Research Article: 2020 Vol: 19 Issue: 6

Guidelines for Innovation Development for Increasing Logistics Efficiency of Manufacturing Industrial in Thailand

Sudawan Leepaitoon, King Mongkut’s University of Technology North Bangkok

Pannarai Lata, King Mongkut’s University of Technology North Bangkok

Sakrapee Worawattanaparinya, King Mongkut’s University of Technology North Bangkok

Abstract

Aim: The objective of this research was to study the guidelines for innovation development for increasing logistics efficiency of manufacturing industrial in Thailand.

Methodology: This research was an inductive research with mixed-methodology research including the qualitative research through in-depth interview and the quantitative research by collecting the quantitative data of 500 workplaces which received the rewards or standard organizations on the supply chain system management, production and manufacturing, transportation, warehouse or inventory of the logistics divided into large enterprises, small and medium enterprises to analyze and improve the structural equation model (SEM). And finally, the structural equation model was fit an in accordance with empirical data.

Finding: The results of the research revealed that the guidelines for innovation development for enhancing the logistics efficiency of manufacturing industrial with the highest means consisted of (1) logistics knowledge management i.e., providing the employees a chance to further study logistics to enhance their knowledge and skills, (2) contemporary technology i.e., exchanging the technology, data, information both in the internal and external organizations through the internet system, (3) management i.e., appointing the executives with keen vision, foresight, and creativity to lead the organization for the sustainable success, and (4) cooperation network i.e., setting the updated and easily accessible customer’s database system. For the result of hypothesis test, it was found that large enterprises, small and medium enterprises weighed the guidelines for innovation development for increasing logistics efficiency of manufacturing industrial in Thailand with the difference at the statistically significant level of 0.05.

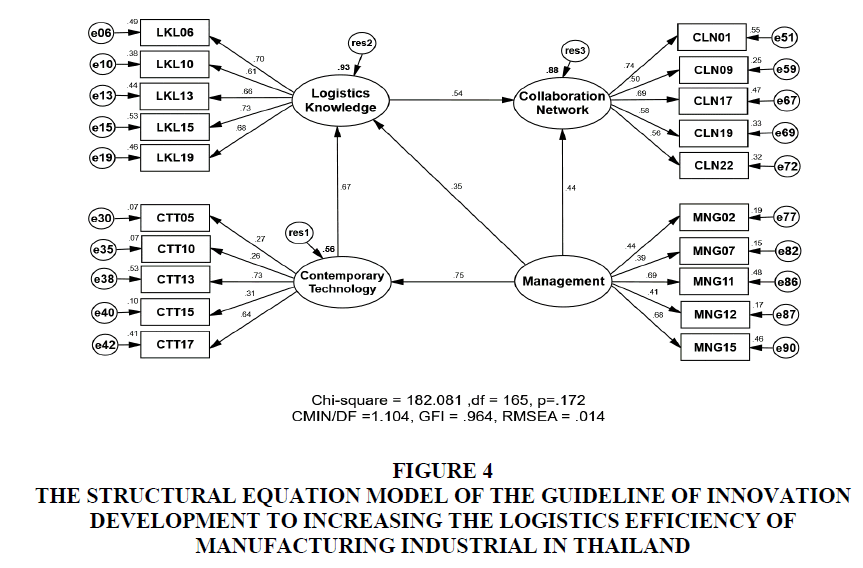

Conclusion: This research could be concluded that the innovation development of logistics helped the organization reduce the operation costs to create the basis of enhancing the logistics capacity and entrepreneurs’ international competitiveness. The results of the structural equation model analysis were proved through the evaluation criteria with the empirical data with the Chi-square probability of 0.172, the relative Chi-square of 1.104, the correlation index of 0.964, and the root index of the mean square of the error estimate of 0.014.

Keywords

Logistic Innovation, Logistics Knowledge, Contemporary Technology, Management, Collaboration Network.

Introduction

Logistics is widely known throughout the world. It’s not merely transportation because in the past, logistics was originally a military-based term that was used to describe how military force obtained, stored and moved equipment and supplies. Today the terms of logistics, and logistics and supply chain process widely used are the supply chain management and plans, control of the efficient and effective forward and reverse flow, storage of goods and services to fulfill the requirements of consumers or corporations (The Council of Logistics Management: CLM). The supply chain is a systematic relation of the strategic coordination among the organizations, and strategies among the businesses for sustainable operation efficiency improvement (Mentzer et al., 2001).

The logistics management of the country is a crucial process of reducing costs and increasing profits for Thailand’s businesses with the effective management as well as the management of customer’s requirements, procurement, flow of raw materials, manufacturing, ready products, transportation, and information involved. It enhances the strength of all the people and supply chain, speed of domestic and international commercial transactions, and trade expansion opportunities and it finally gets some advantages of the global competitiveness, and sustainable economic growth (Department of International Trade Promotion, 2019).

