Research Article: 2021 Vol: 20 Issue: 2

The Effect of Information System on the Reverse Logistics Performance

Ahmed Attia, University of Business and Technology

Abstract

The objective of this study is to test the effect of information system on reverse logistics performance by proposing a research model, to demonstrate the effect of information system on reverse logistics cost and process performance, a conceptual model proposed to illustrate the different hypothesized relationships between the study variables. Different techniques such as factor analysis, correlation analysis, and structural equation modeling were used to verify the validity of the proposed conceptual model and to test the suggested hypotheses, using data collected from 165 companies in the Saudi food industry (representing a response rate of 66.5%).

According to the study’s findings, information systems capability, compatibility and technology are positively affecting the reverse logistics cost and process effectiveness. The needed data to test the hypothesized model has been collected only from the food industry in Saudi Arabia, so the results of the current study can be accepted only to the collected sample. The findings recommend that both information system capability as well as supply information system compatibility will contribute to improve the reverse logistics cost and reverse logistics process effectiveness. In addition, information system technology will help in improving the cost of reverse logistics and the effectiveness of the process.

Keywords

Information System, Cost Effectiveness, Reverse Logistics Performance, Reverse Logistics Process Effectiveness, Saudi Food Industry.

Introduction

The global economy and the international competition are driving the companies to highlight the importance and effect of the reverse logistics on company performance. In fact, Customers are expecting more benefits and value from the return policy for products or services, which force the company to maximize the value out of returned items (Daugherty et al., 2005; Attia, 2015b). There are several reasons for returning products such as: defect products, wrong product, replacement, warranty, etc. Any company must be ready to handle the returned items effectively and efficiently to make sure of maintaining an adequate customer satisfaction level in order to keep the possibility of future transactions with the customers (Richey et al., 2005; Schultmann et al., 2006).

Just recently the academia started to investigate the reverse logistics, its effect on performance and how could it be used as a strategic weapon (Daugherty et al., 2005; Mollenkopf et al., 2007; Nuss et al., 2015; Attia, 2015a & 2013). Due to the nature of reverse logistics, which involves different activities such as receiving the returned items, replacement, fixing the defect items, recycling, etc., a higher degree of efficiency is required to perform the required tasks on time with the lowest possible cost.

Huscroft et al. (2013) summarized the research in the area of reverse logistics and identified different areas for future research, one of them being the effect of information System on improving the performance of reverse logistics. In 2019, García-Sánchez et al. collected data from 160 high-tech European firms for a purpose of testing the effect of information system on reverse logistics performance, the statistical analysis for the collected data support the positive effect for information system on the performance of reverse logistics. In addition, Morgan et al. (2016) discovered a positive moderating effect for IT competency on the relationship between collaboration and a reverse logistics competency. Thus, the current study investigated the role of information system in achieving high performance for reverse logistics processes.

Theory and Hypothesis Development

Information system plays a vital role in the changes of industry and competition. Many well-known and successful firms to create its place in the market have used information system. Technology is personified in every value activity of the company. The technology can be employed in the value activities because of other drivers such as cost, sales and timing. In addition, technology could be itself an independent driver, when it requires a policy change or, it is the one, which the competitors do not have, and then technology gives competitive advantage. Accordingly, technology has an effect on the cost and differentiation, and the company can use it to make these factors in their favor (Porter, 2008).

Efficiency and information sharing are the two main objectives of supply chain and logistics, because of their effect on their performance through minimizing delays in delivery and productions and achieving the internal and external integration (Stank et al., 1996; Daugherty et al., 2005; Attia, 2015b). A substantial amount of research has focused on testing the effect of information system on business and supply chain operations, and from another side different research tested the effect of supply chain capability on company performance. Information system helps in providing on time information about product, which is a crucial competitive weapon in today’s global market (Bharadwaj, 2000).

Some previous empirical studies showed that information systems and technology could enhance the logistics performance and provide the company with a competitive advantage (Closs & Savitskie, 2003; Richey et al., 2005; Nevo & Wade, 2010). Overall, information system has proven to have a good effect on the logistics’ performance and in the same time the overall company performance, by helping in achieving efficiencies and streamlining information flow (Closs et al., 1997; Daugherty et al., 2005; Hazen & Byrd, 2012).

