Research Article: 2023 Vol: 22 Issue: 2

An Empirical Study of Quality Management System in the Algerian Construction Projects

Bouzidi Y, University of Constantine 3

Louafi S, University of Constantine 3

Saighi O, University Constantine 3

Citation Information: Yousra, B., Samira, L., & Ouafa, S. (2023). An empirical study of quality management system in the Algerian construction projects. Academy of Strategic Management Journal, 22(2), 1-16.

Abstract

The overall objective of this paper is to measure the extent of knowledge and implementation of QMS in Algeria and to assess the degree of reliability of Algerian construction companies to implement QMS and make appropriate use of quality tools.A questionnaire survey was conducted to assess the perceptions of all actors in the construction industry, the target population for this study consists of architects, engineers and project managers with experience in the implementation of QMS in construction projects in Algeria. An exploratory approach was adopted by studying the available literature to create and build on a quality management framework for construction projects and based on this, lists of measures and quality control tools were developed in consultation with the staff. The results show a high degree of misunderstanding of the strategies, tools and techniques of the QMS in the construction companies, the tools and techniques used for quality control are not reliable and consistent. There is a need to further standardize procedures and processes as well as inputs for the Algerian construction industry to adopt a QMS in true spirit, our research gives a global overview of the functioning of the QMS and aims to simplify the reading and understanding of its different principles by interested managers and it can help the construction project management team to have an idea of how to effectively manage construction activities throughout the project life cycle, through the integration of QMS. To date, only limited research has been conducted on the application of ISO 9001 in construction projects in Algeria. This is the first article providing empirical evidence on the status of QMS application in construction projects in Algeria.

Keywords

Quality Management, Quality Management System, Construction Projects, Quality Control, Quality Planning, Quality Assurance.

Introduction

Limited by fierce competition and increasing consumer demand, quality has become a fundamental factor in the country's market survival, profitability and overall economic development of the country, especially for specific industries and types of businesses. Modern business strategies are based on the intention to control the quality of products and services. Today's quality is not manufactured, but used as a management tool (Holjevac, 1996). Many companies have obtained the label through the certification of the ISO 9001 quality system, which represents one of the most widely used management practices in the world. It reflects a common understanding of the basic characteristics that a quality system must have to ensure the effective functioning of any organization (Boulfoul et al., 2017).

Organizations are affected by multiple factors, technological or social factors that force them to transform themselves. The term “quality management system” refers to equipment that allows a company to manage its processes or activities so that its products or services meet the objectives it has set. Our research will focus on Quality Management System or QMS, which can be defined as a set of coordinated activities to guide and control the quality of the organization; this includes quality control and quality assurance, as well as the concept of quality policy, quality planning and quality improvement (Boumenad, 2016), reminding that the ISO 9001 standard defines the concept and the model of the accreditation principles. Through ISO certification, the company obtains a written guarantee from a credibility agency that the product or service regularly displays a specific quality, derived from the characteristics well identified in the official standard (AFNOR). Indeed, the implementation of the quality management system first of all involves the implementation of management tools to improve the organization and operations of the company (Slimani & Boukrif, 2016). The previous literature has focused primarily on the success factors of implementing SQM in construction and the limited research documented on QMS based on ISO 9000 (Arditi & Gunaydin, 1997) believes that the factors of importance affecting quality in construction correspond to TQM elements (Haupt & Whiteman, 2004) studied the success factors of transferring TQM to the construction site, also for (Abdullah et al., 2015) his research aims to explore the current implementation of the QMS and to identify the critical success factors of the project associated with the indicators for each critical success factor identified (Idris Othman et al., 2020) in their research identified the high impact factors affecting the successful implementation of quality management system practices in the construction project. Other works (Leong et al., 2014) focused on the role of quality management system (QMS) and total quality management, and their approaches in the construction projects, lately some studies have focused on the effectiveness of QMS such as (Neyestani, 2016) furthermore in the construction filed, according to quality systems include both internal and external aspects. An internal quality system includes activities designed to convince the management of an organization that the expected quality will be achieved. This is called a “quality management system”. An effective quality management system can help improve product quality, improve processing and efficiency, reduce waste and increase profits. Meanwhile, external quality systems include activities designed to convince customers that the supplier's quality system will provide products or services that meet the customer's quality requirements. This is called a “quality assurance system”.

Also Mane & Patil (2015) in his article also states that quality planning, quality control and quality assurance are the main elements of the quality management system and that in order to succeed in the construction project, it is necessary to pay attention to all these elements.

Several researchers also interested in quality control and its impact on the construction project such as Salvi & Kerkar (2020); Bhattacharjee (2018). As for quality assurance (Bhattacharjee, 2018) defined it as the regular evaluation of overall project performance to ensure that the project will meet the relevant quality standards. Salvi & Kerkar (2020) states that the process of implementing the quality assurance and quality control system is clearly understood that quality does not happen by chance, it must be managed at every stage of the product. A quality system is a mechanism by which a company can organize and manage its resources to achieve, maintain and improve quality in a cost-effective manner.

According to various authors (Abdullah et al., 2015; Alaudin & Hassan, 2011; Mane & Patil, 2015; Rauzana, 2017; Chin-Keng, 2011) in the field of construction there are currently three basic concepts for the quality management system: quality planning, quality control and quality assurance, many research have been conducted to study the role of the QMS in various industries (e.g. manufacturing, food, services, etc.), but in construction (Leong et al., 2014) thinks there is a lack of studies especially on the role of SMQ (Akhund et al., 2018) He also thinks that ISO 9000 quality management standards in construction companies have not been significantly implemented but they are very common in manufacturing companies. On the other hand (Willar et al., 2014) thinks that The most widely adopted QMS in construction companies is the ISO 9000 series, This standard is actually a generic standard that can be successfully used by construction companies in their projects, several other researchers share the same opinion (Chini & Valdez, 2013; Farooqui & Ahmed, 2009; Pheng & Teo, 2003; Turk, 2006).

