Research Article: 2022 Vol: 26 Issue: 3

Factors Affecting the Implementation of Total Quality Management (Tqm) In Small and Medium-Sized Enterprises (Smes): The Case of South Africa

Mengsteab T Beraki, State University of New York

Mussie T Tessema, Winona State University

Malgorzata Plecka, Winona State University

Mahamat Abdourrahmane, St Ambrose University

Citation Information: Beraki, M.T., Beraki, T.M.,Plecka, M.& Abdourrahmane, M.(2022). Factors affecting the implementation of total quality management (tqm) in small and medium-sized enterprises (smes): The case of south africa. Journal of Organizational Culture Communications and Conflict, 26(3), 1-14.

Keywords

Total Quality Management (TQM), Manufacturing Industry, Small and Medium-Sized Enterprises (SMEs), South Africa, Emerging Economies.

Introduction

In the current turbulent business environment and hyper technology-savvy epoch, companies of all sizes continue to encounter several dimensional challenges to survive sustainably and grow in their business domains (Clune & Zehnder, 2020; Singh & Kumar, 2020; Watson et al., 2018). Companies, particularly smaller ones, face stiff competition and challenges locally and internationally. One of the challenges is the failure to adhere to continuous improvement efforts, that is, the failure to do the right things at the right time and place, with the right means of production, and with appropriate designs and aesthetics that attract diverse customers in their market domains. To achieve the strategic objectives expressed in sustainable competitiveness, at least in their market domain, companies need to perform the following tasks: formulate effective and appropriate business and functional policies and strategies, design effective and efficient operational functions, apply the appropriate technology, and implement a relatively efficient and effective production system (Singh & Kumar, 2020; Simek & Cempirek, 2021). Failure to apply these and other vital elements of the value chain directly produces mediocre products that emanate from poor operational processing systems (Li et al., 2019; Sundram et al., 2018). This scenario has high potential to jeopardize customer satisfaction (Simon & Sohal, 1995; Shen et al., 2021). However, as a supportive approach, Total Quality Management (TQM) can be instrumental in enhancing the operational efficiency and effectiveness of companies, in this case, Small and Medium-Sized Enterprises (SMEs).

With the ever-increasing sophistication of customers’ preferences, companies should endeavor not to put customer satisfaction in jeopardy. In other words, companies should strive to continuously improve their value chain from an economic rationality point of view. The production process is an integrated system comprising vital elements to achieve efficiency and effectiveness. Because of its dynamic nature, it requires continuous improvement in all dimensions. With this understanding, we would like to engage in the HOWs and WHYs of applying TQM in SMEs operating in a development environment that has unique circumstances, impacts, and objective realities on the ground.

TQM may be defined as a continuous quest for excellence by creating the right skills and attitudes in people to prevent defects and satisfy customers-users totally at all times (Worlu et al., 2019; Yanya & Mahamat, 2020). It is essentially a way of organizing and involving the entire organization, every department, activity, and person at every level. The development of TQM is the way back to inspection, quality control, quality assurance, and total quality control (Hamdan & Alheet, 2021; Sahoo, 2019).

SMEs have continued to play a pivotal role as steppingstones for global industrialization. Advanced economies, such as the United States, Germany, the United Kingdom, France, Israel, and Singapore have attributed their growth and development to the vibrant role of their SMEs. Studies by Hatega (2007); Kauffmann (2005) attest that SMEs cover more than 60% of all firms in Sub-Saharan Africa, and they are regarded as engines of economic growth and sustainability. Due to the holistic nature of the developmental agenda of African nations, they have not been promoted to capture their rightful position. However, many of them have recently started to give TQM a priority in their developmental continuum. South African SMEs are dominant players in the economy’s agenda (Zondo, 2018), and they contribute to mass employment and industrial production. According to recent official South African economic performance reports, SMEs have contributed to half of the total employment and about one-third of the output of the manufacturing sector alone (World Bank Report, 2014). Moreover, SMEs' contribution towards South Africa’s total exports has reached a significant level. For example, South Africa’s SMEs’ export level to the EU market has reached 40% of the total national exports (Killian et al., 2007). Summarily, the contribution of SMEs has been so important that various initiatives have already been taken by the South African government and other stakeholders in the private sector to enhance the overall role of SMEs in the industrial development process (Bophela & Khumalo, 2019; Boikanyo & Heyns, 2019; Nkomo & Marnewick, 2021).

As one of the emerging nations, South Africa has a fairly developed industrial sector coupled with relatively advanced infrastructure in its industrial regional hubs, such as Western Cape, Gauteng, Eastern Cape, and Natal. Its industrial sector has a long and well-established history of innovation, diversity, and achievement. Above all, the country is blessed with abundant natural endowments in virtually all core minerals, such as diamond, gold, zinc, platinum, copper, base metal, cobalt, and coal, and other valuable minerals (CIA World Factbook, 2021). These massive reserves have helped the country develop the ability to establish a modern industrial sector with its solid foundations and backward and forward links (Oxford Business Group Report, 2008). The advancement of industrial capacity can facilitate the implementation of TQM in SMEs in South Africa. This study enriches our understanding of the factors that promote and hinder the implementation of TQM in South Africa and other emerging nations with unique socio-cultural situations and developmental phases.

