Research Article: 2019 Vol: 18 Issue: 1

The Role of Total Quality Management in the Face of Challenges: A Study in Lafarge-Jordan

Asaad Hameed Al-Ali, Al-Ahliyya Amman University Amman

Ayman Abu-Rumman, Al-Ahliyya Amman University Amman

Abstract

This paper presents the findings of a study investigating how the application of Total Quality Management (TQM) can help organizations to tackle the different business challenges brought about as a consequence of the recent global financial crisis including those associated with planning, cost reduction and increasing competition. The study focuses on the experiences of employees based within the leading concrete and cement producer ‘Lafarge-Jordan’. Using a qualitative approach and the use of convenience sampling, a questionnaire was developed to gather the views of the company’s employees on the perceived impact of TQM in their organization on its ability to meet different business challenges. 73 employees completed the survey. Partial Least Squares (PLS) were chosen using SmartPLS 3 software with a two-stage approach in measurement and structural model testing. The results showed that customer focus and senior management support are the two most important variables that enhance the ability to face different types of challenges. Integrative relationships with suppliers and continuous improvement were found also to have a significant impact on reducing quality costs to help overcome competition. Based on the previous literature and results, this research recommends the orientation towards greater employee involvement because they are the cornerstone to successful TQM; further, it is more advantageous to analyze both the soft and hard effects of TQM to overcome challenges.

Keywords

Total Quality Management (TQM), TQM Dimensions, Overcome Challenges, Lafarge-Jordan.

Introduction And Problem

Many companies are facing significant challenges as a result of the global financial crisis which has affected their ability to practice their main activities and gain profits. These challenges have led them to narrow their budgets in line with the financial difficulties they face especially in developing countries such as Jordan. As a result of the economic and political conditions in surrounding areas, many companies, including Lafarge-Jordan, are facing challenges to survive and grow, which has highlighted the importance of Total Quality Management (TQM) as a potential strategy for tackling these challenges.

Jordan provides an interesting location in which to examine TQM as although over the last decade, the country has delivered significant structural reforms in health, education and industry, more work is required to enhance the investment climate in the country and political instability involving the Syria and Iraq crises, remains a significant difficulty.

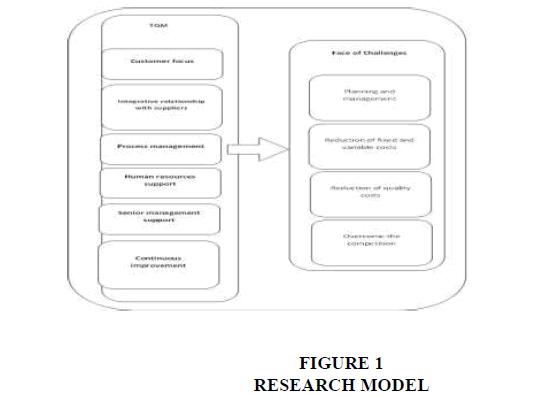

Therefore, this study seeks to ascertain how employees working within a large organization in Jordan perceive the benefits of TQM in addressing some of the problems businesses such as it are currently facing in terms of securing their continued survival and growth. The study focuses more specifically on the TQM dimensions associated with customer focus; integrative relationship with suppliers; process management; human resources support; senior management support; and continuous improvement. It focuses on the challenges faced for companies in relation to planning and management; cost reduction; and gaining competitive advantage.

Research Importance

Currently there is limited empirical evidence available about the effect of alternative TQM practices on different business performance measures (Sadikoglu & Zehir, 2010), particularly within the context of a company operating within a developing country such as Jordan. There are therefore a number of research gaps that need to be addressed including: gaining a better understanding of the key challenges facing companies such as Lafarge-Jordan when trying to grow and further establish itself within its sector in the face of significant business challenges; and acknowledging that differences in the perceptions of the acceptability of different TQM tools amongst the workforce in this sector, in this global setting is still relatively unexplored.

Literature Review And Previous Studies

Understanding Total Quality Management

Due to the vast diversity and perspectives of quality management and Total Quality Management (TQM), achieving a consensual definition is problematic (Idris & Zairi, 2006). However, according to Baird et al. (2011), TQM can be described as an integrative organisational-wide philosophy that aims to continuously improve the quality of products, services and processes to meet customer expectations. Similarly, Talib et al. (2011) describe TQM as a total system approach which works across all functions and departments, involves all employees, and aims to consistently meet or exceed customer requirements.

There are many different types of TQM practices identified in the current literature including those which are focused around factors such as: senior management support and leadership (Talib & Rahman, 2010; Khamalah & Lingaraj, 2007); customer focus, satisfaction and orientation (Mahapatra & Khan, 2006); employee support, engagement and involvement (Lakhal et al., 2006; Samat et al., 2006); training and education (Ueno, 2008); and continuous improvement (Fotopoulos & Psomas, 2009). Furthermore, a distinction is often made between these practices into “hard” and “soft” TQM. “Hard” practices are those which are considered to be most pertinent to production and operations management, where statistical techniques or performance standards, for example, are used to assess quality. “Soft” practices, on the other hand, are those which have a more qualitative focus incorporating elements such as leadership, employee involvement and team work (Yunis et al., 2013). According to Khan & Naeem (2018), who examined the impact that soft quality practices have on hard quality practices, found that soft quality practices can lead to improved innovation which in turn impacts on organizational performance.