According to Rauzana (2017) during the implementation of construction in Indonesia, encountered many construction failures to cause one as a result of construction work that does not comply with the specified quality standards, construction companies need to improve the quality of the project according to market needs and technological in Febation.

As for the tools of quality (Mane & Patil, 2015) believe that checklists are used as a tool for quality, quality control measures as manufacturing quality and importance to be given to customer satisfaction. As developing countries, Algeria is no exception, like other organizations in the world, are looking for a new approach to improve their competitiveness in the face of changes in the environment. Today, the establishment of many standards is a very big, because the performance of companies depends on it (Benyettou & Abdellatif, 2018). Thus, from the 1990s, the government initiated a national plan to encourage companies to adopt a quality management system in accordance with the ISO 9001 standard. This is why more and more Algerian companies choose to implement quality management system certified ISO 9001 within their organization. Even if this strategic choice affects all functions of the company (Boumenad, 2016), on the other hand for the moment in Algeria none of the previous studies has studied the application of QMS especially in construction there is therefore an acute need to focus on this system and to know the extent of its use in organizations. Based on the above studies, we summarize as follows:

• The majority of researchers have focused on the effectiveness of QMS and its impact on project performance

• Many studies have studied the key factors of the success of the QMS

• The number of researchers who have focused on the three main QMS elements is very limited

• In Algeria none of the previous studies studied the application of QMS in the field of construction

Therefore, to fill these gaps, the present study aims to identify the level of understanding of the personnel on the full content of the quality management system itself. To our knowledge, this study is a pioneer in the field of project management in Algeria, with a focus on the main elements of QMS planning, control and quality assurance.

Research Objectives

This study aims to achieve the following objectives: Define the level of awareness and application of the quality management system in Algeria. Verify of the implementation of the three principles of quality management system (quality planning, quality control and quality assurance) in construction projects in Algeria. Obtain an overview of the level of understanding of project stakeholders on the content of the QMS.

Research Methodology

This research was designed to assess the extent and use of QMS in construction projects based on descriptive methods. Thus, the literature review was first conducted to understand the subject and the concepts of the study, in order to develop an appropriate survey questionnaire to obtain data on construction projects.

The questionnaires were randomly distributed among the respondents (architects, engineers and project managers) working in ISO 900

| Table 1 Results Of The Implementation Of Qms |

|

|---|---|

| Country | Research results |

| Pakistan | The primary stakeholders in the construction sector's understanding and awareness of TQM were judged to be insufficient. They frequently use conventional quality control procedures. |

| Malaysia (Kiew et al., 2016) | This article argues that in order to achieve better monitoring of construction activities, the system of quality management (SMQ) must be integrated into industry practices. |

| Malaysia (Chin-Keng & Hamzah, 2011) | Total quality management is an uncommon concept; construction businesses typically employ traditional techniques in terms of quality management tools and processes. |

| UK (Delgado-Hernandez & Aspinwall, 2008) | The collected data indicates that the sector has started to step up to the challenge, and as a result, businesses have seen an increase in return customers, market share, and client satisfaction. However, member businesses indicated that there are still issues with their procedures, such as a lack of internal communication, inefficient decision-making procedures, and a failure to properly identify client needs. |

| Arabie Saoudi (Aichouni et al., 2014) | The results indicate a high level of misunderstanding regarding QMS strategies, tools and techniques among construction companies surveyed. The study shows that organizational culture is a real obstacle to the implementation of his QMS and quality control measures in the Saudi construction sector. |

| The United States (Chini & Valdez, 2013) | Although the ISO 9000 standard has been concluded to be an appropriate and effective tool for US construction companies, several obstacles prevent its implementation and acceptance by construction companies. |

| The United States (Farooqui & Ahmed, 2009) | ISO 9000 certification drives continuous improvement and contributes to improved bottom line |

| Malaysia | Research shows that ISO 9000 certified companies perform at a higher level in project environments than non-certified companies. |

| Indonesia (Trigunarsyah et al., 2011) | The survey results showed that the majority of the sectors surveyed were “not fully implementing” the items. A careful review of the data revealed that the elements were “minimally implemented” but none fell into the “fully implemented” category. |

| Indonesia (Willa et al., 2014) | The results also suggest that many of the G-7 entrepreneurs, although certified, have not yet reached sufficient performance levels to be truly competitive in global markets outside of Indonesia. . |

| Turkey (Turk, 2006) | The data evaluation shows that construction companies surveyed are generally positive about ISO 9000 QMS and that ISO 9000 QMS has significant benefits for their companies. |

| Slovenia (Bogataj, 2017) | The results show that at present the participation of the quality management system in the management system of the organization is not sufficient. Therefore, it can be said that the quality management system is too much oriented towards the prevention and correction of errors, but not enough towards the development of the organization. |

1 certified and non-certified design offices and construction companies in Algeria. A total of 400 questionnaires were distributed, 308 of which responded, of which only 52 already had experience in implementing a QMS in construction projects.

A similar approach has been applied in other research around the world on the implementation and effectiveness of quality management systems in construction projects (Abdul-Rahman, 1996; Chin-Keng & Hamzah, 2011; Moatazed-Keani IV & Ghanbari-Parsa Sechi, 1999; Delgado-Hernandez & Aspinwall, 2008; Mane & Patil, 2015; Shammas-Toma et al., 1996). Table 1 shows the results of the implementation of QMS in construction projects of various countries.

