Research Article: 2021 Vol: 20 Issue: 6S

The Effect of Lean Supply Chain Activities in Reducing Pollution in Manufacturing Processes a Field Study of the Iraqi Central Refineries Company - Dora Refinery as a Sample

Suzan-Abdul Ghani-Ali, Kirkuk University

Nahda Ali Abbas, ALMustansiriyah University

Mohamed Sodad A Wnal Rafek, Kirkuk University

Abstract

The Research aims to present and analyze the indicators of the activities of the lean supply chain (lean procurement, lean transportation, lean storage) and their impact on achieving a high level of pollution reduction in manufacturing processes (waste management, renewable energy, environmental education), the research problem crystallized in the following question (Do the activities of the lean supply chain affect the reduction of pollution in the manufacturing processes in the midland refineries company? What is the nature of the relationship between the two variables?), the midland Refineries Company was chosen to accommodate the applied field space for the research and its main tools represented by the questionnaire designed to test the aforementioned variables, That is, when the organization’s management is more interested in purchasing, transporting and storing the inputs in a lean form and manner, this will result in achieving a higher level of pollution reduction in the manufacturing processes in those organizations, The research concluded with a number of recommendations, the most important of which is the need to raise the level of interest in the axis of environmental pollution in its general form and in particular what is produced by industrialization processes, as it is an important source for the strategic orientation of contemporary organizations and at the same time it is an obsession that moves the whole world and the preoccupation of humanitarian and human rights organizations and others, therefore it is not an option for organizations as much what is inevitable.

Keywords

Lean Supply Chain Activities, Reducing Pollution in Manufacturing Processes

Introduction

In light of the continuous and relentless pursuit of companies to seize all the opportunities that appear in the business environment and follow up the state of development in modern technologies in the field of business in order to increase their market share and establish a solid base for the competitive advantage of each of them, in light of the rapid technological and information development and the enormous information revolution that dominated all business sectors in the world, specifically the organizations operating in the oil industry sector, as a result of the frenzied competition that dominated this sector, the impact of adopting modern approaches to managing supply chains in this sector has clearly emerged clearer, As the processing operations in this industry and its development push for the expansion of the commercial market by creating more sophisticated and modern entrances and mechanisms that were difficult to build through traditional frameworks in industry, export and exchange.

During the past years, the pace of concern for the level of pollution has increased in the world as a whole, and it has become a preoccupation for international organizations, human rights institutions and states, and conferences have been held and agreements and other activities have been concluded that set environmental pollution as a basic standard that controls the activities of all individuals, organizations and societies, which the research seeks to explain in more detail, the research included four sections, the first includes the methodology, while the second one was devoted to studying the research variables, activities of the lean processing chain and the reduction of pollution in manufacturing processes, while the third section was devoted to the field and statistical study of the sample data and the fourth section included the most important conclusions and recommendations that came out of the research.

Methodology Research

The Research Problem

Therefore, the problem of research lies in answering the following main question: -

Do the activities of the lean supply chain affect the reduction of pollution in the manufacturing processes in the midland refineries company? What is the nature of the relationship between the two variables?

A number of the following sub-questions stem from this main question:-

1- What are the most prominent philosophical contributions of the two variables of research embodied in each of (the lean processing chain and pollution in manufacturing processes).

2- What is the degree of awareness and understanding of the characteristics and concepts of the research variables and their relationship with the responsibilities entrusted to the administrations of the researched organization?

The Importance of Research

The research, after realizing the scientific and practical frameworks, and the interaction between them, is expected to achieve the following importance:

1-The importance of demonstrating the theoretical continuity of the relationship between the two variables (lean supply chain activities and reducing pollution in manufacturing processes.

2-The importance of research stems from the distinguished position that supply chains occupy in general and lean ones in particular in contemporary management thought.

The Aims of Research: Objectives of the Research can be Drawn with the Following Points

1- Providing concerned and interested parties with practical and theoretical information that clarifies the nature of the research variables, their sources, their causes and the extent of their reflection on the research sample to direct the attention of the management of the researched organization and make it more suitable for the reality of the required performance in light of the turmoil and uncertainty of the Iraqi work environment.

