Research Article: 2020 Vol: 19 Issue: 6

The Structural Equation Model of Guidelines for Garment Industry Management for Sustainability

Taweesak Roopsing, King Mongkut’s University of Technology

Thanapol Suk-kavessako, King Mongkut’s University of Technology

Abstract

Aim: This research aims at developing a structural equation model of guidelines for garment industry management for sustainability.

Methodology: The study has been designed as a mixed-methodology research comprising 3 parts as qualitative research using in-depth interview, quantitative research using survey data collection, and qualitative research using focus group discussion. The sample of a survey involving quantitative data consisted of entrepreneurs or management executives in garment industry. Descriptive statistics, inferential statistics, and multiple statistics were used in the study.

Finding: The results revealed that garment industry management for sustainability consisted of marketing management, innovation management, resource management, and manufacturing management. Each guideline had the highest mean score as follow: marketing management, i.e. customer needs analysis survey was used as supplementary data for product design; innovation management, i.e. information technology, both hardware and software, was brought to design products; resource management, i.e. provision of modern machinery being environmentally friendly for garment production; and manufacturing management, i.e. production quality was controlled to ensure that it meets international standards. Hypothesis test result indicated there was no statistically significant difference (p 0.05) among small, medium, and large size businesses giving importance to guidelines to garment industry management for sustainability.

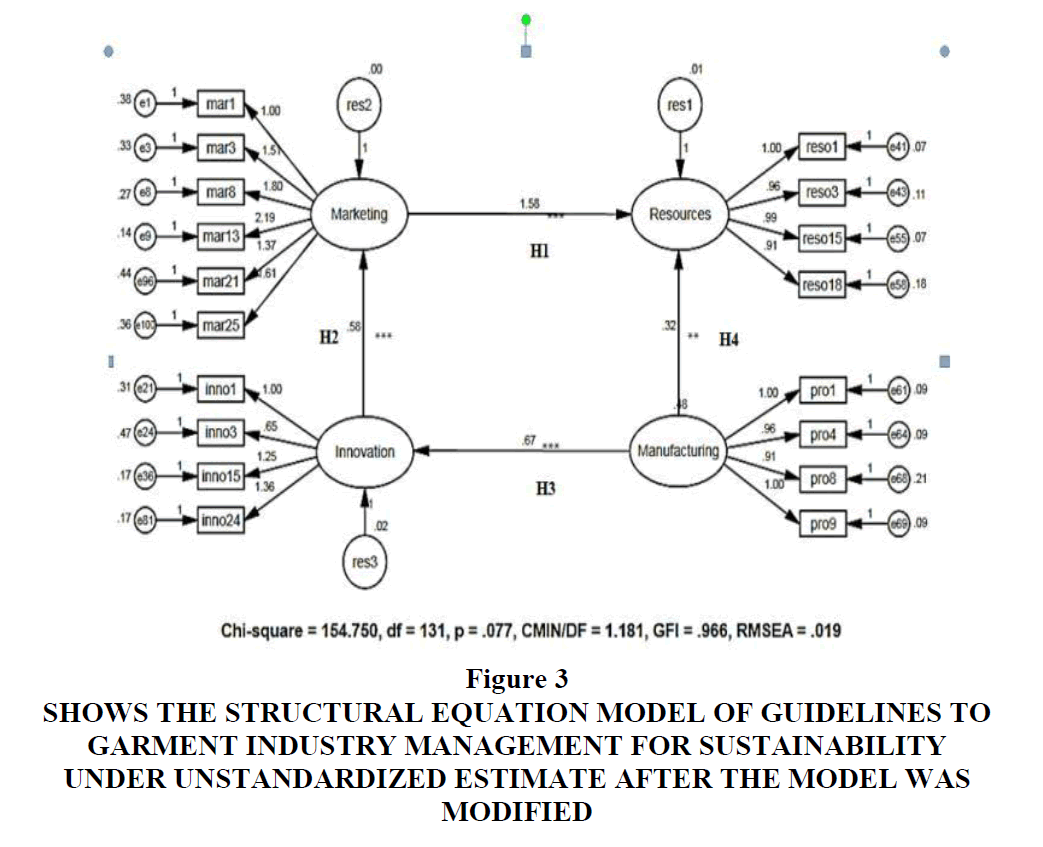

Conclusion: The developed structural equation model consisting of 4 major components. All of the components are important to sustainability of garment industry management. The components are arranged in significant orders as marketing management, innovation management, resource management, and manufacturing management. No difference was found among different sizes of business giving importance to the 4 components. Development outcome of the structural equation model of guidelines to garment industry management for sustainability passed the criteria of assessment and was consistent with empirical data, chi-square probability was 0.077, relative chi-square was 1.181, goodness of fit index was 0.966, and root mean square error of approximation was 0.019.

Keywords

Garment Industry, Management, Sustainability, Structural Equation Model.