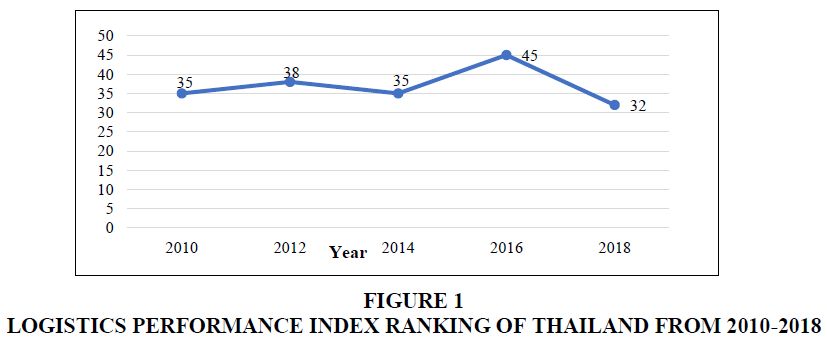

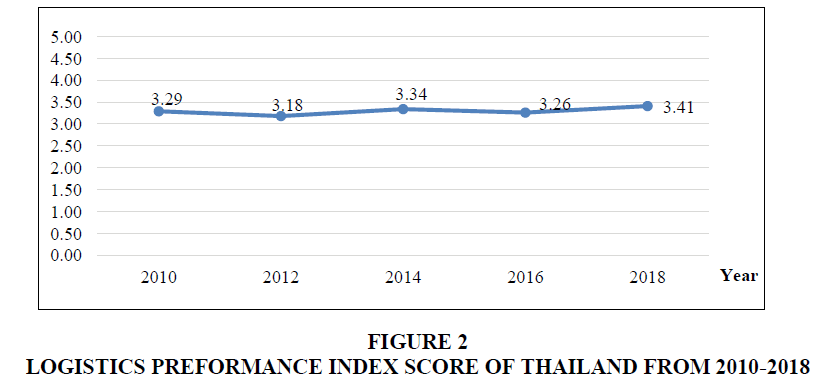

From the data, it was found that the overall Thailand’s ranking and scores of the Logistics Performance Index (LPI) from 2010-2018 were not stable and not tended to increase. The numbers shown in Figure 1 represented the ranking of Thailand’s Logistics Performance Index. The number shown in Figure 2 represented the scores of Thailand’s Logistics Performance Index surveyed from 160 countries worldwide (Department of ASEAN Affairs, 2017) The index indicators were divided into two parts: 1) input indicator or policy regulation indicator, 2) output indicator or service delivery performance indicator (Division of Logistics Development Strategy, 2019), 2010-2018 (The World Bank, 2020).

The World Bank considered the 6 components of the overall logistics efficiency of Thailand from 2010-2018, and provided some fluctuating scores as shown on the Table 1. It reflects the problem of Thailand’s logistics efficiency which lacks of the international business competitiveness.

| Table 1 Proportion of Thailand’s Logistics Costs, 2010-2018 | |||||

| Thailand’s Logistics Performance Index (LPI) | Scores | ||||

| 2010 | 2012 | 2014 | 2016 | 2018 | |

| Overall | 3.29 (35) | 3.18 (38) | 3.43 (35) | 3.26 (45) | 3.41 (32) |

| 1. Customs Efficiency | 3.02 (39) | 2.96 (42) | 3.21 (36) | 3.11 (46) | 3.14 (36) |

| 2. Infrastructure Quality | 3.16 (36) | 3.08 (44) | 3.40 (30) | 3.12 (46) | 3.14 (41) |

| 3. International Shipments | 3.27 (30) | 3.21 (35) | 3.30 (39) | 3.37 (38) | 3.46 (25) |

| 4. Logistics Quality and Competence | 3.16 (39) | 2.98 (49) | 3.29 (38) | 3.14 (49) | 3.41 (32) |

| 5. Tracking and Tracing | 3.41 (37) | 3.18 (45) | 3.45 (33) | 3.20 (50) | 3.47 (33) |

