Research Article: 2021 Vol: 20 Issue: 4

Management Guidelines for Electronics and Electrical Manufacturing towards the Smart Electronics Industry

Sompop Vittayaprapat, King Mongkut’s University of Technology North Bangkok

Nilawan Sawangrat, King Mongkut’s University of Technology North Bangkok

Porntip Shoommuangpak, King Mongkut’s University of Technology North Bangkok

Abstract

Aim: This research studies management guidelines for electronics and electrical manufacturing towards the smart electronics industry.

Methodology: This research created new bodies of knowledge by using Mixed Method Research. The research was firstly started with Qualitative Research using in-depth interview technique to find factors for developing structural equation model, followed by Quantitative Research; having data from a sample group of 500 executives of large and small and medium electronics and electrical manufacturing collected in order to analyze and develop the structural equation model. Qualitative Research using focus group technique was finally carried out to verify the guidelines.

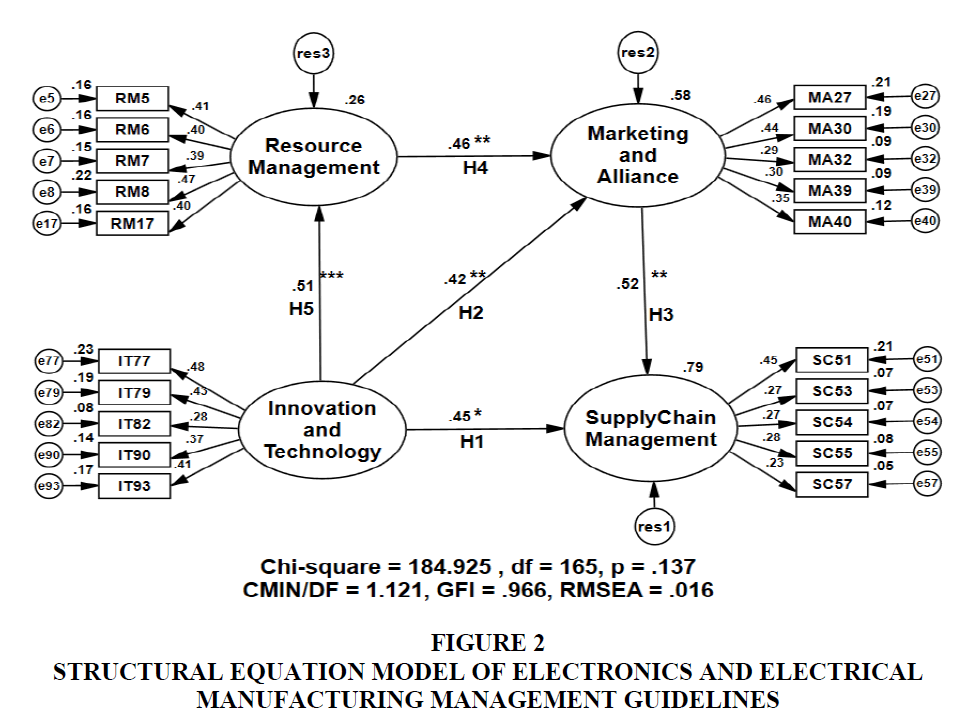

Finding: The results provided new bodies of knowledge that industrial business organizations were able to apply them to enhance organizational operational standards to smart electronics industry and maintain competitiveness in global market. Analysis results of the developed structural equation models were found that they corresponded to the evaluation criteria and were fit to empirical data with 0.137 of Chi-Square, 1.121 of Relative Chi-Square (CMIN/DF), 0.966 of Goodness of Fit (GFI) and 0.016 of Standard Root Mean Square Actual (RMSEA).

Conclusion: Research results reveal that management guidelines for electronics and electrical manufacturing towards the smart electronics industry consisted of 4 high-significant factors. The highest average guidelines of each component were as follows: (1) innovation and technology management; be able to develop innovation directly effecting on organizational data management, (2) resource management; be able to train labors to be expert in quick manufacturing, (3) marketing and alliance; provide channels for customer’s complaint for improvement, (4) supply chain management; be able to set up business alliances from providers to customers and have them be impressed with the business collaboration.

Keywords

Smart Electronics Industry, Innovation and Technology Management, Resource Management, Marketing and Alliance, Supply Chain Management.