Since its formation, the TQM concept has evolved considerably resulting in the development of a range of models and techniques such as Six Sigma, Kanban, Total Productive Maintenance, Lean, Just-in-time, and Productivity Improvement which are all commonly used today in a range of different settings and industries (Dhongade et al., 2013; Shafiq et al., 2017).

Understanding Organizational Performance and Challenges

In general, organizational performance refers to the extent to which an organization meets its stated objectives and in the existing literature, a wide range of measures exists to assess levels of performance including both financial and non-financial measures (Jabeen et al., 2014). Studies assessing the impact of TQM on performance identify a wide range of performance variables including: customer satisfaction levels (Lin et al., 2005); financial and market results (Sila, 2007); employee satisfaction and loyalty (Jun et al., 2006); and innovation and quality outcomes (Prajogo & Sohal, 2004). Others, such as Idris & Zairi (2006) propose the use of established models such as the Balanced Scorecard developed by Kaplan & Norton (1996) to gauge performance outcomes related to different critical factors of TQM implementation. Much less is written about how a TQM model can be used to face challenges during difficult periods Callejo, 2012).

The Relationship between TQM and Performance

Tanninen et al. (2010) claim that TQM practices can influence organisational performance through two key processes. The first is through improved internal performance resulting in increased efficiency, reduced waste and subsequently a higher return on assets. The second is through improved customer satisfaction which results in enhanced brand value and customer loyalty which in turn leads to higher levels of sales and market share.

In line with this, Summers (2006) argues that TQM practices can lead to the improvement of the quality of products, make better use of resources, lower costs, minimize errors, and reduced delays in production and delivery time schedules which all subsequently enable an organization to acquire greater market share and boost performance. This view is supported by Kumar et al. (2009) who found from their study of TQM and performance that TQM practices significantly improved employee participation and morale, increased efficiency in operating procedures, reduced the level of customer complaints, and ultimately enhanced profitability. Similarly, Sinkovics & Roath (2004) argue that TQM practices help to direct performance by influencing the way in which routine business operations are carried out and by providing a foundation for longer term business success and overcome different kinds of challenges.

Despite these identified benefits, there are some mixed findings on the effectiveness of TQM in achieving competitive advantage. Across different countries including the US, the UK and Australia, certain studies have indicated that there has been a lack of tangible results associated with the implementation of TQM (Sadikoglu & Zehir, 2010; Soltani et al., 2005; Taylor & Wright, 2003; Sohal & Terziovski, 2000). Similarly, according to Sabella et al. (2014), the performance improvements resulting from implementing different TQM practices are not ubiquitous and are very mixed in nature.

In particular, previous studies have reported variable results with regards to the relationship between hard and soft TQM practices and organizational performance (Yunis et al, 2013). Rahman & Bullock (2005) argue that when measuring the impact of TQM, the distinction between these hard and soft elements of TQM is essential as they claim that they affect performance in different ways. They concluded that the elements of soft TQM including workforce commitment, shared vision, customer focus, team working and cooperative supplier relationships, were all significantly correlated with organizational performance, and discovered that in order for certain hard TQM elements to have an impact on performance, such as technology utilization and continuous improvement enablers, the soft TQM elements must first be in place. This suggests that organizations should not view individual TQM practices in isolation, but instead view them as a collective means of promoting quality improvement across all areas in order to ultimately enhance performance and should also acknowledge the unique individual relationships between them (Baird et al., 2011).

Enablers and Inhibitors

Enablers and inhibitors have an influence over the relative impact of TQM, with enablers being the positive forces that facilitate the speed of positive progress, and inhibitors being the negative forces that impedes it (Idris & Zairi, 2006). Within the current literature on TQM and performance, a range of enablers and inhibitors have been proposed, and indeed Talib et al. (2012) highlighted seventeen such TQM enablers.

One of the most common factors that is identified in previous studies as impacting on the effectiveness of TQM is organizational culture (Prajogo & McDermott, 2005; Kumar & Sankaran, 2007) with numerous authors referring to the need to change the organizational culture and workforce attitudes in order to TQM to be effective (Baird et al., 2011). This view is supported by Singh et al. (2018) in their study of TQM in a sample of Indian manufacturing companies. From their study, they stressed the importance of strong leadership in ensuring that an organization’s culture is ready to successfully embrace TQM practices to tackle key challenges proactively. Non-traditional cultures, in particular, have been suggested as being more receptive to TQM practices (Bonavía Martín & Marin-Garcia, 2006) and from their study of TQM in the textile industry in Pakistan, Shafiq et al. (2017) concluded that TQM has the potential to have a positive effect on organizational performance not only in companies based in developed nations, but also on those based in developing countries such as Jordan. In addition, employee involvement and participation has frequently been identified as a significant contributing factor to changing organizational culture into one which embraces quality improvement (Gul et al., 2012; Chuang et al., 2015; Bakoti? & Rogoši?, 2015). In their study of the impact of TQM in the service industry, Psomas & Jaca (2016) found that the TQM factors relating to customers, employees and top management had the most significant impact on performance.