| 6. Timeliness | 3.73 (48) | 3.63 (39) | 3.96 (29) | 3.56 (52) | 3.81 (82) |

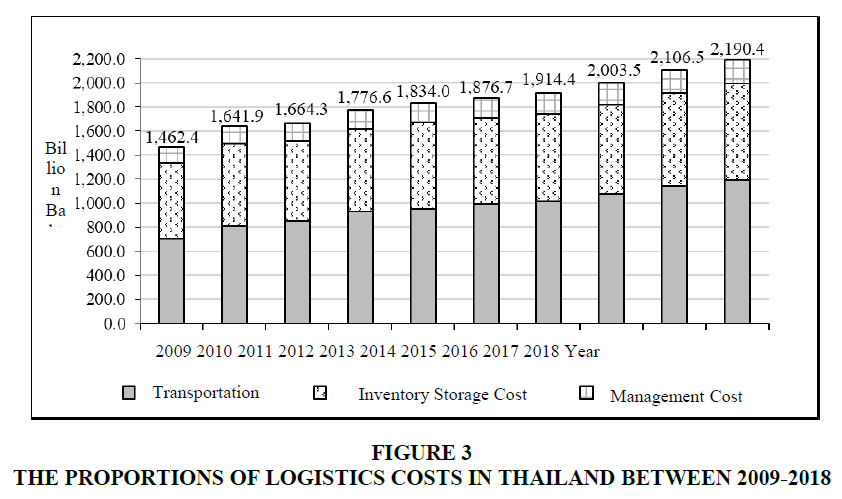

The proportion of Thailand’s logistics costs from 2009-2018 had been steadily increased (Figure 3). The reduction of logistics costs and the increase of logistics competitiveness were a crucial point, especially the development of innovation for logistics. If the organizations have the proper innovation creativity, development and management, they will have a high competitiveness in the business environment with fast (Flynn et al., 2003).

The innovation development for enhancing logistics efficiency means the guidelines or new ways which are different from the former ones in logistics operation activities starting from how to plan, how to expect customer’s demand, how to communicate, how to deal with the orders and purchase, how to handle materials, how to package, how to transport and distribute goods, and how to set the reverse operation system to add some operational values through the effective management, appropriate contemporary technology, logistics knowledge and creativity. This creates the collaboration network of a group of individuals or organizations to update the operation management and reduce the logistics operation costs with 4 components to develop. The guidelines for logistics development to enhance logistics efficiency of manufacturing production industrial in Thailand are as follows.

Management

Management is the process of planning, organizing, directing, and controlling in logistics field including (Rossi et al., 2013) planning, expecting the customers’ demand, providing the customer’ services, communicating, dealing with orders and purchasing, handling materials, packaging, managing warehouses, managing inventory, transporting and distributing goods, and setting the reverse operation system (De Martino et al., 2013) to update the operation management and reduce the logistics operation costs.

Contemporary Technology

The application of the implemented technology together with the modern technology for logistics work (Razzera & Machado, 2018) such as equipment, tools, devices, machinery, materials, network system, internet, radio frequency, electrical signals, radio signals, digital signals, processing systems, computer programs including the new operational ways (Ren et al., 2019), as well as the storage and implementation of production data, sales data, traffic data, oil data, transportation route data, closely controlled by the information technology specialists in accordance with the research article entitled “The Implementation of Digital Technology for Guidelines with the Most Important Weight” (Silpcharu & Wantanakomol, 2017a) to get ready for operations and create the know-how in each person (Singhry et al., 2016) and organization for the logistics operations efficiently and expedite the network data link.

Logistics Knowledge

Logistics knowledge is a process of creating the knowledge base and understanding of the people in organizations (Pedrosa et al., 2015) based on the former knowledge of the persons with their past experience, emulation, comparison, added study and workshop, knowledge sharing within the organization for the application of logistics operation process, as well as doing research and continuously developing their work to improve their work performance style (Ardito et al., 2018), motivating them to attend some training programs and share some knowledge among people in the organization until they can analyze and synthesize their work systematically (Björklund & Forslund, 2018), and becoming a good logistics management through the implementation of contemporary technology and a proper collaboration network (Ho & Chang, 2015).

Collaboration Network

Collaboration network is a process of building up a good relationship both formal and informal with a group of people (Amling & Daugherty, 2018) i.e. customers, distributors, financial institutions, government agencies, focusing on both vertical and horizontal relationship to encourage them to communicate each other continuously (Grawe, 2009) and information sharing, dependence/reliance and voluntary activities to help each other whenever needed in order that the benefits and overall management will be fulfilled soon.

Objectives

The purpose of the study was to develop the structural equation model of the guidelines for innovation development to increase the logistics efficiency of manufacturing industrial in Thailand.

Hypothesis

In accordance with the objective and related literature, the researcher determined five hypotheses based on the related theories as follows.

H1 The management variables directly influence the contemporary technology variables.

The logistics data (Wu & Chen, 2018) is depended on the collaboration of the viewpoints on ecosystem services and the implement of a variety of technologies, i.e. internet of things, mobile internet technology, cloud computing technology to bring about the accurate and reliable information clusters, as well as a proper management of selecting and developing the technologies, for example, the database management system of the organization is easy to access and adjustable to the former information technology. Moreover, the organizations must have the management of changes, and provide the logistics information. These are the aims and tasks of the organization. This is in accordance with the research entitled “Sustainable Logistics Innovation (SLI)” of (Forlund and Bjorklund, 2018) which claimed that there are three models: 1). Softness concerning technology, product, services, processes and organization, 2). Extent of change concerning the inbound-outbound process, customers, suggestions, standardization and choices, and 3). Scope concerning the processes, i.e. purchasing, delivery, warehouses, production, environment, economics. However, all of these could be effective if there is a proper management.