Introduction

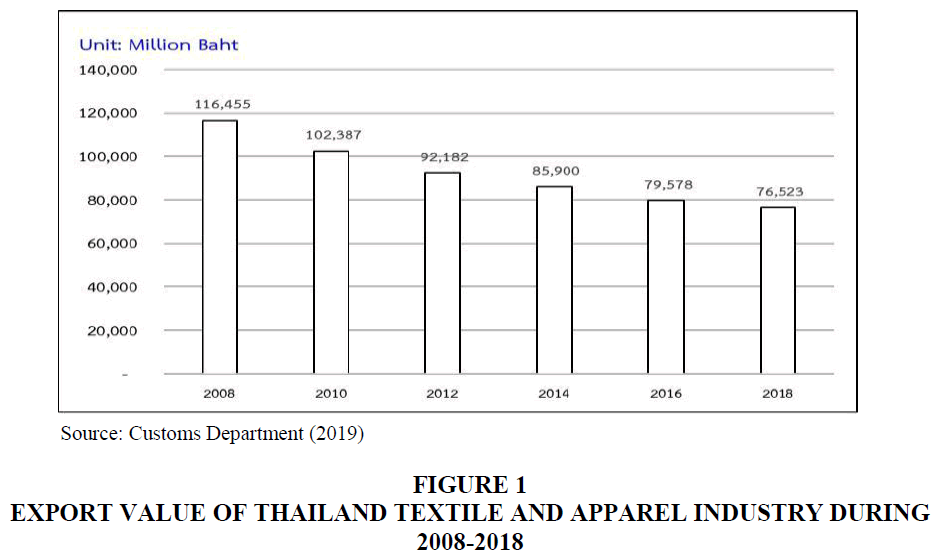

Thailand has a mixed economic system and Thailand itself is a newly industrialized country. In 2018, the gross domestic product (GDP) value of Thailand (market value) was ranked the 25th of the world, and GDP at purchasing power parity (PPP) was ranked the 20th of the world, the 2nd largest economy in Southeast Asia (Aphichat, 2018). The industrial and service sectors are the main sectors in the Thai gross domestic product (GDP), with the former accounting for 39.2% of GDP in which textile and apparel industry added 3.4% to the GDP which was quite low. Previously, Thailand textile and apparel industry faced various obstacles in terms of out-of-date production technology, higher labor cost, and difficulty in accessing sources of financing. Such obstacles contribute to an increase in production costs, making Thailand could not compete with foreign countries as seen from The Customs Department statistical data surveyed by Bank of Thailand from 2008-2018 showing that the export value from textile and apparel industry declined continuously (Customs Department, 2019) as seen in Figure 1.

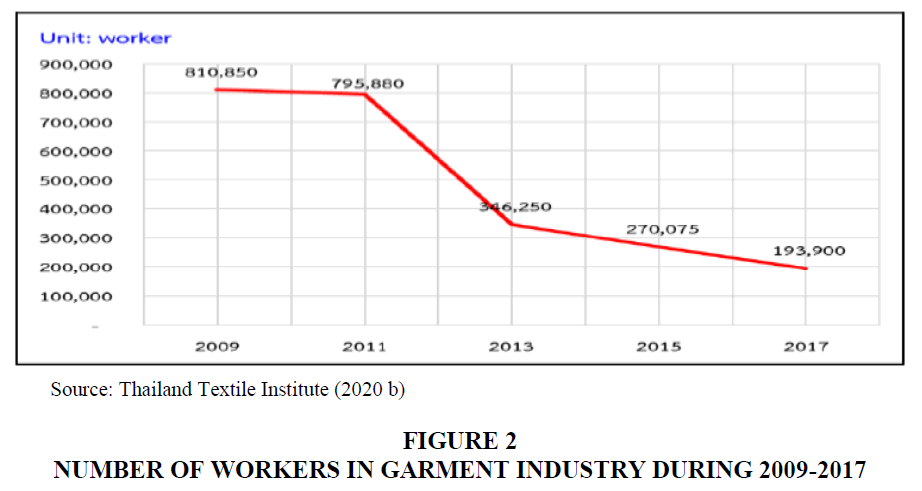

From Figure 1 it can be seen that Thai textile and apparel products are among export items bringing revenue to the country averagely as high as 100,000 million baht per year. The statistical data in 20018 indicated that the country’s revenue from export was 116,455 million baht but the recent year, 2018, export revenue decreased to 76,523 million baht accounting for 34.29%, compared to the revenue in 2008 and 2018. Therefore, a problem obviously noticeable is the overall export value of Thai textile and apparel products lie in a decreasing direction by 3.43% per year. An in-depth study on each part in each industry ranging from upstream, midstream, and downstream industries found that the most problematic industry is downstream industry which is garment industry or garment factory and many garment industries end up with dissolution. During January-March 2020, 14 textile and apparel factories had to be shut down and among them were 7 garment factories (Thailand Textile Institute, 2020a). This is consistent with statistical data related to labor force in garment industry during 2009-2017 that showed that the number of workers declined continuously which can be obviously seen in Figure 2.

Figure 2 clearly shows statistical data. Namely, in 2009 garment industry had as many as 810,850 workers but in 2015 the number of labor force in the garment industry declined and there were only 270,075 workers, and in 2017 there were only 193,900 workers left in the garment industry. These data indicate that garment industry had a severe impact and numerous factories needed to be shut down.