Another factor that has been identified in the current literature relates to the implementation process surrounding TQM. According to Talib et al. (2011) this process is crucial to its long-term success and advises that is not something that can be applied generically, but instead is organization-specific. In support of this view, Weingarten et al. (2013) found that the successful implementation of TQM depends on a range of contextual factors such as organizational size, local and national culture, and the scope of operations, and concur with the view of Foster (2006), that “one size does not fit all” in relation to implementing TQM practices. This view is also supported by Sila (2007) who draws on institutional theory and contingency theory to analyze the different contexts in which TQM impacts on performance.

A further enabler of TQM on organizational performance is said to be effective supplier quality management (Zakuan et al., 2010). According to Lee (2004) and Temtime & Solomon (2002), the adoption of supplier management in TQM programs can assist organizations to achieve competitive advantage in both domestic and international markets. This requires establishing a strong relationship with suppliers based on trust, cooperation, mutual collaboration and stability. Similarly, in their study of the relationship between supplier management and operational performance, Prajogo et al. (2012) found that supplier management impacted positively on quality performance through the establishment of long-term strategic relationships and the integration of logistics to facilitate positive outcomes in terms of delivery, flexibility, and cost performance.

With regard to the inhibitors influencing the relationship between TQM and performance, in their study of quality management, Goetsch & Davis (2014) identified five key barriers to successfully implementing TQM practices. These included: weak leadership and senior management delegation; “team mania” whereby teams are insufficiently supported or established to deliver TQM practices effectively; poorly constructed deployment processes to deliver linkages with all of the organization’s key functions; taking an overly dogmatic approach to TQM implementation; and having a lack of required skills and experience around TQM in the affected workforce.

Similarly, in their work on implementing TQM in the construction industry, Haupt & Whiteman (2004) found that the main inhibitors stemmed from a lack of commitment from senior management to the principles of TQM, difficulties in transferring responsibility for TQM to the “front-line”, perceptions that TQM is overly bureaucratic, difficulties associated with measuring results, and disinterest and general apathy from staff. This view was also supported by Polat et al. (2011) in their similar study of TQM within the field of construction.

Lafarge, TQM and Challenges

It is known that the global financial crisis occurred in the middle of 2007 after the bursting of the “real estate fizz” in the United States. The world economy has been negatively affected; the most important indicators of this are the impoverishment of some companies and banks, a higher unemployment rate, the increasing restrictions on credit granting, liquidity shortage, and slowing economic growth , which in turn has affected the volume of demand for Lafarge's products. In Jordan, Lafarge is currently the leading cement and concrete supplier, with an annual production capacity of around 1.9 million m³ (Lafarge, 2018). However, back in the first quarter of 2009, the impact of the crisis began to hit as demand declined 4% as compared to the previous year, and there was a continued decline in the company's activity until the company eventually offered some of its assets for sale from factories and lands.

In 2016, the company's financial statements showed a net loss of JD (1.712) million against a net profit of 2015 of 9%. The company's sales decreased by 12.8% due to the decline in demand in the local market because of the slowdown in construction activity, the decrease in the capital expenditure of the state and the competition, as well as the increase in administrative expenses and the suspension of operations in the factory of Al-Fuhais. The main challenges facing the company included:

1. A continuous rise in energy prices, mining fees and electricity.

2. Limited size of the Jordanian market and the presence of 5 rival companies producing cement.

3. The impact of the economic slowdown on the cement product market.

4. An increase in the number of employees compared to the volume of operations and production.

5. Government pressure to reduce the sale price of product and compensation of residents for some environmental issues rose on the company.

Research Hypothesis And Model

Based on the findings from the literature review, the following research hypotheses were identified:

H1: The dimension of TQM (customer focus) has a significant statistical impact on the face of challenges (planning and management; reduction of fixed and variable costs, reduction of quality costs, and overcome the competition).

H2: The dimension of TQM (integrative relationship with suppliers) has a significant statistical impact on the face of challenges (planning and management; reduction of fixed and variable costs, reduction of quality costs, and overcome the competition).

H3: The dimension of TQM (process management) has a significant statistical impact on the face of challenges (planning and management; reduction of fixed and variable costs, reduction of quality costs, and overcome the competition).

H4: The dimension of TQM (human resources support) has a significant statistical impact on the face of challenges (planning and management; reduction of fixed and variable costs, reduction of quality costs, and overcome the competition).

H5: The dimension of TQM (senior management support) have a significant statistical impact on the face of challenges (planning and management; reduction of fixed and variable costs, reduction of quality costs, and overcome the competition).

H6: The dimension of TQM (continuous improvement) has a significant statistical impact on the face of challenges (planning and management; reduction of fixed and variable costs, reduction of quality costs, and overcome the competition).

To test the above hypotheses, the following research model was adopted (Figure 1).

Research Methodology

Data Collection Method and Sampling Framework

This study adopted a pragmatist approach and used a quantitative methodology of a postal questionnaire (Appendix). It was felt that this would effectively gather the views of the case example organization’s employees in a practical and cost effective way.

