Research Article: 2021 Vol: 24 Issue: 1S

An Investigation of the Role of Supply Chain Visibility into the Scottish Blood Supply Chain

Samer Hamadneh, The University of Jordan

Olger Pedersen, Heriot-Watt University

Muhammad Alshurideh, The University of Jordan and University of Sharjah

Barween Al Kurdi, The Hashemite University

Haitham M. Alzoubi, Skyline University College

Abstract

The management of the blood supply chain is considered of vital importance. This study explores the role of supply chain visibility in the inventory and demand planning of blood products. The study is based on a qualitative and inductive research design. Data were collected through interviewing staff at various stages of the Scottish blood supply chain, and a template analysis technique was used to analyse the collected data. Results showed that supply chain visibility plays a vital role in the daily material flow of blood products, enabling an effective response to emergencies with demand or supply shortages. Further, the study identified some gaps associated with the Scottish blood supply chain in terms of providing their staff with the information they desire. This study contributes to both supply chain visibility and blood supply chain management literature. It highlights perceived benefits by having end-to-end visibility in supply chains, especially in the context of blood supply chains. In addition, the study offers insight into what information staff at various stages of the BSC believes they require. Practitioners can utilise the identified visibility gaps to determine future development projects, target resources to overcome the identified inhibitors and seek to develop further the factors that enable SCV.

Keywords

Supply Chain Visibility, Blood Supply Chain, Inventory and Demand Management, Information Sharing

Introduction

Inventory management of perishable products involves balancing on-shelf availability with minimization of expiry related wastage (Ketzenberg et al., 2015). Consequently, failing to do so can lead to unnecessary costs, lost sales or a weakened reputation for commercial businesses (Zubi et al., 2012; Alshurideh et al., 2019; Aburayya et al., 2020a; Joghee et al., 2021). However, this unbalance in the context of the blood supply chain can potentially have fatal consequences (Stanger et al., 2012). While the blood shortage can lead to deaths and complications for patients, blood wastage generates high costs (Pirabán, Guerrero and Labadie, 2019). Indeed, managing the material flow of blood has been widely perceived as a challenging task. Firstly, both demand & supply are uncertain and irregular (Beliën & Forcé 2012). Secondly, blood’ perishability restricts the possibility of keeping buffer stocks to cope with such uncertainties (Duan & Liao, 2014; Tsang et al., 2018). Thirdly, blood is a scarce and limited resource only produced by humans (Osorio et al., 2015). These challenges suggest that more efforts need to be pursued when managing the demand and supply of blood products.

Central to the entire discipline of Supply Chain Management (SCM) is the concept of Supply Chain Visibility (SCV) (Bailey & Francis, 2008). SCV refers to the ability of the supply chain managers to access and share information pertinent to the SC strategy and the operations of SC partners (Caridi et al., 2014). It has been conclusively shown that greater visibility reduces demand and supply uncertainties and reduces shortages, increases product freshness and consequently reduces outdated (Kaipia et al., 2013; Ketzenberg et al., 2015; Lusiantoro et al., 2018).

Extant research on inventory management of blood products tends to focus on developing complex models and frameworks for minimizing expiry and shortages (Kopach et al., 2008; Osorio et al., 2015). However, in their review of blood supply chain management, Pirabán and colleagues noted that most of the studies on the topic are limited to focusing on hospital blood banks as opposed to the entire blood supply chain. Therefore, authors have called for further qualitative research to comprehensively study the multiple echelons that comprise the supply chain, their operational processes, and their connections (Stanger et al., 2012; Pirabán, Guerrero & Labadie, 2019).

Hence this study responds to these calls and attempts to to understand the role of SCV in the inventory and demand planning of blood products. To do so, it will use the Scottish Blood Supply Chain (SBSC) as the unit of analysis. Consequently, the central question in this study is: What is the role of supply chain visibility in inventory and demand planning in the Scottish blood supply chain?’

To answer the research question, three research objectives have been formulated as follows:

(1) To identify what information drives inventory and demand planning decisions in the Scottish BSC.

(2) To evaluate the current level of SCV in the Scottish BSC, hereunder the quantity and quality of data captured, accessed and utilised in inventory and demand planning decisions.

(3) To identify enablers and inhibitors of SCV in the Scottish BSC.

The paper is organised as follows. Section 2 provides the theoretical foundation, which informs the study and summarises the relevant literature. Section 3 outlines the research design utilised in this study to answer the research questions. The fourth section presents key findings and discusses these findings in relation to previous research. Section 5 summarises key findings, highlights main contributions and outlines some limitations of this study.