Various studies have concluded that implementing TQM techniques in SMEs in developing countries is a Herculean task. However, it is a potentially viable task if the necessary resources and capabilities are in place (Chakraborty et al., 2019; Mpwanya & Letsoalo, 2019; Onyinyi & Kaberuka, 2019; Temtime & Solomon, 2002). Although several studies have been conducted on TQM, there is a scarcity of empirical studies on critical factors that promote and hinder the implementation of TQM in Sub-Saharan Africa, in general, and South Africa, in particular. Most studies in the literature have dealt with this topic at a theoretical and conceptual level. Hence, our study addresses the existing research gap using a sampWatsonle of SMEs in South Africa. The current study aims to answer the following research questions:

1. What are the most important factors that promote the implementation of TQM in South African SMEs?

2. What are the most important factors that hinder the implementation of TQM in South African SMEs?

3. What are the implications of the findings of this study?

Literature Review

Evidence in the literature indicates that TQM is currently a core strategy for most manufacturing firms. The degree of TQM implementation depends mainly on entrepreneurs’ attitudes to and for change, employees’ level of involvement in strategic and operational decisions, firms’ policies on quality management and control, culture and dynamism, managerial competency, and the overall resourcefulness towards achieving a sustainable competitive advantage (Andres et al., 2001; Gonyora et al., 2021; Hill, 1997; Potgieter & Mokomane, 2020; Rambakus et al., 2020; Refiloe et al., 2020). Organizational learning, which refers to exposing organizational members to new ideas, expanding their knowledge, altering their behavior, and internalizing new insights, should be regarded as one of the main driving forces for the introduction of TQM. Several studies have suggested that notable attributes, mainly quality circles, should be considered useful vehicles for the early stages of the learning journey. Organizations wishing to progress beyond ISO 9000 certification and towards TQM must address the issue of organizational learning (Hill, 1997; Frances, 2001). Change and learning go hand-in-hand. Prior studies identified many important forces that promote or hinder the implementation of TQM strategy by SMEs in Sub-Saharan Africa (Aletaiby et al., 2021; Mersha, 1997; Salaheldin, 2003). The most important driving forces for successful TQM implementation are as follows: entrepreneurs (owner/managers) who appreciate the benefits of customer orientation, employees who understand the mutual benefits of employee involvement, and governmental facilitators who recognize the benefits of TQM implementation for economic development. The involvement of all these stakeholders undoubtedly promotes continuous improvement as a vital requirement for business growth and sustainability. Additionally, the introduction of TQM can be blocked by the scarcity of local capital, lack of competent managers, and strong government involvement in economic activities, lack of competition, and an inadequate knowledge base (Salaheldin, 2003). Likewise, Chase et al. (2004) state that the need for leadership, planning, and improvement initiatives is considered the main driving force for the implementation of TQM. Furthermore, lack of experience in quality management, scarcity of resources, absence of effective strategies, and resistance to change are some of the core constraining factors for TQM implementation (Yusof & Aspinwall, 2000). Although it seems abstract, TQM approaches can act as a means of achieving strategic targets and key drivers in implementing business strategies for SMEs in emerging nations.

Stakeholder entrepreneurs of SMEs generally believe that implementing TQM methods and paradigms can create genuine competition and efficiency (Killian et al., 2007; Aletaiby et al., 2021). TQM can lead to the production of high-quality goods and services at a reasonable cost that provides acceptable customer satisfaction (Chakraborty et al., 2019). It may also help increase the share of locally made goods and services in the domestic market as a push factor for enhancing the local economy through viable import substitution action plans. The summation of all these achievements can potentially foster competitiveness and boost the export market share (Gemude, 2000; Matthee & Heymans, 2013). Therefore, the common consensus among SME stakeholders is that TQM techniques need to be implemented in SMEs in any feasible way (Winzker, 1999). Implementing TQM in an emerging economy requires special consideration that should reflect the particular objective reality on the ground (Leonard & McAdam, 2002; Ngowi, 2000). This demands proper recognition of the importance of formulating economically viable and technically sound TQM implementation strategies that can reflect objective reality. It is important that positive appreciation and understanding of TQM attributes for competitiveness come first from top stakeholders, such as the government, firm owners, and senior management.