Regardless of the previously mentioned benefits for information system, several studies indicated that the information system is often purchased and used to serve the forward distribution channel needs. Moreover, since there is a little concentration on fulfilling the needs of the reverse logistics process, and consequently, fewer resources are provided (Stock & Lambert 2001). Although the reverse logistics process consists of several activities which can be done in the forward logistics, like transportation, inventory, and storage. The movement of products on the two flows has completely different goals. Consequently, the activities on both flows are similar. However these activities are unique and those variations must be addressed (Genchev et al., 2011; Bernon et al., 2011).

To attain the appropriate effectiveness, the variations in objectives and activities must be taken into consideration as well as incorporated in the logistics info system to the business (Richey et al., 2005). A limited number of scientific researchers have examined the information system acquisition, capabilities, implementation and compatibility and just how it pertains to some factors and reverse logistics performance (Iacovou et al., 1995; Russell & Hoag, 2004; Grawe et al., 2011; Hazen & Byrd, 2012). The ability to procure and implement an adequately designed information system is a vital resources allocation decision for the company. The objective must be improving the effectiveness of the processes, cost reduction, and meet customer needs in a timely manner.

Based on Daugherty et al. (2005) information system support is actually composed of three unique components: compatibility, technologies, and capability. To make efficient and cost saving technology resources allocation decisions, the integration of these dimensions must be accomplished. In case these dimensions are not properly integrated, the information system will not operate efficiently. The same is true for the compatibility of the information systems with the reverse logistics process. On the other hand reverse logistics faces the problems of demand uncertainty and the need to act quickly and on time, in processing the returned products to meet customers’ satisfaction requirements. Moreover, the managers needs to be ready to process and deal with the returned items efficiently and quickly even in case they are not aware when the product will or perhaps could be returned. This is a vital cause for considering sharing accurate and prompt information with partners as a high priority (Daugherty et al., 2002 & 2005).

Since the supply chain would consists of along with external companies, processes and multiple parties, this sharing of information and coordination may be a difficult task. Blumberg (1999) mentioned that there is an increase in demand for coordinating the activities between the different parties on the supply chain to guarantee optimum efficiency and to satisfy the customers’ needs on time. Mutual communication between supply chain partners is hence crucial for harmonizing interactions and transactions and it helps to enhance and develop the company long-term relationships. This is the reason a company would like to embrace and put into effect an information system which would correctly meet up with the requirements of the reverse logistics processes (Bernon et al., 2011; Genchev et al., 2011).

A good reverse logistics is usually a chance for the company to be distinctive in the marketplace. In addition, the reverse logistics capabilities are linked directly with the trustworthiness of the company and become a part of the requirements for choosing the company to deal with it (Daugherty et al. 2005). Companies must make an effort to create and nurture capabilities which are unique and difficult to duplicate, which will help the company to gain a stable competitive advantages over other the competitors (Day, 2000). Generally, capability can be described as a set of competences and know-how that helps in shaping and sustaining the competitive advantages as well as include behavior which allows regular customer support and reduced customer orders (Daugherty et al., 2001; Hazen & Byrd, 2012). Thus, information system should be responsive and accurate to turbulences in the surrounding environment to be able to forecast as well as conciliate the fluctuation in customers' demand (Huscroft et al., 2013).

Information system must provide useable and timely information that meets the requirements of the managers. In order to achieve the previous, information has to be reachable to everybody in the external and internal flow of the reverse logistics processes. This particular degree of information support is vital for the reverse logistics activities to achieve success and keep fulfilling the consumers’ needs (Ellram & Cooper, 1990; Nevo & Wade, 2010). Information support will help the reverse logistics efforts to retrieve value which otherwise may be lost, additionally, it functions to improve customers support (Huscroft et al., 2013; Hazen & Byrd 2012). According to the previous discussion, hypotheses one and two are formulated as follow:

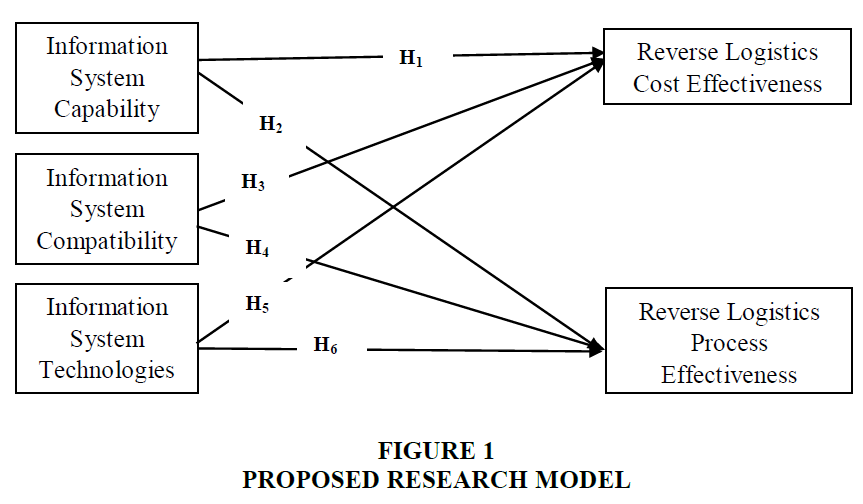

H1 Information systems support capability has an impact on the reverse logistics cost effectiveness.

H2 Information systems support capability has an impact on the logistics process effectiveness.

Companies recognize the benefits of information support within the company, and managers make an effort to concentrate on achieving both information system capability and information system compatibility when taking resources allocation decision. The information system must be suitable for the company and its reverse logistics activities. Information systems support capability points out to a practicability, but information system compatibility illustrates the simplicity of using of the system by the users (Daugherty et al., 2005; Grawe et al., 2011). To enhance the efficiency and the effectiveness of the reverse logistics processes requires the external members in the supply chain have compatible information system with the ones the company owns. All active partners in the supply chain have to be in a position to quickly and effectively share the correct and on time information. This information interchange helps in solving many of the problems that arise from unstable and infrequent demands in the reverse logistics processes. Information system compatibility refers to the presence of systems that are similar and or suitable middleware systems which interpret and facilitate information or data interchange between different companies (Richey et al., 2005).

Due to the globalize nature of the markets nowadays, the use of information systems and its implementations spread all over the supply chain. These implementations have actually revolutionized the way of transactions and activities are nowadays carried out between partners in the reverse logistics flow (Grawe et al., 2011). Moreover, information system provides the company with the needed capabilities to improve supply chain effectiveness by offering on spot information on different events and processes about the supply chain. The information system compatibility helps in smoothing the activities and collaboration between the reverse logistics partners by interchange and revealing information about product and shipments information.

With the growth of globalization, the information exchange compatibility across different companies in the supply chain has become a critical issue (Williams et al., 1997). Because the majority of partner companies on the supply chain have business agreements with different distributors, third-party logistics provider, and multiple suppliers, so achieving compatibility between the different software for supply chain partners could be hard. However, the software compatibility is actually needed to enhance the efficiency and effectiveness of the operations. Thus, software compatibility is essential to boost the effectiveness of reverse logistics processes (Hazen & Byrd, 2012; Huscroft et al., 2013). According to the previous discussion, hypothesis three and four are formulated as follow:

H3 Information systems support compatibility has an impact on the reverse logistics cost effectiveness.

H4 Information systems support compatibility has an impact on the logistics process effectiveness.

Information system technologies are one of the most critical enabler, which helps in achieving the company’s goals and gain competitive advantages. The worldwide complexity and the importance of time in reverse logistics activities make information system and its related technologies a major concern at the top management and the optimal allocation of resources. Companies try to use and design the reverse logistics processes in a way to help in utilizing and improving the assortment of technologies used within the operations of theirs. These particular technologies must provide a little advantage to both the reverse logistics performance and overall company performance (Daugherty et al., 2002 & 2005; Hazen & Byrd, 2012). According to the previous, hypothesis five and six are formulated as follow:

H5 Information systems technologies has an impact on the reverse logistics cost effectiveness.

H6 Information systems technologies has an impact on the logistics process effectiveness.

Research Model

Figure 1 shows the research hypotheses and the proposed research model:

Methodology

This section describes the sampling procedures and the development of the study survey.