Introduction

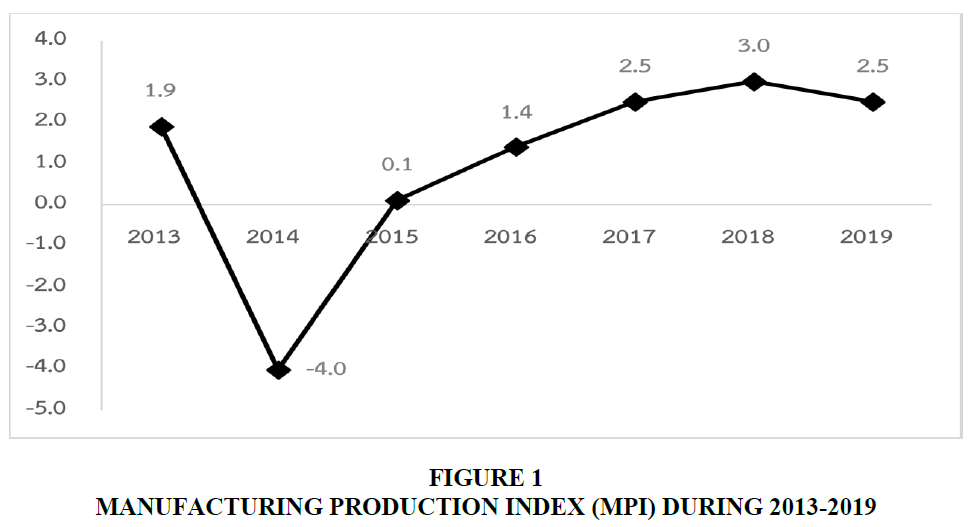

Thailand is being in a restructuring process of industry-driven to innovation and technology-driven economy. The concept is to change manufacturing of commodity to innovative and technological products. Industrial sectors must therefore be prepared for rapid changes in both competitive environments and technological sudden transition. Such changes are not limited only to Thailand but to global economic system as well. As a consequence, Thailand should learn and apply guidelines of successful countries in restructuring industry-driven to innovation and technology-driven economy with Thai economy. Industrial sector of Thailand, especially the electronics and electrical appliance industry is highly significant to national overall economic system. For nearly three decades, Thailand had occupied the perch as one of Southeast Asia’s top destinations for foreign direct investment (FDI) in the EEE industry by a variety of world-class companies, such Seagate, Western Digital, Hitachi, and Sony (Thunyarat et al., 2016). According to previous statistics, Thailand was well able to compete world’s markets. Considered about manufacturing, exportation, and employment nowadays, Thailand has more than 700,000 industrial labors and greater than 30% of national overall exportation. Although electronics and electrical appliance industry is still the top exporting main industry of Thailand, the situation seems to be declining due to world’s market deflation which obviously lower the number of exportations during January – April 2019. During that time, export values of electronics products were at 3.47 hundred thousand million Baht which is 11.29% lower than the same period of the previous year (Ministry of Industry, 2019) as shown in Figure 1.

According to co-synthesis of qualitative research using in-depth interview technique and an analysis of internal and external competitive environments of Thai electronics and electrical appliance industry, 4 significant factors which were obstacles and restriction of electronics and electrical appliance industry development to smart electronics industry were identified as follows: 1) Lack of innovation and technology integration and application in organizational operation or problem-solving including lack of using different bodies of knowledge as practical guidelines to enhance operational standards and develop the organization to smart industry. The organization should apply innovation and technology to add more value to products and services and maintain sustainable competitiveness for the organization (Barefoot et al., 2018). Application of innovation and technology will enable the organization to analyze and find new business opportunities because such application is a transformation process by turning resources into products and services that meet target customers’ requirement. Application of research and development also plays an important role in developing the organization to smart industry for new product and service discovery including building on and remarking them (Saunila, 2017). The development of innovation and technologies enables the application of the Internet of Things (IoT) in urban environments, creating smart cities. Hence, the optimal management of data generated in the interconnection of electronic sensors in real time improves the quality of life (Mariana-Daniela et al., 2020), 2) Lack of efficient resource management; resource management is an increase of competitive efficiency to the organization and an enhancement of organizational efficiency to reach the standards leading to the development to smart industry via regular and progressive learning process by providing business required-skill development to personnel and collaborating organizational culture focusing on becoming a learning organization. This will positively effect on organizational efficiency (Sawangrat, 2020). Resource Based View emphasizes on internal resource management which results in organizational capability to maintain its sustainable competitiveness (Chams & Garcia-Blandón, 2019), 3) Lack of efficient marketing and alliance establishment; this causes shortage of business collaboration networks including supporting capitals for organizational operations. Therefore, the organization should set up efficient marketing collaboration together with alliance collaboration network management by connecting and coordinating internal and external organizations together. Marketing and alliance collaboration is a form of strategic innovation effecting on market launching. According to studies, it was found that levels of innovation and technology development lead to different products and result in lower cost and higher profit. This is one of important purposes of transforming the organization to smart industry (Sugiyarti & Ardyan, 2017) Being a part of marketing innovation development to meet customer’s requirement, marketing and alliance collaboration relies on customer’s need-based manufacturing. This will simultaneously lead to competitive advantage and organizational customer’s satisfaction. Moreover, every sector’s participation for marketing and alliance collaboration will decrease problems and restrictions of supplying integral resources for business (Peters et al., 2016), 4) Lack of efficient supply chain management; everyone in the supply chain must collaborate in order to achieve goals of organizational standard enhancement to become smart industry by applying technology to add value for products and services and deliver the best services for customer’s satisfaction (Mas'udin & Kamara, 2017). Due to always-changing competitive environment, technology must be applied in the management and classification of a number of disrupted data in supply chain process to set up its transparency, data traceability, high security (Saberi et al., 2019). Using the Internet of Things (IoT) devices it is easy to manage the record with the chain of supply. When such devices do not work properly, it is necessary to repair and maintain them. Using such monitor production of toxic gases, it is easy to eliminate the chances of workers' health and environment (Radhika, 2020).