Source: Author

A comprehensive list of quality management practices (quality planning activities, quality control tools, quality control measures) were developed by studying the available literature to create and build on a quality management framework for construction projects and based on this, (Table 2 shows the practices and their codes) a list of measures and quality control tools.

| Table 2 Research Questions With Their Id |

||

|---|---|---|

| Research Questions ID | Research questions | |

| Quality planning activities | E1 | Prepare the implementation of a quality management system (based on a process approach for example) |

| E2 | Prepare the quality management plan (specific activities related to a product or activity, such as a training plan) | |

| E3 | Try to improve quality (continuous improvement approach, partnership with suppliers, etc.) | |

| E4 | Define monitoring activities and measure process effectiveness | |

| E5 | Measure and improve performance | |

| E6 | Determine the processes of the organization | |

| E7 | Define the scope of the quality management system (geographical sector, topology of customers, activities, etc.) | |

| Quality control tools | E8 | Pareto diagram |

| E9 | Fishbone diagram | |

| E10 | Check list | |

| E11 | Organization charts | |

| E12 | Scatter plot | |

| E13 | Control card | |

| E14 | Histogram | |

| E15 | Statistical Analysis | |

| Quality contrôl measures | E16 | Site review meetings with staff |

| E17 | Maintain the build sequence | |

| E18 | Set up procedures to control quality | |

| E19 | Perform appropriate sampling and testing | |

| E20 | Implementation of a BIM process | |

| E21 | Develop a project quality plan | |

| E22 | Inspection and test report | |

| E23 | Assessing quality through auditing | |

| Quality assurance | E24 | Has your organization been able to develop rules intended to guarantee the quality of service? |

Source: Author

Questionnaire Design

The data was collected through a questionnaire survey. The questionnaire was divided into two main parts: The first part asked for general information about the respondents (position, years of experience, region and field of activity). The second part of the questionnaire dealt with the implementation of the principles of the quality management system in Algerian construction projects.

A variety of dissemination methods were used to ensure the rapid dissemination of the questionnaire: questionnaires sent by e-mail, hard copy delivered by hand and via interviews. In addition, in order to gain the trust of the participants interviewed and to promote the response rate, we assured the participants that all the information collected will remain strictly confidential, and we promised them to ensure their anonymity and to share with them the results of our study. The questionnaire survey started in October 2021 in Algeria; over three months, 308 questionnaires were returned; only 52 respondents among the 308 had already used the quality management system in their projects.

Data Collection

The data sources were classified into primary and secondary sources. The primary sources provide original data for this research. The teleological and convenience sampling method was used to select the respondents. The study participants were architects, engineers and managers. In total, 308 usable questionnaires were collected and used in the statistical analysis. Secondary sources were from published journals, books, articles and reviews, to identify data on the research topic and also to conduct a study for further details in research.

Data Analysis

The data was analyzed based on descriptive statistics, the questionnaire designed could allow respondents to give their answers corresponding to their personal experiences and opinions, to the different variables by single-choice YES and NO answers and point Likert scale (for example a scale of 1 to 5, very little used = 1, to very heavily used = 5). Likert scales are appropriate and widely used in opinion measurement

Reliability of the Questionnaire

Cronbach's alpha was measured to test the reliability of the questionnaire and determine the internal consistency of 52 items. According to (Santos, 1999) “a Cronbach's alpha value greater than 0.7 implies that the instrument is acceptable”; as shown in Table 3, the value of Cronbach's alpha was 0.702, which guarantees internal consistency and good reliability of the questionnaire. The value of Cronbach's alpha for the first files (intended for those who have already used the SMQ rules) was 0.724, which ensures internal consistency and good reliability of the questionnaire.

| Table 3 Cronbach’s Alpha For Qms |

|

|---|---|

| Reliability statistics | |

| Cronbach's Alpha | Number of elements |

| 0.702 | 52 |

Respondent Profile

A total of 400 questionnaires were distributed to public and private practitioners’ construction project in Algeria. 308 completed answers were collected. Only half of the respondents (51.64%) who know our research theme, Among the 308 respondents only 52 have already used the QMS implementation rules This is why we have changed the questionnaire in two parts to facilitate the work, one part to measure the extent of knowledge of QMS and the other for the application of QMS rules

From Table 4 we can see that:

| Table 4 Summarizes The Status Of The Respondents |

||

|---|---|---|

| Description | Numbers | Pourcentage |

| Respondents’ positions | ||

| Architect | 262 | 86,8% |

| Engineer | 19 | 6,3% |

| Project Manager | 21 | 7% |

| Their fields of activity | ||

| Management | 41 | 13,6% |

| expertise | 27 | 8,9% |

| Design office | 180 | 59,8% |

| Design | 89 | 29,6% |

| Company | 115 | 38,3% |

| Their years of experience | ||

| less than 1 year | 9 | 2,95% |

| 1-10 years | 223 | 73,11% |

| 11-20 years | 52 | 17,05% |

| 21-40 years | 21 | 6 ,88% |

• The majority of respondents are architects (86.8%) • 59.8% of multiple responses opted for design offices (architects are in the majority in our sample) with a response rate of 99.35% • 73.11% of respondents have experience ranging from a one year to 10 years

Evaluation of the Application of QMS Principles According to Respondents

Evaluation of the application of the first principle of the QMS concept “Quality planning” according to the respondents