Sample

The suggested hypotheses and model were tested based on collected data from the Saudi food industry, which contains a sum of 697 operating companies (medium and large size companies), as stated on the General Authority for Statistics web site (2017). Based on the sampling table of Krejcie & Morgan (1970) and the population size, the recommended sample size for the study would be 248. The geographical distribution of the companies working on the food industry shows that almost 62% of the food companies are situated in three regions (see Table 1). The study, thus, concentrated on gathering the needed data from medium and large size companies established in these three regions. In addition, the collected valid questionnaires are 165, representing a response rate of 66.5% (Table 2).

| Table 1 The Percentage of the Saudi Food Companies in the Main Three Geographical Regions | ||||

| Region | Makkah | Riyadh | Eastern Region | Total |

| Percentage of companies | 23.7% | 21.3% | 16.9% | 61.9% |

| Table 2 Summary of the Response Rate | ||

| Region | Response number | Response rate |

| Makkah | 86 | 52.12% |

| Riyadh | 51 | 30.9% |

| Eastern Region | 12 | 7.28% |

| Total | 165 | 100% |

The Saudi food industry is one of the leading industries in the kingdom because it ranks the third regarding the job numbers, as providing 9.4% of local employment in 2017. Additionally, it stands fourth regarding the amount of operating revenue, which represents 5.4% of the total generated operating revenue in Saudi Arabia (General Authority for Statistics, 2017). Accordingly, in this study, a survey was prepared to collect the data and validate the research model and hypotheses (see Table 3). To gather the needed data, the study survey was distributed by mails and emails to the total sample size (248 companies) in the main three industrial regions in Saudi Arabia mentioned in Table 1.

| Table 3 Variables Measures | |||||||

| Construct | Source | Number of Items | Factor Loading | Cronbach’s alpha Reported |

Cronbach’s alpha Calculated | Mean | SD |

| Information System Support Capability | Daugherty et al. (2005) | 5 | 0.81 0.89 0.90 0.95 0.91 |

0.89 | 0.97 | 4.79 | 0.85 |

| Information System Support Compatibility | Daugherty et al. (2005) | 7 | 0.86 0.85 0.88 0.87 0.89 0.90 0.89 |

0.86 | 0.96 | 5.49 | 0.92 |

| Information System Technology | Daugherty et al. (2005) | 4 | 0.83 0.80 0.86 0.90 |

0.98 | 0.92 | 5.19 | 1.50 |

| Reverse Logistics Cost Effectiveness | Richey et al. (2005) | 4 | 0.95 0.85 0.90 0.80 |

0.86 | 0.95 | 5.16 | 1.43 |

| Reverse Logistics Processing Effectiveness | Richey et al. (2005) | 3 | 0.95 0.92 0.82 |

0.9 | 0.93 | 5.93 | 1.01 |

Measures

The study used a mix of measures that has been used before in different studies. The dependent variables (reverse logistics cost effectiveness and reverse logistics processing effectiveness) were measured using the statements recommended by Richey et al. (2005). The remaining 4 independent variables were measured using the statements recommended by Daugherty et al. (2005).

Common Method Bias

In order to lessen the common method bias, a group of procedures were applied. In order not to contain large-number items, only previously validated measures have been used. (Lindell and Whitney, 2001). Moreover, unrevealing of identity was ensured for the all participants. Independent variables were almost segregated from dependent variables (Podsakoff et al., 2003); items were cautiously revised, and finally a pilot test was used to assure conveyance of content and not using the negatively worded or reverse-scored items (Swanson & Holton, 2005).

Analysis

For the purpose of data analysis, the Structural Equation Modeling Techniques (SEM) was chosen to test the validity of the suggested research model and test the research hypotheses. In addition, the SEM was chosen for several reasons. To allow to test of the effect of one or more independent variables. To incubate Multiple Statistical Methods. And to allow the study of the relations among latent variables unaffected by errors of measurement in the indicators (Jeon, 2015).

