Research Article: 2021 Vol: 20 Issue: 6S

Towards a Decade of Smart Manufacturing (2011-2019): A Bibliometric Analysis and its Future Outlook

Syed Radzi Bin Rahamaddulla, University Putra Malaysia

Zulkiflle Bin Leman, University Putra Malaysia

B.T Hang Tuah Bin Baharudin, University Putra Malaysia

Abstract

This article encapsulates the expansion structure of Smart Manufacturing between 2011 and 2019 and offers a brief contextual impression on Smart Manufacturing interrelated publications and the application areas as well as the outlook. With the aim to provide a systematic review on the research topic, the analysis is conducted by PRISMA method, together with the adoption of the R language in analyzing the literature retrieved from Scopus and Web of Science databases. Four stages of data analysis with several performance metrics are employed and discussed. From this analysis, the total number of citations (TC), the total number of papers published (TP), and publication percentage are reported. Besides, Top 20 of most-cited authors, major subject area, source of the journal and total cited percentage are successfully assessed. From numerous researchers in the field, it can be concluded that Li D was the most competitive authors based on their large numbers of papers and citations.

Keywords

PRISMA Method, Smart Manufacturing, Most-Cited Authors, Major Subject Area

Introduction

During the 18th and 19th centuries, the world witnessed a leap in technology with the development of steam engines and the commercialization of electricity. This led to rapid developments in Information and Communication Technology (ICT) and automation during the later parts of the 20th century. As one of the main enablers in the technological paradigm, ICT development has shown positive progress through both Hardware (H/W) and Software (S/W) innovation. In recent years, manufacturing industry is more flexible, in which capable of producing variety products. It is a known fact that customers today are more open to customized products and the conventional factory finds it challenging to cope with such a demand. Despite the challenge, the manufacturing firm is striving to ensure that productivity is maximized at minimal cost without sacrificing the quality of products. A fully integrated and collaborative manufacturing system is the answer to such customer needs. To date, numerous technologies have been developed and proven to support the realization of Smart Manufacturing. For instance, Internet of Things (IoT) (Kumar & Mallick, 2018; Plageras, Psannis, Stergiou, Wang & Gupta, 2018), Cloud (Plageras et al., 2018), Cyber-Physical System (CPS) (Lee, Bagheri & Kao, 2015) and Expert Learning (EL) (Roldán, Crespo, Martín-Barrio, Peña-Tapia & Barrientos, 2019) are among the cutting-edge technologies that have been proven as a viable solution to achieving a smart factory.

The term “Smart Factory” is predominantly used in Europe, Asia and Korea, which also refers to the term of “Smart Manufacturing” (predominantly used in the USA) or “Industry 4.0” (predominantly used in Germany/Europe) (Davis, 2017; Thoben, Wiesner & Wuest, 2017). To date, Smart manufacturing (SM) technology has gained significant momentum in the industry and academic circles (Mittal, Khan, Romero & Wuest, 2018). SM is an ideal solution that provides flexible and adaptive production processes that will resolve problems that arise from a production facility with dynamic and rapidly changing boundaries. In the context of SM, machines nowadays redefine, interact and perform the specific tasks themselves without human interventions (Muhuri, Shukla & Abraham, 2019). This special solution could be related to automation, which is understood as a combination of software, hardware and/or mechanics, which lead to optimization of the manufacturing process resulting in the reduction of unnecessary labor and resource wastage. Industrial and non-industrial partners may see this as an opportunity to collaborate in making a dynamic organization (Hozdi?, 2015).

Nevertheless, despite many success stories and long-listed advantageous of SM, it can be argued that the SM framework is complex, where no SM framework could fit all industry type at once. This is proven by the abundance of published literature worldwide, in which each article presents SM implementation to its specific industry. Based on the Scopus database, 3,465 documents were published under the keyword of “Smart Manufacturing” with the earliest paper published in 1985 (Kaplan, 1985). Nonetheless, by refining the literature search with including other similar terms of SM (Smart factory, Industry 4.0, Intelligent Manufacturing and Future Factory), it has resulted 14,594 documents being published to date. This proves that the small difference in the literature finding method could lead to the chances of missing information that might be useful for SM future outlook.

Accordingly, with the aims to provide a systematic review in Smart Manufacturing, a thorough bibliometric analysis of “Smart Manufacturing” was carried out based on the published literature from Scopus and Web of Science (WoS) databases. This work explicitly highlights the most influential author, most cited discipline, total citation, and top 10 publishers in the field. Besides, this paper visualized the most relevant keyword to avoid missing information from the relevant published studies. Furthermore, in order to provide a coherent picture of the emergent research in SM (especially for the new researcher), 15 most cited papers from both databases are listed and discussed.