H2 The management variables directly influence the logistics knowledge variables.

The Sustainable Logistics Innovation (SLI) or creativity is about the development in many points of view and the necessity behind the success of implementation (Björklund & Forslund, 2018). He also claimed that the management of understanding the science of sustainable logistics innovation is not only creating some ideas, but also selecting them to develop the businesses. The data of this research were collected from the organization of Wholesales for Logistics Service Providers with six Swedish case studies. Nilsson (2019) stated that the logistics management and supply chain management (SCM) is a complicated point of view of science. He studied the logistics work and the daily work performance of supply chain managers in 12 international firms, and found that a proper human and social management would help the operators reduce the logistics complexity and create the logistics know-how process.

H3 The Management variables directly influence the collaboration network variables

The business ecosystem (Graça & Camarinha-Matos, 2016) designed the ecosystem of the business which is similar to the creation of a large structure with condense services and the creation of user’s experiences for customers with a trigger that enables organizations, customers or target group to get successive services and stay sustainable in the business cycle. The business ecosystem will be driven by communication, cooperation, and a variety of network systems, which is recently considered as competitive advantages as well as the collaboration of various social groups so that the customer’s information can be accessed easily. This will enhance the business opportunities to manage the information for learning and creating the innovation for business advantages and competitiveness enhancement. This is in accordance with the research of (Cichosz et al., 2017) which claimed that today the Logistics Service Providers (LSPs) with a high competitiveness will increase the abilities for the competition based on the strategy focusing on the customers to make them extremely happy but it may not be a sustainable competition. Therefore, finding the ways of management through the creation of innovation such as merging the customers with the logistics innovation process will lead to the sustainable customers’ satisfaction.

H4 The contemporary technology variables directly influence the logistics knowledge variables

The framework (Zhang et al., 2018) for smart manufacturing and logistics systems with Cyber-Physical Systems (CPS) and Internet of Things (IoT) in the industry fields such as Wifi, RFID, Mechanical Arm, Smart Material Handling System, it was found that Industrial Internet of Things (IoT) was increasingly attracted by both academic institutions and industry sectors because there are always wasted things and time consumption in the industrial operations. Therefore, the solutions of the problem are necessary and the implementation of the technology reduces the energy, time and the wastes and enhances the work performance efficiency and affects the implementation of the big data and real-time status information for logistics operations. And the research of (Ardito et al., 2018) studied the effect of on manufacturing innovation, information technology innovation and logistics innovation. In short those three innovations affect the work performance efficiency of the organization and the organizations learn and transfer the knowledge to balance the survey, the implementation, knowledge management, and activities for more know-how.

H5 The knowledge directly variables influence collaboration network variables

The major responsibility of logistics innovation implementation (Razzera & Machado, 2018) of third-party logistics providers (TPLs) in Brazil, the research stated that the implemented innovation must be developed through the investigation of entire process to build a clear understanding. This process may have both advantages and disadvantages to the creation of innovation but it should focus on the communication of information in relation to both inside and outside of the organization and have a team work and good relationships with customers. This is consistent with the research of Daudi et al. (2016) which studied behavioral factors to determine partner's trust to cooperate through logistics performance. The logistics cooperation becomes an important strategy used for individual and organization to work together to achieve success. Successful cooperation depends on the organization’s accessible information being synthesized and becoming the process information for all. This helps to consider the behavior of the suppliers, the creation of trust, the interactive communication, and the cooperation. But if there is without trust, it will be difficult to form this cooperation.

Methodology

This study was designed as an inductive research with mixed methodology.

1. The qualitative research with in-depth interview: population in this research included nine experts who were selected through the purposive sampling method with the criteria of qualifications of experts undertaken by the doctor of Business Administration Program, Faculty of Administration, King Mongkut’s University of Technology North Bangkok. There were three groups of these experts: (1) three representatives of entrepreneurs and executives, (2) three representatives of government and other related organizations, and (3) three representatives of academic staffs.

2. The quantitative research: population in this research included industrial business executives whose industries were operated in Thailand and registered with the Department of Business Development, the Ministry of Commerce and also received the rewards or standard organizations on the supply chain system management, production and manufacturing, transportation, warehouse or inventory of the logistics. Large enterprise was defined as an industrial with fixed assets of >200 million Baht or a size of > 200 employees. Medium and small enterprise was defined as an industrial with fixed assets of ≤ 200 million Baht or a size of ≤ 200 employees regarded the Ministerial Regulation Determining the Number of Employment and Value of the Fixed Asset of Small and Medium Enterprises B.E. 2545 (2002) with a total of 21,603 employees (Department of Business Development, 2019).