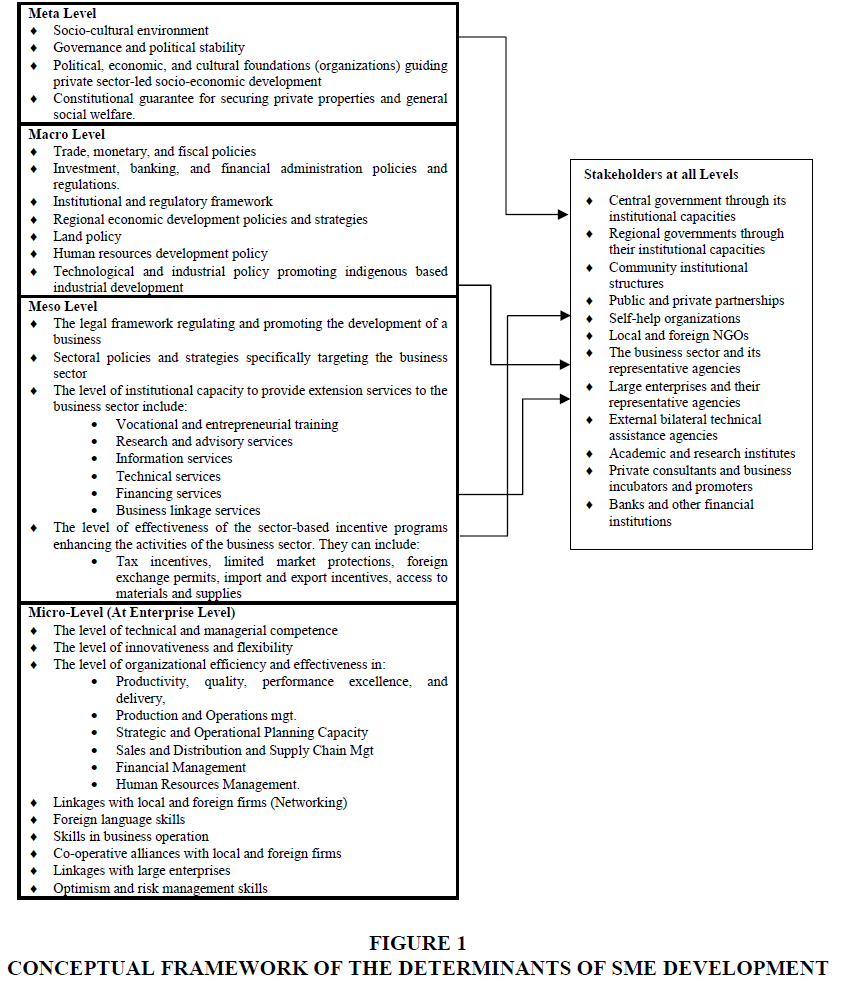

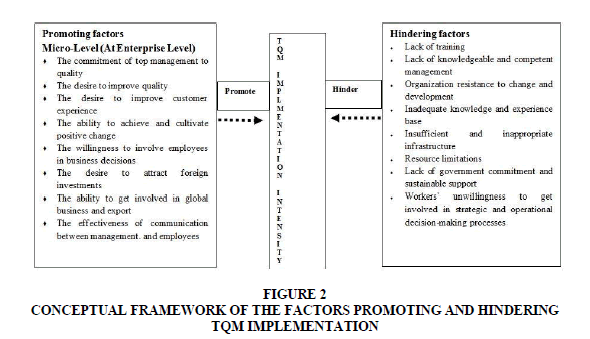

Factors affecting the implementation of TQM in SMEs are directly or indirectly related to the broad determinants of overall SME development at the mega, meso, macro, and micro levels, as shown in Figure 1. Based on this comprehensive framework, we formulated a focused conceptual framework that contained factors that promote and hinder the implementation of TQM in SMEs in emerging economies, such as South Africa (Figure 2). We adopted the framework of Salaheldin (2003).

Research Methodology

In scientific investigation, the dominating process always identifies and evaluates the crucial factors affecting the realization of the intended changes in firms. In line with this objective, we regard the empirical survey analysis as a useful technique for identifying the determinant factors that need to be engaged before introducing a change (e.g., introducing TQM). This can help to understand problems, perceive the desired factors, and strengthen them further to better organizational operational and strategic activities. The results of such analysis can equip entrepreneurs of SMEs with vital information as a prerequisite to formulating appropriate strategies for implementing the change process.

Research Instruments

We constructed the questionnaire used for this study to reflect the theoretical and preliminary empirical investigations conducted by Curry and Kadasah (2002). These studies directly focused on the modalities and techniques of TQM implementation. The questionnaire consisted of 24 questions. We organized them into the following four categories: (1) Questions 1-5 focused on obtaining personal data on the respondent (age, education, and work experience). (2) Questions 6-12 were used to obtain data on the factors promoting the introduction of TQM in South African SMEs. (3) Questions 13-21 were used to obtain data on the factors hindering the effective introduction of TQM in South African SMEs. (4) Question 22-24 was used to obtain data on the state of ISO 9000 quality systems in the South African industrial sector. We conducted a pilot test to validate the questionnaire using a sample of 20 South African SMEs. After conducting the pilot study, we made all necessary adjustments and distributed the questionnaire to 96 South African SMEs.