Results

Validity and Reliability Results

The validity and reliability of the study measures is the base of the quality of a study results. There are several types of validity such as convergent and predictive validity (Garver & Mentzer 1999). The normed-fit index (NFI) coefficient is the measure for the convergent validity. All NFI coefficients for the study's variables are above 0.9 (Table 4) which reflects an adequate convergent validity according to Ahire et al. (1996).

| Table 4 Validity and Reliability Results | ||||||||||

| Scale | RMSEA | NFI | NNFI | CFI | GFI | SRMR | Relative c2 | |||

| ISCP | 0.99 | 0.95 | 0.93 | 0.91 | 0.88 | 0.66 | 3.03 | |||

| ISCO | 0.98 | 0.94 | 0.91 | 0.89 | 0.87 | 0.64 | 2.97 | |||

| IST | 0.96 | 0.94 | 0.91 | 0.89 | 0.87 | 0.64 | 2.97 | |||

| RLCE | 0.97 | 0.94 | 0.91 | 0.89 | 0.87 | 0.64 | 2.96 | |||

| RLPE | 0.96 | 0.94 | 0.91 | 0.89 | 0.87 | 0.64 | 2.96 | |||

| Reliability results | ||||||||||

| Scale | Cronbach’s alpha | Construct reliability | Variance extracted | |||||||

| ISCP | 0.97 | 0.95 | 0.93 | |||||||

| ISCO | 0.96 | 0.94 | 0.92 | |||||||

| IST | 0.92 | 0.83 | 0.81 | |||||||

| RLCE | 0.95 | 0.80 | 0.81 | |||||||

| RLPE | 0.93 | 0.91 | 0.89 | |||||||

According to Kenny (2012), the correlation value is a strong indicator for the discriminant validity. If the correlation value is 1 or close to it, that shows a poor discriminant validity and the same conclusion if the correlation value is -1 or close to it. Table 5 shows the value of the correlation between each two variables of the study's variables, the lowest and highest value for the correlation between each two variables are 0.467 and 0.672, which reflect high discriminant validity.

| Table 5 Correlation Results | |||||

| Scale | ISCP | ISCO | IST | RLCP | RLPE |

| ISCP | 1 | ||||

| ISCO | 0.475* | 1 | |||

| IST | 0.601* | 0.492* | 1 | ||

| RLCE | 0.519* | 0.672* | 0.514* | 1 | |

| RLPE | 0.467* | 0.559* | 0.609* | 0.535* | 1 |

According to Ahire et al. (1996), the existing of correlation relationship between the study variables reflects another type of validity, which is predictive validity. Table 5 shows the existence of correlation relationships between the study's variables, which indicate the existence of predictive validity. To test the reliability of the study's variables, Cronbach’s alpha has been calculated, Cronbach’s alpha values for all the study's variables are above 0.9, which exhibit adequate reliability for the variables according to Garver & Mentzer (1999).

Moreover, a factor analysis was implemented, for information system support capability (ISCP) variable, five items used to measure it. The lowest standardized coefficients between all the five items are 0.81, and for Information system support compatibility (ISCO) variable, the lowest standardized coefficients between all the seven items are 0.85. For information system technology (IST) variable, the lowest standardized coefficients between all the four items are 0.80.

For the dependent variables, the standardized coefficients for reverse logistics cost effectiveness (RLCE) variable is at least 0.8, and for reverse logistics processing effectiveness (RLPE) variable is at least 0.82. The previously mentioned standardized coefficients show a valid fit between the data and measurement model (Kline, 1998; Koufteros, 1999).

Correlation Analysis

The first step to test the study's hypotheses is to measure the intensity and tendency of the linear relationship between the variables representing the study's conceptual model. The results of the correlation analysis in Table 5 show a significant and positive relationship between the study's three independent variables and the two dependent variables. In addition, there are significant and positive relationships between all the study's independent variables from a side and all the dependent variables from the other side.