This work is delivered in 5 main sections, including the Introduction and Conclusion, respectively portrayed in Sections 1 and 5. Following the Introduction Section, the methodology is discussed in Section 2. In Section 3, the extensive bibliometric analysis performed in this work is shown. Accordingly, the outlook of smart manufacturing obtained after the analysis are discussed in Section 4. The final section concludes this work with the research outcome is summarized.

Methodology

A bibliometric analysis is a research practice that investigates the latest study trend in literature. Introduced by Pritchard (1969), bibliometric analysis has become a viable method for understanding a research field's temporal evolution from a multi-disciplinary perspective. To date, numerous bibliometric analysis has been conducted in many distinguished topics, including in accounting (Kumar, Marrone, Liu & Pandey, 2020), waste management (Tsai, Bui, Tseng, Lim & Hu, 2020), neurosurgery (Kiraz & Demir, 2020) and energy management (Cabeza, Frazzica, Chàfer, Vérez & Palomba, 2020). Following the trends, Ahmi, Elbardan & Raja Mohd Ali (2019); Bertoncel & Meško (2019); Muhuri, et al., (2019) presented bibliometric analysis in advance manufacturing and industrial 4.0. Also, several studies that can be categorized in manufacturing include the analysis in augmented reality (Karakus, Ersozlu & Clark, 2019), cybersecurity (Jalali, Razak, Gordon, Perakslis & Madnick, 2019) and additive manufacturing (Caviggioli & Ughetto, 2019).

Generally, a bibliometric analysis provides a guideline and insight to the specific area of the presented work. With bibliometric analysis, the most relevant authors, publisher, topics, and impact of a paper can be identified (Cancino, Merigó, Coronado, Dessouky & Dessouky, 2017; Merigó, Pedrycz, Weber & de la Sotta, 2018; Muhuri et al., 2019).

This would help the future researcher to determine the research path at an early stage. In most bibliometric analysis, Web of Science and Scopus databases are most used in the analysis. Besides, the use of accurate keyword in searching the articles are highlighted (Cabeza et al., 2020; Caviggioli & Ughetto, 2019; Kiraz & Demir, 2020).

Despite many researchers focusing on screening the search by only keywords, Rejeb, et al., (2020) screened the literature by considering search performed in the title, abstract and keywords fields. To ensure the high quality and academic nature of the literature, Rejeb, et al., (2020) only considered peer-reviewed journal articles in English. Similarly, Caviggioli and Ughetto (2019) also limit their analysis to the document published in English that further limited to the articles in scientific journals, conference proceedings and book chapters published between 1982 and July 2017. This indicating flexibility in performing the bibliometric analysis, in which the author could limit the study in many ways. From the previously published bibliometric analysis, several tools in data analysis are identified. For instance, VOS viewer and R language have been widely employed in data analysis (Kiraz & Demir, 2020; Kumar et al., 2020; Rejeb et al., 2020). By referring the previously published studies, this work started with setting the conceptual boundaries that define the research aims. The following subsections discussed the methods used in conduct the review. This study employs PRISMA method that includes the resources from both SCOPUS and Web of Science. The exclusion criteria and eligibility are checked, followed by steps of data abstraction and analysis using the R language.

Prisma

PRISMA (Preferred Reporting Items for Systematic reviews and Meta-analyses) provides the analysis protocol in systematic review. PRISMA is often used in the management field. It provides three unique advantages: viz., defining a clear research question that permits systematic research, identifying inclusion and exclusion criteria, and examining a large database of scientific literature in a defined time period (Sierra-Huelsz & Kainer, 2018).

Resources

Scopus and Web of Science (WoS) database were used for this analysis. Both databases are robust and rich in research disciplines. Table 1 explains the generic information of both databases. Journals in both these categories cover interdisciplinary subjects.

| Table 1 The Source Database General Information |

||

|---|---|---|

| Database/details | Scopus | Web of Science (WOS) |

| No of journals | > 22, 800 | > 33, 000 |

| No of disciplines covered | > 330 | > 250 |

| Temporal coverage | 2004 to present | 1900 to present |

| Provider | Elsevier | Clarivate analysis |

Eligibility and Exclusion Criteria

Eligibility and exclusion criteria are being included in this analysis to ensure that the right resources are reviewed. This analysis process only includes journal articles and excludes all the other resources from review articles, book series, books, chapters in books and conference proceedings. To evade any difficulty in translation, the non-English publication was omitted, and articles published in English were only selected. As the term of SM and Industry 4.0 can be interchangeably used, the timeline of the database is limited from 2011 to 2019, providing a review before it (Industry 4.0) reaches 10 years. Lastly, in line with the focus of this study in Smart Manufacturing, articles focusing on Smart Manufacturing are selected (see Table 2).