Previous researches on Thai electronics and electrical alliance industrial business management are still lack of methodology which emphasizes on providing new bodies of knowledge via Mixed Method Research in order to find out factors or guidelines that can be applied for solving problems caused by the aforementioned obstacles and restrictions. They are significant reasons why Thailand has still been facing declining trend of exportation. The author therefore studied guidelines of electronics and electrical appliance industry development-related management in order to enhance the standards to become smart electronics industry and to maintain competitiveness of Thai electronics industry in global markets by enhancing operational standards of the organization starting from applying Innovation and Technology together with Resource Management, collaborating for Marketing and Alliance and setting efficient Supply Chain Management beginning from manufacturing process to product and service delivery for customers and their satisfaction which allows the organization to maintain its competitiveness (Zhong et al., 2017). According with guidelines for successful supply chain management in industrial businesses, there are 4 factors by following 1. Strategies management, 2. Information technology, 3. Knowledge management and 4. Integration (Siwasilchai et al., 2021)

According to theoretical review, academic documents and qualitative research by using in-depth interview technique to find significant factors of management guidelines that can be applied for enhancing operational standards of electronics and electrical appliance industry to smart electronics industry in order to maintain competitiveness in world’s market and reducing impact of declining trend of exportation, there are 4 components of the significant factors as follows:

Innovation & Technology

Innovation and technology mean to use the technology in thinking, doing, and create new things that have never existed before (Meksawat, 2013). Moreover, the ability to create organizational innovation directly effects on maintaining sustainable competitive advantage. Innovation and technology management will be successful if the organization has efficient innovation-creation process that can be applied with organizational overall operational systems (Yari, 2018). Innovations & Technology take the form of reducing production costs, creating new goods and services, new materials, and components, improving quality, new forms of labor organization (Alexey et al., 2021).

Resource Management

Resource management theory is a framework used for considering important issues on resource attributes in the organization that can lead to competitive advantage of the business (Sinkovics et al., 2018). Internal resource can be divided into 3 types: 1) physical resource; asset, equipment, machine, and location, 2) human resource; staff, knowledge and ability, and experience, 3) organizational resource; organizational culture, database, trademark, patent, and fame. Such resources are important factors that allow the organization to have competitive advantage. There are both tangible and intangible resources.

There are 4 main characteristics of strategic resources causing competitive advantage: 1) valuable for business operation; be able to provide opportunities and decrease organization obstacles, 2) rare; there are no competitors in the same industry, 3) unique and inimitable or the cost is high if the competitor wants to copy, and 4) irreplaceable. These 4 strategic resources can be used as criteria for assess organizational competitiveness (Gupta et al., 2018).

Marketing & Alliance

Collaborating marketing with business alliance will help decrease restrictions of resource provision for business operations. It provides mutual profit and meets customer’s requirement. Manufacturing collaboration will provide opportunities for the alliance to take part in discovering methods and activities leading to knowledge sharing and creativity for better product and service presentation. It also helps finding raw materials that meet customer’s requirement and decreases raw material provision giving higher profit and organizational sustainability (Fang et al., 2016).

Supply Chain Management

Supply chain management is the conduction of overall processes effecting on customer’s satisfaction starting from purchasing, manufacturing, storage, information technology, distribution, and transportation. All the processes must be flexibly and compatibly managed (Hugos, 2018). In addition, roles, duties, and responsibilities in internal supply chain management must be comprehensively determined from the executives to relating departments such as purchase, manufacturing, quality control and logistics etc. to increase competitiveness to the organization (Dubey et al., 2017).

Objectives

Objective of this study is to develop structural equation model of electronics and electrical manufacturing management towards the smart electronics industry.

Hypotheses

According to objectives of research, academic document studies, and in-depth interview, the author determined research hypotheses following to theoretical principles in order to study the transfer of impacts between components. Entrepreneurs and executives in the organization are able to apply the hypothesis-tested results in strategic planning for prioritization of setting up guidelines of electronics and electrical manufacturing management towards the smart electronics industry to maintain competitiveness and reduce impact of declining trend of exportation. There are 5 research hypotheses as follows:

H1 Innovation and technology directly effect on supply chain management.