The study population of interest consisted of all administrators and engineers working in the Lafarge -Jordan factories in both the Al-Fuhais and Tafileh sites. The company was chosen as one of the first companies to implement quality control systems and continuous improvement. The company had also installed a policy of cooperation, trust and mutual collaboration in its supplier management system. The company faces exceptional circumstances and challenges, which necessitated the discontinuation of production at many times, thus the researchers, believed that this company provided a good case example which warranted further investigation. A convenience sampling technique was used to select the participants. To determine the suitable sample size; (150) members was considered to be a representative sample for the study population based on published scientific guidelines of sample size decisions (Krejcie and Morgan, as sited in Sekaran & Bougie, 2009). It should be noted that the company faced some legal and environmental law suits forced it to close Al- Fuhais factory and layoff a lot of employees. Just Al- Rashadia factory is working now, which is 400 Km away from Amman the capital. The number of returned questionnaires was (79) with a response rate of around (53%); however, the number of questionnaires included in the analysis was (73); since (6) were not considered to be suitable for analysis (Table 1).

| Table 1 Sample Characteristics |

|||

| Measure | Value | Frequency | Percentage (%) |

| Gender | Male | 66 | 90.4 |

| Female | 7 | 9.6 | |

| Age | 18 less than 24 | 7 | 9.6 |

| 24 less than 40 | 20 | 27.4 | |

| 40 less than 54 | 31 | 42.4 | |

| More than 54 years | 15 | 20.5 | |

| Academic Qualification | High School or less | 36 | 49.3 |

| Bachelor | 26 | 35.6 | |

| Master | 4 | 5.5 | |

| PhD | 5 | 6.8 | |

| Other | 2 | 2.7 | |

| Management level | Top Level | 19 | 26 |

| Middle Level | 26 | 35.6 | |

| Low Level | 25 | 34.2 | |

| Experience | Less than 5 years | 26 | 34.2 |

| 5-10 years | 15 | 35.6 | |

| 10-15 years | 13 | 17.8 | |

| 15-20 years | 12 | 16.4 | |

| More than 20 years | 7 | 9.6 | |

| Factory | Al Fuhais | 15 | 20.5 |

| Al Rashadia | 56 | 76.7 | |

| Other | 2 | 2.7 | |

| Nationality | Jordanian | 61 | 83.6 |

| Non-Jordanian | 12 | 16.4 | |

Instrument Design

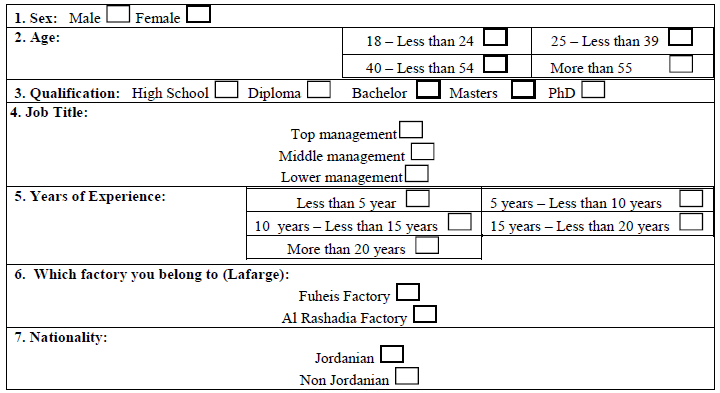

The researchers developed a questionnaire designed following a review of the current literature. The questionnaire comprised of two parts; the first part measured factors related to demographic characteristics of the participating employees: gender, age, length of service, and academic qualifications, aiming at describing the sample. The second part included items measuring the research variables. The answers were classified according to a five-point Likert scale.

Public Relations Dept. in the company distributed the questionnaire according to their policy. No chance for the researchers to make pilot study. However, for the validity of the study tool, nine professors and experts in the field of business and quality were contacted to obtain suggestions for necessary modifications.

Data Analysis

Partial Least Squares (PLS) were chosen for the current study using SmartPLS software. It was used in a two-stage approach, measurement and structural model testing. It is assumed that both methods “PLS-SEM vs. CB-SEM” are complementary rather than competitive. The primary purpose of the PLS approach is to predict the indicators by means of the components expansion. Jöreskog, 1982). In line with this notion, Hair et al. (2011) recommend:

1. If the goal is predicting key target constructs or identifying key 'driver' constructs, selects PLS-SEM.

2. If the goal is theory testing, theory confirmation, or comparison of alternative theories, select CB-SEM.

3. If the research is exploratory or an extension of an existing structural theory, select PLS-SEM.

Measurement Model

The measurement model can be assessed by examining the reliability, convergent validity and discriminate validity. Specifically, reliability which refers to the internal consistency of measurement, can be assessed by checking if the value of Composite Reliability (CR) is more than 0.7, the Average Variance Extracted (AVE) is greater than 0.5 and Cronbach’s α is greater than 0.6 (Hair et al., 2006). Table (2) below shows that the CR values ranged from 0.79 to 0.91 and the AVE values ranged from 0.52 to 0.72. These values are higher than the acceptance value 0.70 and 0.50 which indicate good construct reliability. Furthermore, in order to check the reliability, Cronbach’s α for each item was calculated. All item values were larger than 0.70, which indicates that the scale has a good reliability.