2- Opening the way for researchers to launch towards future studies and research on the role and impact of the activities of the lean processing chain and its relationship to other variables in other applied fields.

Fourth- Research Hypotheses

It is like a guess that researchers arrive at and adhere to temporarily, as it is more like a preliminary opinion in solving the problem and answering the research questions, and it is not a random conclusion but is based on information expressing the causes and dimensions that made the research problem and based on it the following main and sub-hypotheses were formulated: -

The first main hypothesis there is a correlation between the activities of the lean supply chain and the reduction of pollution in the manufacturing processes of the Midland Refineries Company.

A number of sub-hypotheses emerge from this hypothesis:-

1. There is a statistically significant correlation between the lean procurement activity and the reduction of pollution in the manufacturing processes of the Midland Refineries Company.

2. There is a statistically significant correlation between the lean transport activity and the reduction of pollution in the manufacturing processes of the Midland Refineries Company.

3. There is a statistically significant correlation between the activity of lean storage and the reduction of pollution in the manufacturing processes of the Midland Refineries Company.

The second main hypothesis there is a statistically significant impact relationship to the adoption of the activities of the lean supply chain in reducing pollution in the manufacturing processes of the Midland Refineries Company.

A number of sub-hypotheses emerge from this hypothesis:-

1. There is a statistically significant impact relationship with the adoption of lean procurement activity in reducing pollution in the manufacturing processes of the Midland Refineries Company.

2. There is a statistically significant impact relationship with the adoption of the lean transport activity in reducing pollution in the manufacturing processes of the Midland Refineries Company.

3. There is a statistically significant impact relationship with the adoption of the lean storage activity in reducing pollution in the manufacturing processes of the Midland Refineries Company.

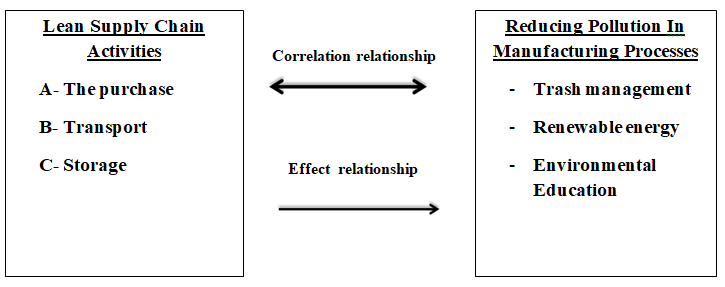

The Hypothetical Outline of the Research

As in Figure 1, As the hypothetical chart of the research refers to the hypotheses that are basically built on the possibility of measuring each variable, as the two-way arrow represents the correlation relationship, while the one-way arrow represents the impact hypothesis, and this chart includes the main and secondary research variables.

Figure 1: The Hypothetical Outline Of The Research

Reference: The figure was prepared by the researchers

Research Community and Sample

A simple random sample was chosen from the group of managers working in the Central Refineries Company at different administrative levels, and some of them are directly dealing with the vocabulary of the research, and some of them are indirectly related, but in the end, the work in the company forms a single unit in which everyone is an influential and influential component of the variables. Which was dealt with by the research, and 50 individuals of the company’s managers were selected and through the statistical indicators, this sample is considered sufficiently adequate and representative of the nature and characteristics of the community of managers and in light of this, 55 forms were distributed, 5 of which were considered invalid or neglected, and were approved. Results and data of (50) questionnaires,

The Theoretical Framework

Lean Supply Chain Activities

Concept

The idea of lean manufacturing as a philosophy and a way of thinking in the field of production and operations is not recent, but rather as a result of the accumulation of efforts made in the field of developing productive work and improving methods of operations. Most specialists return that the origin of this idea was in Japanese companies, particularly the famous TOYOTA Company, especially the deputy director. Taichi Ohno and his assistant Shigo Shingo and with the introduction of the book The Machine That Changed the World authored by both Womack. P James/Daniel Jones/Daniel Roosini specifically in the year 1991, this important author showed that the Japanese company focused on getting rid of all that is extra in the production process, as the authors showed that waste is all that does not add value to the production process. regarding the lean supply chain, it can be defined as all activities through which goods, services and information flow in two directions from the stage of raw materials from suppliers to the stage of finished goods without any waste (Khanna, 2007), while) Frdogan, 2009 ( defined it as that well-designed chain that provides a rapid delivery of products to the final consumer while reducing all forms of waste to a minimum with a rapid response to change. Johansson (2010) defined it as the net of activities through which products flow easily through the chain, which aims to provide added value to consumers by meeting their needs while avoiding any form of waste and errors along the chain.