Strategies for innovation and technology management will support supply chain management cooperating with research and development in order to meet customer’s requirement. The process starts from using researcher’s body of knowledge as a research-knowledge basis leading to actual application. It is also improved and developed with modern technology which finally gives tangible products (Den Hollander et al., 2017).

H2 Innovation and technology directly effect on marketing and alliance.

Innovation and technology abilities take part in adding product values in order to have better products and investment in innovation and technology of the organization to fully utilize them. This helps achieve new concepts and innovation which can be connected to alliance’s innovation and technology by the organization and effects on marketing and alliance by strengthening good relationship among the alliances (Subramanian & Soh, 2017).

H3 Marketing and alliance directly effect on supply chain management.

Choosing alliance by interdependence among one another with trust, determination, good communication, and knowledge sharing in supply chain management is an important process to achieve competitive advantage. It is also found that strategic alliance helps generate new business opportunities or products and increases competitiveness. Alliance-building strategy is considered as a key factor for efficient supply chain management (Chi et al., 2020).

H4 Resource management directly effects on marketing and alliance.

Manufacturing industry requires resource management to meet customer’s demand which helps maintain industrial customer relationship including earning profit by relying on customer’s need-based manufacturing in order to simultaneously have competitive advantage and customer’s satisfaction (Baines, 2015). Every party’s participation in organizational resource management builds marketing and alliance networks to cooperatively reduce restrictions of significant resource provision for organizational operation (Porter & Kramer, 2019).

H5 Innovation and technology directly effect on resource management.

Luo et al. (2017) said that abilities of innovation and technology directly effected on maintenance of sustainable competitive advantage. Technology is methods, processes including skills used for transforming organizational resources into products and services, even better products, process, and practices. Research and development is also an important factor for building competitive advantage from the discovery of new product and service and launching them into the market (Ruiz-Jiménez & del Mar Fuentes-Fuentes, 2016).

Methodology

This study was designed as an inductive research with mixed methodology.

1. Qualitative Research using In-depth Interview technique with 9 experts including 3 experts in entrepreneur or executives level in electronics and electrical manufacturing organization, 3 experts in electronics and electrical manufacturing development from government department and 3 independent scholars in business management academic with structured interview from as opened-end questions followed the concept of four latents which reviewed from theory and literature. The four latents comprised of 1) Resource Management 2) Marketing and Alliance 3) Innovation and Technology and 4) Supply Chain Management. These variables were evaluated the index of the corresponding with objective or content using Item Objective Congruence; IOC analysis that showed 0.60-1.00 value (accepted at >0.5). Finally, we obtained the suitable 100 variables in 4 latents for try-out questionnaire that evaluated the reliability from Cronbach’s Alpha statistic showed at 0.914 (accepted at >0.8) and discrimination both check-list and rating-scale question items (accepted at >0.3) using Standard Deviation (S.D.) analysis obtained 0.36–0.74 and Corrected Item-Total Correlation analysis obtained 0.30–0.84 respectively.

2. Quantitative research: Population of this research is executives of industrial business organizations which are classified into large industrial business with more than 200 million Baht of fixed asset or having more than 200 employees and small and large industrial business with less than 200 million Baht of fixed asset or having less than 200 employees (Ministry of Industry, 2019). Sample size determination was carried out by using criteria of component analysis research. 500 samples were determined in very good level (Tanin, 2020). Multi-stage sampling was used and consisted of cluster sampling, quota sampling and probability sampling using simple random sampling, respectively. Multivariate Statistical Analysis employed Structural Equations Model (SEM) by AMOS with evaluating the Data-model Fit in 4 levels including (1) Chi-square Probability Level over 0.05, (2) Relative Chi-square less than 2, (3) Goodness of fit Index over 0.90, and (4) Root Mean Square Error of Approximation less than 0.08.

3. The model of electronics and electrical manufacturing management guidelines approved by 11 experts using focus group analysis techniques in qualitative research.