3. The qualitative research with group discussion to support the model: population in this research included seven experts who were selected through the purposive sampling method with the criteria of with the criteria of qualifications of experts undertaken by the doctor of Business Administration Program, Faculty of Administration, King Mongkut’s University of Technology North Bangkok.

Results

The results of analysis of guidelines for innovation development for increasing logistics efficiency of manufacturing industrial in Thailand were described as follows (Table 2).

| Table 2 Mean and Standardiviation of Guideline of Innovation Development to Increasing the Logistics Efficiency of Manufacturing Industrial in Thailand | ||||||

| Factors of simulation model of guidelines of innovation development to increasing the logistics efficiency of manufacturing industrial in Thailand | The Medium and Small Enterprises | The Large Enterprises |

||||

|

S.D. | Significant level |  |

S.D. | Significant level | |

| Overall | 3.58 | 0.30 | High | 3.87 | 0.23 | High |

| Logistics Knowledge | 3.66 | 0.36 | High | 3.98 | 0.28 | High |

| Contemporary Technology | 3.74 | 0.23 | High | 3.86 | 0.23 | High |

| Collaboration Network | 3.34 | 0.43 | Moderate | 3.78 | 0.33 | High |

| Management | 3.60 | 0.35 | High | 3.88 | 0.30 | High |

The medium and small enterprises revealed that an overall, it had a high level with the mean of 3.58. Considering by aspects, it was found that the contemporary technology variables, the logistics knowledge variables and the management variables had high levels with the means of 3.74, 3.66, 3.60, and the cooperation variables had a moderate level with the mean of 3.34, respectively.

The large enterprises revealed that an overall, it had a high level with the mean of 3.87. Considering by aspects, it was found the logistics knowledge variables, the management variables and the contemporary technology variables had high levels and the cooperation network had high levels with the means of 3.98, 3.88, 3.86 and 3.87, respectively.

The results of the structural equation model analysis of the guidelines for innovation development for increasing logistics efficiency of manufacturing industrial in Thailand were described as follows (Table 3).

| Table 3 Criteria for Assessing the Empirical of the Moedl | ||

| Evaluating the Data-Model Fit | Criteria | Reference |

| CMIN–p | Value > 0.05 | Arbuckle (2016) IBM SPSS AMOS v.20 |

| CMIN/DF | Value < 2 | Arbuckle (2016) IBM SPSS AMOS v.20 |

| GFI | Value > 0. 90 | Arbuckle (2016) IBM SPSS AMOS v.20 |

| RMSEA | Value < 0.08 | Arbuckle (2016) IBM SPSS AMOS v.20 |

The researcher adjusted the model regarding the modification indices as suggested by Arbuckle through considering the results of the software with academic theory to exclude some inappropriate observed variables one by one and evaluate the new model. And this new model was reevaluated until all four statistical results proved with the empirical data. After the model adjusted, it was found that there were (1) the chi-square probability of 0.172 and this was >0.05 indicating a statistical insignificance, (2) the relative chi-squared (CMIN / DF) of 1.104 which was <2, (3) the goodness of fit index (GFI) of 0.964 which was >0.90, and (4) the root mean square error of approximation (RMSEA) of 0.014 which was <0.08 so these all 4 statistical results passed the evaluation criteria. Therefore, the structural equation model of the guidelines of innovation development to increase logistics efficiency of manufacturing industrial in Thailand after adjusted perfectly fit the empirical data.

From Figure 4, it was found that the structural equation model of the guidelines of innovation development to increase the logistics efficiency of manufacturing industrial in Thailand after adjusted consisted of four latent variables; (1) one exogenous latent variable which was the management variable, and (2) three endogenous latent variables which were the contemporary Technology, logistics knowledge and collaboration network variables.

Figure 4 The Structural Equation Model of the Guideline of Innovation Development to Increasing the Logistics Efficiency of Manufacturing Industrial in Thailand

The management variable was found to have a variance of 0.14. It directly influenced (1) the cooperation network with a standardized regression weight of 0.44, at a statistically significant level of 0.001, a squared multiple correlation (R2) of 0.88 and a variance of 0.05, (2) the contemporary technology variables with a standardized regression weight of 0.75, at a statistically significant level of 0.001, a squared multiple correlation (R2) 0.56, and a variance of 0.02, (3) the logistics knowledge variables with a standardized regression weight of 0.35, at a statistically significant level of 0.001, a squared multiple correlation (R2) of 0.93, and a variance of 0.03.

The contemporary technology variables directly influenced the logistics knowledge variables with the standardized regression weight of 0.67, at a statistically significant level of 0.001, a squared multiple correlation (R2) of 0.93, and a variance of 0.03.