Sample Data

Our survey was limited to SMEs engaged in manufacturing activities and located in the core industrialized areas of Gauteng Province (Greater Johannesburg and surrounding areas). In South Africa, all registered private firms with 5 to 200 paid full-time employees are categorized as SMEs (Ntsika, 1997). With the help of the Chambers of Commerce and Industry of Greater Johannesburg and its surroundings, 96 firms were considered (Table 1). The basic criterion for the choice of respondents was the capability of the respondents to provide the necessary information. The target respondent in each company was the CEO or plant manager, but in certain cases, it was both of them. We discovered that almost 60% of CEOs were owners-entrepreneurs or immediate family members of owners. For convenience, a mail survey was used for data collection. The mail consisted of a cover letter, questionnaire, and a paid self-addressed envelope for reply. Of the 96 questionnaires sent by mail to the selected SMEs, 50 usable questionnaires were returned, resulting in a response rate of 52%. We noted that 40% of the respondents were plant managers, 54% were production and quality managers, and the remaining 6% were both CEO and production managers.

Data Analysis

After collecting the data, we processed and analyzed the data using Statistical Package for the Social Sciences (SPSS) to answer the research questions. In this study, we performed several statistical analyses, including frequency distribution and ANOVA tests (Tables 1-5).

Findings

Table 1 shows the frequency distribution of the SMEs that participated in the survey. It indicates that a significant number of the sample South African SMEs involved in TQM implementation have several employees (about 44% of them have more than 100 employees).

| Table 1 Number Of Employees In The Sample South African Smes |

||

|---|---|---|

| Employment Size | No. of Firms | Percentage |

| Less than 50 | 15 | 30 |

| 50 - 100 | 12 | 26 |

| 101 - 200 | 23 | 44 |

| Total | 50 | 100` |

Table 2 presents the number of SMEs engaged in manufacturing activities. It reveals that a significant percentage (above 40%) of the SMEs were engaged in electrical and electronics engineering.

| Table 2 Type Of Manufacturing Business Of The Sample Smes |

|||

|---|---|---|---|

| Type of Manufacturing companies | No. of Firms | Percentage | |

| Food and Beverages | 8 | 16 | |

| Electrical and Electronics Engineering | 21 | 42 | |

| Chemicals and Pharmaceuticals | 13 | 26 | |

| Metal and Woodwork Engineering | 8 | 16 | |

| Total | 50 | 100 | |

As shown in Table 3, while 34% of the manufacturing companies received ISO certification, 66% did not receive ISO certification.

| Table 3 Iso 9000 Certification Of The Sample Smes |

||

|---|---|---|

| The state of ISO 9000 Certification | No. of Firms | Percentage |

| Received ISO certification | 17 | 34 |

| Did not receive ISO certification | 33 | 66 |

| Total | 50 | 100 |

Table 4 shows the factors that promote and hinder the implementation of TQM as reported by the sample South African SMEs. It displays the proposed factors generally regarded by the respondents as important factors that could promote and hinder the introduction of TQM into South African SMEs.

| Table 4 Factors That Promote And Hinder The Implementation Of Tqm As Reported By The Sample Smes |

|||

|---|---|---|---|

| Promoting Factors | Mean | Hindering Factors | Mean |

| The commitment of top management to quality | 4.88 | Lack of employee training | 4.51 |

| The ability to involve in global business and export | 4.77 | Lack of competent management | 4.38 |

| The desire to attract more foreign investments | 4.23 | Organizational resistance to change | 4.31 |

| The desire to improve quality | 3.98 | Insufficient infrastructure | 4.17 |

| The desire to improve customer experience | 3.67 | Resource limitations | 3.78 |

| The willingness to involve employees in business decisions | 3.52 | In-adequate knowledge base | 3.63 |

| The ability to achieve and cultivate a positive change | 3.27 | Lack of government support to SMEs | 3.31 |

| The effectiveness of communication between mgmt. and employees | 3.02 | Employee’s reluctance to get involved in decision | 3.11 |

Table 5 shows the results of the ANOVA tests. ANOVA tests were conducted to determine how much variation exists among the sample of South African SMEs engaged in manufacturing activities concerning their perceptions of the critical factors that promote and inhibit the introduction of the TQM strategy.

| Table 5 Results Of Anova Tests |

|||

|---|---|---|---|

| Promoting Factors | ANOVA | Hindering Factors | ANOVA |

| The desire to improve quality | 0.09 | Lack of employee training | 0.13 |

| The desire to improve customer experience | 0.13 | Lack of competent management | 0.11 |

| The commitment of top management to quality | 0.07 | Organizational resistance to change | 0.01 |

| The willingness to involve employees in business decisions | 0.23 | In-adequate knowledge base | 0.17 |

| The ability to involve in global business and export | 0.12 | Insufficient infrastructure | 0.12 |

| The desire to attract more foreign investments | 0.09 | Resource limitations | 0.00 |

| The ability to achieve and cultivate a positive change | 0.03 | Lack of government commitment to SMEs | 0.02 |

| The effectiveness of communication between mgmt & employees | 0.17 | Employee’s reluctance to get involved in the decision | 0.12 |