As of the current situation, the overall international trade of Thai textile and apparel industry in March 2020 found that the export value of textile and apparel products was worth US$ 523.6 million, decreasing by 14.4% compared to the same month last year, which divided into (1) export of textile worth US$ 339.5 million, decreasing by 14.6%, and (2) export of apparel worth US$ 184.1 million, decreasing by 14.0%. The overall of textile and apparel import was worth US$ 414.3 million, decreasing by 7.2%, which divided into (1) import of textile worth US$ 290.4 million, decreasing by 7.8%, and (2) import of apparel worth US$ 123.9 million, decreasing by 5.6%. This contributes to surplus balance of trade in general, accounting for US$ 109.3 million (Thailand Textile Institute, 2020c).

Based on the above-mentioned points, garment industry manufacturers need to give importance to improve their business management to achieve efficiency to ensure that their businesses can survive under changing circumstances with regard to higher numbers of competitors, domestic and international economic situations, advancement of technology, including changes in customer behaviors. Guidelines to solve the ongoing problems lie partly in the study results of the structural equation model of guidelines to garment industry management for sustainability. The objective is to study and seek management guidelines for garment industry so as to adopt the obtained body of knowledge to develop garment industry to achieve efficiency and sustainability in the future.

Marketing Management

Management means processes that executives practice to achieve success as set by organizational goals by means of personnel and management resources. Considered a wide angle, it can be noticeable that management consists of 3 characteristics as 1) Processes of implementing activities associated with continuous integration; 2) emphasis is placed on organizational goals, and 3) working to achieve the established goals by integrating personnel and management resources. Consideration of management function, it is found that prior to management function which encompasses planning, organizing, leading, and controlling, organizations need to firstly have resources or known as input. Once the input enters processes, they will shape efficiency of the given output. When management process is mentioned, in order to achieve efficient outputs, it is a must to have input plus efficient management process.

Marketing management is art and science. It is a process of management planning of pricing, promotion, distribution, service, etc to exchange satisfaction or respond to demands of target audiences and achieve organizational goals (Kotler & Keller, 2006). Therefore, it can be concluded that marketing management is activities that arise for responding to demands of target audiences and being able to achieve organizational objectives.

Marketing management encompasses 6 concepts that businesses and organizations have adhered to from the past until present so as to achieve marketing objectives (Armstrong & Kotler, 2003) as follow: 1) production concept, 2) the product concept, 3) sales concept, 4) the marketing concept, 5) the customer concept and 6) the societal marketing concept.

Innovation Management

Chesbrough (2003) describes that innovation plays an important role in a business process and compared to a key showing creative thinking abilities brought to utilization. Innovation management is a key for survival and growth of organizations. This process includes searching internal and external environment, opportunity, and threat leading to a starting point of future change, and selecting being decision-making on application to gain maximum benefits for organizations. In this regard, selecting needs to be consistent with organizational strategies as well.

Ubben et al. (2015) defined innovation as bringing new and improved way of doing things into practice, after being tested or developed hierarchically starting from inventing to developing.

Paul (2012) stated that in order to survive, organizations need to develop innovative products and defines innovation as things created by the integration of various sciences to obtain newly creative things for social and economic benefits.

Kuczmarski (1996) mentioned innovation management is inventive and operation processes that serve commercial and social benefits, originated from new way of thinking.

Morton & Lewis (2005) mentions that innovation means improving old things to be new things and capacity development of personnel including agencies or organizations is improvement, modification, and development for the survival of systems. In the era of knowledge-based economy, innovation management is vital science and tool. Changes in technology shall affect industries and organizations. Morton & Lewis (2005) refer to 4 types of innovation as 1) product innovation, 2) process innovation, 3) market innovation, and 4) management innovation.

Resource Management

Barney (2001) said that rare, valuable, inimitable and non-substitutable resources were considered strategic resources that provide an organization a golden opportunity to develop competitive advantage over its rivals in a sustainable manner because resources come in tangible and intangible asset forms of organizations and they are considered creative assets of organizations for business benefits.

Barney & Clark (2007) – Business resources are important features in conducting business to gain competitive advantage for responding to customer demands. Resources with business value consist of 4 factors which must be valuable, rare, imperfectly imitable, and non-substitutable in terms of business structure and business cost.

Gillespie et al. (2010) – Competitive advantage in business is typically triggered by business resources which should contain 4 major characteristics as business value, difference from competitors, difficulty to imitate, and non-substitutability. Competitive advantage is business value created to respond to customer demands with respect to costs and creating a unique point of difference, which can be divided into 1) financial resource, 2) human resource, 3) physical resource, and 4) business resourced capabilities.

Manufacturing Management

Prasong (2004) defined manufacturing management as planning and making decision in production.

Pichit (2003) gave the meaning of tasks of production executives as managing production and transformation processes to be able to carry out production and managing how factor inputs are converted into product outputs or required services in an efficient manner. Management activities comprise 5 procedures as planning, organizing, staffing, leading/direction, and controlling.

