Research Article: 2018 Vol: 17 Issue: 5

Organizational Factors Affecting the Implementation of Green Supply Chain Management

Abdulah M. Aseri, College of Business Administration, Imam Abdulrahman

Bin Faisal University, Dammam,Saudi Arabia

Abstract

Successful Green Supply Chain Management (GSCM) implementation requires a clear identification and understanding of organizational factors including internal and external factors. Towards this end, this research explores and investigates the organizational factors that affect the willingness of management to implement GSC management in the Jordanian food industry. Structural Equation Modeling (SEM) was employed to analyze research data and to test its hypotheses. The results showed a significant impact for the management willingness on implementation of GSC. In addition, Existing Facilities-as an internal organizational factor- had a significant impact on management's willingness to implement it. The results also revealed that suppliers - as an external organizational factor- had a significant impact on management's willingness to implement GSC.

Keywords

Green Supply Chain, Green Manufacturing, Supply Chain Management.

Introduction

The increasing globalization combined with a rapidly changing business environment have led to the growth of a technological and cultural revolution characterized by a wide, quick growth and spread of companies, which led to increased challenges and responsibilities for companies. The probability of success for companies that focus on the environment and what is happening around is high. Accordingly, they are able to avoid barriers and challenges .Due to the supply chain focus which is caring for customers and responding to them, as well as taking into consideration the company's capabilities and knowledge of the external environment it requires a high degree of efficiency. It can be defined as a complex network of procedures (raw materials, production, distribution, recycling) resulting in the delivery of the product to the end-customer) (Sarkis et al., 2011). GSC is focusing on the same tasks and processes experienced by the traditional SC with large emphasis on environmental concerns by reducing the pollution ratio of the production (Hervani et al., 2005). Furthermore, building strong collaboration with GSC members such as suppliers, distributers, customers, community and government have become a critical factor for implementing and maintaining the green management strategy and it is considering as critical factor for keeping competitive advantage. Nevertheless, there are a several external and internal organizational factors influencing the implementation of GSC in all industry generally and in the food sector in particular. Therefore, this study will explore the external and internal organizational factors that might affect the implementation of this process in the Jordanian food industry.

Problem Statement

Companies today are seeking to gain and maintain competitive position and to achieve their goals efficiently and effectively. The companies, as part of society, are responsible for applying the regulations and laws, especially laws relating to environmental protection and conservation. In addition, many people have become concerned within the environment .They have contributed to the increased sense of responsibility for companies to preserve the environment by acting to reduce the proportion of pollution caused by manufacturing and transportation and waste by taking advantage of recycling. The goal of GSC is to apply all possible tools to minimize the percentage of all pollution types, and to use all resources efficiently and effectively and benefit from recycling operations. Food companies in Jordan are considered one of the developed industries, which are characterized by significant production activity. Since they are one of the most consumed products, they produce a lot of waste and pollution. However, there are many organizational factors affecting the implementation of GSC in the Jordanian food sector including internal and external factors. Investigation of these factors is still poor and the gap in the available studies is still huge especially within the context of developed countries. Accordingly, the current study attempts to explore this issue in a systematic research as a replacement of the fragmented efforts that are made.

Literature Review

Supply Chain Management (SCM)

SCM can defined as a network or system of units directly interested in the production of goods and services, assembled, and converted from suppliers to customers according to their demands (Leukel & Kirn, 2008). On the other hand, (Hugos, 1122) defined SC as the coordination of production, inventory, location, and transportation between the participants in the SC to achieve better efficiency of products. The essence of the supply chain is to minimize the costs of processes such as procurement of resources, manufacturing, transportation, and recycling cost while satisfying customers (Boubekri, 2001). People who care about environmental issues often wonder about the negative effects of the factories and the transport of goods and waste. Because of that, companies and governments around the world are wondering about what they can apply to address this problem. This raised the issue that is known as the GSC.

Green Supply Chain (GSC)

GSC management as a term consists of three main parts: the first is management, which is the main activities of the organization: planning, organizing, leading, and controlling, the second part is the chain means interdependence between the main parts, the third part is the processing includes processing materials, products, services. The green refers to the environmentally friendly processing activities, which is a sequence of processing, storage and distribution operations (Chien & Shih, 2007; Malviya & Kant, 2015). As global environment issues have become more notice about the consumers, companies and governments have also taken notice as a result of increased production and consumption levels (Green et al., 2002; Azzone & Manzini, 1994; Plambeck, 2007; Roberts, 2009). As Result of these concerns, GSC was established (Srivastava, 2007).

