significant threats of innovation and technological advancement lie in its effect on the people lying at the lower ends of the ceramic goods chain. Labourers who have the talent are slowly getting replaced by the machinery and advancement of technology (About Indian ceramic industry, 2020).

Conclusion

The Indian ceramic industry has seen a growth from all hands-on deck industry to no hands-on deck. With the new developments and trends in ceramics, the vendors can achieve more than they could ever have. The paper has traced the Indian ceramics industry's growth from the Neolithic era to the present time. The report has discussed the technology used to develop high-class pottery products and the underlying ideas about them. This section of the analysis has traced the growth and development of technology in ceramics. It has highlighted how, from a foot wheel, the industry has grown to use pyro-technology and modern machines. The advancement of technology has empowered the industry to manage bulky orders, produce new designs, and use various colours. Not only this, but there is also new material being used in the industry. CERMAT2 is a unique material that ceramic producers are widely adopting in today's times. The growing use of tiles in non-conventional areas is creating a surge in demand for tiles. The technology is aiding to meet this demand substantially. The customary creation of ceramics has shifted from the artisans' creative hands to digital or computerized designs. This digital printing has helped the vendors meet bulk orders and mass production with much ease. The paper has illustrated the new trends in the market and the new ceramic products doing the market rounds. Technology has proven to be blissful for the ceramic market vendors; however, it has had many adverse effects on the traditional potters and small-scale setups that rely on conventional creation methods. Since these methods are slow and time-consuming, the overall production cost becomes much more extensive than machine-produced goods. The ceramic industry's patrons need to devise a strategy to secure all the industry stakeholders' interests and establish a balance.

In a nutshell, today, Alumina, Zirconia, etc., the primary raw materials used for advanced ceramics, are not available in adequate quantities in India, and those found are impure. As a result, these are imported; consequently, the cost of products produced from them are much more than the products made from natural and traditional raw materials. The direct effect is that about eighty per cent of the people categorized as a middle-income group or even below in India cannot buy these products. This is a significant component that is affecting the desired development of advanced ceramics in India. A high-class R&D work in India is at the experimentation level and ongoing in public sector research centres and defence laboratories. It is necessary to review all these efforts; at the same time, there is a need to develop new technology. If India is to be an advanced ceramic leader, it will have to explore cutting-edge technology through R&D programs taking care of its available natural resources.

India's top priority in the 21st century will be to meet the growing demand for power due to the increasing population and high living standards. Besides, work has to be carried out on a war footing in housing for all, education for all, and infrastructure development (road, rail, port, airport, telecommunication, insurance and banking development etc.) Which will result in the creation and promotion of direct and indirect demands of various ceramic products.

In the coming time, more than double the increase in houses in urban areas and the possibility of a half-fold growth in the homes in rural areas are being increased. Emphasis is being given continuously for quality enhancement in rural houses. Today, there is a gradual increase in the number of Pucca houses instead of Kutcha houses in the villages. Thus, the demand for sanitary, tiles, porcelain, decorative products, plaster of Paris products, etc., is likely to increase encouragingly. Therefore, it can be said that the future of the ceramic industry in India is brighter.

Limitation/ Further Scope/ Going Forward

The research has been limited to evaluating and discussing the existing literature that dates to the last few years. The research paper's further scope lies in studying the empirical data collected via primary research. In the future, the research should consider a quantitative analysis for better results.

References

Abinaya, S., Moni, P., Parthiban, V., Sahu, A.K,. & Wilhelm, M. (2019). Metal silicide nanosphere decorated carbon rich polymer derived ceramics: Bifunctional electrocatalysts towards oxygen and their application in anion exchange membrane fuel cells. ChemElectroChem, 6(13), 3268-3278.

Choudhary, A., Pratihar, S.K., Agrawal, A.K., & Behera, S.K. (2018). Macroporous SIOC ceramics with dense struts by positive sponge replication technique. Advanced Engineering Materials, 20(3), 1700586.

Dias, F.G., Segadães, A.M., Perottoni, C.A., & Cruz, R.C. (2017). Assessment of the fluxing potential of igneous rocks in the traditional ceramics industry. Ceramics International, 43(18), 16149-16158.