Through the answers collected (Table 5). it was found that the majority of engineers (64 %) and project managers (52.38%) answered “yes”. they confirm the application of quality planning activities. unlike architects who 49.77% of them answered “no” and they think that the planification activities are not used on the construction projects. In order to know if there is a significant difference between the opinions of the stakeholders (architects. engineers and project managers) concerning the application of quality planning activities and their workstations. we have proposed two hypotheses:

| Table 5 Application Of Quality Planning Activities According To Stockholders |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Activities | Total | Architect | Ingineer | Project Manager | ||||||||||||

| N | % | N | % | N | % | N | % | |||||||||

| Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | |

| E1 | 17 | 20 | 41.5 | 48.8 | 11 | 16 | 35.5 | 51.6 | 4 | / | 100 | / | 2 | 4 | 33.3 | 66.7 |

| E2 | 19 | 18 | 46.3 | 43.9 | 14 | 13 | 45.2 | 41.9 | 2 | 2 | 50 | 50 | 3 | 3 | 50 | 50 |

| E3 | 20 | 17 | 48.8 | 41.5 | 13 | 14 | 41.9 | 45.2 | 3 | 1 | 75 | 25 | 4 | 2 | 66.7 | 33.3 |

| E4 | 17 | 20 | 41.5 | 48.8 | 11 | 16 | 35.5 | 51.6 | 2 | 2 | 50 | 50 | 4 | 2 | 66.7 | 33.3 |

| E5 | 20 | 18 | 48.8 | 43.9 | 13 | 15 | 41.9 | 48.4 | 3 | 1 | 75 | 25 | 4 | 2 | 66 .7 | 33.3 |

| E6 | 18 | 19 | 43.9 | 46.3 | 12 | 15 | 38.7 | 48.4 | 3 | 1 | 75 | 25 | 3 | 3 | 50 | 50 |

| E7 | 11 | 26 | 26.8 | 63.4 | 8 | 19 | 25.8 | 61.3 | 1 | 3 | 25 | 75 | 2 | 4 | 33.3 | 66.7 |

| Total | 122 | 138 | 42.5 | 46.92 | 82 | 108 | 37.78 | 49.77 | 18 | 10 | 64 | 36 | 22 | 20 | 52.38 | 47.61 |

Source: Author

H0: There is no significant difference (the two variables are independent)

H1: There is a significant difference (the variables are not independent)

To validate one of these hypotheses, the Chi-2 test was conducted, and the rule is to accept H0 if the Sig ≥ 5% and to refuse H0 (to accept the alternative H1) if the Sig <5%.

The value of the chi-square test is found 2.938 at a degree of freedom dof=2; and a level of Significance Sig=0.230> 5% so we accept H0; there is no significant difference between the stakeholders (architect. engineer. project manager), in their knowledge of methods for applying quality planning activities (Table 6).

| Table 6 Chi Square Test Results |

|||

|---|---|---|---|

| Chi square test | |||

| Value | ddl | Asymptotic significance (two-sided) | |

| Pearson's chi-square | 2.938a | 2 | 0.230 |

| likelihood ratio | 3.667 | 2 | 0.160 |

| Association linear by linear | 0.000 | 1 | 1.000 |

| of valid observations | 35 | ||

As no significant difference was found between the responders, it suffices to make a total analysis of the responses without taking into consideration the case of each responder separately.

The analysis of the responses showed that the most dominant activities are that of E5 “measuring and improving performance” and E3 “trying to improve quality (continuous improvement approach partnership with suppliers etc.)” with a percentage of Quotes from 48.8%. followed by E2 “prepare the quality management plan (specific activities related to a product or activity, such as a training plan)” with 46.3%.followed by E6 “Determine the processes of the organization” with 43.9 then E4 “define monitoring activities and measure the effectiveness of the processes” and E1 “Prepare the implementation of a quality management system (based on a process approach for example)” with 43.9% and finally. E7 define the scope of the quality management system geographical sector, topology of customers, activities, etc. with 39%.

Evaluation of the application of the Second principle of the QMS concept “quality assurance” according to the respondents

In order to check if there is a difference in the opinion of the 3 groups (architects. engineers. project managers), the chi-square test was used (Table 7), which is why we proposed two hypotheses:

| Table 7 Quality Assurance According To Stockholders |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Activities | Total | Architect | Ingineer | Project Manager | ||||||||||||

| N | % | N | % | N | % | N | % | |||||||||

| Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | |

| E24 | 29 | 9 | 70.7 | 22 | 21 | 7 | 67.7 | 22.6 | 3 | 1 | 25 | 75 | 5 | 1 | 83.3 | 16.7 |

Source: Author

H0: There is no significant difference

H1: There is a significant difference

To validate one of these hypotheses, the Chi-2 test was conducted and the rule is to accept H0 if the Sig ≥ 5% and to refuse H0 (to accept the alternative H1) if the Sig <5%

The found value of Chi square is 0.804 (Table 8). Here sig= 0.669 > 0.05 so we reject H1. There is no significant difference. That is to say there is no relationship between the 3 groups of respondents in their knowledge of the application of quality assurance activities and their workstations. The analysis of the answers showed that the majority of respondents answered yes (70.7%). they think that their organizations have been able to develop rules intended to guarantee the quality of service.