Punsuk (2007) defined manufacturing management as managing transformation system that converts various factors to products or services. Transformation system of production reacts accordingly to its environment. The mentioned environment is divided into 2 types as internal environment of organizations; higher level executives of an organization; manufacturing division may adjust policies, resources, prediction, goals or regulations, and external environment of organizations, i.e. legal change, political, social, and economic circumstances that affect changes in factor of production, products, and transformation system to improve the implementation of manufacturing system management to generate products and efficient production must consider the following appropriate factors – quantity, quality, time, and cost.

According to the various meaning mentioned earlier, it can be concluded that manufacturing management is managing manufacturing process or transformation process of factor of production (input) or managing factor of management to obtain products and services in accordance with specifications based on determined quantity and time with minimum expenses.

Manufacturing management is important to serve the following 4 reasons.

1) Manufacturing management is one of major duties comprising marketing (sales), finance (accounting), and production (operation) and it is related with other business duties of all organizations. Thus, it is essential to know management methods in relation to duties of production activities so as to drive an organization to become a productive enterprise.

2) Manufacturing management occurs due to demands for knowing how products and services are made. Duty of production is considered a part of the society as it produces products to the society.

3) To have understanding of manufacturing management duty that will facilitate development of necessary skills for being promoted to staff management executives.

4) Since manufacturing management is a part of an organizational structure that requires high costs. Therefore, if an organization has appropriate management, a chance to gain greater profits will increase as well as good services to the society.

Manufacturing management is one of major duties in business management while organizations are committed to major mission as profit that makes organizations to survive and grow over the long term. Mission divided into objectives of each major duty shows that marketing division performs its duty to increase market share and build customer satisfaction. The main objectives of finance division are profitability and maintain liquidity and the main objectives of manufacturing division are to ensure that products meet quality standards and to achieve productivity which are the keys of production (Rungnapa, 2007), Ten Decisions of Production Management.

Objective

To develop a structural equation model of guidelines to garment industry management for sustainability.

Hypotheses

H1 Marketing management component has a direct influence on resource management component.

Marketing management has an influence on resource management in terms of management process. Good management process must comprise good quality production resources or good inputs. Once resources are entered into a management process, executives need to have good planning in management as this shall affect quality marketing and organizations can determine prices and profits on their own.

H2 Innovation management component has a direct influence on marketing management component

Innovation management and marketing management are commonly related to and affect each other. Businesses cannot survive if they are deprived of knowledge about marketing management because factors of production are developed continuously, making trading environment and market sizes change in a bad way. If organizations pay attention to production that has a good effect on markets, profits will come. This is consistent with a study conducted by Martin (Martin, 2014) that showed that efficient production planning would affect greater market value and when efficient marketing was mentioned, it definitely relied on quality products as well. Thus, to obtain quality products, efficient production management must have to play an important role. This is consistent with a study conducted by Scoburgh (Scoburgh, 2009) that found that production planning required relationship built with efficient marketing management.

H3 Manufacturing management component has a direct influence on innovation management component

Manufacturing system development affects innovation management in the current trading era. If organizations can successfully invent new innovation products, it will result in outstanding production compared to competitors who have not developed innovation products. With regard to trading or production in the past, it was in the form of being employed or original equipment manufacturing, making costs of production increase every year and organizations had more difficulty to survive, which is consistent with a study conducted by Hailey who found that creating innovation to replace old products had an effect on marketing as it enabled organizations to increase their sales volume and improve marketing at the same time. When textile and apparel industry is mentioned, the most necessary approach is heading to innovation technology that can create products responding to market needs. A study conducted by Chen (Chen & Huang, 2009) that found that textile and apparel industry could survive when supply chains were necessarily developed and innovation of products in textile and apparel industry was successfully created.

H4 Manufacturing management component has a direct influence on resource management component

To help ensure business succeeds, efficient resource management is required through the adoption of efficient manufacturing system. This is consistent with Paul (Paul, 2012) who said that organizations seeding survival must build good manufacturing system with innovation, good innovation necessarily required quality and a locatable resources. When quality resources achieve organizational learning, new organizational innovation would be brought.

H5 Importance levels of guidelines to garment industry management for sustainability as a whole separated by business sizes are different.

Management guidelines of each industry are typically different but what entrepreneurs or business operators are unable to avoid is competition in trading. When businesses step to global competition, most business operators will encounter restrictions when doing business; that is adjustment of working system that is unable to keep pace with changes in organizational surrounding factors that are expanding and growing. An important problem that business operators most likely encounter is lack of preparedness or they do not give importance to guidelines for increasing capacity, making them be unable to maintain or generate more revenue including market shares, which is consistent with a study conducted by Sally that indicated that business operators needed to have preparedness and develop organizations to be able to compete in the world of trading.

Methodology

1. This is a mixed-methodology research comprising 3 parts as qualitative research using in-depth interview; quantitative research using survey data collection; and qualitative research using focus group discussion.

2. As for the qualitative research using in-depth interview, the population in the study consisted of 9 experts, i.e. 3 persons of business operators or executives in business organizations, 3 persons of independent academics, and 3 persons of executives in government sector organizations or public organizations.