Lean Supply Chain Activities

By informing the researchers of the various sources that dealt with the topic of activities involved in supply chains in their general form and lean ones in particular, I found a great diversity and diversity in those activities, but the research will be limited to three of them as they are the most prominent and most important for the organization that The research sample (Jabr & Abdullah, 2017).

Lean Purchase

Purchasing is one of the supporting activities referred to by Porter in the value chain and integrated into the supply chain to improve its administrative procedures. The purchase costs of raw materials and various supplies take up a high percentage of the total costs of the organization. In the field of industries, the cost of purchasing operations ranges 60%-70% of the cost Hence, the great interest in the concept of lean procurement processes came to address the problem of high purchasing costs and to meet the challenges of market fluctuations, short product life cycles, false predictions, and the increasing and diversification of consumers’ needs and desires (Reddy et al., 2016( . Lean procurement depends on a true understanding of what the needs and desires are and conveying this accurate picture to suppliers to determine what the organization needs from the inputs and provide them by them, lean procurement is characterized by its ability to reduce costs and prices by building strong relationships with suppliers, to make the purchasing activity lean requires adherence to the set of practices of these practices are (Costantino et al., 2015), Continuous improvement/relationship with suppliers/relationship with customers/timely supply/synchronization of production schedules with the logistics function.

Lean Transportation

Specialists believe that many organizations, in various fields of work, have adopted the approach of graceful transportation, due to their belief in the value it adds and their ability to eliminate waste, which is inevitable in the performance of most organizations, and (Arriaga et al., 2013 ( believes that lean transportation can be considered a strategic direction aimed at eliminating waste through the transportation process. The results of his study indicated that lean transportation can reduce the production cycle time by 46%, the number of roads by 35%, and reduce packaging losses by 60%,which is a reduction in the overall overhead costs, The adoption of lean transportation contributes to improving the efficiency of the transportation process by eliminating waste in transportation processes represented in waiting times, services that do not add value and excessive distances, as well as delivering materials and products to customers on time, which enhances the improvement of the services provided (Hezbon, 2016) .

Lean Storage

Lean storage activity is considered one of the most important activities in industrial and service systems. Production systems and supply chains depend on this vital activity for its great impact on the quality and cost of products and the level of service provided, it uses lean with warehousing to improve its operations and maintain inventory and to reduce operations that do not add value and reduce warehouse spaces. It also contributes to the collection and management of warehousing orders in the best way and achieves efficiency in them, which reduces activities that do not add value in receiving, warehousing, packaging, shipping of materials and also contributes By increasing response to customer demand and reducing high costs by simplifying distribution processes (Manzini, 2012).

Pollution in Manufacturing Processes

The Concept

Industrial pollution is defined as (that unwanted change that industrial waste causes in the natural, chemical and biological lines of the surrounding environment from the desert, water and soil that leads to direct or indirect harm to living organisms or causes disturbance in human living conditions. Ebadi (2010) While (Al-Mahshoul, 2013) defined it as the environmental effects and changes caused by all kinds of waste as a result of various industrial activities that have a direct or indirect negative impact on humans and environmental components in general, It was also defined by (Hassan & Al-Na’ma, 2020) as that damage to the ecosystem as a result of the activity of industrial organizations,

Types of Industrial Pollution

Of course, the problem of pollution is so vast and complex that it is difficult to limit it to a specific form or pattern, but the most prominent types can be clarified through the following points:-

A- Physical pollution: It is divided into a number of types, namely (Al-Azzawi & Al-Naqar, 2015)

Air pollution includes a number of manifestations, including physical particles and gases/water pollution includes chemical, physical and biological pollutants/soil pollution and is the result of the use of harmful substances or irrational exploitation and cultivation of narcotic substances and other polluting practices/radioactive pollution and varies according to levels and degrees of impact or equivalent dose.