Discussion

The main goal of the current study is to identify and explore the critical factors affecting the implementation of TQM attributes in South African SMEs engaged in manufacturing activities. To this end, we collected and analyzed the relevant data as presented above. Our study identified and ranked eight factors that promote the implementation of TQM: the commitment of top management to quality, the desire to improve customer experience, the desire to improve quality, the ability to engage in global business and export, the desire to attract foreign investments, the willingness to involve employees in business decisions, the effectiveness of communication between management and employees, and the ability to achieve and cultivate positive change (Ntsika Enterprise Promotion Agency, 1997). Additionally, we also identified and ranked the following eight factors that hinder the implementation of TQM: lack of competent management, lack of employee training, organizational resistance to change, insufficient infrastructure, resource limitations, inadequate knowledge base, the lack of government commitment to SMEs, and employees’ reluctance to get involved in the decision-making process (Table 3).

The findings of our study indicate that the commitment of top management to quality and the ability to get involved in global business and export were the two most important factors in promoting the implementation of TQM. In contrast, the lack of employee training and the critical shortage of competent management were the two most important factors hindering the implementation of TQM. (Table 3) Our findings agree with those of Mann & Kehoe (1995); Sahoo (2019); Temtime (2004) in that top management commitment is regarded as the most important motivating factor in the introduction of the TQM strategy. This suggests that when top management implements new innovative managerial tools, the need to introduce TQM tools increases, improving organizational performance. Our findings also agree with prior studies in that factors such as lack of employee training and lack of competent management are likely to hinder the introduction of TQM (Aletaiby et al., 2021; Curry & Kadasah, 2002; SalaheSalaheldindin, 2003; Temtime, 2004).

Our study underscored that SMEs should wholeheartedly support the implementation of TQM, as it may have a positive impact on continuous improvement and sustainable growth (Sahoo, 2019; Yusof & Aspinwall, 2000). This is a proven and well-documented experience in industrialized nations, such as Germany, the United States, and Japan. Our findings can encourage SMEs to work more on the factors that promote the implementation of TQM and overcome the factors hindering its implementation.

Furthermore, our findings indicate that South African SMEs with more than 100 employees were more likely to implement the TQM strategy than those employing less than 100 employees. This finding is consistent with Mann & Kehoe (1995); Salaheldin (2003), who found that companies with many employees are more likely to implement the TQM strategy.

Our findings also suggest that the overwhelming majority of respondents involved in TQM implementation were from firms engaged in electrical and electronics engineering, chemicals and pharmaceuticals business, and metal and woodwork engineering (Table 2). We can interpret this finding considering that these sectors are exposed to severe competition on quality from large-scale domestic and international firms. Therefore, they are more willing to implement TQM to improve the quality of their products, which is essential for their sustainability and viability in increasingly stiff domestic and international competition.

The firms that participated in our sample survey believed that ISO certification means full implementation of TQM. However, in this study, we want to emphasize that this assumption is flawed. The ISO certification should be regarded as the first step towards fully implementing TQM (Demir et al., 2021; Latan et al., 2020; Samuel, 1999). TQM is a comprehensive and organization-wide inclusion system. Adopting ISO certification may ensure that a company's products meet customer specifications; having a quality assurance system may not be sufficient if there is no continuous improvement strategy that represents the core of TQM implementation (Latan et al., 2020; Yusof & Aspinwall, 2000).

The findings of this study indicate that many respondents believed that resource limitations were one of the factors that hindered the introduction of TQM in South African SMEs. This may stem from the fact that the South African government started reducing funds and grants provided to SMEs because of the implemented privatization policy. According to recent studies, resource limitation is one of the main difficulties that impedes the development of a quality culture (Hamdan & Alheet, 2021; Sahoo, 2019).

An interesting finding of our study is that organizational resistance to change was found to be one of the resisting forces that inhibit the implementation of TQM. A possible explanation for this is that most respondents believed that any change could threaten their current position. Our findings also agree with those of previous studies (Boikanyo & Heyns, 2019; Nkomo & Marnewick, 2021; Samuel, 1999).

There is a significant difference among respondents concerning the role of the South African government's control over the introduction of the TQM strategy. We can interpret this in light of the glaring fact that the South African national economy is now transforming itself into a heavier liberal economic system. Consequently, some respondents believed that the South African government could play a pivotal role in the desired quality improvement efforts nationwide. The South African SMEs sector is the engine of national economic growth and development, and the importance of the quality issue is paramount.

Recommendations and Implications

The main objective of our study was to identify the factors that promote and hinder the implementation of the TQM strategy. We used South African SMEs as a case study. This study can contribute to ongoing efforts in other emerging African and other nations. It underlines that concepts, methods, and techniques are instrumental in continuously improving the manufacturing process by identifying and removing quality defects. We regard this as a foundational tool that enables manufacturers to remain sustainably competitive while satisfying the requirements of emerging environmental constraints. This study underscored that the identified factors could support or inhibit the successful implementation of TQM. They can be instrumental in enhancing or hindering the successful implementation of TQM. Although the implementation of TQM does not guarantee the success of SMEs, we argue that the absence of TQM implementation is more likely to impair the success of SMEs.