Structural Relationship Model

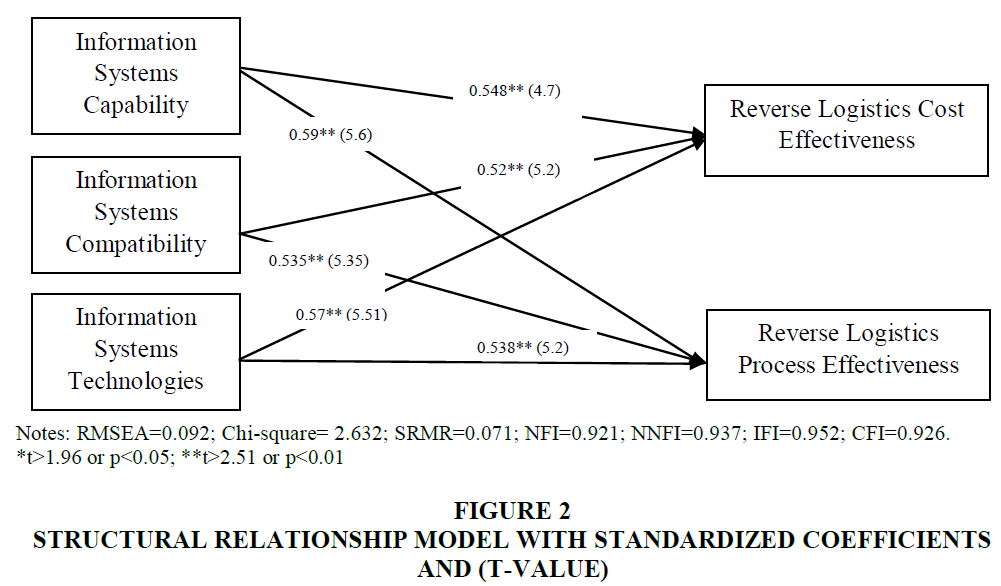

The chi-square, CFI and NNFI were calculated to determine whether to accept the study's suggested model or not, the values of chi-square, CFI and NNFI are 2.632, 0.926 and 0.937 respectively. The previous values support the acceptance of the study model (Garver & Mentzer, 1999).

In addition, the relationship between information system capability from aside and reverse logistics cost effectiveness and reverse logistics processes effectiveness from another side was statistically significant (0.548 at p<0.01 and 0.59 at p<0.0 respectively). Moreover, the relationship between information system compatibility from aside and reverse logistics cost effectiveness and reverse logistics processes effectiveness from another side was statistically significant (0.52 at p<0.01 and 0.5935 at p<0.0 respectively). Lastly, a statistically significant relationship between information system technology from aside and reverse logistics cost effectiveness and reverse logistics processes effectiveness from another side was statistically significant (0.57 at p<0.01 and 0.538 at p<0.0 respectively). Based on previously mentioned results and the standardized coefficients for the study’s model shown in Figure 2, all the study’s hypotheses were supported and accepted.

Discussion and Conclusion

Upon completion of the analysis of the model, it is obvious that there is a significant effect for information system on the performance of reverse logistics. The previous result supports the acceptance of the study’s six hypotheses. The significant and positive relationship between information system technologies and reverse logistics performance is logical because of using the new technology like RFID, EDI and barcodes, which help in simplifying and improving the efficiency of the reverse logistics processes. The ultimate effect of using such technologies is reducing cost. This finding goes along with the findings of previous several studies (Daugherty et al., 2005; Hazen & Byrd, 2012; Huscroft et al., 2013).

In addition, the current study’s results match with the previous studies results (Daugherty et al., 2005; Hazen & Byrd, 2012; Huscroft et al., 2013), regarding the information system compatibility effect on the reverse logistics performance. Indeed, sharing accurate and timely information between the different members along the supply chain helps in simplifying the reverse logistics processes and make it more effective and efficient. Lastly, this study’s results support the positive effect of information system capability on the reverse logistics performance. These current results match with those of different studies such as (Lee, 2000; Chopra & Meindl 2007). Their findings show the positive effect for information system capability on reducing cost and increasing the responsiveness of the whole supply chain.

The results of the current study contribute to the professionals in the area of reverse logistics and information system. Indeed the results show the importance of establishing and running information system dedicated to the reverse logistics processes, in order to simplify the processes and improve the performance. Also, the results stressed on the importance of using compatible software by the different members of the supply chain. The idea of using compatible software between different members raises the issue of building a long-term relationship with the supplier to perform a mutual planning and purchasing for the compatible software.