The logistics knowledge variables directly influenced the collaboration network variables with the standardized regression weight of 0.54, at statistically significant at level of 0.001, a squared multiple correlation (R2) of 0.88, and a variance of 0.05 (Table 4).

| Table 4 Statistically of Structural Equation Model afm, 6ytter Adjusted | ||||||

| Variables | Estimate | R2 | Variance | C.R. | P | |

| Standard | Unstandard | |||||

| Management | 0.14 | |||||

| Collaboration Network | 0.44 | 0.77 | 0.88 | 0.05 | 3.64 | *** |

| Contemporary Technology | 0.75 | 0.46 | 0.56 | 0.02 | 4.63 | *** |

| Logistics Knowledge | 0.35 | 0.58 | 0.93 | 0.03 | 3.75 | *** |

| Contemporary Technology | 0.56 | 0.02 | ||||

| Logistics Knowledge | 0.67 | 1.81 | 0.93 | 0.03 | 4.44 | *** |

| Logistics Knowledge | 0.93 | 0.03 | ||||

| Collaboration Network | 0.54 | 0.57 | 0.88 | 0.05 | 4.9 | *** |

| Logistics Knowledge | 0.93 | 0.03 | ||||

| LKL06 | 0.7 | 1 | 0.49 | 0.39 | ||

| LKL10 | 0.61 | 0.78 | 0.38 | 0.38 | 12.69 | *** |

| LKL13 | 0.66 | 0.83 | 0.44 | 0.33 | 13.7 | *** |

| LKL15 | 0.73 | 0.96 | 0.53 | 0.31 | 14.88 | *** |

| LKL19 | 0.68 | 0.9 | 0.46 | 0.36 | 13.97 | *** |

| Contemporary Technology | 0.56 | 0.02 | ||||

| CTT05 | 0.27 | 1 | 0.07 | 0.68 | ||

| CTT10 | 0.26 | 0.96 | 0.07 | 0.67 | 3.9 | *** |

| CTT13 | 0.73 | 2.67 | 0.53 | 0.33 | 5.4 | *** |

| CTT15 | 0.31 | 1.18 | 0.1 | 0.68 | 4.27 | *** |

| CTT17 | 0.64 | 2.35 | 0.41 | 0.42 | 5.3 | *** |

| Collaboration Network | 0.88 | 0.05 | ||||

| CLN01 | 0.74 | 1 | 0.55 | 0.35 | ||

| CLN09 | 0.5 | 0.65 | 0.25 | 0.55 | 10.46 | *** |

| CLN17 | 0.69 | 1.07474 | 0.47 | 0.55 | 14.61 | *** |

| CLN19 | 0.58 | 0.75 | 0.33 | 0.49 | 12.22 | *** |

| CLN22 | 0.56 | 0.87 | 0.32 | 0.7 | 11.9 | *** |

| Management | 0.14 | |||||

| MNG02 | 0.44 | 1 | 0.19 | 0.59 | ||

| MNG07 | 0.39 | 0.85 | 0.15 | 0.57 | 6.4 | *** |

| MNG11 | 0.69 | 1.65 | 0.48 | 0.41 | 8.61 | *** |

| MNG12 | 0.41 | 1 | 0.17 | 0.68 | 6.65 | *** |

| MNG15 | 0.68 | 1.61 | 0.46 | 0.42 | 8.54 | *** |

Discussion

The most important issues derived from this research results of the guidelines of innovative development to increase logistics efficiency of manufacturing industrial in Thailand can be the ways for businesses to study and learn to establish the guidelines of innovative development of the logistics performance under the recent era with a rapidly environmental changes and an increase in a competitiveness to create the long-term success. From the research results, the researcher discussed the results together with the review of related literatures in 5 points described as follows.

1. From the research results, when comparing the components of the guidelines of innovation development to increase the logistics efficiency of manufacturing industrial in Thailand between the small and medium enterprises and large enterprises, there were statically different at a significant level of 0.05 for both overall and individual component due to large enterprises have good management systems and continuously improve logistics innovation in their organization (Silpcharu & Wantanakomol, 2017b). Under the variety of activities, the employees’ participation from all levels is highly highlighted to gather ideas share with each other until it becomes the knowledge, this is consistent with the concept of Dr. W. Edwards Deming as the father of modern quality (Zawawi et al., 2017) and the research results of Yoon et al. (2016) which studied the impact of the leadership and innovation in the supply chain.

2. From the results of hypothesis testing, it was found that the management variable directly influenced the contemporary technology variables with the highest standardized regression weight of 0.75. The logistics management of the manufacturing industrial focuses on achieving the maximum customers’ satisfaction with the limited resources. (Wei et al., 2019) stated that the modern logistics has entered the smart logistics era with fewer workers and more control systems leading to a change from modern services and manufacturing to smart logistics. Tu (2018) said that the internet of things (IoT) is considered as the fundamental infrastructure of global network resulting in the network of the efficient and fast logistics and supply chain systems.