Green et al. (1998) defined GS as a method in which the perspective of the environment is foremost in SC manufacturing management. While Srivastava (2007) and Zhu & Sarkis (2004) on the same definition, Interest in the management of recycling Goods after completion of used in order to preserve the environment and took advantage of resources. Lee & Klassen (2008) however define it as a planning and implementation of the activities of the organization with what is compatible with environmental issues and performance as well as dealing with suppliers and consumers, according to this consideration. Organization needs to focus on implementing green activities to be able to adapt to supply-chain change and requirements (Hervani et al., 2005). Additionally, the green implementation reduces the production life cycle and uses the materials effectively and efficiently, as well as reducing the energy used to produce the product. Shankar & Shirish (2008) stated that the importance of the GSC is in reducing the size of the gases emitted in operations transport, storage, processing and represented gas carbon, and increasing the size of the profit achieved by companies environmentally friendly production processes. Furthermore, Studies have varied in determining how to achieve the implementation of GSC. Where their activities are different depending on the nature of the work, activities, operations and characteristics of the organizations as well as industrial sector (Huang et al., 2015; Cosimato & Troisi, 2015). The previous studies have discussed many of the activities such as green purchasing, green distribution, green marketing, green reverse logistics, green procurement, green operations, green manufacturing, green materials management, green purchasing and green production (Ninlawan et al., 2010; Amemba et al., 2013; Srivastava, 2007).

Jordanian Food Industry

Over the recent years, Jordanian food industry has grown due to large investments in this area in addition to the use of modern industrial technologies. It acquires around 80% of local market and its play a critical role in economic development. As well as, the total number of companies working in the food industry as registered in Jordan chamber of industry in many Jordanian cities like Amman, Zarqa and Irbid which around (2132) by the end of 2017 with more than 670 million JD.

Researches Hypotheses

H1: Management willingness has a significant statistical impact on the implementation of GSC within the context of Jordanian food industry.

H2: Internal organizational factors including (existing facilities, employee qualifications, strategic direction and cost of implementation) have a significant statistical impact on the Management willingness for implementation of GSC within the context of Jordanian food industry.

H3: External organizational factors including (Suppliers, customer orientation, Legal environment, Government Pressure and Competition) have a significant statistical impact on the Management willingness for implementation of GSC within the context of Jordanian food industry.

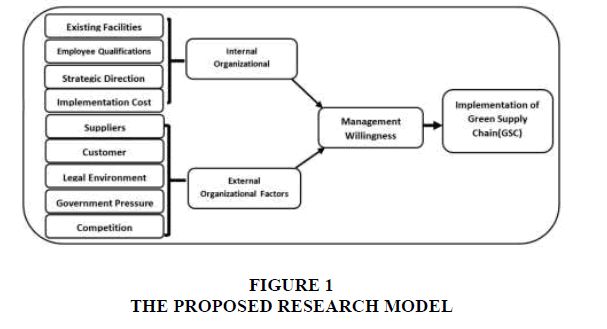

Research Conceptual Model

Research Methodology

Quantitative research method will be adopted to achieve the research aim (Figure 1). The population of interest includes the operational and logistic managers, Logistic heads and operational, recycle managers within the context of Jordanian food industry. This population is chosen because the main discipline of this study is GSCM. Different levels of managerial positions are very critical and important for implementation of GSCM. There are many reasons for choosing the food industry. This industry is changing quickly due to technological advances and the growing marketing demand. Moreover, environmental issues and concerns are becoming important and growing fast and many significant regulatory acts have been enforced and others are expected to be introduced on the global, regional as well as local levels. A list of the Jordanian food companies was obtained from the Jordan chamber of industry. A total of 520 questionnaires were distributed and 410 were collected and were suitable for analysis. However, Structural Equation Modeling (SEM) was used to analyses research data. Moreover, Confirmatory Factor Analysis (CFA) was used to test a pre-specified relationship of observed measures. CFA result shown that total scores were ranged between (0.20-0.80) and the entire correlations coefficients are significant at the level of 0.01 or less, at the same time all the correlations coefficient is above 0.30. Overall, the items have accepted level of construct validity. To confirm this, loading values for all the study variables ranged from (0.375-0.918). All the loading values are above 0.40, which indicated that all factor loading values are above the acceptable range (0.40). In addition, the researchers were used the Average Variance Extracted (AVE) as measure of validity. AVE values ranged from (0.53-0.78), which means the items for each study variable explained more than (50%) of the variance in the variables (Table 1).