| Table 2 Result Of Construct Assessment |

|||

| Constructs | CR | Cronbach’s α | AVE |

| TQM Dimensions | |||

| Customer focus | 0.89 | 0.87 | 0.52 |

| Integrative relationship with suppliers | 0.88 | 0.82 | 0.65 |

| Process management | 0.9 | 0.86 | 0.6 |

| Human resources support | 0.91 | 0.88 | 0.64 |

| Senior management support | 0.91 | 0.87 | 0.72 |

| Continuous improvement | 0.89 | 0.84 | 0.68 |

| Face of Challenges | |||

| Planning and management | 0.85 | 0.79 | 0.53 |

| Reduction of fixed and variable costs | 0.85 | 0.78 | 0.53 |

| Reduction of quality costs | 0.89 | 0.85 | 0.58 |

| Overcome the competition | 0.79 | 0.72 | 0.52 |

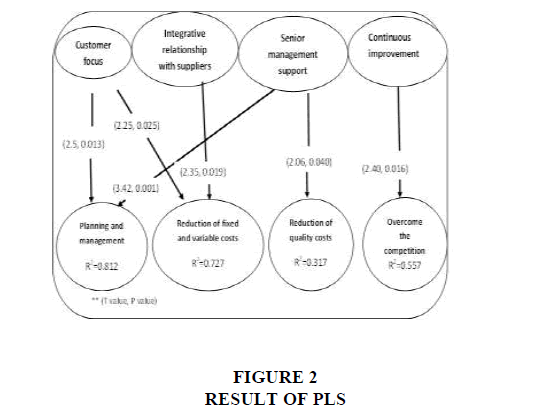

Bootstrapping method (SmartPLS 3) software was used to test the statistical significance of path coefficients. Figure 2 shows the P value for all research variables and the PLS model of the study.

Results

The analysis revealed that four of TQM dimensions (customer focus, integrative relationship with suppliers, senior management support, and continuous improvement) have a significant impact on face of challenges, whereas two dimensions (process management, human resources support) have no impact on face challenges. In summary, the results show that (customer focus) as a TQM dimension has a significant impact on (planning and management) and (reduction of fixed and variable costs) with (t=2.5, p ≤ 0.05), (t=2.25, p ≤ 0.05) respectively. Thus, H1 is supported.

In addition, (integrative relationship with suppliers) as a TQM dimension has a significant impact on (reduction of fixed and variable costs) with (t=2.35, p ≤ 0.05). Thus, H2 is supported. As well as, (customer focus) and (integrative relationship with suppliers) explain 0.73 percent of (reduction of fixed and variable costs) variance.

Moreover, the results revealed that (senior management support) as a TQM dimension had a significant impact on (planning and management) with (t=3.42, p ≤ 0.05). In addition, (customer focus and senior management support) explain 0.81 percent of (planning and management) variance. Moreover, (senior management support) has a significant impact on (Reduction of quality costs) with (t=2.06, p ≤ 0.05) and it explain 0.32 percent of (reduction of quality costs) variance which support H5.

Furthermore, (continuous improvement) as a TQM dimension has a significant impact on (overcome the competition) with (t=2.40, p ≤ 0.05) and it explain 0.56 percent of (overcome the competition) variance which support H6. Accordingly, the result reflect that there is no significant impact for (process management, and human resources support) as a TQM dimension on the face of challenges which lead to reject and not support H3 and H4.

Discussion And Conclusion

The major finding of this study is that there was clear evidence that practicing TQM through the dimensions of (customer focus) and the (integrative relationship with suppliers) have the most significant effect on facing the company’s key challenges by providing the guidelines for better planning and management in one hand and by reducing fixed and variable costs in the other. In addition, (continuous improvement) and (senior management support) have also a statistical significant impact on addressing the fierce competition in the cement industry and through enabling better planning and management to face different challenges more effectively. These results are similar to the results of Tanninen et al. (2010), Summers (2006), and Prajogo et al. (2012). Surprisingly, the results revealed that there was no significant impact for (process management) and (human resources support) as a TQM dimension on the face of challenges. This result warrants further investigation because successful implementation and adoption of TQM practices require training, education, and employee involvement.

Theoretically, the study results extended the literature concerning TQM through investigating its dimensions that affecting facing of challenges within the context of Jordan. Considering the scarcity of the available empirical as well as theoretical studies within this context as well as the overall Arab countries context, the study and its outcomes provided some insights and useful contribution that could open the door for more research to create awareness concerning TQM issues. The overflow of the research process might also provide systematic guideline for future researcher in terms of the foundation of the research, building up of its model, methodological procedures, analysis of data as well as the validation of the proposed model.

Practically, the outcomes of this research may serve decision makers in the Lafarge Company in their attempts to consider quality issues that have become a must for most stakeholders in this industry including consumers, government as well as investors.

This research outcome provides an original contribution to the available body of knowledge concerning the important and potential leading role of organizational management in the TQM. The empirical findings mentioned before in addition to the theoretical evaluation of Lafarge Company have led to the identification of particular strategic direction to improve the state of the art concerning the concept of TQM.

Recommendation

Building on the discussion of findings and the conclusions drawn, the researchers recommend the company focus on developing employee involvement and engagement as they are critical stakeholders in the successful application of TQM. For further research, we believe it would be advantageous to analyze the impact of different soft and hard forms of TQM in overcoming business challenges. In addition, there is a need for further investigation of the cultural and behavioral issues of companies operating in developing countries, which can influence the successful application of TQM in the face of difficult times.