Results

The results of this research in electronics and electrical manufacturing towards the smart electronics industry were further discussed as follows:

It was found that overall significance of 4 factors was high with 4.22 mean values. The significance of innovation and technology management, resource management, marketing and alliance, and supply chain management was high with the following mean values; 4.26, 4.23, 4.21 and 4.17, respectively (Table 1).

| Table 1 Mean and Standard Deviation the Management Guidelines for Electronics and Electrical Manufacturing Towards the Smart Electronics Industry | |||

| Factors and guidelines of simulation model of management guidelines for electronics and electrical manufacturing towards the smart electronics industry |

|

S.D. | Significant level |

| Overall | 4.22 | 0.25 | High |

| 1. Innovation and technology management (Factor) | 4.26 | 0.32 | High |

| The ability of innovation and technology development directly effected on organizational data management (Guideline) |

4.37 | 0.74 | High |

| 2. Resource management (Factor) | 4.23 | 0.30 | High |

| Be able to train labors to be expert in quick manufacturing (Guideline) | 4.36 | 0.76 | High |

| 3. Marketing and alliance (Factor) | 4.21 | 0.29 | High |

| Provide channels for customer’s complaint for improvement (Guideline) | 4.32 | 0.75 | High |

| 4. Supply chain management (Factor) | 4.17 | 0.30 | High |

| Be able to set up business alliances from providers to customers and have them be impressed with the business collaboration (Guideline) | 4.39 | 0.75 | High |

For highest average guidelines of each Factor were as follows: (1) innovation and technology management; be able to develop innovation directly effecting on organizational data management with 4.37 mean value, (2) resource management; be able to train labors to be expert in quick manufacturing with 4.36 mean value, (3) marketing and alliance; provide channels for customer’s complaint for improvement with 4.32 mean value, (4) supply chain management; be able to set up business alliances from providers to customers and have them be impressed with the business collaboration with 4.39 mean value.

It was found that overall significance of small and medium businesses was high with 4.19 mean values. The significance of innovation and technology management, resource management, marketing and alliance, and supply chain management was high with the following mean values; 4.23, 4.20, 4.18 and 4.15, respectively (Table 2).

| Table 2 Mean and Standard Deviation the Management Guidelines for Electronics and Electrical Manufacturing Towards the Smart Electronics Industry Classified by Industry Size | ||||||

| Factors of simulation model of management guidelines for electronics and electrical manufacturing towards the smart electronics industry | Small and Medium | Large | ||||

|

S.D. | Significant level |  |

S.D. | Significant level | |

| Overall | 4.19 | 0.24 | High | 4.25 | 0.24 | High |

| 1. Innovation and technology management | 4.23 | 0.31 | High | 4.30 | 0.30 | High |

| 2. Resource management | 4.20 | 0.33 | High | 4.26 | 0.32 | High |

| 3. Marketing and alliance | 4.18 | 0.30 | High | 4.24 | 0.29 | High |

| 4. Supply chain management | 4.15 | 0.29 | High | 4.20 | 0.28 | High |

For large businesses, overall significance was found high with 4.25 mean values. The significance of innovation and technology management, resource management, marketing and alliance, and supply chain management was high with the following mean values; 4.30, 4.26, 4.24, and 4.20, respectively.

The author therefore improves the model by considering Modification Indices (MI) according to the study of Arbuckle (2012) (Table 3). Values of results from software and theoretical academic principle are considered to cut inappropriate observative variables out. The model had been reevaluated until the model with 4 qualified statistical values was achieved. Therefore, the structural equation model was considered complete and fit to the empirical data. After the completion of model improvement, it was found that Chi-Square possibility value equaled to 0.137 which was greater than 0.05 and implied that this number is statistically significant. Relative Chi-Square value was 1.121 which was less than 2. Goodness of Fit Index was .966 which was greater than 0.90 and Standard Root Mean Square Actual (RMSEA) was 0.016 which was less than 0.08. These can be concluded that all 4 statistical values were qualified. Therefore, the structural equation model of electronics and electrical manufacturing management guidelines towards the smart electronics industry was fit to the empirical data as shown in Figure 2.

| Table 3 Criteria for Data-Model Validity Evaluation | ||

| Data-Model Fit Evaluation | Criteria | Reference |

| 1. CMIN-p | more than .05 | Arbuckle (2012) IBM SPSS AMOS v.21 |

| 2. CMIN/DF | less than 2 | Arbuckle (2012) IBM SPSS AMOS v.21 |

| 3. GFI | more than .90 | Arbuckle (2012) IBM SPSS AMOS v.21 |

| 4. RMSEA | less than .08 | Arbuckle (2012) IBM SPSS AMOS v.21 |

From Figure 2, it was found that the post-improvement structural equation model of electronics and electrical manufacturing management guidelines towards the smart electronics industry showed hypothesis-tested results that corresponded to the 5 research hypotheses. The model consisted of 4 latent variables which are 1 exogenous latent variable; innovation and technology and 3 endogenous latent variables; resources management, marketing and alliance, and supply chain management.

Variance of innovation and technology component was found 0.11. This component effected on resource management component at 0.51 Standardized Regression Weight with .001 statistical significance, 0.26 squared multiple correlation (R2), and 0.07 variance. The component directly effected on marketing and alliance component at 0.42 Standardized Regression Weight with .01 statistical significance, 0.58 squared multiple correlation (R2) and 0.05 variance. The component directly effected on supply chain management component at 0.45 Standardized Regression Weight with .05 statistical significance, 0.79 squared multiple correlation (R2) and 0.02 variance.