Literature Review

Supply Chain Management, Inventory, & Demand Planning

Mentzer, et al., (2001, p.4) defined a supply chain as a set of three or more entities (organizations or individuals) directly involved in the upstream and downstream flows of products, services, finances, and/or information from a source to a customer. Supply Chain Management (SCM) on the other hand, refers to the synchronisation and coordination of these activities to reach a common goal which benefits both the individual supply chain actors and the supply chain as a whole (Christopher, 2011; Mentzer et al., 2001). Inventory management is key part of SCM and it is concerned with all decisions associated with stock in an organisation (Waters, 2008). The literature has emphasized the importance of inventory management because it contributes to an efficient material flow throughout the supply chain so that the goal of SCM can be met (Cachon & Fisher, 2000). Inventory planning seeks to balance inventory levels with service levels by minimising stock-outs, backorders and stock holding costs (Choi 2016). In other words, inventory planning decisions determine quantities and timing of inventories with the purpose of aligning demand and supply (Tsou, 2008; Syntetos et al., 2009, Taxakis & Papadopoulos, 2016; Mallidis et al., 2018; Aburayya et al., 2020b, c & d). Such decisions are interconnected with those involved in demand planning. Demand planning has been conceptualised as the process of forecasting demand as well as transforming forecasts into actions taken to meet that demand (Christopher, 2011; Kilger & Wagner, 2015; Al Mehrez et al., 2020 a&b; Al Naqbia et al., 2020; Al-Khayyal et al., 2021; Hayajneh et al., 2021). The next section reviews the literature on supply chain visibility which has been considered of vital importance to increase the accuracy of demand forecast (Somapa, Cools & Dullaert, 2018).

Supply Chain Visibility

Despite the literature on Supply Chain Visibility (SCV) suffers from inconsistent definitions, the concept generally refers to the ability of the supply chain managers to access and share information pertinent to the SC strategy and the operations of SC partners (Caridi et al., 2014). However, to provide visibility of high quality, the shared information must be accurate, relevant, timely and complete (Barratt & Oke, 2007). Previous research reports that high level of SCV is achieved when the supply chain actors have access to the same information (Barratt & Barratt, 2011; Costantino et al., 2014; Caridi et al., 2014). This is accomplished through collecting, integrating and extracting intelligence from supply chain data (McIntire, 2016).

SCV has been increasingly viewed as a key part in SCM research (Francis, 2008; Yu et al., 2001),Particularly, Earlier research suggests that visibility can positively affect many SC activities including manufacturing, planning, supplying, and evaluation (Lancioni et al., 2000). Similarly, Kulp, et al., (2004) add that visibility can improve forecasting, planning, scheduling, and execution activities within a SC. Additionally, visibility has been identified as an enabler for strong relationship, enhancing the level of trust and having a common vision of the future among SC actors (Spekman et al., 1998).

Previous research has established that visibility can be assessed by the quantity and quality of the information shared between the supply chain leader and other supply chain members at different tires (Caridi et al., 2010). The quantity dimension refers to how much of the desired data is captured, shared and made accessible (Messina et al. 2018, McIntire 2016, Caridi et al. 2010). In contrast, the quality dimension can be measured in terms of accuracy and timeliness of the shared information among SC partners (Caridi et al., 2010; Messina et al. 2018) and the relevance, usability, accessibility of this data (McIntire,2016). In short, the reviewed literature indicates that sharing relevant and timely information enhances SC visibility (Barratt & Oke, 2007; Lusiantoro, Yates, Mena & Varga, 2018; Williams, Roh, Tokar & Swink, 2013). Most importantly, SCV becomes more important when the product lifetime is short, suggesting that product perishability can strengthen the relationship between information sharing and perishable products supply chain performance (Ferguson & Ketzenberg, 2006). Hence, the section that follows critically examines the blood supply chain management literature.

Blood Supply Chain Management

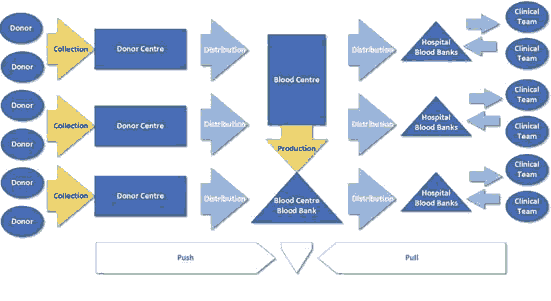

The fundamental goal of blood supply chain management (BSCM) is to satisfy demand while keeping wastage at a minimum (Stanger et al., 2012a; Beliën & Forcè, 2012; Yates et al., 2017). From an SCM perspective, the blood supply chain (BSC) can be divided into four main activities, namely (1) blood collection, (2) production of blood products, (3) inventory and (4) distribution of blood and blood products (Osorio et al., 2015, Pierskalla, 2005, Stanger et al., 2012a). Figure 1 below illustrates this in a linear fashion where material flows upstream from donors and information flows downstream from the recipients.

First, whole blood is collected from voluntary donors at donor centres (Stanger et al., 2012a, SNBTS, 2019b). Collected whole blood is distributed to blood centres BCs for processing. This involves testing for diseases and separating whole blood into blood products and components with different characteristics and purpose of usage (Stanger et al., 2012a, Osorio et al., 2018). After blood is processed, blood units will be preserved in the BCs’ inventories or moved to Hospital Blood Banks (HBBs). The HBBs will further issue out blood to the clinical teams and smaller hospitals. In Scotland, there are 39 blood banks (SNBTS, 2019b). Distribution takes place several times between donation and transfusion. However, it mainly concerns the material flow of blood products downstream towards hospitals and patients. Nevertheless, in some BSCs, distribution also occur horizontally to reallocate blood units to ensure usage of blood near it is their shelf-life (Stanger et al., 2013) or in case of shortages.