Appendix

Employee Questionnaire

(Part One: Basic Information)

(Lafarge) please fills out this questionnaire by answering all the questions in it, and by

ticking in the appropriate box

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 1 | The company continuously recognizes the needs and desires of customers through market studies. | |||||

| 2 | The company is keen to provide products with suitable prices to the customers. | |||||

| 3 | The company is seeking to provide products in places and ports distributional that achieve customer satisfaction. | |||||

| 4 | The company is keen to provide the products within the international standards of quality. | |||||

| 5 | The company relies on the principle of honesty and enrichment in their promotional. | |||||

| 6 | The company constantly emphasizes that the customer's satisfaction is the core of its efforts. | |||||

| 7 | The company has an advanced system to handle customer complaints. | |||||

| 8 | The company is keen to implement an advanced system to meet its commitments and obligations to customers. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 9 | The company maintains strong long term relationships with suppliers. | |||||

| 10 | The company seeks to share suppliers in its plans and future vision. | |||||

| 11 | There is cooperation between the company and suppliers to achieve the highest quality standards. | |||||

| 12 | The company seeks to diversify sources of supply to reduce the risk. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 13 | The company is working on the sovereignty of the concept of quality is everyone's responsibility. | |||||

| 14 | Processes are designed to ensure the smooth flow of work. | |||||

| 15 | Ensure the application of quality principles in the design stages. | |||||

| 16 | There is a review of production processes in order to overcome obstacles. | |||||

| 17 | Ensure the application of the principles of quality in the production stages. | |||||

| 18 | The company considers TQM as a high-quality productivity function. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 19 | There is support provided from the company for the staff to continuous improvement. | |||||

| 20 | Evaluation of staff performance is characterized by a system of justice and objectivity in terms of quality it depends on the results of the application. | |||||

| 21 | The company encourages the formation of teams and quality circles Quality Cycle. | |||||

| 22 | The company provides the required incentives for employees when adhering to the principles of quality. | |||||

| 23 | The company offers appropriate training courses for successful implementation of quality principles. | |||||

| 24 | The company is keen on the safety of workers through the application of safety and security standards. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 25 | Senior management company is keen to clarify the importance of applying the principles of quality. | |||||

| 26 | Senior management supports quality teams by giving them the necessary powers to apply quality. | |||||

| 27 | The senior management provide a guidance for the appliances whom have experience in the application of quality concepts. | |||||

| 28 | Senior management is keen to read and analyses the reports of quality management. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 29 | The company management believes that continuous improvement leads to reduced delivery time. | |||||

| 30 | The company continuous improvement to reduce the number of products that need to re-design or production. | |||||

| 31 | The company management believes that continuous improvement contributes to the reduction of the damaged. | |||||

| 32 | The company encourages a comprehensive review of the administrative and technical operations to find the best ways to get the job done. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 33 | The company is conducting a comprehensive review of all additional activities that carry the company's costs but adds a simple value to the customer. | |||||

| 34 | The company is constantly pursuing the health of workers and employees to ensure workers to avoid absences due to health conditions safe environment and thus increase productivity. | |||||

| 35 | The company is keen to retain human resources who understand the importance of applying the principles of quality and motivation, which enhances the company's inventory competencies to overcome the crisis. | |||||

| 36 | Intensify staff training efforts in order to increase productivity. | |||||

| 37 | The company reward and motivate employees who innovate innovative ideas that reduce costs or increase customer satisfaction. | |||||

| 38 | Understanding the principles of quality makes communication between the administrative levels without obstacles and is characterized by speed and accuracy. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 39 | The application of quality principles creates a positive atmosphere for employees to encourage creative initiatives aimed at reducing design and production costs. | |||||

| 40 | The application of quality principles are encouraged to look for alternatives to the provision of energy used, such as wind power and solar energy. | |||||

| 41 | Raise production efficiency either by increasing output at the same level of inputs or outputs installed and reduced input. | |||||

| 42 | The application of quality concepts increases flexibility in the production of certain materials outside the company's factories (supply from outside outsourcing). | |||||

| 43 | Quality can be reduced costs by contracting with specialized companies to conduct the required tests as needed them. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 44 | In crises, it becomes possible to reduce the number of employees to quality as long as the quality philosophy of culture is pervasive throughout the company. | |||||

| 45 | In crises, it is possible to simplify quality procedures and steps. | |||||

| 46 | To meet the challenges and reduce costs can be customers use laboratories to check the quality of materials. | |||||

| 47 | When you understand the principles of quality and reduce costs it becomes possible to use laboratories suppliers when examining the materials and devices | |||||

| 48 | Reduce the costs of failure (the damaged internal). | |||||

| 49 | Reduce the costs of external (damaged) failures. | |||||

| No. | Statement | Strongly Agree |

Agree | Neutral | Disagree | Strongly Disagree |

| 5 | 4 | 3 | 2 | 1 | ||

| 50 | To face the competition , the company is looking for long-term contracts (government projects + institutions concerned with infrastructure). | |||||

| 51 | Lower prices and offers to attract more customers. | |||||

| 52 | Search for regional customers in neighboring countries to reduce dependence on local customers. | |||||

| 53 | Building alliances with some of the competitors to meet the challenges facing the cement industry. | |||||

| 54 | In order to face competition must diversify investments in economic sectors and different from the building materials sector. |

References

- Baird, K., Jia Hu, K., & Reeve, R. (2011). The relationships between organizational culture, total quality management practices and operational performance. International Journal of Operations & Production Management, 31(7), 789-814.