The results of the current study show the importance of sharing information between the reverse supply chain members and stress the importance on enhancing the technological infrastructure for the supply chain members to facilitate the processing of the returned items in a sustainable way. The growing increase in the environmental awareness and the environmental laws lead to an enormous pressure on companies to handle the returned items with a safe environmental method as soon as possible. Many companies consider the returned items as a waste for their initial investments in the products, with the results of the current study the companies' view about the returned items will change and will be considered as a source for profit if the reverse logistics process managed properly (Lee, 2000; Chopra & Meindl, 2007).

Limitations and Further Research

The future research recommendations were extracted from the limitations of the study. First, the model needs to be tested in different industries, not only the Saudi food industry. In addition, the model needs to be tested in different developed and developing countries to compare the findings in different economical environments, therefore. Second, the sample size needs to be increased as the data collected only from 165 companies, which limits the findings of the study. Third, the data may be collected over different times to track the effect of information system on reverse logistics performance. Finally, more variables that affect the process of developing and purchasing the information system could be added to model and tested.

References

- Ahire, S.L., Golhar, D.Y., & Waller. M.W. (1996). Development and validation of TQM implementation constructs. Decision Sciences, 27(1), 23-56.

- Attia, A. (2015a). The impact of returned product disposition strategies on organizational performance applied to the Egyptian household appliance industry. International Journal of Business and Management, 10(9), 143.

- Attia, A. (2015b). Testing the effect of marketing strategy alignment and triple-A supply chain on performance in Egypt. EuroMed Journal of Business, 10(2), 163-180.

- Attia, A.M. (2013). Logistics strategy in Egypt: An empirical study on the pharmaceutical industry. In 2013 International Conference on Advanced Logistics and Transport. IEEE.

- Bernon, M., Rossi, S., & Cullen, J. (2011). Retail reverse logistics: A call and grounding framework for research. International Journal of Physical Distribution & Logistics Management, 41(5), 484-510.

- Bharadwaj, A.S. (2000). A resource-based perspective on information technology capability and firm performance: an empirical investigation. MIS Quarterly, 169-196.

- Blumberg, D.F. (1999). Strategic examination of reverse logistics & repair service requirements, needs, market size, and opportunities. Journal of Business Logistics, 20(2), 141.

- Chopra, S., & Meindl, P. (2007). Supply chain management. Strategy, planning & operation. In Das summa summarum des management, 265-275.

- Closs, D.J., Goldsby, T.J., & Clinton, S.R. (1997). Information technology influences on world class logistics capability. International Journal of Physical Distribution & Logistics Management, 27(1), 4-17.

- Closs, D.J., & Savitskie, K. (2003). Internal and external logistics information technology integration. The International Journal of Logistics Management, 14(1), 63-76.

- Daugherty, P.J., Autry, C.W., & Ellinger, A.E. (2001). Reverse logisitics: The relationship between resource commitment and program performance. Journal of Business Logistics 22(1), 107-123.

- Daugherty, P.J., Myers, M.B., & Richey, R.G. (2002). Information support for reverse logistics: The influence of relationship commitment. Journal of Business Logistics, 23(1), 85-106.

- Daugherty, P.J., Richey, R.G., Genchev, S.E., & Chen, H. (2005). Reverse logistics: superior performance through focused resource commitments to information technology. Transportation Research Part E: Logistics and Transportation Review, 41(2), 77-92.

- Day, G.S. (2000). Managing market relationships. Journal of the Academy of Marketing Science, 28(1), 24-30.

- Ellram, L.M., & Cooper, M.C. (1990). Supply chain management, partnership, and the shipper-third party relationship. The International Journal of Logistics Management, 1(2), 1-10.

- García-Sánchez, E., Guerrero-Villegas, J., & Aguilera-Caracuel, J. (2019). How do technological skills improve reverse logistics? The moderating role of top management support in information technology use and innovativeness. Sustainability, 11-58.

- Garver, M.S., & Mentzer, J.T. (1999). Logistics research methods: employing structural equation modeling to test for construct validity. Journal of Business Logistics, 20(1), 33-57.

- Genchev, S.E., Glenn Richey, R., & Gabler, C.B. (2011). Evaluating reverse logistics programs: A suggested process formalization. The International Journal of Logistics Management 22(2), 242-263.