Resource management component directly effected on marketing and alliance component at 0.46 Standardized Regression Weight with 0.01 statistical significance, 0.26 squared multiple correlation (R2) and 0.07 variance.

Marketing and alliance component directly affected on supply chain management component at 0.52 Standardized Regression Weight with .01 statistical significance, 0.79 squared multiple correlations (R2) and 0.02 variance. Statistical analysis of structural equation model for electronics and electrical appliance industrial business management to smart electronics industry in standardized estimate mode is shown in Figure 2 and summarized in Table 4.

Figure 2 Structural Equation Model of Electronics and Electrical Manufacturing Management Guidelines

| Table 4 Statistical Analysis of Structural Equation Model for Electronics and Electrical Manufacturing Management Guidelines Towards the Smart Electronics Industry in Standardized Estimate Mode | ||||||

| Variables | Estimate | R2 | Variance | C.R. | P | |

| Standard | Unstandardized | |||||

| Resource Management | 0.26 | 0.07 | ||||

| Marketing & Alliance | 0.46 | 0.52 | 0.58 | 0.05 | 3.25 | 0.001 |

| Marketing & Alliance | 0.58 | 0.05 | ||||

| Supply Chain Management | 0.52 | 0.52 | 0.79 | 0.02 | 2.69 | 0.007 |

| Innovation & Technology | 0.11 | |||||

| Resource Management | 0.51 | 0.45 | 0.26 | 0.07 | 4.09 | *** |

| Marketing & Alliance | 0.42 | 0.42 | 0.58 | 0.05 | 3.10 | 0.002 |

| Supply Chain Management | 0.45 | 0.45 | 0.79 | 0.02 | 2.53 | 0.018 |

| Resource Management | 0.26 | 0.07 | ||||

| RM5 | 0.41 | 1.00 | 0.16 | 0.46 | ||

| RM6 | 0.40 | 1.03 | 0.16 | 0.50 | 4.90 | *** |

| RM7 | 0.39 | 0.97 | 0.15 | 0.48 | 5.35 | *** |

| RM8 | 0.47 | 1.22 | 0.22 | 0.46 | 4.97 | *** |

| RM17 | 0.40 | 1.02 | 0.16 | 0.49 | 4.98 | *** |

| Marketing & Alliance | 0.58 | 0.05 | ||||

| MA27 | 0.46 | 1.00 | 0.21 | 0.45 | ||

| MA30 | 0.44 | 0.96 | 0.19 | 0.45 | 5.73 | *** |

| MA32 | 0.29 | 0.58 | 0.09 | 0.42 | 4.43 | *** |

| MA39 | 0.30 | 0.70 | 0.09 | 0.60 | 4.45 | *** |

| MA40 | 0.35 | 0.76 | 0.12 | 0.48 | 5.03 | *** |

| Supply Chain Management | 0.79 | 0.02 | ||||

| SC51 | 0.45 | 1.00 | 0.21 | 0.44 | ||

| SC53 | 0.27 | 0.60 | 0.07 | 0.52 | 4.12 | *** |

| SC54 | 0.27 | 0.59 | 0.07 | 0.50 | 4.13 | *** |

| SC55 | 0.28 | 0.61 | 0.08 | 0.51 | 4.21 | *** |

| SC57 | 0.23 | 0.45 | 0.05 | 0.41 | 3.66 | *** |

| Innovation & Technology | 0.11 | |||||

| IT77 | 0.48 | 1.00 | 0.23 | 0.38 | ||

| IT79 | 0.43 | 0.98 | 0.19 | 0.47 | 5.67 | *** |

| IT82 | 0.28 | 0.62 | 0.08 | 0.51 | 4.27 | *** |

| IT90 | 0.37 | 0.77 | 0.14 | 0.44 | 5.16 | *** |

| IT93 | 0.41 | 0.88 | 0.17 | 0.43 | 5.53 | *** |

According to Table 4, summary of observed variable analysis on each component is as followed;

Resource management consisted of 5 observed variables. The variable which had the highest Standardized Regression Weight was having suitable location of factory and easy-to-find raw materials to reduce production time (RM8) and valued 0.47 at 0.001 of statistical significance. R2 was 0.22 and variance was 0.46.

Marketing & Alliance consisted of 5 Observed Variables. The variable which had the highest Standardized Regression Weight was production management focusing on consumer’s demand and just-in-time production so that the consumers are satisfied to rebuy (MA27) and valued 0.46. R2 was 0.21 and variance was 0.45.

Supply chain management consisted of 5 observed variables. The variable which had the highest Standardized Regression Weight was setting up business alliances in supply chain and creating impression and business cooperation (SC51) and valued 0.45. R2 was 0.21 and variance was 0.44.