- Bakoti?, D., & Rogoši?, A. (2015). Employee involvement as a key determinant of core quality management practices.Total Quality Management & Business Excellence, 1-18.

- Bonavia, T., & Marin, J.A. (2006). An empirical study of lean production in the ceramic tile industry in Spain. International Journal of Operations & Production Management, 26(5), 505-531.

- Callejo, M.B. (2012). Using total quality management model to face the economic crisis: The case of Mercadona. In Quality Management and Practices. Retrieved from: http://www.intechopen.com/books/quality-management-and-practices/using-total-qualitymanagement- to-face-the-crisis-the-case-of-mercadona

- Chuang, S.S., Chen, K.S., & Tsai, M.T. (2015). Exploring the antecedents that influence middle management employees' knowledge-sharing intentions in the context of total quality management implementations.Total Quality Management & Business Excellence,26(1-2), 108-122.

- Dhongade, P.M., Singh, M., & Shrouty, V.A. (2013). A review: Literature survey for the implementation of Kaizen. International Journal of Engineering and Innovative Technology (IJEIT), 3, 57-60.

- Foster Jr, S.T. (2006). One size does not fit all.Quality Progress, 39 (7), 54.

- Fotopoulos, C.B., & Psomas, E.L. (2009). The impact of soft and hard TQM elements on quality management results.International Journal of Quality & Reliability Management,26(2), 150-163.

- Goetsch, D.L., & Davis, S.B. (2014). Quality management for organizational excellence. Essex: Pearson.

- Gul, A., Jafery, S.A.S., Rafiq, J., & Naeem, H. (2012). Improving employees performance through total quality management.International Journal of Economics and Management Sciences,1(8), 19-24.

- Hair, J.F., Black, W.C., Babin, B.J., Anderson, R.E., & Tatham, R.L. (2006). Multivariate data analysis. Pearson Prentice Hall Upper Saddle River.

- Hair, J.F., Ringle, C.M., & Sarstedt, M. (2011). PLS-SEM: Indeed a silver bullet. Journal of Marketing Theory and Practice, 19(2), 139-152.

- Haupt, T.C., & Whiteman, D.E. (2004). Inhibiting factors of implementing total quality management on construction sites.The TQM Magazine,16(3), 166-173.

- Idris, M.A., & Zairi, M. (2006). Sustaining TQM: A synthesis of literature and proposed research framework.Total Quality Management and Business Excellence,17(9), 1245-1260.

- Jabeen, R.U.B.I.N.A., Shehu, M.S., Mahmood, R.O.S.L.I., & Kofarmata, B.A. (2014). TQM and knowledge management impacts on SME performance.International Postgraduate Journal Business Journal,6(2), 23-43.

- Joreskog, K.G. (1982). The ML and PLS techniques for modeling with latent variables: historical and comparative aspects.Systems Under Indirect Observation, part I, 263-270.

- Jun, M., Cai, S., & Shin, H. (2006). TQM practice in maquiladora: Antecedents of employee satisfaction and loyalty.Journal of Operations Management,24(6), 791-812.

- Kaplan, R.S., & Norton, D.P. (1996). The balanced scorecard: Translating strategy into action. Boston, MA: Harvard Business School Press.

- Khamalah, J.N., & Lingaraj, B.P. (2007). TQM in the service sector: A survey of small businesses.Total Quality Management,18(9), 973-982.

- Khan, B.A., & Naeem, H. (2018). Measuring the impact of soft and hard quality practices on service innovation and organisational performance.Total Quality Management & Business Excellence,29(11-12), 1402-1426.

- Kumar, R.M., & Sankaran, S. (2007). Indian culture and the culture for TQM: A comparison.The TQM Magazine,19(2), 176-188.

- Kumar, V., Choisne, F., de Grosbois, D., & Kumar, U. (2009). Impact of TQM on company's performance.International Journal of Quality & Reliability Management,26(1), 23-37.

- Lafarge (2018). https://www.lafarge.com.jo/en/1_1-Lafarge_in_Jordan

- Lakhal, L., Pasin, F., & Limam, M. (2006). Quality management practices and their impact on performance.International Journal of Quality & Reliability Management,23(6), 625-646.

- Lee, C.Y. (2004). TQM in small manufacturers: An exploratory study in China.International Journal of Quality & Reliability Management,21(2), 175-197.

- Lin, C., Chow, W.S., Madu, C.N., Kuei, C.H., & Yu, P.P. (2005). A structural equation model of supply chain quality management and organizational performance.International Journal of Production Economics,96(3), 355-365.

- Mahapatra, S.S., & Khan, M.S. (2006). A methodology for evaluation of service quality using neural networks.

- Martin-Pena, M.L., & Diaz-Garrido, E. (2008). A taxonomy of manufacturing strategies in Spanish companies. International Journal of Operation & Production Management, 28(5), 455-477.

- Niven, D. (1993). When times get tough, what happens to TQM? Case study.Harvard Business Review,71(3), 20-2.

- Polat, G., Damci, A., & Tatar, Y. (2011). Barriers and benefits of total quality management in the construction industry: Evidence from Turkish contractors. InProceedings of Seventh Research/Expert Conference with International Participation QUALITY 2011, 1115-1120.