| Table 1 Reliability, Validity And Collinearity Test |

|||||

| Variables | Cronbach's Alpha | AVE | Composite Reliability | Collinearity Statistics | |

| Tolerance | VIF | ||||

| Competition | 0.78 | 0.69 | 0.87 | 0.57 | 1.76 |

| Implementation costs | 0.57 | 0.55 | 0.77 | 0.56 | 1.77 |

| Customer Orientations | 0.83 | 0.67 | 0.89 | 0.41 | 2.43 |

| Employee Qualifications | 0.84 | 0.75 | 0.90 | 0.35 | 2.88 |

| Existing Facilities | 0.81 | 0.73 | 0.89 | 0.44 | 2.29 |

| Government Pressure | 0.75 | 0.66 | 0.85 | 0.56 | 1.77 |

| GSC implementation | 0.86 | 0.53 | 0.89 | - | - |

| Legal Environment | 0.82 | 0.74 | 0.90 | 0.42 | 2.37 |

| Management willingness | 0.88 | 0.68 | 0.91 | 0.67 | 1.50 |

| Strategic Direction | 0.84 | 0.68 | 0.89 | 0.42 | 2.40 |

| Suppliers | 0.86 | 0.78 | 0.91 | 0.46 | 2.17 |

Table 2 indicates Hypothesis Testing results.