B- Non-physical pollution: it is divided into a number of groups as follows ( Al-Shahat, 2011)

Reducing Pollution in Manufacturing Processes

stands the most important and largest international organization the United Nations UN and its subsidiary organizations specialized in protecting the environment and reducing pollution levels, which is the most prominent sponsor of all agreements and legislation in this field to the extent that environmental impacts and pollution have reached one of the criteria that can be a reason for closing a factory or stopping a certain activity, etc., In this context, the researcher reviewed many of the mechanisms adopted to reduce pollution in manufacturing processes. The most prominent of them will be exposed, according to the researchers’ point of view, which will be the sub-dimensions that will be addressed in the theoretical side of the study as follows:-

A- Waste Management: It is defined as all treatment processes for wastes that are dangerous to the lives of individuals and living organisms in general, according to their nature or quantities, such as collection, disposal, recycling, and others (Ghazi, 2010).

Industrial waste has many economic, health and environmental impacts when mismanaged with the risk of being transferred to open, uncontrolled landfills. Thus, the importance of waste treatment emerges as it constitutes a basic and urgent issue that needs radical solutions.

B-Recycling: It is the reuse of waste to produce other products similar to the original product. It is a strategy in place in many different countries, organizations and industries.

• Heat recovery, which includes burning waste in safe ways to produce thermal energy used in industrial projects, heating, and other fields.

And) Al-Ansari, 2009( indicates that the process of waste management has many benefits, the most important of which are:

• Reducing production costs as a result of improving efficiency and good management of various projects.

• The economic resource through the use of waste in other production processes.

• Waste management operations can be a source of providing many job opportunities.

Renewable Energy

Renewable energy is defined as energy derived from natural resources that do not run out and are constantly renewed, such as wind, water and the sun available in most countries of the world, and can also be produced from movement and tides or from geothermal energy and other innovations )OAPEC, 2019( The 2015 Paris Agreement, as the most important outcome of the United Nations Climate Change Conference No. 21, has had a significant impact on many countries of the world, especially developing countries, where, as of 2016, they have shown greater interest in specific voluntary national contributions to reduce the effects of climate change and achieve sustainable development aims, including the seventh energy aim, by including renewable energy aims in its national plans to diversify the energy mix and developing and implementing related policies.

Environmental Education

Environmental education, according to American law, is defined as (an educational process concerned with the relationships between man and nature, and includes the human relationship and pollution, resource distribution, depletion and conservation, transportation, technology, urban and rural planning with the overall human environment) (Adnan et al., 2007).

• Raising the level of public awareness of the importance of the various environmental vocabularies and considering it the main source for preserving the life of different organism.

• Providing individuals with the skills and ideas that put them in an advanced position in the process of dealing with the general environment and building sound environmental behavior.

The Field Study

Presenting the Results of the Sample Members' Responses

To measure the level of response of the sample members, the answers were transformed on the five-point Likert scale that is distributed from the highest weight, which was given 5 scores to represent the answer field completely agree to its lowest weight, and which was given 1 one score to represent the answer field I do not agree at all And between them, three other weights are 2,3,4 to represent the answer fields agree, neutral, disagree respectively.

On the other hand, the hypothetical mean 3 was adopted as a criterion for measuring and evaluating the degree obtained through the responses of the sample members, within the verbal estimate of the weights of the five questionnaire form, noting that the hypothetical mean 3 is the arithmetic mean of the scale weights, according to the following equation:

Based on the foregoing, a detailed description of the responses of the sample members will be given:-

A- Presentation of the results of the responses of the sample members about the elements of the lean supply chain activities variable:- Table (1) below indicates the general description of the responses of the sample members to the variable Lean supply chain activities and its sub-elements.