Implementing the TQM strategy is a formidable challenge in terms of time and complexity. We suggest that SMEs willing to implement TQM require patience and persistence. In line with this, we recommend the following: (a) Top senior managers must demonstrate the desired commitment, participation, and support to implement TQM methods and concepts effectively. The respondents ranked the commitment and support of top managers of SMEs to TQM as the main factor promoting the implementation of TQM. Similarly, previous studies indicated that the commitment and support of top managers to TQM efforts play a significant role in its success. When top managers believe in and are committed to TQM efforts, they are more likely to allocate the required resources in terms of time and money. The adequacy and reliability of the financial resources allocated to TQM initiatives are key factors for success. The support of top managers enables the concerned departments to be well-staffed and trained. Equally, their assistance encourages and requires line managers to cooperate in implementing TQM effectively. (b) Providing relevant employee training and the availability of a competent management team is cardinal. Although the provision of relevant employee training and the availability of competent management are crucial for the implementation of TQM, the respondents ranked the lack of employee training and the low competency of management as the second reason that hindered the effective implementation of TQM. This amplifies the need to enhance the capacity of all stakeholders in the implementation of actions. SMEs should provide relevant employee training and improve management competence at all levels. Improving workers' skills and quality consciousness through enhancing customized employee training programs is important for TQM implementation (Zondo, 2018; Hill, 1997). (3) SMEs demonstrate the desired commitment and interest to allow employees to become involved in strategic and operational business decisions. Our study indicates that the willingness of SMEs to allow the active participation of employees in firms’ vital business decisions is instrumental in promoting the introduction and implementation of TQM in SMEs. (4) Earning an ISO certification is very useful as a component of TQM. We need to be aware that possessing an ISO certification does not necessarily mean that SMEs have successfully implemented TQM in its entirety. It is just partial. It is generally accepted that SMEs need to know that there is a marked difference between ISO certification and TQM strategy, where the former is a prerequisite for the latter. (5) SME owners and managers should work hard and skillfully to scale up the resources and capabilities of SMEs for effective TQM implementation. However, boosting the resources and capabilities of SMEs should not be left to the owners and managers alone. External actors should play a supportive role. For example, government policymakers in the industrial sector should grant SMEs the desired structural and institutional support to induce their willingness to implement TQM methods, concepts, and tools through increased funding, grants, incentives, and educational programs.

Our recommendation, highlighted above, brings two important issues to the attention of concerned SME entrepreneurs and other stakeholders, including government agencies. Achieving overall quality means a sustainable competitive advantage at all levels, including the national level. Emerging countries such as South Africa are concerned with the quality and sustainability of their industries in emerging economies, namely integration and eradication. While integration refers to how a company assimilates new management practices, eradication refers to how a company eliminates old practices that may impede the successful implementation of TQM. Policymakers of SMEs must understand the issues of integration and eradication. They need to determine what in their specific context is conducive to effectively implementing TQM and what represents a threat to such an endeavour. They need to determine what works and what does not, rather than attempting to change current practices completely.

Conclusion

This study extends previous research on the factors that impact the implementation of TQM. Hence, it is a good addition to the extant literature, although it has limitations, including its small sample size representing only South African SMEs, preventing generalization of the findings. Thus, future research should be directed at conducting a similar study with a large sample size from different sectors and regions of South Africa. Second, future research should be directed at determining the relative effect of the identified factors that impact the implementation of TQM (causation) using regression analysis. Multi-faceted and sophisticated empirical research should be conducted to evaluate the relative strength of the driving and restraining forces in different developing countries. Third, future research should study the factors that impact implementation in detail by conducting case studies. Fourth, the role of organizational culture in TQM implementation should be examined. Fifth, future research should also examine the main factors that impact the implementation of TQM based on employees’ point of view instead of a managerial point of view.

References

Aletaiby, A.A., Rathnasinghe, A.P., & Pramodh, K. (2021). Influence of top management commitment towards the effective implementation of TQM in Iraqi oil companies. Journal of Petroleum Exploration and Production Technology, 11(4), 2039-2053.

Indexed at, Google Scholar, Cross Ref

Andres, S., Halvard, N., & Henry, W. (2001). A cross-cultural study of the differing effects of corporate culture on TQM in three countries. International Journal of Quality & Reliability Management, 18(7), 744-761.

Indexed at, Google Scholar, Cross Ref

Boikanyo, D.H. & Heyns, M.M. (2019). The effect of work engagement on total quality management practices in a petrochemical organisation. South African Journal of Economic and Management Sciences, 22(1),1-7.

Indexed at, Google Scholar, Cross Ref

Bophela, M.J.K., & Khumalo, N. (2019). The role of stokvels in south Africa: A case of economic transformation of a municipality. Problems and Perspectives in Management, 17(4), 26-37.