However, due to the characteristics of blood products and its demand and supply patterns, there is no clear practical way of calculating optimal policies for inventory management despite the large number of proposed models and frameworks (Osorio et al., 2015). In addition, most commercial techniques are not directly applicable because of the consequences of inventory shortages (Chapman et al., 2004) as well and the complexity of blood inventory practices (Stanger et al., 2012a). Hence, authors called for further qualitative research on methods with higher usability in practice where the human factor is taken into account (Stanger et al., 2012; Pirabán, Guerrero & Labadie, 2019). Additionally, the same scholars noted that further research should look into the sources of data required and how staff can access and interpret this in order to support their decision-making process. Meanwhile, few empirical studies have proven the benefits of visibility beyond dyadic buyer-supplier relationships (Kembro & Näslund, 2014; Kembro et al., 2017). A similar gap was found in the literature on inventory management on blood products; despite highlighted the importance of visibility and information sharing (Chapman, 2007; Stanger et al., 2012a; Delen et al., 2011). Consequently, this study sets out to understand the role of supply chain visibility in the inventory and demand planning of blood products.

Methodology

In order to study the role of SCV in the inventory and demand planning of blood products, a phenomenon that is not sufficiently explored in existing research, an inductive qualitative research method was employed because of the exploratory nature of the study (Patton, 2002; Alshurideh, 2014; Ghannajeh et al., 2015; Al-Khayyal et al., 2020; Mashaq et al., 2020; Leo et al., 2021). Given than the study focuses on the blood supply chain as a unit of analysis, a case study reach strategy is deemed to be useful to gain deeper understanding and allows discussion with different actors involved in BSC (Yin, 2003). Hence, the study adopts a case study strategy where the Scottish BSC is considered a single case and the various supply chain echelons are viewed as embedded cases (Sanders, 2016; Yin, 2003).

During the summer 2019, data were collected in the form of interviews with participants involved in SBSC. Specifically, 7 interviews were conducted with 7 participants with responsibilities related to the material flow of blood and blood products at various stages and levels in the BSC. A purposeful sample technique was adopted to identify and select key-individuals that are especially experienced with the phenomenon of interest (Creswell & Plano Clark, 2011; Tongco, 2007; Alshurideh, 2010; Al Kurdi, 2016). The selection of both interviewees and number of interviewees was done in collaboration with Scottish National Blood Transfusion Service to ensure that the sample would provide meaningful insights of various aspects of the BSC. The sample included staff both at the donor- and hospital-end of the supply chain as well as staff positioned centrally with manufacturing or strategic responsibilities. Five participants are in middle or senior level management positions whereas P3 and P4 is considered being at a lower level of the organisational hierarchy. Participants’ experience in the blood transfusion service ranges from 3 to 21 years. The participants’ profile is presented in Table 1.

| Table 1 Participants’ Profile | |||

|---|---|---|---|

| Participant | Position in the supply chain | Main responsibilities | Years of experience |

| P1 | Donor Market Engagement Team (DME) | Communication with donors Daily manipulation of blood stocks Direct marketing and donor recruitment | 20 years |

| P2 | Strategy and Business Planning Team (SBP) | Analytics Planning Forecasting | 12 years |

| P3 | Manufacturing & Dispatch (BC) | Receiving donated blood Processing and testing Issuing to HBBs | 3 years |

| P4 | Manufacturing & Dispatch (BC) | Receiving donated blood Processing and testing Issuing to HBBs Ensuring that blood products meet quality regulations | 5 years |

| P5 | Manufacturing & Dispatch (BC) | Head of blood components and dispatch laboratory Overseeing the entire processing procedure Ensuring blood is received, processes & utilised, & issued safely | 10 years |

| P6 | Patient services (HBB) | Regional head of services Issuing blood products to patients Additional responsibilities for IT development and supply chain interaction | 21 years |

| P7 | Hospital transfusion laboratory (HBB) | Providing compatible blood for patients. Blood ordering Quality management responsibilities | 18 years |

Semi-structured interviews were adopted as being most likely to yield new insights during the conversation between the interviewee and the participants (Myers & Newman, 2007). In addition, participants were encouraged to express their views freely and raise new issues relevant to the studied phenomenon (Ryan, Tähtinen, Vanharanta & Mainela 2012). An interview guide consisting of 18 questions derived from the reviewed literature were developed. The interview guide was sent to the participant days in advance to enable an efficient interview and well-thought-out answers. Based on the nature of the conversation, the order of the questions was not consistent from one interview to another and not all questions were asked explicitly. The interview guide is presented in Appendix 1. Each interview lasted between 25 minutes and 40 minutes on average and were all recorded and transcribed. Most interviews were conducted face-to-face and two interviews were made by phone.

Given that core existing theoretical constructs of supply chain visibility and blood supply chain were available from the literature review section, template analysis technique was used to analyse the data. Template analysis is a style of thematic analysis which combines a thorough structure in analysing data with the flexibility to fit the analysis to the need of a particular study (King, 2012). This technique is highly suitable when the researchers take an experiential and phenomenological approach and in situations where the objective is to compare different perspectives in a particular context (King, 2004). The template for this study was developed around a hierarchy of themes where the three objectives serve as the top-level themes.