| Table 1 Results of Variable Analysis of Lean Supply Chain Activities N=50 |

||||||

|---|---|---|---|---|---|---|

| Seq | Lean supply Chain Management | Arithmetic Mean | Standard Deviation | Variation Coefficient | Weight Percentile | Relative Arrangement |

| 1 | Lean purchase | 3.47 | 1.24 | 0.35 | 55.22% | the third |

| 2 | lean transport | 3.53 | 1.18 | 0.33 | 55.15% | The second |

| 3 | lean storage | 3.46 | 1.12 | 0.32 | 54.33% | the first |

| lean supply chain management | 3.48 | 1.18 | 0.33 | 56.64% | ||

It is clear from the above table that the variable of lean supply chain activities came with a weighted average of 3.48, which is slightly higher than the hypothetical mean, with a standard deviation of 1.18, percentage weight 56.64% and a coefficient of variation 0.33, Through the mentioned values, which indicate the rise in the average variable of the lean supply chain management variable from the hypothetical average at a slight level, it can be said that the management of the company urgently and necessary needs, If it wants to enter the real competition market and adopt the mechanisms of modern work, to strive to actively seek to understand and adopt the methodology, mechanisms and programs for managing the modern lean supply chain in a more effective manner and to establish programs effectively and efficiently at a higher level.

B- Presenting the results of the sample members’ responses about the dimensions of pollution reduction in manufacturing Processes: Table 2 below indicates the general description of the sample members' responses to the variable dimensions of reducing pollution in manufacturing processes and its sub-elements.

| Table 2 The Results of Analyzing The Pollution Reduction Dimensions Variable in Manufacturing Processes N=50 |

||||||

|---|---|---|---|---|---|---|

| Seq | Lean supply Chain Management | Arithmetic Mean | Standard Deviation | Variation Coefficient | Weight Percentile | Relative Arrangement |

| 1 | Waste management | 3.39 | 1.2 | 0.35 | 51.64% | The third |

| 2 | Renewable energy | 3.42 | 1.1 | 0.32 | 50.00% | The second |

| 3 | Environmental education | 3.24 | 1.21 | 0.37 | 45.08% | The first |

It is clear from the results contained in the table above, that the reduction of industrial pollution in the researched company in question came with a weighted average of 3.35, which is slightly higher than the hypothetical mean, with a standard deviation of 1.17 and a percentage weight of 48.90%, it is clear from the results contained in the table above, that the reduction of industrial pollution in the researched company in came with a weighted average of 3.35, which is slightly higher than the hypothetical mean, with a standard deviation of 1.17 and a percentage weight of 48.90%.

Third: Analyzing and testing the correlation between the research variables:

This paragraph is concerned with measuring the correlation between the research variables included in the first main hypothesis, which states there is a correlation between the activities of the lean supply chain and the reduction of pollution in the manufacturing processes in the Iraqi Central Midland Refineries Company, The simple correlation coefficient was used in order to discover the nature of the relationship contained in this hypothesis, and Table 3 shows the results of the correlations between the elements of the lean supply chain management and the reduction of pollution in the manufacturing processes.

| Table 3 Results of The Correlation Between the Activities of the Lean Supply Chain and the Reduction of Pollution in the Manufacturing Processes |

|||||

|---|---|---|---|---|---|

| Dependent variable Independent Variable | Reducing pollution in manufacturing processes | ||||

| R | Calculated T | TableT | Level of significance | Degree of confidence | |

| Lean purchase | 0.93 | 3.64 | 2.353 | 5% | 95% |

| Lean transport | 0.96 | 6.019 | 4.541 | 1% | 99% |

| Lean storage | 0.98 | 9.566 | 4.541 | 1% | 99% |

| Total index | 0.95 | 6.467 | 4.604 | 1% | 99% |

In order to give a sound scientific decision regarding the acceptance of the first main hypothesis, and based on the results contained in Table 3, it is necessary to test the sub-hypotheses emanating from it as follows:-

A - Testing the first sub-hypothesis there is a statistically significant correlation between the Lean Purchasing Activity and pollution reduction in the manufacturing operations of Midland Refineries Company.