| Table 2 Hypothesis Testing Result |

|||||||

| Standardized .Est | S.E | C.R | P | Results | |||

| GSC implementation |  |

Management willingness | 0.594 | 0.045 | 11.724 | *** | Supported |

| Management willingness (MW) |  |

Internal Factors | 0.58 | 0.072 | 9.567 | *** | Supported |

| MW |  |

Existing Facilities | 0.43 | 0.07 | 6.41 | *** | Supported |

| MW |  |

Employee Qualifications | 0.11 | 0.07 | 1.52 | 0.13 | NOT Supported |

| MW |  |

Strategic Direction | 0.07 | 0.07 | 1.02 | 0.31 | NOT Supported |

| MW |  |

Implementation costs | 0.10 | 0.07 | 1.69 | 0.09 | NOT Supported |

| MW |  |

External Factors | 0.01 | 0.064 | 0.020 | 0.98 | NOT Supported |

| MW |  |

Suppliers | 0.24 | 0.079 | 3.680 | *** | Supported |

| MW |  |

Customer Orientations | -0.04 | 0.064 | -0.56 | 0.57 | NOT Supported |

| MW |  |

Legal Environment | 0.04 | 0.58 | 0.54 | 0.58 | NOT Supported |

| MW |  |

Government Pressure | 0.092 | 0.049 | 1.52 | 0.12 | NOT Supported |

| MW |  |

Competition | 0.10 | 0.054 | 1.73 | 0.084 | NOT Supported |

*** indicate that P value less than (0.05).

Research Findings And Discussion

The results showed a significant impact for the management willingness on the implementation of GSC. As well as, the results showed that existing facilities-as an internal organizational factors-had a significant impact on management's willingness to implement GSC. Finally, the results revealed that suppliers-as an external organizational factors-had a significant impact on management's willingness to implement GSC. Many recent studies have discussed green issues, and have argued and debated about factors that affect the implementation of it in organizations. Lee (2015) identified three main factors that influence the implementation of this process including buyers, government and suppliers. However, Sarkis et al. (2010) extended the classification of these factors to include cultural, technological organizational, proximal, political, informational, temporal, legal, and economic. More systematic classification of these factors was provided by Lee & Klassen (2008) who classified these factors into internal and external factors. Nevertheless, their external factors included a limited set of factors including functional, political and social factors. Additionally, internal factors included firm's strategies, internal resources and capabilities. One could argue that in spite of the importance of such factors, there might be more relevant external and internal factors that could have more potential impact on the implementation of GSCM. Recently, Huang et al. (2015) stated more comprehensive list of factors including: Regularity pressures (environmental rules and regulations, cost, marketing), Customer pressures, Public pressures and Supplier. However, one of the interesting findings of this research is concerned with the impact of three of internal organizational factor (cost of implementations, employee qualifications and strategic direction) on the management willingness for implementation of GSC within the context of Jordanian food industry that was not supported. One the contrary, the results provides evidence that existing facilities as internal organizational factor has a significant impact on the management willingness to implement GSC within the context of Jordanian food industry. One could argue that this result seems a realistic and logical due to the fact that the issue of GSCM itself is still new phenomena within the context of the study. In this initiative stage of consideration, the issue of the available facilities, resources or physical capabilities seem critical and of high priority. Moreover, this result is contrary to many of the previous studies as will be shown subsequently. For instance, Huang et al. (2015) concluded that customer orientation is considered as critical factor that has a significant pressure on organization to reduce waste and pollution and to become more aware with environment through implementing green practices. Moreover, government pressure and legal environment have been addressed by previous studies (Wu et al., 2012; Huang et al., 2015) two influential factors that force modern organizations to become green organization through implementing GSC. Whereas, Hemel & Kramer (2002) revealed that competition plays an important role and is considered as a critical factor that forces and encourages organizations to implement GSC in order to achieve competitive advantages and keep market share. On the other hand, suppliers have a significant role in GSC since the provision of green materials that are required for the production process is directly related to suppliers. This is consistent with the study by Lee (2015) and Walker et al. (2008) who claimed that supplier is one of most important factors that has an impact on management an organization to implement GSC.

Theoretical Implications

This study contributes in enriching the literature in many ways. Firstly, the study results extended the literature concerning GSCM through investigating and measuring the organizational factors affecting the implementation of GSCM within the context of Jordanian food industry. Considering the scarcity of the available empirical as well as theoretical studies within this context as well as the overall Arab countries context, the study and its outcomes provided some insights and useful contribution that could open the door for more research to create awareness concerning GSCM issues. Secondly, based on an extensive review of the most recent studies and previous literature regarding GSCM, this study developed a proposed model outlining some important internal and external organizational factors that are expected to have a significant impact on the implementation of GSCM as mediated by management willingness to initiate such initiative. The overflow of the research process might also provide systematic guideline for future researcher in terms of the foundation of the research, building up of its model, methodological procedures, analysis of data as well as the validation of the proposed model. Thirdly, throughout this research, we argued that the ongoing pressure on organizations to introduce GSC practices successfully should be based first of all on a clear understanding of not only the concept of GSC to create awareness but also on the process of GSCM. Toward this end, this research explored the factors that must be carefully considered to increase the rate of success for any GSCM initiative. The investigation of the internal and external organizational factors that might influence such initiative can enhance the formulation of successful GSCM strategy.

Practical Implications

The food industry is one of the important industries in Jordan. In addition, the growing demand towards green issue by customers is forcing decision makers in all industries and most importantly in the food industry's context to consider such issue as part of the future strategic plans. Production of friendly-environment products and the protection of the environment from pollution in addition to more effective utilization of the environmental resources have become a must for most stakeholders in this industry including consumers, government as well as investors. To achieve this goal, the outcomes of this research may serve decision makers in the food industry in their attempts to consider green issues. Moreover, as the results showed a significant impact for the management willingness on the implementation of GSC, this research outcome provides an original contribution to the available body of knowledge concerning the important and potential leading role of organizational management in the implementation of GSCM. The empirical findings mentioned above in addition to the theoretical evaluation of Jordanian food industry have led to the identification of particular strategic direction to improve the state of the art concerning the concept of GSCM. Moreover future research will have to assess the internal and external validity of proposed model within and outside this research particular context. An extension of the components of this framework may also improve its appropriateness for other contexts.

Research Recommendations

Based on the findings of this research, the following recommendations might be provided. Firstly, considering the significant statistical impact of management willingness on the implementation of GSCM, all organizations that are considering the introduction of GSCM must attempt to promote a supportive managerial culture that can facilitate any GSCM initiative. From the perspective of this research study, this is seen as a pre-requisite for successful GSCM. Secondly, Successful preparation of the implementation of GSCM requires real consideration of the existing facilities including all the resources, capabilities, devices, equipment, systems, instructions and infrastructure in the organization at the moment. Thirdly, organizational suppliers must be seen as an important supportive factor for successful implementation of GSCM. In this direction, partnerships and possibly strategic alliances initiates might be considered. Finally, future research must consider some other organizational factors on the MICRO and MACRO environmental levels that might influence successful implementation of GSCM and the interrelationships between the concept of GSCM and other emerging concept such as corporate social responsibilities, global business environment, green marketing and green technology.