Findings and Discussion

The primary aim of this study was to develop a better understanding of the role of SCV in inventory and demand planning in the Scottish BSC. Specifically, the research objectives were: (1) To identify what information drives inventory and demand planning decisions in the Scottish BSC; (2) To evaluate the current level of SCV in the Scottish BSC, hereunder the quantity and quality of data captured, accessed and utilised in inventory and demand planning decisions; and (3) To identify enablers and inhibitors of SCV in the Scottish BSC. To achieve these objectives, semi-structured interviews were conducted with practitioners in the BSC. Interview transcription was analysed using template analysis as presented by King (2018). The template was developed around a hierarchy of themes where the three objectives serve as the top-level themes. These themes are presented and discussed in the next subsections.

Information Driving Inventory & Demand Planning

The first objective of this study was to identify what information drives inventory and demand planning decisions in the Scottish BSC. Findings suggest that inventory and demand planning decision in the Scottish BSC is not only a based demand & supply information shared upstream and downstream; but also depends on horizontal information sharing and this should comprise relevant inventory information. For example, centrally in the BSC, P2’s team develop monthly demand forecasts based on hospital demand trends, stock levels and blood usage. Demand forecasts are shared upstream with donor teams, hereunder P1, so they can plan their donor sessions. While ideally everything should be planned, P1 states that they often end up being reactive to declines in downstream stock levels. Based on daily updated inventory information, ad-hoc marketing activities are carried out to bring stock levels back to desired levels. While Stanger et al. (2012a) stated that BSCs are push-oriented between at this stage, findings suggests that both push and pull elements are present. In long term, collection is driven by forecasts (i.e., push), whereas short term stock manipulation is driven by demand (i.e., pull) derived from stock level variations. Previous research suggested that keeping large buffer-inventories to cope with demand and supply uncertainties is not feasible due to blood’s perishability (Duan & Liao, 2014; Tsang et al., 2018; Osorio et al., 2015). Hence, enabling a reactive blood collection by frequently sharing downstream stock-levels helps the BSC to work around that problem.

Information such as turnover, wastage levels & stock levels are shared among HBBs for benchmarking purposes and for learning how to better manage inventories. While both P6 and P7 highlighter this as important, P7 suggested this was the main benefit from SCV. Similarly, from P2’s perspective, such information from HBBs is used for identification of areas for improvement and to target resources. Overall, all, these findings regarding the information that drives inventory and demand planning are in line with information classification proposed by Caridi & colleagues (2010).

Supply Chain Visibility in the Scottish Blood Supply Chain

The second objective of this study was to evaluate the current level of SCV in the Scottish BSC, particularly the quantity and quality of data captured, accessed and utilised in inventory and demand planning decisions. All participants were asked to assess the current visibility in terms of the measures proposed in the literature review, particularly quantity and quality (i.e., accuracy and timeliness) of the information sharing. The analysis resulted in two main themes, namely (1) information quality and (2) information quantity. information quality is made up of accuracy and timeliness. In terms of accuracy, no significant gaps were identified. All participants stated that the exchanged information is generally reliable and correct. However, some expressed concerns about the timeliness of the information exchange. Regardless, a general assumption among the participants was that the relevant information was considered as time-sensitive:

“One of the most difficult aspects of the BSC is its dynamic nature and the many delays which exists in the system” (SBP, P2).

P5 expressed that accessing closer to real-time inventory information would be beneficial due to the highly fluctuating stock levels. Hence, decisions made regarding the material flow at various stages of the BSC would often be based on slightly outdated information. Consequently, enhanced timeliness would facilitate better decision making. P7, who uses hospital data for benchmarking purposes, suggested that closer to real-time updates of HBBs’ inventories would increase the utility of the information. Hence, enhanced timeliness would allow both more accurate replenishment decisions and better help identify areas for improvement. While it was expressed that timeliness could be improved, findings suggest that the most substantial gaps relate to desired information not being accessible or shared. Table 2 outlines the main identified visibility gaps.

| Table 2 Identified SCV Gaps As Emerged From Data Analysis |

|

|---|---|

| Supply Chain Visibility Gaps | |

| Information quality | Timelessness of hospital information |

| Information quantity | Hospital demand information Hospital Stock information BC stock information Marketing effectiveness |

The participants experienced inefficiencies which they perceived could be mitigated by an increased level of visibility. P2 stated that not having to access real-time hospital data was one of the supply chains current gaps. While daily updates are sufficient during routine operations, real-time information were believed to be valuable in case of shortages or emergencies. Consequently, moving to real-time information exchange with hospitals could be viewed as an investment in enhanced resilience. Other participants experienced that the timeliness of the information was satisfactory. While previous research has demonstrated that SCV promotes forward planning (Barratt & Barratt, 2011; Sithole et al., 2016) and resilience (Brandon?Jones et al., 2014; Mandal et al., 2016), little research on traditional supply chains focused on the ability to benchmark supply chain actors against each other. However, Chapman (2007) have identified this benefit in other BSCs, arguing it significantly improves inventory performance. Thus, based on P7’s perceptions, increased timeliness could help the BSC improve their inventory practises.

On the other hand, the quantity aspect of SCV were defined as the amount of desired data captured, shared and made accessible for decision makers. Participants were asked specifically to assess whether they felt they could access the amounts of data they needed to support their inventory and demand planning decisions. Sometimes, marketing is simply reacting to normal fluctuations in demand. Thus, while stock is naturally building itself up after a decline, marketing has already taken corrective actions. Therefore, stock levels end up being higher than desired. Consequently, the risk of outdates increases. While scholars have warned about strictly sharing order information as that creates a delayed and distorted picture of real demand (Prajogo & Olhager, 2011; Disney & Lambrecht, 2008), P1’s experiences show that this also applies when only stock levels are shared. While Zhang, et al., (2011) highlighted the value of inventory visibility downstream, they also emphasised making end-customers’ demand visible. Hence, findings suggest that the complete demand signal is not being shared as far upstream as to the donor teams. This is further demonstrated as P1 explained that they do not receive information of planned increases in clinical activities.