| Table 8 Chi Square Test Results |

|||

|---|---|---|---|

| Chi square test | |||

| Value | ddl | Asymptotic significance (two-sided) | |

| Pearson's chi-square | 0.804a | 2 | 0.669 |

| likelihood ratio | 1.241 | 2 | 0.538 |

| Association linear by linear | 0.338 | 1 | 0.561 |

| N of valid observations | 36 | ||

Source: Author

Quality Control

Quality control tools

We used a 5-point Likert scale ranging from 0 to 5 as shown in the following Table 9:

| Table 9 Intervals And Levels Of Importance |

|||

|---|---|---|---|

| LIKERT scale | Intervals | Description | LEVEL |

| 1 | 1.00-1.79 | Not used a lot | LOW |

| 2 | 1.80-2.59 | Little used | |

| 3 | 2.60-3.39 | Moderately used | MODERATE |

| 4 | 3.40-4.19 | Heavily used | HIGH |

| 5 | 4.20-5.00 | Very heavily used | |

Source: Author

The Table 10 above shows the descriptive results from which it can be seen that the highest average was attributed to E10 which correspond to the check lists and these are the same results obtained by the search for (Mane & Patil. 2015) with an average of 2.94 and a deviation of 1.459 followed by E13 which corresponds to the "control chart" with an average of 2.57 and a deviation of 1.569 then the other tools with almost the same average and deviation while the lowest average was attributed to E8 “Pareto chart” with an average of 1.85 and a deviation of 1.309.

| Table 10 Quality Control Tools Application’s Ranking According To Stockholders |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Questions | 1 | 2 | 3 | 4 | 5 | MEAN | STD | Rank | |

| E8 | N | 11 | 6 | 1 | 2 | 20 | 1.85 | 1.309 | 8 |

| % | 26.8 | 14.6 | 2.4 | 4.9 | 48.8 | ||||

| E9 | N | 7 | 7 | 0 | 1 | 2 | 2.06 | 1.345 | 6 |

| % | 17.1 | 17.1 | 0 | 2.4 | 4.9 | ||||

| E10 | N | 3 | 16 | 0 | 4 | 8 | 2.94 | 1.459 | 1 |

| % | 7.3 | 39 | 0 | 9.8 | 19.5 | ||||

| E11 | N | 10 | 13 | 1 | 2 | 8 | 2.56 | 1.561 | 3 |

| % | 24.4 | 31.7 | 2.4 | 4.9 | 19.5 | ||||

| E12 | N | 5 | 10 | 1 | 0 | 3 | 2.26 | 1.327 | 5 |

| % | 12.2 | 24.4 | 2.4 | 0 | 7.3 | ||||

| E13 | N | 9 | 11 | 1 | 2 | 7 | 2.57 | 1.569 | 2 |

| % | 22 | 26.8 | 2.4 | 4.9 | 17.1 | ||||

| E14 | N | 8 | 9 | 1 | 0 | 2 | 1.95 | 1.191 | 7 |

| % | 19.5 | 22 | 2.4 | 0 | 4.9 | ||||

| E15 | N | 12 | 11 | 1 | 2 | 6 | 2.34 | 1.516 | 4 |

| % | 29.3 | 26.8 | 2.4 | 4.9 | 14.6 | ||||

| Weighted mean | 2.31 | ||||||||

| Std deviation | 1.409 | ||||||||

Source: Author

The weighted average of E10 is 2.94 with a deviation of 1.482 which indicates that the checklists are moderately used according to the 5-point Likert scale as indicated in Table 9 since 2.94 is in the interval “2.60 -3.39”. Therefore the average of the quality control tools is 2.31 which are considered a low level. Because the range of levels is as follows: Low level: 1-2.59. Medium level: 2.60-3.39 High level: 3.40-5.

Quality Control Measures

The Table 11 below shows the descriptive results from which it can be seen that the highest average was attributed to E18 which corresponded to “Put in place procedures to control quality” with a mean of 2.63 and standard deviation of 1.496 which indicates that they are moderately used according to the 5-point Likert scale as shown in Table 9 since 2.63 is in the interval “2.60-3.39.” followed by E22 and E23 “Inspection and test report” and “Assessing quality through auditing” with a mean of 2.58 then the other tools with almost the same mean and standard deviation and lastly the lowest mean was assigned to E20 which corresponds to the “implementation of a BIM process” with a mean of 2.12 and a standard deviation of 1.641. The weighted mean of the quality control measures is 2.47 which are considered a low level. Because the range of levels is as follows: Low level: 1-2.59; Medium level: 2.60-3.39; High level: 3.40-5.

The implementation of quality tools and measures from the point of view of the respondents (architects. engineers. project managers)

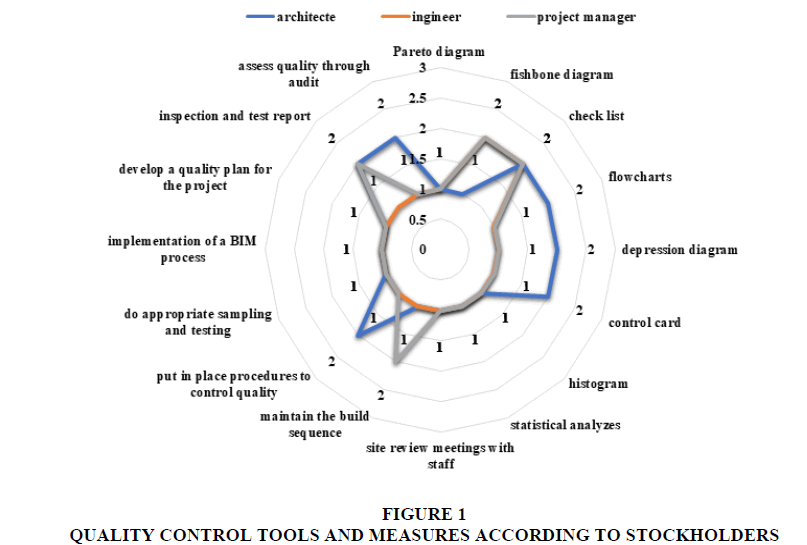

The implementation of quality tools and measures resulting from the perception of the main stakeholders (architects, engineers, project managers) are presented in the radar charts. In order to facilitate reading and comparison, 3 areas of importance have been identified using the range value of the Likert scale as follows:

Where: Ai is the amplitude of the interval. Xmax=5; Xmin=1 and n is the number of intervals (areas of importance=3). So Ai=1.33. The level of application of the 16 quality control tools and measures from the point of view of architects, engineers and project managers have been presented in the same Figure 1. The radar chart (Figure 1) shows that the three groups of respondents (architects. engineers. project managers) think that checklists are moderately used as quality control tools. however architects, engineers and project managers had several answers in common they think that “pareto diagram, histogram, site review meeting with staff, statistical analysis, do appropriate sampling and testing, implementation of a BIM process and develop a quality plan for the project” are low applied in the projects of construction. The following section is designed to compare the perceptions of architects, engineers and project managers using the “one-way AFEBA test”.

| Table 11 Quality Measures Application’s Ranking According To Stockholders |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Questions | 1 | 2 | 3 | 4 | 5 | Mean | STD déviation | Rank | |

| E16 | N | 19 | 16 | 0 | 2 | 8 | 2.50 | 1.521 | 6 |

| % | 24.4 | 39 | 0 | 4.9 | 19.5 | ||||

| E17 | N | 11 | 10 | 0 | 1 | 8 | 2.50 | 1.656 | 5 |

| % | 26.8 | 24.4 | 0 | 2.4 | 19.5 | ||||

| E18 | N | 9 | 16 | 1 | 4 | 8 | 2.63 | 1.496 | 1 |

| % | 22 | 39 | 2.4 | 9.8 | 19.5 | ||||

| E19 | N | 11 | 13 | 1 | 2 | 8 | 2.51 | 1.560 | 4 |

| % | 26.8 | 31.7 | 2.4 | 4.9 | 19.5 | ||||

| E20 | N | 15 | 3 | 1 | 1 | 5 | 2.12 | 1.641 | 8 |

| % | 36.6 | 7.3 | 2.4 | 2.4 | 12.2 | ||||

| E21 | N | 9 | 19 | 0 | 1 | 7 | 2.39 | 1.420 | 7 |

| % | 22 | 46.3 | 0 | 2.4 | 17.1 | ||||

| E22 | N | 10 | 11 | 0 | 2 | 8 | 2.58 | 1.628 | 2 |

| % | 24.4 | 26.8 | 0 | 4.9 | 19.5 | ||||

| E23 | N | 6 | 17 | 1 | 2 | 7 | 2.58 | 1.415 | 3 |

| % | 14.6 | 41.5 | 4.9 | 2.4 | 17.1 | ||||

| Weighted mean | 2.47 | ||||||||

| Std deviation | 1.542 | ||||||||

Source: Author

| Table 12 Scale And Level Of Application |

|

|---|---|

| Scale | Level of application |

| [1.00- 2.59] | Low application |

| [2.60-3.39] | Moderate application |

| [3.40- 5.00] | High application |

Source: Author

Quality Control Tools and Measures According To Stakeholders (Architect, Engineer, Project Manager)

A “ONE WAY AFEBA” test is performed to test whether there is a significant difference (disagreement) between the three groups of respondents (architects. engineers. project managers) regarding the QMS principles. Two hypotheses have been proposed:

H0: There is no significant difference (good agreement) between the three groups (if the p-value is greater than 5%).

H1: There is a significant difference (disagreement) between the 3 groups (if the p-value is less than 5%).

Table 13 illustrates the results of the one-way AFEBA, we see that the P is greater than 5%, so we accept H0, and there is no significant difference between the 3 groups. There is a good agreement between the 3 groups as to the quality control tools and measures.