References

- Amemba, C.S., Nyaboke, P.G., Osoro, A., & Mburu, N. (2013). Elements of green supply chain management.European Journal of Business and Management,5(12), 51-61.

- Azzone, G., & Manzini, R. (1994). Measuring strategic environmental performance.Business Strategy and the Environment,3(1), 1-14.

- Boubekri, N. (2001). Technology enablers for supply chain management.Integrated Manufacturing Systems,12(6), 394-399.

- Chien, M. K., & Shih, L. H. (2007). An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational performances.International Journal of Environmental Science and Technology,4(3), 383.

- Cosimato, S., & Troisi, O. (2015). Green supply chain management: Practices and tools for logistics competitiveness and sustainability. The DHL case study.The TQM Journal,27(2), 256-276.

- Green, K., Morton, B., & New, S. (1998). Green purchasing and supply policies: do they improve companies' environmental performance?Supply Chain Management: An International Journal,3(2), 89-95.

- Hemel, V. C., & Kramer, J. (2002). Barriers and stimuli for eco-design in SMEs. Journal of Cleaner Production, 10 (5), 439-453.

- Hervani, A. A., Helms, M. M., & Sarkis, J. (2005). Performance measurement for green supply chain management.Benchmarking: An International Journal,12(4), 330-353.

- Huang, X., Tan, B. L., & Ding, X. (2015). An exploratory survey of green supply chain management in Chinese manufacturing small and medium-sized enterprises: Pressures and drivers.Journal of Manufacturing Technology Management,26(1), 80-103.

- Hugos, M. H. (2011).Essentials of supply chain management.

- Lee, S. Y. (2015). The effects of green supply chain management on the supplier’s performance through social capital accumulation.Supply Chain Management: An International Journal,20(1), 42-55.

- Lee, S. Y., & Klassen, R. D. (2008). Drivers and enablers that foster environmental management capabilities in small and medium sized suppliers in supply chains.Production and Operations Management,17(6), 573-586

- Leukel, J., & Kirn, S. (2008). A supply chain management approach to logistics ontologies in information systems. InInternational Conference on Business Information Systems, pp. 95-105. Springer Berlin Heidelberg.

- Malviya, R. K., & Kant, R. (2015). Green supply chain management (GSCM): A structured literature review and research implications.Benchmarking: An International Journal,22(7), 1360-1394.

- Ninlawan, C., Seksan, P., Tossapol, K., & Pilada, W. (2010, March). The implementation of green supply chain management practices in electronics industry. InProceedings of the International Multiconference of Engineers and Computer Scientists, pp. 17-19.

- Plambeck, L.E. (2007). The greening of Wal-Mart’s supply chain.Supply Chain Management Review, 18-25.

- Roberts, D. (2009). Wal-Mart CEO lays out ambitious social and environmental goals for his company.

- Sarkis, J., Gonzalez-Torre, P., & Adenso-Diaz, B. (2010). Stakeholder pressure and the adoption of environmental practices: The mediating effect of training.Journal of Operations Management,28(2), 163-176.

- Sarkis, J., Zhu, Q., & Lai, K. H. (2011). An organizational theoretic review of green supply chain management literature.International Journal of Production Economics,130(1), 1-15.

- Shankar, M., & Shirish, S. (2008). Greening supply chain for a better environmental management. National Institute of Industrial Engineering, Powai, India.

- Srivastava, S. K. (2007). Green supply-chain management: a state-of-the-art literature review.International Journal of Management Reviews,9(1), 53-80.

- Walker, H., Di Sisto, L., & McBain, D. (2008). Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors.Journal of Purchasing and Supply Management,14(1), 69-85.

- Wu, G. C., Ding, J. H., & Chen, P. S. (2012). The effects of GSCM drivers and institutional pressures on GSCM practices in Taiwan’s textile and apparel industry.International Journal of Production Economics,135(2), 618-636.

- Zhu, Q., & Sarkis, J. (2004). Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises.Journal of Operations Management,22(3), 265-289.