In addition, findings suggest that there are gaps relating to inventory information. For most participants located upstream from HBBs however, the concern is not having access to the information in the first place, especially under exceptional circumstances. At the BC, all participants thought that having access to all HBBs in Scotland would be beneficial. Participants explained that they could only see inventories of the SNBTS HBBs. The reason why they could not access the remaining blood banks is because most HBB use of different IT-platforms. However, the participants perceived having this additional information would not be required during routine operations, which is in line with P2’s considerations. Instead, in case of shortages, surplus or emergencies, it would be useful to know downstream stock levels to better allocate blood throughout the country. At the HBBs, participants wished they had better visibility of the BC’s inventories. However, similarly to participants at the BC, P6 thinks that accessing this information would beneficial during times with low supply or high demand. In contrast, P7 stated that having that visibility would allow better planning also of daily operations. Thus, sharing the BC’s stock levels would promote better alignment of supply and demand: “If we knew what was available at [the BC], we could move [transfusions] around from start to finish of the week. If we had more visibility of the supply chain, we could plan those things better” (HBB, P7).

The final gap relates to not having sufficient information regarding the supply side. This was mentioned by P2 & P2. However, P1 also suggested that donor teams generated unshared information which could be valuable further downstream. P5 stated that the lack of visibility of what donor teams were collecting in terms of volumes, blood groups and dates of collection forced them to make daily judgements on which products to produce. In line with this, P2 explained that it was difficult to provide a full picture of the marketing activity. Information on this was not captured properly anywhere. As the marketing activities have been proven to be very effective, P2 said that better understanding of this would enable better planning of inventories.

Enablers & Inhibitors of SCV

The third objective of this study was to identify enablers and inhibitors of SCV in the Scottish BSC. The analysis on this aspect generated two main themes, namely (1) technological, (2) organisational. At the technological level, the Scottish BSC currently uses a shared platform which is known as ‘dashboard’ to connect the different HBBs by automatically pulling data out of their Laboratory Information Management Systems (LIMS). This enables an exchange of stock and trend data across the BSC, which participants perceived enhances planning, benchmarking and resilience. However, the identified inhibitors relate to capabilities of the IT-systems, the inability to communicate via IT-systems or staff not having accessed to the desired IT-platform. While the ‘dashboard’ allows information sharing across various IT-systems, it is limited by only providing daily updates. Participants interviewed at both the hospital-end and the BC desire that closer to real-time information. P2 explained that the reason why they are not having real-time updates today is due to IT-limitations. As enabling this would require investments, there must be incentives to do so. According to P2, it was uncertain whether there was a real requirement to have this capability. Hence, as scholars have suggested earlier, the fact that IT requires financial investment do act as an inhibitor of SCV (Fawcett et al., 2008; Kembro et al., 2017).

At the organisational level, the enablers relate to incentives, culture and having common KPIs. According to P2, incentives to invest in IT infrastructure would likely contribute to maturing most of the technological inhibitors into enablers. Further, The HBB participants recognised mutual benefits in terms of the ability to benchmark and learn from others. Interestingly, both P2 and P6 wished they could benchmark themselves against other countries. Thus, it can be argued that there are incentives to share information and a culture for doing so. This could further be grounded in the use of KPIs. P1 explained that they had KPIs depending on performance downstream the BSC. For instance, keeping target stock levels, how well they support production of certain blood products and wastage in the BSC. Thus, donor teams are encouraged to purse SCV through their KPIs. Furthermore, wastage and expiry were highlighted by all participants as a KPIs. As wastage numbers are highly dependent on balance between demand and supply, it could act as common goal and a motivation to pursue closer collaboration. Indeed, Aligning goals throughout the supply chain have been demonstrated as a key to success for SCV efforts (Bailey & Francis, 2008; Capó-Vicedo et al., 2011).

However, the identified inhibitors at the organisational level are primarily relate to the risk of misinterpretation. Kembro & Selviaridis (2015) found that risk of misinterpretation was a main contributor to why SCV efforts are not pursued. This is supported by findings from the Scottish BSC. BC participants believed there were potential benefits in sharing their stock levels. However, they also recognised certain risks by doing so. Two of the participants expressed concern about just-in-case ordering from HBB if they interpreted BS’s stocks as low:

“It is obviously good if they knew what our stock are, but at the same time they could end up panic buying and ordering for example 10 O-negative when they do not actually need it” (BC, P3).

This statement was confirmed by P6, who believed multidisciplinary working could increase the risk to misinterpretation. As staff at smaller hospitals have a different skill set than those working within the transfusion service, they might not have the same understanding of the BSC system. Thus, it is crucial that HBBs understands the possibilities and constraints of the supply side of the BSC. From P2’s perspective, the case is not to be able to share information but rather doing that in appropriate format to the right people. It was further added that the participant was unsure whether the managers in the supply chain were used to act on information. Hence, SCV is not enabled just by sharing the information; it needs to be utilised as well. Similar issues were expressed by the HBBs. While hospitals were sharing their forecasts, P6 assumed that it required a cultural change for the supply chain to truly act on that information.