3. The guidelines of innovation development to increase logistics efficiency of manufacturing industrial in Thailand was found to have the logistics knowledge variables the highest mean of 3.82, indicating the importance of the logistics knowledge that an individual or an organization must have. The logistics knowledge is important because it affects the efficiency of the team and the abilities of sustainable competition over the others to promote the organization's success (Timm et al., 2019). This knowledge must be accurate and truly related to the work of industry (Lawrence, 2020).

4. The guidelines of innovation development to increase the logistics efficiency manufacturing industrial in Thailand was found to have the short-term and long-term logistics plans in order to deal with any of business changes with the highest mean of 3.92 (S.D.=0.90), indicated the importance of these variables due to the industries now face with many uncertainties i.e., the entry of various technologies, high competition in both the same and different types of business and also other influential situations. For the enhancement of relationship efficiency between supplier or contractor and the organization in the logistics fields, it was found that the organization with good management clearly defines systematic plans by executives with expertise (Zybell & Wallenburg, 2017).

5. From the correlation analysis between variables of the guidelines of innovation development to increase logistics efficiency of manufacturing industrial in Thailand after adjusting the structural equation model, it was found that the variables of retaining personnel with expertise and experience in applying technology to logistics performance had the highest correlation with variables of storing knowledge from different places and used as a database for enhancing the logistics innovation with the weight of 0.530. This can be seen that employees with expertise and work experience are valuable assets of the organization (Dessler, 2006) leading to the importance of retaining these employees in the organization and having a team with high capacity can be as a new opportunity for organizational development (Wang, 2017).

Conclusion

The creation of logistics innovation is for the growth of organization as a business goal. At present, small and medium enterprises often overlook or ignore innovation in a traditional market. They hope to use new innovation to differentiate themselves from the others and become the business leaders but opening a new market or creating a new technology is not easy. It should start from changing the prior ideas to enhance the existing products or knowledge through emphasizing on market surveys to build the relationships among existing customers and enhance the current work without ignoring the existing knowledge and technology. This will lead to the creativity of new and interesting innovation and a chance of success. Entrepreneurs must have logistics goals in line with the organization's goals because some organizations only have them as the overall and these are not broken down to the operational level. This causes the operational level to not know the guidelines of implementation. And entrepreneurs should create a system for each department with logistics activities to connect and disclose realistic and available information at all times to efficiently contribute to the flow of information, promote collaborative team from multiple departments because the logistics activities are interrelated throughout the supply chain, create work motivation, have a clear path of career advancement for employees and also implement a policy that can encourage employees to continue their education or learn about logistics until receiving the approval of the occupational standard system as the enhancement of logistics personnel with advanced skills.

Recommendations for Further Research

1. For the study of the guidelines of innovation development to increase the logistics efficiency of manufacturing industrial in Thailand, the population used in this research has quite different characteristics in each type, size and authorized capital of the industrial, therefore, it should be studied for each organization or size or compare to get the structural equation model for specific type or size of the organization or may be analyzed at multiple levels including both the personal and organizational factors to make more accurate research results which can better explain the rational factors. This is due to organizational factors can affect personal factors as well.

2. This framework should be used to further study the similar industries i.e., transportation industrial, logistics service industrial and so on to support the research results.

References

- Amling, A., & Daugherty, P.J. (2018). Logistics and distribution innovation in China. International Journal of Physical Distribution & Logistics Management.

- Arbuckle, J.L. (2016). IBM SPSS Amos 24 User’s Guide. U.S.A.: IBM Corporation.

- Ardito, L., Besson, E., Petruzzelli, A.M., & Gregori, G.L. (2018). The influence of production, IT, and logistics process innovations on ambidexterity performance. Business Process Management Journal, 24(5), 1271-1284.

- Björklund, M., & Forslund, H. (2018). Exploring the sustainable logistics innovation process. Industrial Management & Data Systems, 118(1), 204-217.

- Cichosz, M., Goldsby, T.J., Knemeyer, A.M., & Taylor, D.F. (2017). Innovation in logistics outsourcing relationship-in the search of customer satisfaction. LogForum, 13(2), 209-219.

- Daudi, M., Hauge, J.B., & Thoben, K.D. (2016). Behavioral factors influencing partner trust in logistics collaboration: A review. Logistics Research, 9(1), 19.

- De Martino, M., Errichiello, L., Marasco, A., & Morvillo, A. (2013). Logistics innovation in seaports: An inter-organizational perspective. Research in Transportation Business & Management, 8, 123-133.