Innovation & Technology consisted of 5 observed variables. The variable which had the highest Standardized Regression Weight was applying modern and convenient technology and discovering new products and services into the market to develop and always uniquify the products (IT77) and valued 0.48. R2 was 0.23 and variance was 0.38.

Discussion

Key issues from research results on management guidelines for electronics and electrical manufacturing towards the smart electronics industry are guidelines to maintain competitiveness and set up sustainable success for the organization. According to the research results, 4 to-be-discussed topics referred from relating research documents were presented below.

1. According to the hypothesis-tested results, it was found that marketing and alliance component directly effected on supply chain management component and gave 0.52 Standardized Regression Weight which was in accordance with the study of O'Connor et al. (2018) finding that the greatest challenge was strategic marketing operations based on customer’s different characteristics highly motivating on partner’s strategic response in supply chain management for competitive advantage.

2. Management guidelines for electronics and electrical manufacturing towards the smart electronics industry showed that on Table.1 mean value of innovation and technology component was 4.26 which was the highest mean and reflected the importance of smart electronics industry. This was in accordance with the study of Lu & Weng (2018) who found that the relation of smart manufacturing industrial development and market-trend forecasting by using expert system was an important basis for understanding and smart manufacturing technology development as they can add higher value and relate to strategic technology investment.

3. For innovation and technology management, it was found that on Table.1 the ability of innovation and technology development directly effected on organizational data management and provided 4.37 mean values showing the highest significance. The study of Duan et al. (2020) showed that directly building culture of driving data-based organizational strategies played an important role to new products. The research results showed positive impact of business analysis on innovation and key roles of culture driving organizational strategies by data.

4. According to an analysis of relations between electronics and electrical manufacturing management after the improvement of structural equation model, it was found that the variables brought modern and convenient technologies and the discovery of new products and services into the market in order to regularly develop and build on outstanding products. They had the highest relation when stimulating personnel in the organization to commonly create concepts for new innovations. This was in accordance with the article from the book called “Relation survey between organizational IT, innovation creation, and agility”. The organization must be agile to adjust strategies and operations for success. Organizational agility positively effects on theoretical and practical overall operation of the organization (Ravichandran, 2018).

Conclusion

The research results were found that electronics and electrical manufacturing whose operational standards required to be enhanced to smart electronics industry should prioritize their operational guidelines as follows: starting from using the integration and application of innovation and technology to enhance the operational standards because innovation and technology bring about higher management efficiency for becoming smart electronics industry including other aspects like resource management and marketing and alliance. Statistical analysis-based results of the research model showed that 3-aspect processes overall effect on the efficiency enhancement of supply chain management up to 79%. Supply chain management is nowadays considered the main key for electronics and electrical appliance industrial business competition. The organization is able to apply this body of knowledge to maintain competitiveness in global market and reduce impact of declining-trend exportation.

Suggestions for Further Study

The author expects further study on success strategies of electronics and electrical manufacturing organizations using smart technology to enhance the standards of manufacturing process, accordingly.

References

- Alexey, I.S., Alla, A.Y., Elmira, S.S., & Elena, Y.I. (2021). Methodology development for assessing innovation level spread in the state economic area. Academy of Strategic Management Journal, 20(3), 1-8.

- Arbuckle, J.L. (2012). IBM SPSS Amos 21 User’s Guide. U.S.A.: IBM Corporation.

- Baines, T. (2015). Exploring service innovation and the servitization of the manufacturing firm. Research-Technology Management, 58(5), 9-11.

- Barefoot, K., Curtis, D., Jolliff, W., Nicholson, J.R., & Omohundro, R. (2018). Defining and measuring the digital economy. US Department of Commerce Bureau of Economic Analysis, Washington, DC, 15.

- Chams, N., & García-Blandón, J. (2019). On the importance of sustainable human resource management for the adoption of sustainable development goals. Resources, Conservation and Recycling, 141, 109-122

- Chi, M., Huang, R., & George, J.F. (2020). Collaboration in demand-driven supply chain: Based on a perspective of governance and IT-business strategic alignment. International Journal of Information Management, 52.

- Den Hollander, M.C., Bakker, C.A., & Hultink, E.J. (2017). Product design in a circular economy: Development of a typology of key concepts and terms. Journal of Industrial Ecology, 21(3), 517-525.

- Duan, Y., Cao, G., & Edwards, J.S. (2020). Understanding the impact of business analytics on innovation. European Journal of Operational Research, 281(3), 673-686.

- Dubey, R., Gunasekaran, A., Papadopoulos, T., Childe, S.J., Shibin, K.T., & Wamba, S.F. (2017). Sustainable supply chain management: framework and further research directions. Journal of Cleaner Manufacturing, 142, 1119-1130.