| Table 13 One-Way Afeba Test |

|||||||

|---|---|---|---|---|---|---|---|

| Sum of Squares | f | Mean² | F | Sig | Décision | ||

| E8 | BG | 5.021 | 2 | 2.511 | 1.453 | 0.848 | H0 |

| WG | 25.923 | 17 | 1.728 | ||||

| TOTAL | 30.944 | 19 | |||||

| E9 | BG | 11.721 | 2 | 5.861 | 4.086 | 0.213 | H0 |

| WG | 17.212 | 14 | 1.434 | ||||

| TOTAL | 28.933 | 16 | |||||

| E10 | BG | 0.7 | 2 | 0.35 | 0.148 | 0.932 | H0 |

| WG | 61.3 | 28 | 2.358 | ||||

| TOTAL | 62 | 30 | |||||

| E11 | BG | 1.708 | 2 | 0.854 | 0.327 | 0.698 | H0 |

| WG | 75.792 | 31 | 2.614 | ||||

| TOTAL | 77.5 | 33 | |||||

| E12 | BG | 5.313 | 2 | 2.657 | 1.445 | 0.233 | H0 |

| WG | 25.745 | 16 | 1.839 | ||||

| TOTAL | 31.059 | 18 | |||||

| E13 | BG | 2.69 | 2 | 1.345 | 0.512 | 0.447 | H0 |

| WG | 65.738 | 27 | 2.63 | ||||

| TOTAL | 68.429 | 29 | |||||

| E14 | BG | 1.021 | 2 | 0.511 | 0.295 | 0.719 | H0 |

| WG | 25.923 | 17 | 1.728 | ||||

| TOTAL | 26.944 | 19 | |||||

| E15 | BG | 2.048 | 2 | 1.024 | 0.423 | 0.356 | H0 |

| WG | 65.318 | 29 | 2.419 | ||||

| TOTAL | 67.367 | 31 | |||||

| E16 | BG | 2.703 | 2 | 1.351 | 0.554 | 0.845 | H0 |

| WG | 75.679 | 33 | 2.441 | ||||

| TOTAL | 78.382 | 35 | |||||

| E17 | BG | 0.395 | 2 | 0.198 | 0.067 | 0.812 | H0 |

| WG | 74.283 | 27 | 2.971 | ||||

| TOTAL | 74.679 | 29 | |||||

| E18 | BG | 0.425 | 2 | 0.212 | 0.088 | 0.83 | H0 |

| WG | 79.214 | 35 | 2.4 | ||||

| TOTAL | 79.639 | 37 | |||||

| E19 | BG | 0.502 | 2 | 0.251 | 0.092 | 0.926 | H0 |

| WG | 81.679 | 32 | 2.723 | ||||

| TOTAL | 82.182 | 34 | |||||

| E20 | BG | 9.635 | 2 | 4.818 | 1.843 | 0.32 | H0 |

| WG | 52.278 | 22 | 2.614 | ||||

| TOTAL | 61.913 | 24 | |||||

| E21 | BG | 0.389 | 2 | 0.195 | 0.086 | 0.846 | H0 |

| WG | 69.846 | 33 | 2.253 | ||||

| TOTAL | 70.235 | 35 | |||||

| E22 | BG | 0.537 | 2 | 0.269 | 0.095 | 0.387 | H0 |

| WG | 73.67 | 28 | 2.833 | ||||

| TOTAL | 74.207 | 30 | |||||

| E23 | BG | 0.652 | 2 | 0.326 | 0.146 | 0.77 | H0 |

| WG | 62.703 | 30 | 2.239 | ||||

| TOTAL | 63.355 | 32 | |||||

Source : Developed by authors

Note: BG: Between the groups; WG: Within the groups

Conclusion

The objective of this research is to measure the extent of knowledge and use of the quality management system in Algeria and to assess the perceptions of the main project stakeholders regarding the implementation of the three principles of quality management, quality management system (planning. quality assurance and control) in Algerian construction projects.

The overall analysis of the responses shows that the knowledge and awareness of the main stakeholders in the construction projects regarding the QMS was found to be insufficient (among the 308 respondents, only 50 have experience in the implementation of QMS rules).

It can be seen that engineers are the least involved in the implementation of the QMS Only 6% of respondents are engineers.

There is no organized system used by project personnel for the deployment of QMS tools and techniques in small and medium-sized projects, so there are no mandatory provisions in construction contracts regarding strict compliance with QMS standards, tools and techniques.

Quality control is mainly based on checklists and flowcharts, quality control tools and measures in general are little used in construction projects, and only traditional methods were identified by the respondents, expresses an important need for training programs in modern methods. In addition, these results indicate a lack of knowledge and expertise in quality control and management methods and techniques.

The current study provides important information to construction project practitioners and helps them choose the appropriate actions to implement a QMS to ensure that projects will be completed successfully and smoothly with the best quality, quantity and the lowest cost possible. This research could also eventually help researchers by using the same approach to address with the application of the QMS in other fields not yet addressed in Algeria such as tourism and service projects in particular.

This research can be considered important as it contributes to a deeper understanding and knowledge of the QMS, especially with regard to its development and effective implementation. This is the first article providing empirical results on the application of quality management system in the field of construction in Algeria. The study will also enrich the existing literature with a contemporary perspective of the organizational culture characteristics and QMS practices of construction companies in Algeria.

Finally, although we obtained useful results, some limitations may be inherent in this research. such as the resources available where the study was limited to a relatively small sample size and low sample diversity in terms of sectors and type of integration used. Contracts for construction projects should be reviewed. Contract specifications and specific quality control requirements should be examined, and contemporary QMS tools and practices can be included into these papers. Workshops on the QMS for construction projects can be offered to raise awareness and increase capacity as part of the CEP Continuing Professional Development (CPD) program. The involvement of the Contractants' base engineering staff in these workshops and seminars may also be related to the renewal and advancement of Contractants.

Acknowledgements

The authors would like to acknowledge the support and assistance of all participating organizations and especially their senior managers who answered the questionnaires and made this research study possible. The authors declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article. The authors received no financial support for the research, authorship, and/or publication of this article.

References

Abdullah, M.N., Asmoni, M., Mohammed, A.H., Mei, J.L.Y., & Ting, L.S. (2015). Critical success factors of project quality management system for Malaysian construction industry.Jurnal Teknologi,74(2).

Indexed at, Google Scholar, Cross Ref

Abdul-Rahman, H. (1996). Some observations on the management of quality among construction professionals in the UK.Construction Management & Economics,14(6), 485-495.

Indexed at, Google Scholar, Cross Ref

Aichouni, M., Ait Messaoudene, N., Al-Ghonamy, A., & Touahmia, M. (2014). An empirical study of quality management systems in the Saudi construction industry.International Journal of Construction Management,14(3), 181-190.

Indexed at, Google Scholar, Cross Ref

Akhund, M.A., Khahro, S.H., Siddiqui, F.H., & Khoso, A.R. (2018). Adaptability of ISO quality standards in construction industry.Journal of Engineering and Applied Sciences,13(4), 926-9.

Alaudin, M.A., & Hassan, N.H. (2011). Integrating quality management system in construction management.