| Table 2 The Inclusion And Exclusion Criteria |

||

|---|---|---|

| Criterion | Entitle | Exclusion |

| Literature type | Journal (research articles) | Journal (systematic review), book series, book, chapter in book, conferences, and proceedings |

| Language | English | Non-English |

| Timeline | From 2011 to current | < 2011 |

Bibliometric Analysis Process

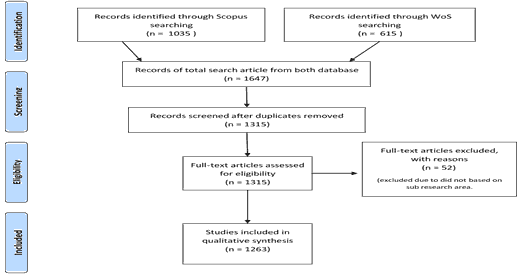

There were four stages involved in this analysis process. This analysis was done on the publications within the year of 2011 to 2019. The first phase is the keyword search phase. Based on past studies and wordlist, keywords that match smart manufacturing were used (see Table 3). Then, the duplication of an article from the two databases was removed. Among the 1,647 qualified papers to be reviewed, 332 papers were removed to avoid duplication.

| Table 3 Search Keyword String Used In This Analysis |

|

|---|---|

| Databases Source | Keyword’s string |

| Web of Science | TS=(("Smart Manufacturing" OR "Smart Factory" OR "Future Factory" OR "Intelligent Manufacturing" OR "Industrial 4.0") Refined by: Publication Years: (2019 or 2018 or 2017 or 2016 or 2015 or 2014 or 2013 or 2012 or 2011) And Languages: (English) And Document Types: (ARTICLE)) |

| Scopus | Title-Abs-Key (("Smart Manufacturing" or "smart factory" or "future factory" or "Intelligent Manufacturing" or "Industrial 4.0") Refined by: Publication Years: (2019 OR 2018 or 2017 or 2016 or 2015 or 2014 or 2013 or 2012 or 2011) and Languages: (English) and Document Types: (article)) |

In the third stage, the eligibility is checked. The focus of the eligibility criteria is more on the subject area, topic, language, and type of the article as this study focuses only on journal articles. After diligent review, another 52 articles were excluded due to meeting the eligibility and exclusion criteria. The fourth and final stage of this analysis is to review the result from the remaining 1,263 best suitable articles using a qualitative approach (Figure 1).

Bibliometric Analysis

In this section, analysis from the various performances is shown. Among many, Total Papers (TP) indicates the total number of papers from the publisher an author, Total Citation (TC) specify the number of times a paper is being cited, Most Cited Article, most relevant author, keyword concurrent and to name many more in the area of “Smart Manufacturing”.

Research Progression in Smart Manufacturing Research Area

Over the years, Smart Manufacturing topic has attracted profound interest that covers a wide range of sub research areas from service, manufacturing, computer, electrical and electronic and many more. The idea of Industrial 4.0 was incepted in the year 2011at the Hannover Fair, by the Industrial 4.0 working group in Germany. Figure 2 exhibits the trend of total publication from 2011 to 2019. In the years 2011 and 2012, both Scopus and WoS published on an average of 11 papers per year on the Smart Manufacturing topic. Nevertheless, the number of papers increased exponentially over the years. In 2018 both WoS and Scopus have recorded the highest numbers of total publications where a total of 498 papers were published.

A total of 6,697 citations count was recorded from both the databases on this topic between the year 2011 and the current year. Both databases started with a total of 94 citations each in the year and the numbers progressively increase over the years. In the year 2016, WoS reached its best with a total citation in the topic of smart manufacturing at 1,125 TC (total count of citations). In contrast, Scopus has recorded its best high TC in the year 2016 while WoS TC in that year has reduced by 31% from the previous year (see Figure 3).

From the total number of publications, citations, and the increasing trend pattern of the chart from the year 2011 till 2019, we can observe that research in the field of Smart Manufacturing is likely to further expand in the coming years. In just 9 years the total publication in WoS is 615 whereas Scopus has scored much higher with the total publications count at 648 papers. There is clear evidence that there is an exponential increase in the number of publications in both databases.

Discipline’s Analysis

Both databases adequately allocate appropriate subject categories in their indexing directory (see table 4). Eight main disciplines were registered in Scopus; meanwhile, WoS has identified six main disciplines in their registry. In general, Computer Science was ranked first in both databases where Scopus has TP of 171, and WoS has TP of 245. The second highest discipline in Scopus was Manufacturing with TP 140, which reflects 21.6% of TP in the area of Smart Manufacturing in the database. Meanwhile, WoS’s second-largest discipline was Engineering with TP of 164. Scopus has a TP score of 120 in the Engineering discipline. There has been an integration of various sub-disciplines in engineering from both databases due to the integration of various industries.