3. Structured interview was used as the study instrument in which the researcher determined interview guidelines with 4 components as marketing management; innovation management; resource management; and production management.

4. The instrument used in the qualitative research was a questionnaire. The index of item objective congruence (IOC) ranged between 0.60 – 1.00, discrimination scores ranged between 0.40 to 0.80, and reliability of the whole questionnaire was 0.95.

The sample responding to the questionnaire consisted of business operators, entrepreneurs, or executives in garment industry from 2,147 factories. Based on the reliability of 95% and separated by margin error of Taro Yamane method at the number of population ∞ the sample consisted of 500 persons ((Thanin, 2017). However, as for a research study related to component analysis, path analysis, and structural equation model, Comrey & Lee (Comrey & Lee, 1992) suggested that a sample size of 500 persons was appropriate and very good (Thanin, 2017); therefore, the sample of 500 persons was determined.

The qualitative research using focus group discussion was conducted to support the population being 7 experts and purposive sampling technique was used to select the sample.

Results

Analysis results of importance levels of guidelines to garment industry management for sustainability as a whole separated by sizes of business is shown in Table 1.

| Table 1 The Mean and Standard Deviation of Importance Levels of Guidelines to Garment Industry Management for Sustainability as a Whole |

||||

| Guidelines for garment industry management for sustainability | SD. | Significant level | ||

| Overall | 4.35 | 0.60 | High | |

| 1. Marketing management | 4.36 |

|

High | |

| 2. Innovation management | 4.35 | 0.60 | High | |

| 3. Resource management | 4.35 | 0.65 | High | |

| 4. Manufacturing management | 4.35 | 0.64 | High | |

From Table 2; analysis results of importance level of guidelines to garment industry management for sustainability as a whole separated by sizes of business indicated the following:

| Table 2 Shows the Mean and Standard Deviation of Importance Levels of Guidelines to Garment Industry Management for Sustainability as a Whole Separated by Sizes of Business |

|||||||

| Guidelines to garment industry management for sustainability |

Small and medium size business | Large size business | |||||

| SD | Level of importance |

SD | Significant level |

||||

| Overall | 4.35 | 0.67 | High | 4.37 | 0.55 | High | |

| 1 | Marketing management. | 4.35 | 0.57 | High | 4.38 | 0.51 | High |

| 2 | Innovation management | 4.35 | 0.63 | High | 4.37 | 0.55 | High |

| 3 | Resource management | 4.35 | 0.68 | High | 4.36 | 0.59 | High |

| 4 | Manufacturing | 4.34 | 0.67 | High | 4.37 | 0.57 | High |

1. The importance as a whole was found at a high level in small and medium size business with the mean of 4.35, marketing management had a high level of importance with the mean of 4.35, innovation management had a high level of importance with the mean of 4.35, resource management had a high level of importance with the mean of 4.35, and manufacturing management had a high level of importance with the mean of 4.3.

2. The importance as a while was found at high level in large business with the mean of 4.37, marketing management had a high level of importance with the mean of 4.38, innovation management had a high level of importance with the mean of 4.37, resource management had a high level of importance with the mean of 4.36, and manufacturing management had a high level of importance with the mean of 4.37.

Assessment result of goodness of fit in the structural equation model of guidelines to garment industry management for sustainability before and after model modification.

The assessment result of goodness of fit in the structural equation model of guidelines to garment industry management for sustainability before and after model modification found that the root mean square error of approximation (RMSEA) was 0.161 which passed the criteria of model fit and consistent with empirical data but chi-square probability level was 0.000, relative chi-square (CMN/DF) was 11.398 and goodness of fit index was 0.637 which did not pass the criteria of model fit and inconsistent with empirical data.

After the model was modified, chi-square probability level – p was 0.077 greater than 0.05. That means the model was not statistically significant. Relative chi-square (CMIN/DF) was 1.181, lower than 3, goodness of fit index was 0.966 greater than 0.90 and root mean square error of approximation (RMSEA) was 0.019, lower than 0.08. It can be concluded that all 4 statistical value passed the assessment criteria. Thus, the structural equation model of guidelines to garment industry management for sustainability after modification was consistent with the empirical data as seen in Figure 3.

Figure 3 Shows the Structural Equation Model of Guidelines to Garment Industry Management for Sustainability Under Unstandardized Estimate After the Model was Modified

Hypothesis test results to analyze causal influence between latent variables in the structural equation model of guidelines to garment industry management for sustainability consist of 4 points as shown below:

H1 Marketing management had a direct influence on resource management with statistical significance level of 0.001; factor loading was 0.67, compliant with the determined hypothesis.

H2 Innovation management had a direct influence on marketing management component with statistical significance level of 0.001, factor loading was 0.99, compliant with the determined hypothesis.

H3 Manufacturing management had a direct influence on innovation management component with statistical significance level of 0.001, factor loading was 0.96, complaint with the determined hypothesis.