Implications & Limitations

This study aimed to examine the role of supply chain visibility in inventory and demand planning of blood products using the Scottish blood supply chain as the unit of analysis. The study contributes to both BSC and SCV research. It provided empirical insight into benefits from SCV beyond dyadic buyer-supplier relationships. Findings suggest that there are benefits at stake for upstream supply chain actors when gaining visibility of downstream demand and inventories. However, due to the context of this study, it also found that visibility of upstream supply patterns and inventories are beneficial for downstream supply chain actors. Additionally, it provided insight into what information is considered essential by practitioners to achieve an efficient flow of blood resources and, consequently, enhance inventory performance. Hence, this is one of few qualitative studies using the blood supply chain as the unit of analysis.

The study also makes practical contributions by offering insights into the practitioners’ needs regarding what information they desire to access when performing inventory and demand planning of blood products. It provides an understanding of the importance of having timely data from both upstream and downstream echelons (i.e., a transparent supply chain) to minimise wastage while meeting the demand for blood. Hence, this study identified areas for implementing big data-enabled applications and analytics to support demand and inventory management in the BSC. Additionally, the study provides insight into what information staff at various stages of the BSC believes they require. Practitioners can utilise the identified visibility gaps to determine future development projects. Specifically, they can target resources to overcome the identified inhibitors and further develop the factors that enable SCV.

Like any other study, this study has some limitations. First, the number of interviews conducted is relatively low. Secondly, the findings of this study must also be generalised with caution. As the BSC is different from other supply chains, it is not easy to generalise the findings from an SCV perspective. Similarly, different BSCs in the world may have numerous configurations, suggesting that this study's findings may not be applicable for all BSCs.

Future research should focus on obtaining data from larger samples to generalise its findings better. Also, conducting a study over a longer time frame could measure actual inventory performance before and after SCV was enhanced. Finally, research in the context of another BSC with a different layout could provide additional insights into our current knowledge.

References

- Aburayya, A., Alshurideh, M., Al Marzouqi, A., Al Diabat, O., Alfarsi, A., Suson, R., & Salloum, S.A. (2020). An empirical examination of the effect of TQM practices on hospital service quality: an assessment study in UAE hospitals. Syst. Rev. Pharm, 11(9), 347-362.

- Aburayya, A., Alshurideh, M., Albqaeen, A., Alawadhi, D., & Ayadeh, I. (2020). An investigation of factors affecting patients waiting time in primary health care centers: An assessment study in Dubai. Management Science Letters, 10(6), 1265-1276.

- Aburayya, A., Alshurideh, M., Alawadhi, D., Alfarsi, A., Taryam, M., & Mubarak, S. (2020). An investigation of the effect of lean six sigma practices on healthcare service quality and patient satisfaction: Testing the mediating role of service quality in Dubai primary healthcare sector. Journal of Advanced Research in Dynamical and Control Systems, 12(8), 56-72.

- Aburayya, A., Alshurideh, M., Al Marzouqi, A., Al Diabat, O., Alfarsi, A., Suson, R., ... & Alzarouni, A. (2020). Critical success factors affecting the implementation of tqm in public hospitals: A case study in UAE Hospitals. Systematic Reviews in Pharmacy, 11(10), 230-242.

- Al-Khayyal, A., Alshurideh, M., Al Kurdi, B., & Aburayya, A. (2020). The impact of electronic service quality dimensions on customers' e-shopping and e-loyalty via the impact of e-satisfaction and e-trust: A qualitative approach. International Journal of Innovation, Creativity and Change, 14(9), 257-281.

- Al-Khayyal, A., Alshurideh, M., Al Kurdi, B., & Salloum, S.A. (2021). Factors influencing electronic service quality on electronic loyalty in online shopping context: Data analysis approach. In Enabling AI Applications in Data Science Springer, Cham.

- AL Kurdi, B. (2016). Healthy-food choice and purchasing behaviour analysis: An exploratory study of families in the UK (Doctoral dissertation, Durham University).

- Al Mehrez, A.A., Alshurideh, M., Al Kurdi, B., & Salloum, S.A. (2020). Internal factors affect knowledge management and firm performance: A systematic review. In International Conference on Advanced Intelligent Systems and Informatics Springer, Cham.

- AlMehrzi, A., Alshurideh, M., & Al Kurdi, B. (2020b). Investigation of the key internal factors influencing knowledge management, employment, and organisational performance: A qualitative study of the UAE hospitality sector. Int. J. Innov. Creat. Chang, 14(1), 1369-1394.

- Al Naqbia, E., Alshuridehb, M., AlHamadc, A., & Al, B. (2020). The impact of innovation on firm performance: A systematic review. Int. J. Innov. Creat. Change, 14(5), 31-58.

- Alshurideh, M. (2010). Customer service retention–A behavioural perspective of the UK mobile market (Doctoral dissertation, Durham University).

- Alshurideh, M.T. (2014). A qualitative analysis of customer repeat purchase behaviour in the UK mobile phone market. Journal of Management Research, 6(1), 109-125.