- Grawe, S.J., Daugherty, P.J., & Roath, A.S. (2011). Knowledge synthesis and innovative logistics processes: Enhancing operational flexibility and performance. Journal of Business Logistics, 32(1), 69-80.

- Hazen, B.T., & Byrd, T.A. (2012). Toward creating competitive advantage with logistics information technology. International Journal of Physical Distribution & Logistics Management , 42(1), 8-35.

- Huscroft, J., Hazen, B.T., Hall, D.J., Skipper, J.B., & Hanna, J.B. (2013). Reverse logistics: past research, current management issues, and future directions. The International Journal of Logistics Management, 24(3), 304-327.

- Iacovou, C.L., Benbasat, I., & Dexter, A.S. (1995). Electronic data interchange and small organizations: Adoption and impact of technology. MIS Quarterly, 465-485.

- Jeon, J. (2015). The strengths and limitations of the statistical modeling of complex social phenomenon: focusing on SEM, path analysis, or multiple regression models. International Journal of Economics and Management Engineering, 9, 1559-1567.

- Kenny, D.A. (2012). Multiple factor models: Confirmatory factor analysis.

- Kline, R.B. (1998). Principles and practice of structural equation modeling. New York, NY: Guilford Press

- Koufteros, X.A. (1999). Testing a model of pull production: a paradigm for manufacturing research using structural equation. Journal of Operations Management, 17(4), 467-488.

- Krejcie, R.V., & Morgan, D.W. (1970). Determining Sample Size for Research Activities. Educational and Psychological Measurement, 30(3), 607.

- Lee, H.L. (2000). Creating value through supply chain integration. Supply Chain Management Review, 4(4), 30-36.

- Mollenkopf, D.A., Rabinovich, E., Laseter, T.M., & Boyer, K.K. (2007). Managing internet product returns: A focus on effective service operations. Decision Sciences, 38(2), 215-250.

- Morgan, T.R., Richey Jr, R.G., & Autry, C.W. (2016). Developing a reverse logistics competency: The influence of collaboration and information technology. International Journal of Physical Distribution & Logistics Management, 46(3), 293-315.

- Nevo, S., & Wade, M.R. (2010). The formation and value of IT-enabled resources: antecedents and consequences of synergistic relationships. MIS quarterly, 163-183.

- Nuss, C., Sahamie, R., & Stindt, D. (2015). The reverse supply chain planning matrix: A classification scheme for planning problems in reverse logistics. International Journal of Management Reviews, 17(4), 413-436.

- Podsakoff, P.M., MacKenzie, S.B., Lee, J.Y., & Podsakoff, N.P. (2003). Common method biases in behavioral research: A critical review of the literature and recommended remedies. Journal of Applied Psychology, 88(5), 879.

- Porter, M.E. (2008). Competitive advantage: Creating and sustaining superior performance: Simon and Schuster.

- Richey, R.G., Chen, H., Genchev, S.E., & Daugherty, P.J. (2005). Developing effective reverse logistics programs. Industrial Marketing Management, 34(8), 830-840.

- Russell, D.M., & Hoag, A.M. (2004). People and information technology in the supply chain: Social and organizational influences on adoption. International Journal of Physical Distribution & Logistics Management, 34(2), 102-122.

- Schultmann, F., Zumkeller, M., & Rentz, O. (2006). Modeling reverse logistic tasks within closed-loop supply chains: An example from the automotive industry. European Journal of Operational Research, 171(3), 1033-1050.

- Stank, T.P., Emmelhainz, M.A., & Daugherty, P.J. (1996). The impact of information on supplier performance. Journal of Marketing Theory and Practice, 4(4), 94-105.

- Stock, J.R., & Lambert, D.M. (2001). Strategic logistics management. McGraw-Hill/Irwin.

- Swanson, R.A., & Holton, (2005). Research in organizations: Foundations and methods in inquiry. Berrett-Koehler Publishers.

- Williams, L.R., Nibbs, A., Irby, D., & Finley, T. (1997). Logistics integration: The effect of information technology, team composition, and corporate competitve positioning. Journal of Business Logistics, 18(2), 31.