H4 Manufacturing management had a direct influence on resource management component with statistical significance level of 0.01, factor loading was 0.33, complaint with the determined hypothesis, as seen in Table 3.

| Table 3 Shows Statistical Values from the Structural Equation Model Analysis after the Model was Modified | |||||||

| Variable | Estimate | R2 | Variances | C.R. | p | ||

| Standardized | Unstandardized | ||||||

| Marketing Management | |||||||

| Resources Management | 0.67 | 1.58 | 0.97 | 0.01 | 5.224 | *** | |

| Innovation Management | |||||||

| Marketing Management | 0.99 | 0.58 | 0.97 | 0 | 8.81 | *** | |

| Manufacturing Management | |||||||

| Resources Management | 0.96 | 0.67 | 0.93 | 0.02 | 17.05 | *** | |

| Innovation Management | 0.33 | 0.32 | 0.93 | 0.01 | 3.01 | 0.003 | |

| Marketing Management | |||||||

| 1-Mar | 0.42 | 1 | 0.17 | 0.38 | |||

| 3-Mar | 0.6 | 1.51 | 0.36 | 0.33 | 8.54 | *** | |

| 8-Mar | 0.7 | 1.8 | 0.49 | 0.27 | 9.08 | *** | |

| ####### | 0.86 | 2.19 | 0.73 | 0.14 | 9.65 | *** | |

| ####### | 0.5 | 1.37 | 0.25 | 0.44 | 7.87 | *** | |

| ####### | 0.6 | 1.61 | 0.36 | 0.36 | 8.56 | *** | |

| Innovation Management | |||||||

| Inno1 | 0.65 | 1 | 0.43 | 0.31 | |||

| Inno3 | 0.41 | 0.65 | 0.17 | 0.47 | 8.779 | *** | |

| Inno15 | 0.83 | 1.25 | 0.68 | 0.17 | 16.21 | *** | |

| Inn24 | 0.85 | 1.36 | 0.72 | 0.17 | 16.54 | *** | |

| Resources Management | |||||||

| reso1 | 0.93 | 1 | 0.86 | 0.07 | |||

| reso3 | 0.89 | 0.96 | 0.79 | 0.11 | 33.39 | *** | |

| reso15 | 0.92 | 0.99 | 0.86 | 0.07 | 37.99 | *** | |

| reso18 | 0.82 | 0.91 | 0.68 | 0.18 | 27.4 | *** | |

| Manufacturing Management | |||||||

| ro1 | 0.91 | 1 | 0.84 | 0.09 | |||

| pro4 | 0.91 | 0.96 | 0.83 | 0.09 | 34.48 | *** | |

| pro8 | 0.81 | 0.91 | 0.65 | 0.21 | 25.66 | *** | |

| pro9 | 0.92 | 1 | 0.85 | 0.09 | 35.24 | *** | |

Based on Figure 3 and Table 3, the analysis results of the structural equation model of guidelines to garment industry management for sustainability after the model was modified found that 4 latent variables divided into 1 exogenous latent variable, i.e. manufacturing management component, and 3 endogenous latent variables, i.e. marketing management component, innovation management component, and resource management component.

Significant statistical values like factor loading under standardized estimate and unstandardized estimate, coefficient of determination or R-square or multiple correlation( R2), critical ratio (CR), and statistical hypothesis testing (P-Value) of components or latent variables and observed variables can be described as follow:

In Manufacturing Management Components, it was found that the variance was 0.48 by directly influencing the components of innovation management at Standardized Regression Weight of 0.96 with statistical significance at the level of 0.001, Squared multiple correlation (R2) at 0.93, the variance at 0.02 and directly influenced the Resources Management component at Standardized Regression Weight of 0.33 with statistical significance at the level of 0.01, Squared multiple correlation (R2) at 0.97, variance at 0.01.

Marketing Management components directly influenced the Resources Management components at Standardized Regression Weight of 0.67 with statistical significance at the level of .001, squared multiple correlation (R2) at 0.97, variance at 0.01.

Innovation Management components directly influenced the Marketing Management components at Standardized Regression Weight of 0.99 with statistical significance at the level of .001, Squared multiple correlation (R2) at 0.97, variance at 0.00.

For the analysis of the weight of latent variable with the observable variable can be explained as follows;

The Marketing Management component consists of 6 observed variables arranged according to the sequence and standardized regression weight as follows: Survey variables of consumer demand to be used as a reference in product design (mar1) had the Standardized Regression Weight of 0.42 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.17, variance at 0.38. The use of Social Network to advertise and promote products such as Website, Facebook, Line etc (mar3) had the Standardized Regression Weight of 0.06 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.36, variance at 0.33. The analysis of competitor potential using Benchmarking method in the same market to be used as basic information in marketing planning (mar8) had the Standardized Regression Weight of 0.70 with statistical significance at the level of 0.001. Squared multiple correlation (R2) at 0.49, variance at 0.27. The existence of showroom for previewing all the products of the business for the convenience of customers' decisions. (mar13) had the Standardized Regression Weight of 0.86 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.73, variance at 0.14. There were advertisements promoting clothes by famous actors and actresses as presenters (mar21) with the Standardized Regression Weight of 0.50 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.25, variance at 0.44., and the invention of the new Incentive Program as a reward for salespeople who achieve sales targets (mar25) had a Standardized Regression Weight of 0.60 with statistical significance at the level of .001, squared multiple correlation (R2) at 0.36, variance at 0.36.