- Alshurideh, M., Alsharari, N.M., & Al Kurdi, B. (2019). Supply chain integration and customer relationship management in the airline logistics. Theoretical Economics Letters, 9(02), 392-414.

- Bailey, K., & Francis, M. (2008) Managing information flows for improved value chain performance. International Journal of Production Economics, 111(1), 2-12.

- Barratt, M., & Oke, A. (2007). 'Antecedents of supply chain visibility in retail supply chains: A resource-based theory perspective', Journal of operations management, 25(6), 1217- 1233.

- Barratt, M., & Barratt, R. (2011) 'Exploring internal and external supply chain linkages: Evidence from the field'. Journal of Operations Management, 29(5), 514-528.

- Beliën, J., & Forcé, H. (2012) Supply chain management of blood products: A literature review, European Journal of Operational Research, 217(1), 1-16.

- Cachon, G.P., & Fisher, M. (2000). ‘Supply chain inventory management & the value of shared information’. Management Science, 46(8), 1032–1048.

- Caridi, M. (2010). Measuring visibility to improve supply chain performance: A quantitative approach. Benchmarking, 17(4), 593–615.

- Caridi, M., Moretto, A., Perego, A., & Tumino, A. (2014). 'The benefits of supply chain visibility: A value assessment model'. International Journal of Production Economics, 151(1-19).

- Chapman, J. (2007). 'Unlocking the essentials of effective blood inventory management'. Transfusion, 47, 190S-196S.

- Chapman, J., Hyam, C., & Hick, R. (2004) Blood inventory management. Vox Sang., 87, 143-145.

- Christopher, M. (2011). Logistics and supply chain management, (4th edition). Financial Times Prentice Hall.

- Choi, T.-M. J. (2016). Information systems for the fashion and apparel industry. Elsevier Science.

- Costantino, F., Di Gravio, G., Shaban, A., & Tronci, M. (2014). 'The impact of information sharing and inventory control coordination on supply chain performances'. Computers & Industrial Engineering, 76(C), 292-306.

- Creswell, J.W. and Plano Clark, V.L. (2011). Designing & conducting mixed methods research, (2nd edition). Thousand Oakes, CA: Thousand Oakes, CA: Sage.

- Delen, D., Erraguntla, M., Mayer, R., & Wu, C.-N. (2011). 'Better management of blood supply-chain with GIS-based analytics'. Annals of Operations Research, 185(1), 181- 193.

- Duan, Q., & Liao, T.W. (2014). 'Optimization of blood supply chain with shortened shelf lives and ABO compatibility'. International Journal of Production Economics, 153.

- Ferguson, M., & Ketzenberg, M.E. (2006). Information sharing to improve retail product freshness of perishables. Production & Operations Management, 15(1), 57-73.

- Francis, V. (2008). ‘Supply chain visibility: Lost in translation?’ Supply Chain Management, 13(3), 180–184.

- Joghee, S., Alzoubi, H.M., Alshurideh, M., & Al Kurdi, B. (2021, June). The role of business intelligence systems on green supply chain management: Empirical analysis of FMCG in the UAE. In The International Conference on Artificial Intelligence & Computer Vision (539-552). Springer, Cham.

- Hayajneh, N., Suifan, T., Obeidat, B., Abuhashesh, M., Alshurideh, M., & Masa’deh, R. (2021). The relationship between organizational changes and job satisfaction through the mediating role of job stress in the Jordanian telecommunication sector. Management Science Letters, 11(1), 315-326.

- Ghannajeh, A.M., AlShurideh, M., Zu'bi, M.F., Abuhamad, A., Rumman, G.A., Suifan, T., & Akhorshaideh, A.H. O. (2015). A qualitative analysis of product innovation in Jordan's pharmaceutical sector. European Scientific Journal, 11(4).

- Kaipia, R., Dukovska-Popovska, I., & Loikkanen, L. (2013). 'Creating sustainable fresh food supply chains through waste reduction'. International Journal of Physical Distribution & Logistics Management, 43(3), 262-276.

- Kembro, J., Näslund, D., & Olhager, J. (2017). 'Information sharing across multiple supply chain tiers: A Delphi study on antecedents'. International Journal of Production Economics, 193, 77-86.

- Ketzenberg, M., Bloemhof, J., & Gaukler, G. (2015). 'Managing Perishables with Time & Temperature History', Production and Operations Management, 24(1), 54-70.

- Kilger, C., & Wagner, M. (2015). Demand planning.

- King, N. (2004). Using templates in the thematic analysis of text. In C. Cassell, & G. Symon (Edition.), Essential guide to qualitative methods in organizational research. London: Sage.

- King, N. (2012). Doing template analysis. Qualitative organizational research: Core methods and current challenges.

- Kopach, R., Balc?o?lu, B., & Carter, M. (2008). 'Tutorial on constructing a red blood cell inventory management system with two demand rates'. European Journal of Operational Research, 185(3), 1051-1059.

- Kulp, S.C., Lee, H.L., & Ofek, E. (2004). Manufacturer benefits from information integration with retail customers. Management Science,50(4), 431–444.

- Lancioni, R.A., Smith, M.F., & Oliva, T.A. (2000). The role of the internet in SCM. Industrial Marketing Management, 29(1), 45–56.