Table 3 indicates that there is a significant correlation between lean purchasing activity and reducing pollution in manufacturing operations, as the value of the correlation coefficient between them reached 0.93, a value that reflects the existence of a positive relationship with statistical significance at a confidence level 95%, This link reinforces the importance of adopting lean mechanisms in procurement processes for different inputs in achieving a distinct level in reducing pollution in manufacturing processes in line with the international standard for industrial work, which is a relationship of significant significance, which confirms that the calculated T value amounted to 3,640, which is greater than The Table value of T is 2.353 at the level of significance 5%, and accordingly, the first sub-hypothesis is accepted.

B - Testing the second sub-hypothesis there is a statistically significant correlation between the activity of lean transport and the reduction of pollution in the manufacturing processes in Midland Refineries Company

It is evident from Table 3 that there is a significant correlation between the transport activity in its lean form and the reduction of pollution in manufacturing processes, as the value of the correlation coefficient between them reached 0.96, which is a high value that means that there is a positive relationship with statistical significance with a confidence level of 99%, this relationship indicates that the more attention is paid to the elements and vocabulary of transportation processes means, distances, timings, this leads to an improvement in the level of performance that ensures the reduction of wasted energy and what is the result of excessive transportation operations, which necessarily means a greater level of pollution operations, and it is a related relationship Significant significance, as the calculated value of T reached 6.019, which is greater than the table value of T 4.541 at a significant level 1%, and accordingly, the second sub-hypothesis is accepted.

C - Testing the third sub-hypothesis there is a statistically significant correlation between the activity of lean storage and the reduction of pollution in the manufacturing processes of the Midland Refineries Company.

Table 4 shows that there is a significant correlation between the element of lean storage and pollution reduction in manufacturing processes, as the value of the correlation coefficient between them reached 0.98, a value that reflects the existence of a strong positive relationship with statistical significance at a confidence level 99%, this relationship explains that the more closely these standards are established and entrenched in storage operations, the more this leads to an increase in the ability of the operating organizations to achieve a higher level of pollution, as the less quantity of stock means less need for warehouse management energies, for example, which causes greater waste in the necessary fuel. Thus, a higher state of emission of exhaust harmful to the environment and causing pollution and other negative phenomena associated with a greater increase in storage operations, It is a significant relationship, as the calculated T value was 9.566, which is greater than the Table T value 4,541 at the level of significance %1, and based on that, the third sub-hypothesis was accepted.

Since the three sub-hypotheses stemming from the first main hypothesis were accepted, so the first main hypothesis is accepted

Analyzing and Testing the Influence Relationships between the Research variables

This paragraph deals with the analysis of the influence relationships of the elements of e-marketing on customer satisfaction in order to test the second main hypothesis of which here is a statistically significant influence relationship to adopt the activities of the lean supply chain in reducing pollution in the manufacturing processes in the Midland Refineries Company, Table 4 shows the results of the influence relationships between the variables.

| Table 4 Results of the Influence Relationships of Lean Supply Chain Activities in Reducing Pollution in Manufacturing Processes |

||||||

|---|---|---|---|---|---|---|

| Regression Sample Number | Independent Variables | Dependent Variables | β | T | Modified Coefficient Of Determination (r²) | The Value Of F and the Significance of the Sample |

| 1 | Lean purchase | -Waste Management -Renewable energy -Environmental Education | 0.749 | 7.488 | 0.550 | ** 56.077 |

| 2 | Lean transport | -Waste Management -Renewable Energy -Environmental Education | 0.763 | 7.833 | 0.573 | ** 61.361 |

| 3 | Lean storage | -Waste Management -Renewable energy -Environmental Education | 0.778 | 8.219 | 0.597 | ** 67.551 |

| 4 | Lean supply chain | Reducing Pollution in Manufacturing Processes | 0.645 | 5.600 | 0.603 | ** 31.365 |

| ** At the level of significance 0.01 | ||||||

From the above Table, the following can be seen:

1- Testing the sub-hypothesis which states there is a significant effect relationship for the adoption of lean purchasing activity in reducing pollution in manufacturing processes in the Midland Refineries Company, where testing the effect of lean purchasing activity on the elements of the pollution reduction variable in manufacturing processes indicated multiple results where there were multiple results where The F value calculated to measure the effect of these independent variables 56.077 with a significant level of 0.01, In addition, the calculated value T was 7.488 with a significant level of 0.01. In both tests, the calculated value was greater than the table value, and this indicates the validity of the sub-hypothesis. This moral effect is explained by the adjusted coefficient of determination r² of 0.550, meaning that the percentage of the explanatory difference in the term The percentage of pollution in manufacturing processes due to the impact of the lean purchasing activity is no less than 55%, and the remaining percentage of change is due to other factors, also, the value of β has reached 0.749, which indicates that the change that occurs in the lean procurement processes by one unit leads to a change in the elements of reducing pollution in the manufacturing processes by 0.749.