The innovation management consists of 4 observable variables arranged in sequence and standardized regression weight as follows: Variables in studying domestic and foreign innovation data related to garment production (inno1) had the Standardized Regression Weight of 0.65 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.43, variance at 0.31. The use of modern information technology, both hardware and software, to design products (inno3) had the Standardized Regression Weight of 0.41 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.17, variance at 0.47. Creating a culture of creativity for employees so that the organization becomes a learning organization (inno15) had the Standardized Regression Weight of 0.83 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.68, variance at 0.17, and the importance of copyright by the innovation from the development of employees in the organization (inno24) had the Standardized Regression Weight of 0.85 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.72, variance at 0.17.

The Resource Management component consists of 4 observable variables arranged in sequence and standardized regression weight as follows: Variables that affect staff training for knowledge and skills in both production and design (reso1) had the Standardized Regression Weight of 0.93 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.86, variance at 0.07. Budget allocation that was sufficient for all departments in the organization (reso3) had the Standardized Regression Weight of 0.89 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.79, variance at 0.11. Procurement of laser fabric cutting equipment for precise cutting and reducing loss from incorrect cutting (reso15) had the Standardized Regression Weight of 0.92 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.86, variance at 0.07, and arrangement of the material, equipments and tools to be easy to use and easy to store. (Reso18) had the Standardized Regression Weight of 0.82 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.68, variance at 0.18.

Manufacturing Management components consist of 4 observable variables arranged in sequence and standardized regression weight as follows: Variables in product development and design using computer aided (Computer-Aided Design: CAD) which allowed design and editing of the subject itself on the image screen (pro1) had the Standardized Regression Weight of 0.91 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.84, variance at 0.09, with factor loading at 0.91. Random product inspections to ensure that products produced were of good quality and standardized (pro4) had the Standardized Regression Weight of 0.91 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.83, variance at 0.09. Systematic data collection of production (pro8) had the Standardized Regression Weight of 0.81 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.65, variance at 0.21, and warehouse management with modern control systems by using software packages to manage warehouse to reduce duplication of raw material purchases (pro9) had the Standardized Regression Weight of 0.92 with statistical significance at the level of .001. Squared multiple correlation (R2) at 0.85, variance at 0.09.

Conclusion and Discussion

The equation of the structure of guidelines for managing ready-to-wear clothing industry sustainability, consisting of 4 components, namely marketing management, Innovation management, Resource management and manufacturing management. The results of the study of the importance of the components in all 4 aspects found that all aspects were at high level of importance. The comparison of the importance levels of the ready-to-wear garment industry management approach to sustainability classified by the size of the business organization found that the importance of the ready-to-wear garment industry management approach to sustainability overall in each aspect and each item had no statistically significant difference at the level of 0.05.

After the model was completed, it was found that the Chi-Square Probability Level (p) equal to 0.077, greater than 0.05, CMIN\DF, equal to 1.181 which was less than 3, the Consistency Index (GFI) was equal to 0.966, which was greater than 0.90, and the Root Index of Mean Square Error (RMSEA) was 0.019 which was less than 0.08. In conclusion, all 4 statistics passed the evaluation criteria. Therefore, the variables will be developed to be a structural equation model for the ready-made garment industry management approach to sustainability.

The industrial sector pays attention to the guidelines for managing ready-to-wear garment industry to sustainability in marketing management more than other aspects, which corresponds to Kotler (2003) who suggested that marketing is an important component of social business competition, and market management is also a management planning process, such as pricing, marketing promotion, distribution, service, and others in order to exchange satisfaction or meet the needs of the target group, as well as to achieve the goals of the organization. It is also in line with Porter (2012) 's concept of marketing that is about creating effective and practical competitive advantage such as the application of the Value Chain Theory to the organization for sustainability in business operations

The innovation management component has a direct influence on the marketing management component which is consistent with Chesbrough (2003) which has proposed that Innovation is an important part of the business process (Innovation as a core business process). It is like the heart that shows the initiatives and makes them useful. In addition, it is in accordance with Morton & Lewis (2005) who said that innovation management is the improvement and development of personnel capabilities as well. Therefore, innovation is at the heart of business operations and the survival of the business will be able to expand the market and new customer base, which increases the productivity of the production process. Innovation management is therefore a science and an important tool for technology changes and affects the industry and organization, and in accordance with Paul (2012) who stated that in order to make an organization survive sustainably, we need to create innovation in the organization. Innovation will allow us to set sales prices and profits as needed. This is in accordance with Scherer (1986) who presented that organizational structure, teamwork behavior, successful operations and high profits depending on innovative management methods. The result from testing of the impact of factors affecting innovation activities suggests that corporate profits have a significant impact on the organization's innovation activities.