Anasica, S., Sweta, B. (2020). Analysing the factors involved in risk management in a business. International Journal of New Practices in Management and Engineering, 9(03), 05 - 10.

Giriraj, K. (2020). IOP Conf. Ser.: Mater. Sci. Eng. 993, 012112.

Giriraj, K. (2003). Performance appraisal of ceramic industries of India, Ph.D. Thesis, MDS University Ajmer, 2003.

Haddar, A.E., Gharibi, E., Azdimousa, A., Fagel, N., Hassani, IEEAE, & Ouahabi, M.E. (2018). Characterization of halloysite (North East Rif, Morocco): Evaluation of its suitability for the ceramics industry. Clay Minerals, 53(1), 65-78.

Hu, Y.C., Wang, J.H., & Huang, Y.J. (2018). Nurturing qualified personnel for the ceramics industry. Asia Pacific Management Review, 23(4), 278-289.

Kalamatas, A. (2019). Low-temperature sintering of porous ceramics via sodium borate addition. Material Science Research India, 16(1), 48-55.

Kisa, N. (2019). The skills of principals to manage the generational differences: A scale development study. Educational Administration: Theory and Practice, 25(4), 745-772.

Lefrancq, C., Hawkes, J., Jazeera, C.M., & Mohanty, R.K. (2019). A typology of practice: The archaeological ceramics from Mahurjhari. Internet Archaeology, 52.

Li, W., Lu, X., Luo, H., Sun, X., Liu, L., Zhao, Z., & Guo, M. (2017). A landmark in the history of chinese ceramics: The invention of blue-and-white porcelain in the tang dynasty (618–907 AD). STAR: Science & Technology of Archaeological Research, 3(2), 358-365.

Mohanasoundari, R., & Kalaivani, A. (2017). A comparative study on selected ceramics industry in India. International Journal of Marketing and Technology, 7(8), 1-9.

Peng, Q., & Chen, J. (2018). Research on the popular style design of daily use ceramics in creative economy. DEStech Transactions on Economics, Business, and Management (accessed).

Rackstraw, P. (2019). Positive outlook for kaolin in ceramics. Industrial Minerals, (609), 24.

Ruys, A.J. (2018). Alumina Ceramics: Biomedical and Clinical Applications. Woodhead Publishing.

Send ur, G.S., Abeens, M., Muruganadhan, R., Arivanandhan, M., Premnath, M., & Rajasekaran, E. (2020). Investigation of nanoceramics added bismuth antimony telluride for energy harvesting applications. Materials Today: Proceedings, 22, 879-883.

Sitdikov, A., Khramchenkova, R., & Bakhmatova, V. (2017). Experimental study of technological changes in the ceramics industry.

Thomas, S., Balakrishnan, P., & Sreekala, M.S. (2018). Fundamental Biomaterials: Ceramics. Woodhead Publishing.

Urunkar, Y., Pandit, A., Bhargava, P., Joshi, J., Mathpati, C., Vasanthakumaran, S., Jain, D., Hussain, Z., Patel, S. & More, V. (2018). Lightweight thermal insulating fly ash cenosphere ceramics. International Journal of Applied Ceramic Technology, 15(6), 1467-1477.

Zhang, Z. (2019). The training model for translation talents majoring in ceramic art. In 2019 3rd International Conference on Education, Economics and Management Research (ICEEMR 2019), Atlantis Press, 81-84. Crossref, GoogleScholar

Ziemann, C., Escrig, A., Bonvicini, G., Ibáñez, M.J., Monfort, E., Salomoni, A., & Creutzenberg, O. (2017). Organosilane-based coating of quartz species from the traditional ceramics industry: Evidence of hazard reduction using in vitro and in vivo tests. Annals of Work Exposures and Health, 61(4), 468-480. Crossref, GoogleScholar

About Indian ceramic industry, 2020).

Growth of ceramic industry, (2020).

Transition from traditional pottery making to ceramics, (2020).

Received: 30-Nov-2021, Manuscript No. JMIDS-21-9306; Editor assigned: 02- Dec -2021, PreQC No. JMIDS-21-9306 (PQ); Reviewed: 11- Dec -2021, QC No. JMIDS-21-9306; Revised: 17-Dec-2021, Manuscript No. JMIDS-21-9306 (R); Published: 05-Jan-2022.