- Leo, S., Alsharari, N.M., Abbas, J., & Alshurideh, M.T. (2021). From offline to online learning: A qualitative study of challenges and opportunities as a response to the covid-19 pandemic in the UAE higher education context. The Effect of Coronavirus Disease (COVID-19) on Business Intelligence, 334, 203.

- Lusiantoro, L. (2018). ‘A refined framework of information sharing in perishable product supply chains’, International Journal of Physical Distribution and Logistics Management, 48(3), 254–283.

- Mallidis, I., Vlachos, D., & Yakavenka, V. (2018). 'Development of a single period inventory planning model for perishable product redistribution', Annals of Operations Research, 1-17.

- Mashaqi, E., Al-Hajri, S., Alshurideh, M., & Al Kurdi, B. (2020). The impact of E-Service quality, E-Recovery services on E-Loyalty in online shopping: Theoretical foundation & qualitative proof. PalArch's Journal of Archaeology of Egypt/Egyptology, 17(10), 2291-2316.

- McIntire, J.S. (2016). Supply chain visibility: From theory to practice, Routledge.

- Mentzer, J.T., DeWitt, W., Keebler, J.S., Min, S., Nix, N.W., Smith, C.D., & Zacharia, Z.G. (2001). 'Defining supply chain management', Journal of Business logistics, 22(2), 1-25.

- Messina, D., Barros, A.C., & Lucas, A. (2018). 'How much visibility has a company over its supply chain? A diagnostic metric to assess supply chain visibility'.

- Myers, M.D., & Newman, M. (2007). ‘The qualitative interview in IS research: Examining the craft’. Information and Organization, 17(1), 2–26.

- Osorio, A.F., Brailsford, S.C., & Smith, H.K. (2015). 'A structured review of quantitative models in the blood supply chain: A taxonomic framework for decision-making'. International Journal of Production Research, 53(24), 1-22

- Patton, M. (2002). Qualitative research & evaluation methods (3rd edition). Thousand Oaks, CA: Sage

- Pirabán, A., Guerrero, W.J., & Labadie, N. (2019). ‘Survey on blood supply chain management: Models & methods. Computers & Operations Research, 112.

- Ryan, A. (2012). ‘Industrial Marketing Management Putting critical realism to work in the study of business relationship processes’. Industrial Marketing Management, 41(2), 300–311.

- Sanders, N.R. (2016). 'How to use big data to drive your supply chain'. California Management Review, 58(3), 26-48.

- SNBTS (2019b). Journey of donated blood, [Accessed 24.05 2019].

- Spekman, R.E., Kamauff, J.W., & Myhr, N. (1998). An empirical investigation into supply chain management: a perspective on partnerships. Int. J. Phys. Distrib. Logist. Manag. 28 (8), 630–650.

- Somapa, S., Cools, M., & Dullaert, W. (2018). ‘Characterizing supply chain visibility – A literature review’, International Journal of Logistics Management, 29(1), 308–339.

- Stanger, S.H.W. (2012). ‘What drives perishable inventory management performance? Lessons learnt from the UK blood supply chain’. Supply Chain Management: An International Journal, 17(2), 107–123.

- Stanger, S.H.W., Wilding, R., Hartmann, E., Yates, N., & Cotton, S. (2013). 'Lateral transshipments an institutional theory perspective'. International journal of physical distribution & logistics management: IJPD & LM, 43(9), 747-767.

- Syntetos, A.A., Boylan, J.E., & Disney, A.M. (2009) 'Forecasting for inventory planning: A 50-year review'. Journal of the Operational Research Society, 60(S1), S149

- Taxakis, K., & Papadopoulos, C. (2016). 'A design model and a production–distribution and inventory planning model in multi-product supply chain networks'. International Journal of Production Research, 54(21), 6436-6457.

- Tongco, M.D.C. (2007). 'Purposive sampling as a tool for informant selection', Ethnobotany Research & applications, 5, 147-158.

- Tsou, C.S. (2008). 'Multi-objective inventory planning using MOPSO and TOPSIS'. Expert Systems with Applications, 35(1-2), 136-142.

- Tsang, H.C., Garcia, A., Scott, R., Lancaster, D., Geary, D., Nguyen, A.T., & Pham, T.D. (2018). 'Streamlining a blood center and hospital transfusion service supply chain with an informatics vendor?managed inventory solution: development, implementation, and 3?month follow?up', Transfusion.

- Waters, D. (2008). Inventory control & management. John Wiley & Sons.

- Williams, B.D. (2013). ‘Leveraging supply chain visibility for responsiveness: The moderating role of internal integration’. Journal of Operations Management, 31(7–8), (543–554).

- Yates, N., Stanger, S., Wilding, R., & Cotton, S. (2017). 'Approaches to assessing and minimizing blood wastage in the hospital and blood supply chain'. ISBT Science Series, 12(1), 91-98.

- Yin, R.K. (2003). Case study research: Design & methods, (3rd edition). Sage, Thousand Oaks, CA

- Yu, Z., Yan, H., & Cheng, T.C.E. (2001). Benefits of information sharing with supply chain partners. Industrial. Management System, 101(3), 114–119.

- Zu’bi, Z., Al-Lozi, M., Dahiyat, S., Alshurideh, M., & Al Majali, A. (2012). Examining the effects of quality management practices on product variety. European Journal of Economics, Finance & Administrative Sciences, 51(1), 123-139.