Research Article: 2019 Vol: 18 Issue: 3

Assessment of Logistic Risks with the Purpose of Strategic Management

Makarenko Petro, Poltava State Agrarian Academy

Piliavskui Volodymyr, International University of Business and Law

Berezina Liudmyla, Poltava State Agrarian Academy

Khorishko Katerina, Poltava State Agrarian Academy

Kolokolchykova Iryna, Poltava State Agrarian Academy

Abstract

The concept of Effective Customer Response of the logistics distribution of agroindustrial products, in which logistic costs represent a systemic pricing factor, is considered, as a result of which they directly affect the market prices of goods and services. A model for logistic risks assessment without taking into account the costs of storing excess stocks over time, based on the axiomatic theory of economic analysis, has been built. The implementation of the existing model for agro-industrial enterprises allows to reduce production costs by reengineering material management systems, saving reserves, revealing “hidden” costs, increasing the rhythm of production, reducing the costs of material flow maintenance

Keywords

Logistic Costs, Effective Customer Response, Logistic Risk.

JEL Classifications

M5, Q2.

Introduction

Today, commercial relations are formed in the face of fierce competition, uncertainty and instability of the market environment. In order to succeed in entrepreneurial activity, it is not enough to use only marketing approaches, it is necessary to apply modern high-efficiency methods and techniques of management of stream processes. The most progressive scientific and applied discipline in this area is logistics. The calculations of specialists have shown that the reduction of logistics costs by 1% is equivalent to about 10% increase in sales (Ka?mierczak, 2013). Based on the above indicators, we can undoubtedly assert the importance of the correct, competent, and educated organization of logistics processes of the enterprise.

Considering the dependence describing the logistic costs at the stage of interaction between the agrarian and industrial processing enterprises as a whole or two different structures for the production of raw materials and their processing it is easy to see that in the complex “supply-production-warehousing-distribution-transportation”, there is a contradiction or duplication in separate components. The individual components of this complex, such as transportation and warehousing, are logistic functions, while supply, production and distribution are functional areas of logistics in which various functions are performed, including transportation and warehousing.

Literature Review

In supply chains, customer relations, intermediaries, and suppliers are managed during the order fulfillment process (Bowersox & Closs, 2008). A description of the interaction of enterprises in the supply chain with one function that corresponds only to costs is an independent business entity with criteria of commercial activity effectiveness, therefore, when forming a model of interaction between agrarian and industrial enterprises in the supply chain, a system of equations describing target indicators is required, in particular, it can be a costs minimization function, corresponding to the classical logistic approach, as well as function of individual enterprises result maximization. At the same time, the quality characteristics of the logistic service may be limitations or one of the objective functions.

In the process of the evolution of logistics, several logistics concepts have appeared: Reguirements/resource planning (RP); Just-in-time (JIT); Lean Production (LP); Supply Chain Management (SCM); Time-Based Logistics (TBL); Value Added Logistics (VAL); E-logistics; Virtual logistics.

The works (Ka?mierczak, 2013) offer an in-depth analysis of the functioning of the model of the process of meeting needs, based on the recognition of needs, conceptual designing, constructing, manufacturing. The improvement of information systems in logistics gradually leads to a reduction in the costs of logistic services, optimally influences the process of marketing pricing in the energy sector (Knecht, 2017). Therefore, it is important to manage logistic flows based on the use of adaptive information mechanisms for the formation of marketing values.

Risks of the enterprise’s logistic potential arise from inefficient interfunctional logistic coordination, inefficient logistic strategy, poor planning and control, low integration of enterprise logistic processes, insufficient qualifications of managers and logistic managers, etc., as well as the risks of ineffective information and computer support systems due to the integration level of the used hardware, software security, etc. The logistic functions of the subjects of agrarian and industrial production, in which most of the risks are by nature are managerial, that is, the risks are largely dependent on the professional and personal qualities of logistics specialists at different levels, include: procurement of material resources, management of order procedures, forecasting of demand for finished products, consumption of material resources and raw materials and some others.

A compromise solution that takes into account the interests of all participants in the supply chain, including the end user, can be found using multi-criteria optimization methods (Tetiana et al., 2018). It is obvious that it is necessary to include in the logistic costs not only damages from risks in the logistics system, but also the costs for its management, including preliminary and current financing.