Indexed at, Google Scholar, Cross Ref

Chakraborty, A., Mutingi, M., & Vashishth, A. (2019). Quality management practices in SMEs: A comparative study between India and Namibia. Benchmarking, 26(5), 1499-1516.

Indexed at, Google Scholar, Cross Ref

CIA World Factbook. (2021). South Africa: The World Factbook. CIA, the US Government. McLean, VA.

Clune, W.H., & Zehnder, A.J. (2020). The evolution of sustainability models, from descriptive to strategic, to the three pillars framework for applied solutions. Sustainability Science, 15(3), 1001-1006.

Indexed at, Google Scholar, Cross Ref

Curry, A., & Kadasah, N. (2002). Focusing on key elements of TQM-evaluation for sustainability. The TQM Magazine, 14(4), 207-216.

Indexed at, Google Scholar, Cross Ref

Demir, A., Budur, T., Omer, H., & Heshmati, A. (2021). Links between knowledge management and organizational sustainability: does the ISO 9001 certification have an effect? Knowledge Management Research & Practice, 1-15.

Indexed at, Google Scholar, Cross Ref

Gemude, V. (2000). Import demand elasticities for South Africa: A co-integration analysis. Journal for Studies in Economics and Econometrics, 24(1), 21-37.

Indexed at, Google Scholar, Cross Ref

Gonyora, A.M., Migiro, S., Ngwenya, B., & Mashau, P. (2021). Investigating open innovation strategic alignment for sustainable competitive advantage in the automotive supply chain in south Africa. Journal of Transport and Supply Chain Management, 15, 1-12.

Indexed at, Google Scholar, Cross Ref

Hamdan, Y., & Alheet, A.F. (2021). Toward Sustainability: The role of TQM and corporate green performance in the manufacturing sector. International Journal of Entrepreneurship, 25(3), 1-15.

Hatega, G. (2007). SME development in Uganda: Private sector foundation Uganda. Paper presented at a local SMEs Conference on 14th March 2007, Sheraton, Kampala.

Hill, M.F. (1997). En Route to TQM: Organizational learning through quality circles. Training for Quality, 5(2), 84-87.

Indexed at, Google Scholar, Cross Ref

Kauffmann, C.(2005). Financing SMEs in Africa. OECD Development Centre Policy Insights. Paris: OECD Publishing.

Indexed at, Google Scholar, Cross Ref

Killian, S., Karlinsky, S., Payne, G., & Arendse, J. (2007). Mixed blessing of being designated a small business: A four country comparison. ATA Journal of Legal Tax Research, 5(1), 16-34.

Indexed at, Google Scholar, Cross Ref

Latan, H., Jabbour, C.J.C., de Sousa Jabbour, A.B.L., de Camargo Fiorini, P., & Foropon, C. (2020). Innovative efforts of ISO 9001-certified manufacturing firms: Evidence of links between determinants of innovation, continuous innovation and firm performance. International Journal of Production Economics, 223, 107526.

Indexed at, Google Scholar, Cross Ref

Leonard, D., & McAdam, R. (2002). The strategic impact and implementation of TQM. The TQM Magazine, 14(1), 51-60.

Indexed at, Google Scholar, Cross Ref

Li, X., Holsapple, C.W., & Goldsby, T.J. (2019). The structural impact of supply chain management teams: Supply chain agility development in multidivisional firms. Management Research Review, 42(2), 290-310.

Indexed at, Google Scholar, Cross Ref

Mann, R., & Kehoe, D. (1995). Factors affecting the implementation and success of TQM. International Journal of Quality & Reliability Management, 12(1), 11-23.

Indexed at, Google Scholar, Cross Ref

Matthee, M., & Heymans, A. (2013). How south African SMEs can become better candidates for export finance. Managing Global Transitions, 11(4), 391-407.

Mersha, T.(1997). TQM implementation in LDCs:Driving and restraining forces. International Journal of Operations & Production Management, 17(2), 164-83.

Indexed at, Google Scholar, Cross Ref

Mpwanya, M.F., & Letsoalo, M.E. (2019). Relationship between service quality, customer satisfaction and behavioural intentions in south Africa’s mobile telecommunication industry. African Journal of Business and Economic Research, 14(2), 67-67-89.

Indexed at, Google Scholar, Cross Ref

Ngowi, A.B. (2000). Impact of culture on the application of TQM in the construction industry in botswana. International Journal of Quality & Reliability Management, 17(4), 20-37.

Indexed at, Google Scholar, Cross Ref

Nkomo, A., & Marnewick, C. (2021). Improving the success rate of business process re-engineering projects: A business process re-engineering framework. South African Journal of Information Management, 23(1), 234-245.

Indexed at, Google Scholar, Cross Ref

Ntsika Enterprise Promotion Agency. (1997). The state of small business in South Africa. Pretoria: Development Division, Information Pamphlet, Ntsika,

Onyinyi, B., & Kaberuka, W. (2019). ICT fusion on the relationship between resource transformation capabilities and quality management practices among SMEs in Uganda. Cogent Business & Management, 6(1), 211-224.