Testing the sub-hypothesis that states there is a significant effect relationship for adopting lean transport activity in reducing pollution in manufacturing processes in the Midland Refinery Company, With regard to the effect of the lean transport activity, according to the regression sample No. 2, the value of F calculated for this sample was 61.361 with a significant level of 0.01,the value of T calculated was 7.833 with a significant level 0.01, and each of the two calculated values was higher than the tabular. This confirms the validity of the sub hypothesis and this significant effect is explained by the modified determination coefficient r² of 0.573, This shows that the percentage of change in the elements of reducing pollution in manufacturing processes resulting from the change in lean transport processes is not less than 57%, and the value of β has reached 0.763, which indicates that the change that occurs in lean transport is by one unit. Lead to a change in pollution reduction in manufacturing processes by 0.763.

3- Testing the sub-hypothesis there is a significant effect relationship for adopting lean storage activity in reducing pollution in manufacturing processes in the Midland Refinery Company, as for the effect of the lean storage activity according to the regression sample No. 3, the following results were indicated, where the value of F for this sample was 67,551 with a significant level (0.01) and the value of T calculated was 8.219 with a significant level 0.01. The two calculated values are higher than the table value, and this confirms the validity of the sub-hypothesis, and this significant effect is explained by the adjusted coefficient of determination r² of 0.597, and this shows that the percentage of the impact of lean storage activity in reducing pollution in manufacturing processes is no less than 59%, Also, the value of β reached 0.778, which indicates that the change that occurs in the lean storage activity by one unit leads to a change in the reduction of pollution in the manufacturing operations by 0.778.

4-Test the second main hypothesis there is a statistically significant impact relationship for adopting the activities of the lean supply chain in reducing pollution in the manufacturing processes in the midland refineries company with regard to the tests of the lean supply chain variable, the tests showed the following results according to the regression sample No. 4, where the F value of this sample was 31.365 with a significant level of 0.01, and the calculated T value was 5.600 with a significant level 0.01. And each of the two calculated values was higher than the table value, and this confirms the validity of the main hypothesis, and this significant effect is explained by the coefficient of determination r² of 0.603, this shows that the effect of the lean supply chain in reducing pollution in the manufacturing processes is not less than 60%, and the value of has reached 0.645, which indicates that the change that occurs in the activities of the lean supply chain by one unit leads to a change In the elements of reducing pollution in manufacturing processes by 0.645.

Conclusion

1- Conclusions of the theoretical side: Through what the research presented of details, opinions and viewpoints of the various studies and sources that dealt with the research variables, a number of conclusions can be indicated as follows:

A- The lean supply chain can be considered the most influential element in the work of modern organizations, which depended in all production activities on lean programs and mechanisms,

B- The attention of international organizations today, regardless of the scope of their work, is directed towards monitoring the performance of any institution or organization and the resulting damages affecting the general environment and raising the levels of pollution, which has begun to take forms of legislation and more stringent laws and is based on the importance of reducing pollution in manufacturing processes.

2- Conclusions of the field side: Through the results of the field study adopted by the two researchers, the following points can be indicated:

A- Results of the field study of the variable Lean supply chain activities:

1- Lean warehousing activity ranked first, which indicates the vitality and importance of the vocabulary of warehousing operations, as it is one of the most important concerns for working departments and the financial and human costs.

2- Lean transport activity came in the second place in the Lean Supply Chain, which indicates that the organization's departments are required to build a structure for transport operations in a systematic and scientific.

3- The Lean Procurement activity ranked third in the ranking of the elements of the Lean Supply Chain activities, which indicates the incompleteness of the picture regarding the establishment of clear frameworks for the standards of this particular activity in the company under study.