Let us formulate an analytical-graphical apparatus for quantitative assessment of logistical risks associated with the functioning of global chains of financial and industrial relations with a diversified sales market, and also consider promising areas for the further development of reengineering methods of universal logistic systems as an adaptive regulator in a competitive environment.

Methods

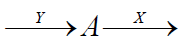

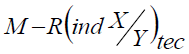

The methodological platform for the study of the ERC-concept (Effective Customer Response) of the logistic distribution, given its integral nature, makes it possible to adapt to market demand and supply. The main idea of creating an ERC concept was the provision that any products are produced in the corresponding global chain consisting of enterprises implementing a certain stage of technological transformation of the initial raw material Y. Thus, the prime cost of main products X is formed taking into account the activities of all enterprises in the global chain. In this regard, there is the problem of measuring logistic costs, which for most modern manufacturing enterprises constitute a significant part of total overhead costs (Waters, 2003). Quantitative estimates of logistic costs in modern economic theory are presented in general form and, as a rule, are selective. At the same time, logistic costs represent a systemic pricing factor, as a result of which they directly affect the market prices of goods and services.

Results And Discussions

In the context of globalization of the world economy and the existence of a single market, the competitive situation manifests itself when at least two universal logistic systems with the same diagram of the local chain of financial and production relations start to operate on the global market:

Where ?, ? and ? means the subjects of economic activity, respectively, the enterprisesupplier of raw materials Y , the enterprise-manufacturer of products X , that are produced partially or completely from raw materials Y , and the sales market for products X .

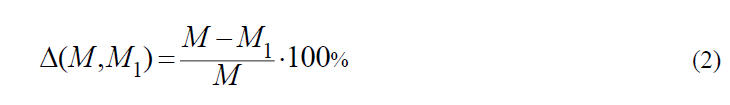

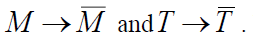

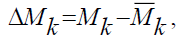

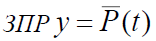

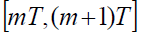

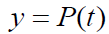

Taking into account the logistic risk, competition changes macro perspectives ? and ?, sales law P(t) , t >0, where M means optimal stock of raw materials Y , and ?-stock turnover time, M = P(T) , in the direction of decreasing the parameter M to  and, possibly, increasing the parameter T to

and, possibly, increasing the parameter T to ,

,  =

= , which is measured by value:

, which is measured by value:

Shares as a percentage of market loss for the period T ,

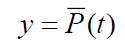

Initial  and modified

and modified in a competitive changing market conditions,

in a competitive changing market conditions,

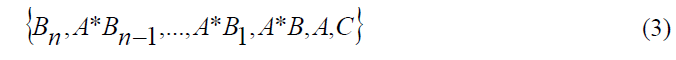

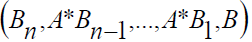

For the logistic risk of the sales law macro-parameters change, we will explicitly write out the maximum technological expansion and the diagram of the commercial expansion of financial and industrial relations (1):

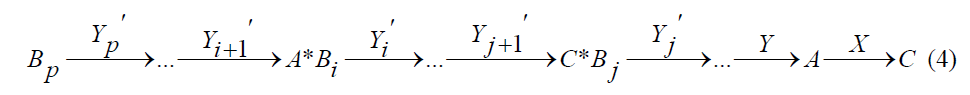

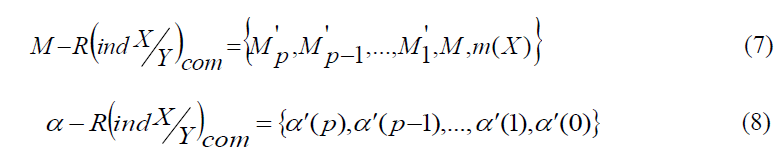

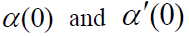

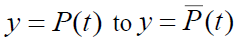

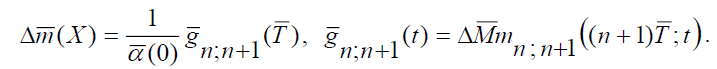

Note that in financial and industrial relations (4) the law of sales y = P(t) (Figure 1), which is characterized by initial parameters M and T . In this connection, M -representation and α-representation of the indicator of production with the maximum technological expansion (4) are respectively:

But with commercial expansion:

In formulas (7) and (9) transformation indexes  are determined by equation:

are determined by equation:

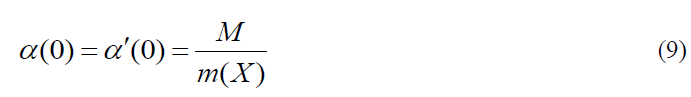

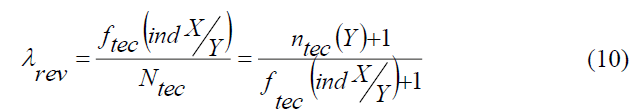

The rating of the reviving of financial and industrial relations is given by:

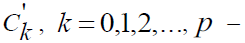

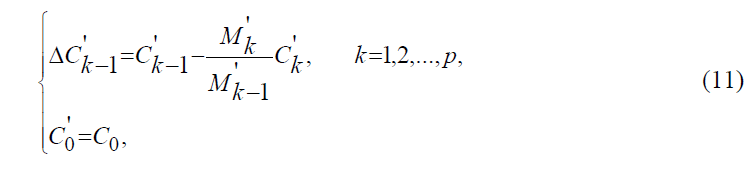

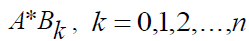

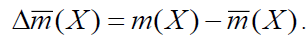

Next, suppose  unit prime cost of raw materials in the condition k , which corresponds to its quantity

unit prime cost of raw materials in the condition k , which corresponds to its quantity  and

and unit prime cost of the main product, taking into account only the component Y . Then the added value at each stage of the transformation of raw materials can be determined by equation:

unit prime cost of the main product, taking into account only the component Y . Then the added value at each stage of the transformation of raw materials can be determined by equation:

And in the elementary structure  - by equation:

- by equation:

Production of products X in the amount of  with new sales law

with new sales law starts at the same moment in time t = mT , that causes the modification of M - and α -representations of product X indicator respectively (4) and (5), associated with the replacement of M to

starts at the same moment in time t = mT , that causes the modification of M - and α -representations of product X indicator respectively (4) and (5), associated with the replacement of M to  . Riving (supply logistics) will also require certain changes that will affect all the laws of equilibrium and supply at transition

. Riving (supply logistics) will also require certain changes that will affect all the laws of equilibrium and supply at transition Note that the restart of financial and industrial relations when replacing the sales law

Note that the restart of financial and industrial relations when replacing the sales law  occurs from the moment of time t = mT , when each manufacturer

occurs from the moment of time t = mT , when each manufacturer has raw material Y in the condition of

has raw material Y in the condition of  in the amount of

in the amount of with above-level stock

with above-level stock and enterprise A in relation to

and enterprise A in relation to  has above-level stock of main products

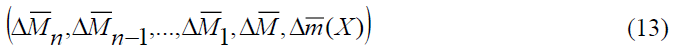

has above-level stock of main products The system of above-level stocks of raw materials and finished products:

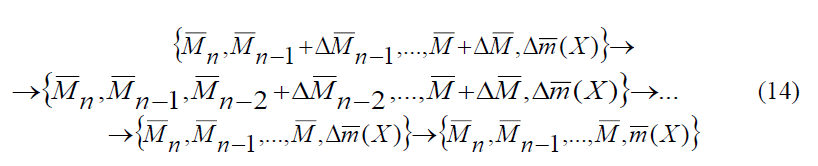

The system of above-level stocks of raw materials and finished products:

The cost of risk essentially depends on how the distribution function of logistic management is implemented, starting from the moment of time t= mT.

financial and industrial relations will operate according to the scheme shown in Figure 1, then the cost of logistic risk should include the costs for the long-term maintenance of abovelevel stocks (14) in the network of warehouses of enterprises  subject to the contract for the supply of finished products X in the link

subject to the contract for the supply of finished products X in the link  in the last time stage

in the last time stage of the transactional sales law action

of the transactional sales law action and the costs for production of above-level stock of finished products X in the amount of

and the costs for production of above-level stock of finished products X in the amount of  in the mode of the new sales law action

in the mode of the new sales law action  in the first time span

in the first time span

Let’s present the corresponding schemes of financial and industrial relations unloading. For Figure 1 at level  and for timet , which satisfies the in equation

and for timet , which satisfies the in equation  , we have:

, we have:

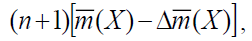

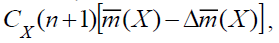

Analysis of modification of M -representations of products X indicator regarding raw materials Y (15) and (16) shows, that the transition to the permanent operation mode will occur respectively for n+1 and n+2 time intervals with a length  , at the same time, in both the first and second cases, it will be undersupplied to the market C of finished products X in the amount of

, at the same time, in both the first and second cases, it will be undersupplied to the market C of finished products X in the amount of  with the same deficit in the amount of

with the same deficit in the amount of but the cost of the risk of the sales law macro-parameters change is shown in the diagram in Figure 1.

but the cost of the risk of the sales law macro-parameters change is shown in the diagram in Figure 1.

Thus, the direct losses of enterprises integrated during the restart period will be no less than  that is part of the cost above the specified logistic risk without taking into account the costs for above-level stocks storage (14) over time.

that is part of the cost above the specified logistic risk without taking into account the costs for above-level stocks storage (14) over time.

The results of our study are confirmed by the following studies. Kraus & Kraus (2016) develops an applied application of the concept of holistic marketing, emphasizing the feasibility of economic laws establishing in the plane of communication ensuring interaction of relationship marketing, integrated, internal and socially responsible marketing. But he described the scientific problem theoretically, while in our study an analytical model was constructed. This allows us to determine the trends of the logistic channels of product sales and to construct forecasts for change (Karpenko et al., 2018).

Recommendations

The authors recommend that in competition between these universal logistic systems use reverse engineering techniques in the framework of the relevant structures in order to enhance synergies and reduce logistics costs, which ultimately have a significant impact on the value added and the cost of the main product.

Conclusion

The developed model for assessing the logistic risks of an enterprise makes it possible to more accurately plan sound financial and economic indicators, in particular, production costs, and reduce production costs by reengineering material management systems, saving inventories, identifying “hidden” costs, increasing production rhythm, reducing costs maintenance of material flows, as well as make reasonable and systematic accounting and analysis of the economic activities of global chains of financial and production relations.

We believe that the traditional functions of distribution logistics in the field under study should be improved due to the presence of industry-specific features of the industry, which include the following limitations: the process of product distribution of agricultural producers, as a rule, cannot be done without the help of commercial intermediaries acting as harvesting, procurement, trade and other enterprises and organizations; in the organization of the distribution of agricultural products and food a significant role is given to storage facilities (elevators, vegetable warehouses, etc.), which are indispensable parts of almost any logistics chain; in the field of agriculture, the cooperation of commodity producers and processors of agricultural products is most likely to provide for the mandatory inclusion of processing enterprises in the logistics system; organizational, economic, and often technical difficulties in entering the market for agricultural products of small and medium-sized commodity producers necessitate the organization of a network of regional wholesale markets for agricultural products and foodstuffs.

Prospects for further study is the creation of an effective mechanism for the implementation of distribution logistics, the necessary condition of which is the direct interaction of functional security subsystems, where each participant of commercial processes performs its function indirectly through information, commodity, financial and service flows.

References

- Bowersox, D.J., & Closs, D.J. (2008). Logistics integrated supply chain,(2nd ed.). Olimp-BusinessCJSC.

- Karpenko, L., Serbov, M., Kwilinski, A., Makedon, V., & Drobyazko, S. (2018). Methodological platform of the control mechanism with the energy saving technologies. Academy of Strategic Management Journal, 17(5), 1-7.

- Ka?mierczak, J. (2013). Production engineering in Poland: A point of view. Management Systems in Production Engineering, 1(9), 5-9.

- Knecht, Z. (2017). Marketing management. Edition threcie/Zdzis?aw Knecht-Warsaw: Publisher C.H. Beck.

- Kraus, N., & Kraus, K. (2016). Implementation of an innovation project by an entrepreneurial structure in the framework of the wind generatorof innovation, 2, p.4-8.

- Tetiana, H., Karpenko, L., Fedoruk, O., Shevchenko, I., & Drobyazko, S. (2018). Innovative methods of performance evaluation of energy efficiency project. Academy of Strategic Management Journal, 17(2).

- Waters, D. (2003). Logistics supply chain management. Unity-Dana, p.503.