Indexed at, Google Scholar, Cross Ref

Oxford Business Group. (2008). South Africa: Annual business, economic and political review. South Africa. Oxford: Oxford Business Group Publications

Potgieter, I.L. & Mokomane, S.E. (2020). Implementation of human resource management functions in selected small manufacturing companies in Ga-Rankuwa industrial area, Gauteng, south Africa. SA Journal of Human Resource Management, 18, 1-11.

Indexed at, Google Scholar, Cross Ref

Rambakus, Z., Hoque, M., & Cecile, N.G.P. (2020). Evaluating the extent of intrapreneurship in a sugar producing company in kwaZulu-natal, south Africa. Cogent Business & Management, 7(1), 47-59.

Indexed at, Google Scholar, Cross Ref

Refiloe, G.K., Derera, E., McArthur, B., & Ndayizigamiye, P. (2020). Barriers to start-up and sustainable growth of SMMEs: A comparative study between south africa and Lesotho. African Journal of Business and Economic Research, 15(2), 137–157.

Indexed at, Google Scholar, Cross Ref

Sahoo, S. (2019). Quality management, innovation capability and firm performance: Empirical insights from Indian manufacturing SMEs. TQM Journal, 31(6), 1003-1027.

Indexed at, Google Scholar, Cross Ref

Salaheldin, I.S. (2003). The implementation of TQM strategy in Egypt: a field-force analysis. The TQM Magazine. 15(4), 266-274.

Indexed at, Google Scholar, Cross Ref

Samuel, K.M. (1999). Changes for the better via ISO 9000 and TQM. Management Decision, 37(4), 381-388.

Indexed at, Google Scholar, Cross Ref

Shen, H., Tu, K., & Chiang, T. (2021). Establish a customer property service strategy framework. International Journal of Strategic Property Management, 25(3), 204-214.

Indexed at, Google Scholar, Cross Ref

Simek, L. & Cempírek, V. (2021). Quality management systems as a tool for increasing competitiveness of logistic services providers in Coronavirus economic recession. Academy of Strategic Management Journal, 20(2), 1-17.

Simon, C.D., & Sohal, A.S. (1995). The changing strategic vision of south African manufacturing: The case of the chemical industry. Industrial Management & Data Systems, 95(8), 14-20.

Indexed at, Google Scholar, Cross Ref

Singh, R.K., & Kumar, R. (2020). Strategic issues in supply chain management of Indian SMEs due to globalization: An empirical study. Benchmarking, 27(3), 913-932.

Indexed at, Google Scholar, Cross Ref

Sundram, V.P.K., Bahrin, A.S., Abdul Munir, Z.B. & Zolait, A.H. (2018). The effect of supply chain information management and information system infrastructure: The mediating role of supply chain integration towards manufacturing performance in Malaysia. Journal of Enterprise Information Management, 31(5), 751-770.

Indexed at, Google Scholar, Cross Ref

Temtime, Z., & Solomon, G.H. (2002). Total quality management and the planning behavior of SMEs in developing economies. The TQM Magazine, 14(3), 181-191.

Indexed at, Google Scholar, Cross Ref

Temtime, Z.T. (2004). Linking environmental scanning to total quality management through business planning. The Journal of Management Development, 23(3), 219-233.

Indexed at, Google Scholar, Cross Ref

Watson, G. H., Sorqvist, L., Keim, E. M., & Ramanathan, N. (2018). Quality confronts global challenges of the coming century. The Journal for Quality and Participation, 40(4), 4-10.

Winzker, D.H. (1999). TQM in south african industry: A vehicle for global competitiveness. Portland International Conference on Technology and Innovation Management. 1(1), 422 -447.

Indexed at, Google Scholar, Cross Ref

Worlu, R.E., Adeniji, A.A., Atolagbe, T.M., & Salau, O. P. (2019). Total quality management (TQM) As a tool for sustainable customer loyalty in a competitive environment: A critical review. Academy of Strategic Management Journal, 18(3), 1-6.

Yanya, M., & Mahamat, N. (2020). The impact of supply chain management practices on competitive advantages: Moderation role of total quality management. Polish Journal of Management Studies, 21(1), 419-431.

Indexed at, Google Scholar, Cross Ref

Yusof, M.S., & Aspinwall, E. (2000). TQM implementation issues: review and case study. International Journal of Operations & Production Management, 20(6), 634-55.

Indexed at, Google Scholar, Cross Ref

Zondo, R.W.D. (2018). Assessing the financial implications of quality management system accreditation on small training providers in kwaZulu-Natal. South African Journal of Economic and Management Sciences, 21(1), 1-8.

Indexed at, Google Scholar, Cross Ref

Received: 08-May-2022, Manuscript No. JOCCC-22-11941; Editor assigned: 09-May-2022, PreQC No. JOCCC-22-11941 (PQ); Reviewed: 23-May-2022, QC No. JOCCC-22-11941; Published: 30-May-2022