Arditi, D., & Gunaydin, H.M. (1997). Total quality management in the construction process.International Journal of Project Management,15(4), 235-243.

Indexed at, Google Scholar, Cross Ref

Benyettou, S., & Abdellatif, M. (2018). Empirical study on the integrated management system in Algerian companies.Journal of Industrial Engineering and Management (JIEM),11(1), 135-160.

Indexed at, Google Scholar, Cross Ref

Bhattacharjee, J. (2018). Quality control and quality assurance in building construction.International Research journal of Management Science and Technology,9(4), 10-16.

Bogataj, V. (2017). Role and status of quality managers in organisation of the future.RUO. Revija za Univerzalno Odlicnost,6(2), 159.

Boulfoul, N., Brabez, F., & Chemma, N. (2017).The contribution of the quality management system to the improvement of the performances of Algerian agrifood companies.International Journal of Economics and Strategic Management of Business Process (ESMB),8(2).

Boumenad, S.E. (2016).The impact of the ISO 9001 certified quality management system on human resources management: Comparative study in 35 industrial companies in Western Algeria.El-Bahith Review,233(4056), 1-11.

Chini, A.R., & Valdez, H.E. (2003). ISO 9000 and the US construction industry.Journal of Management in Engineering,19(2), 69-77.

Chin-Keng, T. (2011). Study of quality management in construction projects.Chinese Business Review,10(7), 542-552.

Delgado-Hernandez, D.J., & Aspinwall, E. (2008). Quality management case studies in the UK construction industry.Total Quality Management,19(9), 919-938.

Indexed at, Google Scholar, Cross Ref

Farooqui, R.U., & Ahmed, S.M. (2009). ISO 9000: A stepping stone to total quality management for construction companies?. InProceedings of the Seventh Latin American and Caribbean Conference for Engineering and Technology(pp. 1-9).

Haupt, T.C., & Whiteman, D.E. (2004). Inhibiting factors of implementing total quality management on construction sites.The TQM Magazine,16(3), 166-173.

Holjevac, I.A. (1996). Total quality management for the hotel industry and tourism.Tourism and Hospitality Management,2(1), 67-80.

Idris Othman, H.M., Napiah, M., Ghani, S.N.M., & Zoorob, S. (2020). Framework to enhance the implementation of quality management system in construction.International Journal of Engineering, (12), 78-91.

Indexed at, Google Scholar, Cross Ref

Kiew, P.N., Ismail, S., & Yusof, A.M. (2016). Integration of quality management system in the Malaysian construction industry.The Journal of Organizational Management Studies,117211.

Lakshmi, R. (2015). Quality control and quality assurance in building construction. InNational Conference on Research Advances in Communication, Computation, Electrical Science and Structures (NCRACCESS-2015).

Leong, T.K., Zakuan, N., & Saman, M.Z.M. (2014). Review of quality management system research in construction industry.International Journal of Productivity and Quality Management,13(1), 105-123.

Indexed at, Google Scholar, Cross Ref

Mane, P.P., & Patil, J.R. (2015). Quality management system at construction project: A questionnaire survey.Int. Journal of Engineering Research and Applications,5(3), 126-130.

Moatazed-Keani IV, R.A.M.I.N., & Ghanbari-Parsa Sechi, A.R. (1999). ISO 9000 standards: Perceptions and experiences in the UK construction industry.Construction Management & Economics,17(1), 107-119.

Neyestani, B. (2016). Effectiveness of quality management system (QMS) on construction projects.

Pheng. L.S.. & Teo. J.A. (2003). Implementing total quality management in construction firms. Journal of Management in Engineering.

Indexed at, Google Scholar, Cross Ref

Rauzana, A. (2017). Implementation of quality management system in construction.American Journal of Engineering Research,6(12), 173-179.

Salvi, M.S.S., & Kerkar, M.S.S. (2020). Quality assurance and quality control for project effectiveness in construction and management.International Journal of Engineering Research & Technology (IJERT),9(2), 26-29.

Santos, J.R.A. (1999). Cronbach’s alpha: A tool for assessing the reliability of scales.Journal of Extension,37(2), 1-5.

Shammas-Toma, M., Seymour, D.E., & Clark, L. (1996). The effectiveness of formal quality management systems in achieving the required cover in reinforced concrete.Construction Management & Economics,14(4), 353-364.

Indexed at, Google Scholar, Cross Ref

Slimani, R., & Boukrif, M. (2016).The quality management system and organizational change: Case of ALCOST Bejaia.Al-Bahith Review,16(1), 199-213.

Indexed at, Google Scholar, Cross Ref

Trigunarsyah, B., Coffey, V., & Willar, D. (2011). An empirical study of applying ISO 9001 elements in large size Indonesian contractors. InProceedings of the 6th International Conference on Construction in the 21st Century (CITC-VI)(pp. 496-503). College of Technology and Computer Science, East Carolina University.

Turk, A.M. (2006). ISO 9000 in construction: An examination of its application in Turkey.Building and Environment,41(4), 501-511.

Indexed at, Google Scholar, Cross Ref

Willar, D., Coffey, V., & Trigunarsyah, B. (2015). Examining the implementation of ISO 9001 in Indonesian construction companies.The TQM Journal,27(1), 94-107.

Received: 12-Nov-2022, Manuscript No. ASMJ-22-12854; Editor assigned: 14-Nov-2022, PreQC No. ASMJ-22-12854(PQ); Reviewed: 05-Dec-2022, QC No. ASMJ-22-12854; Revised: 10-Jan-2023, Manuscript No. ASMJ-22-12854(R); Published: 17-Jan-2023