Recommendations

In light of the previous results, the two researchers point out a set of recommendations, including the following:-

1- Due to the rapid changes facing the work environment which requires the working departments to have high-level cognitive knowledge and an increase in the skills and programs of lean supply chains and their various activities, so they need to build an information base for lean processing activities based on the advanced digital foundation.

2- Setting high standards for purchasing operations by defining distinct specifications and various sources and mechanisms in a way that secures production requirements on a unique level and the attempt to work outside the traditional and routine frameworks.

3- Developing the efficiency of different transport operations by assigning specialized teams to new tasks characterized by diversity and higher levels of cognitive skills in order to reduce the waste of time,

4- Adopting modern programs in warehousing strategies that have reached advanced levels in international companies, as traditional stores have disappeared in many international organizations now and have been replaced by more sophisticated and graceful forms of the store.

References

- Al Mahshoul, A.H.A. (2013). The foundations of continuous improvement and their role in promoting methods of reducing industrial pollution, an exploratory study in the General Company for Mishraq Sulfur and Hammam Al-Alil Cement Factory in Nineveh Governorate, unpublished master's thesis, College of Administration and Economics, University of Mosul.

- Al-Ansari, M.A. (2009). Environmental pollution: Modern dangers and a scientific response, Dar Degla, Amman, Jordan.

- Asmaa, A. (2010). Media treatment of industrial pollution in the Algerian press, an analytical study of the Algerian newspaper EL Watan. Master Thesis, Faculty of Humanities and Social Sciences, University of Mentouri Constantine, Algeria.

- Al-Azzawi, N., & Al-Naqqr, A. (2015). Strategy and requirements of environmental management.

- Dar Al-Yazouri, & Amman - Jordan El-Shahat H.A.L. (2011). Chemical pollutants and their effects on health and the environment. University Publishing House, Cairo, Egypt.

- Abdel, W.S. (2017). Risks of industrial pollution and methods of dealing with it, a case study of the industrial sector in Algeria. PhD thesis of the Faculty of Economic, Business and Management Sciences, Arabi Ben Mahidi Oum El Bouaghi University, Algeria.

- Adnan, M. (2007). Contemporary Issues. Dar Wael, Amman, Jordan.

- Arriaga, J., Cárdenas, C., Rivera, J., & Sada, J. (2013). A lean route to increase transportation lean and food freshness, proceedings of the 2013 industrial and systems engineering research conference Krishnamurthy, A., & Chan, W.K.V. Editions.

- Abdel-Hay, R.A. (2014). Environmental education in the light of the third millennium. Dar Al-Warraq, Amman - Jordan.

- Costantino, F., Gravio, G., & Nonino, F. (2015). Insights from action research: implementing an innovative lean procurement framework for global sourcing. International business management journal, 9(4).

- Ghazi, A.A. (2010). The industrial environment: Its improvement and ways to protect it. Dar Degla, Amman, Jordan.

- Hassan, M.M., & Al-Naama, A.Z. (2020). the role of some sustainable supply chain management activities in reducing pollution resulting from manufacturing processes in industrial organizations, a field study in the North Refineries Company/Qayyarah Refinery in Nineveh Governorate, Tikrit University/College of Administration and Economics. Journal Tikrit for Administrative and Economic Sciences, 16(25).

- Hezbon, K. (2016). Lean supply chain management and operational performance of Almasi beverages company limited. Unpublished MBA project, University of Nairobi.

- Johansson, E. (2010). Can lean be mean? A study of negative consequences of lean in supply chains. Master’s Thesis in Business Administration.

- Khanna, N. (2007). “An ontology for a lean supply chain”. A thesis of bachelors of engineering Agra university India.

- ?ukasz, D. (2012). The origins and evolution of lean management system. Journal of International Studies, 5(1).

- Manzini, R. (2012). Warehousing in the global supply chain: Advanced models, tools and applications for storage systems, Springer-Verlag London Limited.

- Midland Refineries Company official website (https://mrc.oil.gov.iq/).

- OPEC report, (2019). Reality and prospects of renewable energies in the global energy mix and potential repercussions on the oil industry.