- Department of International Trade Promotion. (2019). Diver government action plan of 2019. Retrieved April 30, 2020 from https://www.ditp.go.th/ditp_web61/article_sub_view.php?filename=con-%20tents_attach/559949/559949.pdf&title=559949&cate=1817&d=0

- Dessler, G. (2006). A framework for human resource management. Pearson Education India.

- Division of Logistics Development Strategy. (2019). Logistics trends 2019. Retrieved August 5, 2019, from https://www.nesdc.go.th/ewt_dl_link.php?nid=8586&filename%20=index

- Flynn, M., Dooley, L., O'sullivan, D., & Cormican, K. (2003). Idea management for organisational innovation. International Journal of Innovation Management, 7(04), 417-442.

- Graça, P., & Camarinha-Matos, L.M. (2016). A proposal of performance indicators for collaborative business ecosystems. In Working Conference on Virtual Enterprises. Springer, Cham.

- Grawe, S.J. (2009). Logistics innovation: a literature?based conceptual framework. The International Journal of Logistics Management, 20(3), 360-377.

- Ho, L.H., & Chang, P.Y. (2015). Innovation capabilities, service capabilities and corporate performance in logistics services. International Journal of Organizational Innovation, 7(3), 24-33.

- Lawrence, R.J. (2020). Collective and creative consortia: combining knowledge, ways of knowing and praxis. Cities & Health, 1-13.

- Mentzer, J.T., DeWitt, W., Keebler, J.S., Min, S., Nix, N.W., Smith, C.D., & Zacharia, Z.G. (2001). Defining supply chain management. Journal of Business Logistics, 22(2), 1-25.

- Nilsson, F.R. (2019). A complexity perspective on logistics management. The International Journal of Logistics Management, 30(3), 681–698.

- Pedrosa, A., Blazevic, V., & Jasmand, C. (2015). Logistics innovation development: a micro-level perspective. International Journal of Physical Distribution & Logistics Management, 45(4), 313-332.

- Razzera, A.V., & Machado, M.A. (2018). The role of TPLs in innovative logistics solutions in importation. Innovation & Management Review.

- Ren, S., Zhang, Y., Liu, Y., Sakao, T., Huisingh, D., & Almeida, C.M. (2019). A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: a framework, challenges and future research directions. Journal of Cleaner Production, 210, 1343-1365.

- Rossi, S., Colicchia, C., Cozzolino, A., & Christopher, M. (2013). The logistics service providers in eco-efficiency innovation: an empirical study. Supply Chain Management: An International Journal, 18(6), 583-603.

- Singhry, H.B., Abd Rahman, A., & Imm, N.S. (2016). Effect of advanced manufacturing technology, concurrent engineering of product design, and supply chain performance of manufacturing companies. The International Journal of Advanced Manufacturing Technology, 86(1-4), 663-669.

- Silpcharu, T., & Wantanakomol, S. (2017a). A structure equation modeling of guidelines for sustainable otop production management, using sufficiency economy theory. International Journal of Applied Business and Economic Research, 15(22), 863-872.

- Silpcharu, T., & Wantanakomol, S. (2017b). A structure equation modeling of guidelines for preventing corruptions in industrial business organizations. International Journal of Applied Business and Economic Research, 15(23), 469-477.

- Timm, I., Reuter, L., Berndt, J.O., Ulfert, A.S., Ellwart, T., & Antoni, C. (2019). Analyzing the effects of role configuration in logistics processes using multiagent-based simulation: an interdisciplinary approach. In Proceedings of the 52nd Hawaii International Conference on System Sciences.

- Tu, M. (2018). An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management. The International Journal of Logistics Management, 29(1), 131-151.

- Wang, L. (2017). Brief analysis on the innovation of logistics management in E-commerce. In 2017 International Conference on Humanities Science, Management and Education Technology (HSMET 2017). Atlantis Press.

- Wu, Y., & Chen, J. (2018). Collaborative logistics information service framework and reference model: Based on the perspective of service ecosystem. Journal of Service Science and Management, 11(1), 1-12.

- Yoon, S.N., Lee, D., & Schniederjans, M. (2016). Effects of innovation leadership and supply chain innovation on supply chain efficiency: Focusing on hospital size. Technological Forecasting and Social Change, 113, 412-421.

- Zawawi, N.F.B.M., Wahab, S.A., & Al Mamun, A. (2017). Logistics capability, logistics performance, and the moderating effect of firm size: Empirical evidence from east coast Malaysia. The Journal of Developing Areas, 51(2), 171-182.

- Zhang, Y., Guo, Z., Lv, J., & Liu, Y. (2018). A framework for smart production-logistics systems based on CPS and industrial IoT. IEEE Transactions on Industrial Informatics, 14(9), 4019-4032.

- Zybell, U., & Wallenburg, C.M. (2017). Performance improvements in logistics outsourcing relationships-the hampering role of lsps' mindsets.