Suggestions

Guidelines for sustainable garment industry management are essential for the business sector due to high business competition. Therefore, the researcher has suggested guidelines for managing the ready-to-wear garment industry for sustainability in accordance with the 4 main components as follows;

1. In terms of market management, there should be a demand survey and product development to be modern and popular in order to meet the needs of the target group by integrating with various elements to help the garment industry achieve sustainability. There should be a showroom to display all product samples for the convenience of customers' decisions and to participate in exhibitions at various events organized by the government.

2. In the area of innovation management, there should be support for personnel to develop innovation by using various incentives including research and research to get quality innovation and also to create a competitive advantage. Modern information technology, both hardware and software, should be used in product design. An innovation agency should be established to be directly responsible for creating innovations and to use a dyeing system by not using water to reduce the amount of water and waste water generated from dyeing.

3. In terms of resource management, there is a need for systematic resource management because it will help maximize the efficiency of management, whether it be personnel development, operational potential, financial which will help reduce costs, raw materials which will help reduce production losses. Modern machinery that is environmentally friendly should be procured for use in the production of ready-made garments, and information technology should be used in industrial plants so that buyers can order products conveniently and efficiently choose the format they want, as well as there should have sufficient machinery procurement for production process and ready for use etc.

4. In terms of production management, there should be various enhancements in the production process, including every step of production management planning in order to reduce errors that occur and are constantly being improved. Production quality should be controlled to meet international standards. Schedule production both short-term and long-term should be managed by using software to help predict and determine future demand for products and services and apply modern technology for production.

References

- Aphichat, K.B. (2018). Legal problems regarding the formulation of the national strategy of Thailand. Unpublished doctoral dissertation, Thammasat University.

- Armstrong, G., & Kotler, P. (2003). Marketing and introduction. New Jersey: Pearson Education.

- Barney, J.B. (2001). Is the resource-based “view” a useful perspective for strategic management research? Yes. Academy of Management Review, 26(1), 41-56.

- Barney, J.B., & Clark, D.N. (2007). Resource-based theory: Creating and sustaining competitive advantage. Oxford University Press on Demand.

- Chen, C.J., & Huang, J.W. (2009). Strategic human resource practices and innovation performance-The mediating role of knowledge management capacity. Journal of Business Research, 62(1), 104-114.

- Chesbrough, H.W. (2003). The era of open innovation (Periodical style). MIT Sloan Management Review, 44(3), 35-41.

- Comrey, A.L., & Lee, H.B. (1992). A first course in factor analysis. Hillsdale, NJ: L.

- Customs Department. (2019). Value of Thai exports of textiles and clothing from 2008-2018. Retrieved from http://www.customs.go.th/statistic_report.php?lang=en&ini_content=statistics_report&ini_menu=nmenu_esevice%20&left_menu=nmenu_esevice_007&&left_menu=nmenu_esevice_007

- Gillespie, Jeannet, &Hennessey, D. (2010). Assessing advantage: A framework for firms, Entrepreneurship Theory and Practice.

- Kotler, P. (2003). Marketing Management (11th Editio). northwestern University.

- Kotler, P., & Keller, K.L. (2006). Marketing management: Pearson international edition. Pearson Prentice Hall.

- Kuczmarski, T.D. (1996). Innovation: Leadership strategies for the competitive edge. NTC Publishing Group.

- Morton, W.S., & Lewis, C.M. (2012). China: Its history and culture. New York: McGraw-Hill, 2005. China at War: An Encyclopedia: An Encyclopedia, 326.

- Paul , T. (2012). Innovation management and new product development paperback.

- Pichit, S. (2003). Production engineering management. Bangkok: SE-EDUCATION.

- Prasong, P.P. (2004). Production and operation management. Revised edition, Bangkok: Dimond Din Business World.

- Punsuk, S. (2007). Human relations in organizations. Bangkok: BK Interprint.

- Rungnapa, C. (2007). Effect of production management efficiency on the competitiveness of the domestic textile industry business. Unpublished doctoral dissertation, Graduate School Mahasarakham University.

- Scherer, F.M. (1986). Innovation and growth: Schumpeterian perspectives. MIT Press Books, 1.

- Scoburgh, N.L. (2009). Organizational learning: an exploration of the influence of capabilities and factors. Unpublished doctoral dissertation, Capella University.

- Thailand Textile Institute ( 2020a). Number of labor in the ready-to-wear garment industry during the years 2009 - 2017. https://www.thaitextile.org/th/insign/industrymovement.php#1

- Thailand Textile Institute. ( 2020c). Thai textile statistics 2018/2019. Retrieved from https://drive.google.com/file/d/1wTlz57TbfwmFQ02T8VXCNuhmhyBXlkcX/view

- Thailand Textile Institute. (2020b). Situation of import-export of textile and garment industry. https://www.thaitextile.org/th/insign/statistics.php#1

- Thanin, S.J. (2017). Statistical research and analysis using SPSS and AMOS. Bangkok:Triple Printing Company.

- Ubben, G.C., Hughes, L.W., & Norris, C.J. (2015). The principal: Creative leadership for excellence in schools. Pearson.