- Prajogo, D.I., & McDermott, C.M. (2005). The relationship between total quality management practices and organizational culture.International Journal of Operations & Production Management, 25(11), 1101-1122.

- Prajogo, D.I., & Sohal, A.S. (2004). The multidimensionality of TQM practices in determining quality and innovation performance-an empirical examination.Technovation,24(6), 443-453.

- Prajogo, D., Chowdhury, M., Yeung, A.C., & Cheng, T.C.E. (2012). The relationship between supplier management and firm's operational performance: A multi-dimensional perspective.International Journal of Production Economics,136(1), 123-130.

- Psomas, E.L., & Jaca, C. (2016). The impact of total quality management on service company performance: Evidence from Spain.International Journal of Quality & Reliability Management,33(3), 380-398.

- Rahman, S.U., & Bullock, P. (2005). Soft TQM, hard TQM, and organizational performance relationships: An empirical investigation.Omega,33(1), 73-83.

- Reed, R., Lemak, D.J., & Mero, N.P. (2000). Total quality management and sustainable competitive advantage.Journal of Quality Management,5(1), 5-26.

- Sabella, A., Kashou, R., & Omran, O. (2014). Quality management practices and their relationship to organizational performance.International Journal of Operations & Production Management,34(12), 1487-1505.

- Sadikoglu, E., & Zehir, C. (2010). Investigating the effects of innovation and employee performance on the relationship between total quality management practices and firm performance: An empirical study of Turkish firms.International Journal of Production Economics,127(1), 13-26.

- Samat, N., Ramayah, T., & Mat Saad, N. (2006). TQM practices, service quality, and market orientation: Some empirical evidence from a developing country.Management Research News,29(11), 713-728.

- Sekaran, U., & Bougie, R. (2009). Research methods for business, (5th edition).

- Shafiq, M., Lasrado, F., & Hafeez, K. (2017). The effect of TQM on organisational performance: empirical evidence from the textile sector of a developing country using SEM.Total Quality Management & Business Excellence, 1-22.

- Sila, I. (2007). Examining the effects of contextual factors on TQM and performance through the lens of organizational theories: An empirical study.Journal of Operations Management,25(1), 83-109.

- Singh, V., Kumar, A., & Singh, T. (2018). Impact of TQM on organisational performance: the case of Indian manufacturing and service industry.Operations Research Perspectives,5, 199-217.

- Sinkovics, R.R., & Roath, A.S. (2004). Strategic orientation, capabilities, and performance in manufacturer-3PL relationships.Journal of Business Logistics,25(2), 43-64.

- Sohal, A.S., & Terziovski, M. (2000). TQM in Australian manufacturing: factors critical to success.International Journal of Quality & Reliability Management,17(2), 158-168.

- Soltani, E., Van Der Meer, R., & Williams, T.M. (2005). A contrast of HRM and TQM approaches to performance management: some evidence.British Journal of Management,16(3), 211-230.

- Summers, D.C.S. (2006). Quality, (5th edition) New Jersey: Pearson Prentice Hall.

- Talib, F., & Rahman, Z. (2010). Critical success factors of TQM in service organizations: A proposed model.Services Marketing Quarterly,31(3), 363-380.

- Talib, F., Rahman, Z., & Qureshi, M. N. (2011). A study of total quality management and supply chain management practices.International Journal of Productivity and Performance Management,60(3), 268-288.

- Talib, F., Rahman, Z., & Qureshi, M.N. (2012). Total quality management in service sector: a literature review.In Talib, F., Rahman, Z. and Qureshi, MN (eds.), Total quality management in service sector: A literature review. International Journal of Business Innovation and Research,6(3), 259-301.

- Tanninen, K., Puumalainen, K., & Sandström, J. (2010). The power of TQM: analysis of its effects on profitability, productivity and customer satisfaction.Total Quality Management,21(2), 171-184.

- Taylor, W.A., & Wright, G.H. (2003). A longitudinal study of TQM implementation: Factors influencing success and failure.Omega,31(2), 97-111.

- Temtime, Z.T., & Solomon, G.H. (2002). TQM and the planning behaviour of SMEs in developing economies. The TQM Magazine, 14, 181-191.

- Ueno, A. (2008). Which managerial practices are contributory to service quality? International Journal of Quality & Reliability Management, 25(6), 585-603.

- Voelpel, S. C., Leibold, M., & Eckhoff, R. A. (2006). The tyranny of the Balanced Scorecard in the innovation economy.Journal of Intellectual Capital,7(1), 43-60.

- Wiengarten, F., Fynes, B., Cheng, E. T., & Chavez, R. (2013). Taking an innovative approach to quality practices: Exploring the importance of a company’s innovativeness on the success of TQM practices.International Journal of Production Research,51(10), 3055-3074.

- Yunis, M., Jung, J., & Chen, S. (2013). TQM, strategy, and performance: a firm-level analysis.International Journal of Quality & Reliability Management,30(6), 690-714.

- Zakuan, N. M., Yusof, S. M., Laosirihongthong, T., & Shaharoun, A. M. (2010). Proposed relationship of TQM and organisational performance using structured equation modelling.Total Quality Management,21(2), 185-203.