- Fang, E., Lee, J., Palmatier, R., & Guo, Z. (2016). Understanding the effects of plural marketing structures on alliance performance. Journal of Marketing Research, 53(4), 628-645.

- Gupta, G., Tan, K.T.L., Ee, Y.S., & Phang, C.S.C. (2018). Resource-based view of information systems: Sustainable and transient competitive advantage perspectives. Australasian Journal of Information Systems, 22.

- Hugos, M.H. (2018). Essentials of supply chain management. John Wiley & Sons.

- Lu, H.P., & Weng, C I. (2018). Smart manufacturing technology, market maturity analysis and technology roadmap in the computer and electronic product manufacturing industry. Technological Forecasting and Social Change, 133, 85-94.

- Luo, L., Pairote, S., & Chatpatanasiri, R. (2017). GARCH-type forecasting models for volatility of stock market and MCS test. Communications in Statistics-Simulation and Computation, 46(7), 5303-5312.

- Mariana, D., González, Z., Emilio, A.S., Esteban, V.C., & Eloy L.M. (2020). IoT technology applications-based smart cities: Research analysis. Electronics, 9(1246), 1-36.

- Mas'udin, I., & Kamara, M.S. (2017). Electronic data interchange and demand forecasting implications on supply chain management collaboration: A customer service perspective. Jurnal Teknik Industri, 18(2), 138-148

- Meksawat, P. (2013). Critique of innovation service book. SWU Journal of Library and Information. 6th Year 2nd Edition July – December 2013.

- Ministry of Industry. (2019). Manufacturing Production Index (MPI) 2013 - 2019.

- O'Connor, N.G., Yang, Z., & Jiang, L. (2018). Challenges in gaining supply chain competitiveness: Supplier response and determinants. Industrial Marketing Management, 72, 138-151.

- Peters, M.D., Wieder, B., Sutton, S.G., & Wakefield, J. (2016). Business intelligence systems use in performance measurement capabilities: Implications for enhanced competitive advantage. International Journal of Accounting Information Systems, 21, 1-17.

- Porter, M.E., & Kramer, M.R. (2019). Creating shared value. In Managing Sustainable Business, 323-346. Springer, Dordrecht.

- Radhika, G. (2020). A review on internet of thing for home automation. International Journal of Engineering Research & Technology, 8(10), 80-83.

- Ravichandran, T. (2018). Exploring the relationships between IT competence, innovation and organizational agility. The Journal of Strategic Information Systems, 27(1), 22-42.

- Ruiz-Jiménez, J.M., & del Mar Fuentes-Fuentes, M. (2016). Management capabilities, innovation, and gender diversity in the top management team: An empirical analysis in technology-based SMEs. BRQ Business Research Quarterly, 19(2), 107-121.

- Saberi, S., Kouhizadeh, M., Sarkis, J., & Shen, L. (2019). Blockchain technology and its relationships to sustainable supply chain management. International Journal of Production Research, 57(7), 2117-2135.

- Saunila, M. (2017). Innovation capability higher performance: perspectives of management and employees. Technology Analysis & Strategic Management, 29(8), 903-916.

- Sawangrat, N. (2020). Model development analyzing casual affecting the effectiveness logistic industry organization in the east economic corridor area of Thailand. Psychology and Education, 57(9), 6955-6963.

- Sinkovics, R.R., Kuivalainen, O., & Roath, A.S. (2018). Value co-creation in an outsourcing arrangement between manufacturers and third-party logistics providers: resource commitment, innovation and collaboration. Journal of Business & Industrial Marketing. 33(4), 563-573.

- Siwasilchai, S., Bua-in, N., & Shoommuangpak, P. (2021). Guidelines for successful supply chain management in industrial businesses. Academy of Strategic Management Journal, 20(3), 1-14.

- Subramanian, A.M., & Soh, P.H. (2017). Linking alliance portfolios to recombinant innovation: The combined effects of diversity and experience. Long Range Planning, 50(5), 636-652.

- Sugiyarti, G., & Ardyan, E. (2017). Market sensing capability and product innovation advantages in emerging markets: The case of market entry quality and marketing performance of Batik Industry in Indonesia. DLSU Business & Economics Review, 27(1), 1-12.

- Tanin, S. (2020). Research and Statistics Analysis by SPSS and AMOS. 18th edition, Nonthaburi : Business R&D Part., Limited.

- Thunyarat, A., Danuvasin, C., & Jongsawas, C. (2016). Electrical and electronic equipment cluster in Thailand: Can competitiveness be regained?. Journal of the International Academy for Case Studies, 22(3), 59-84.

- Yari, E. (2018). Investigating the relationship between electronic commerce, innovation and technology with customer satisfaction. Journal of Computers, 13(10), 1177-1184.

- Zhong, R. Y., Xu, X., Klotz, E., & Newman, S.T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616-630.