,/

| Table 4 Disciplines Covered In Both Databases |

|||||

|---|---|---|---|---|---|

| Scopus | WoS | ||||

| Discipline | TP | % | Discipline | TP | % |

| Computer Science | 171 | 26.4 | Computer Science | 245 | 39.8 |

| Manufacturing | 140 | 21.6 | Engineering | ||

| Engineering | 120 | 18.5 | (Automotive, manufacturing, Mechatronics, Electronics, Science & Technology) | 164 | 26.7 |

| (Mix Discipline) | |||||

| Electrical & Electronic | 62 | 9.6 | Automation, Control & Robotic | 84 | 13.7 |

| Robotic | 59 | 9.1 | Social Science and others | 75 | 12.2 |

| Management | 56 | 8.6 | Material & Chemistry | 31 | 5 |

| Material | 25 | 3.9 | Business & Management | 16 | 2.6 |

| Mechatronics | 15 | 2.3 | |||

One interesting observation that can be summarized so far is that the authors from Business and Management disciplines have shown interest in writing papers on the topic of industrial 4.0 and smart manufacturing. However, the number of publications from this discipline has not exceeded 10% of the TP of both the databases (TP=56 in Scopus, TP=16 in WoS and the trend from year 20016 to the year 2019 is on the positive side. Broader integration from various disciplines is expected in years to come to boost the number of TP.

Highly Influential and Most Prolific Authors

Based on the number of publications from Scopus and WoS, the most prominent and prolific authors were extracted. The database was sort based on the total publication across the years. The author with the same number of publications assorted based on their TC rating. Table 5 exhibits the most highly cited authors. In both repertories, Li Dong (Li D) leads the rank with (TP=15; TC=439 in Scopus and TP=23; TC=615 in WoS) respectively. Whereas Jia Fu Wan (Wan J.) was the second highest contributor with (TP=12; TC=421 in Scopus and T P= 16; TC=563 in WoS).

In Scopus, Wan, J. is followed by Liu, C. with 9 TP and 65 TC. While, Li, X., Tao, F., Zhang, Y., and Whang, Y., with eight publications each are respectively ranked fourth, fifth, sixth and seventh in the list. Following that, Lee, S., is at the eighth rank with 7 TP. There are three authors from the top 20 list from rank 9-11, whose TP is 3. These authors are Lee, JY., Kumar, A., and Liu, Y. With 5 publications each and nine more authors are listed from rank 12-20. Regardless of their ranking, some authors like Wang, S., and hang, C., have more than 250 Total citations for their articles that they have produced. While the remaining authors like Wuest, T., Imran, M., Yu, H., Chang, TW., Kim, T., Zhang, J., and Lee, H., have TC of 86, 34, 18, 8, 6, 6, and 5 respectively.

In WoS, Wang, S.Y. with TP of 14 secure rank 3 while Tao, F., and Liu, CL., with TP of 11 take the 4th and 5th rank. Three authors with TP of 7 are ranked from 6th to 8th position namely, Zhong, RY., Imran, M., and Gao, RX. They are followed by 7 other authors with TP of 6 and ranked from 9th to 15th. These authors are Zhang, Ch., Huang, GQ., Edgar, TF., Hua, QS., Trentesaux, D., Kumar, A., and Liuy, Y. The last 5 authors from this top 20 list are Qi, QL., Chien, CF., Baldea, M., Jung, K., and Lee, JY. All 5 authors have published 5 articles each and they have been cited 193 times in the WoS repository in total.

| Table 5 Top 20 Most Highly Cited Author |

||||||

|---|---|---|---|---|---|---|

| N | Scopus | WoS | ||||

| Authors | TP | TC | Authors | TP | TC | |

| 1 | Li D | 15 | 439 | Li D | 23 | 615 |

| 2 | Wan J | 12 | 421 | Wan Jf | 16 | 563 |

| 3 | Liu C | 9 | 65 | Wang Sy | 14 | 537 |

| 4 | Li X | 8 | 126 | Liu Cl | 11 | 99 |

| 5 | Tao F | 8 | 71 | Tao F | 11 | 136 |

| 6 | Zhang Y | 8 | 31 | Zhong Ry | 7 | 207 |

| 7 | Wang Y | 8 | 10 | Imran M | 7 | 154 |

| 8 | Lee S | 7 | 22 | Gao Rx | 7 | 81 |

| 9 | Lee Jy | 6 | 178 | Zhang Ch | 6 | 347 |

| 10 | Kumar A | 6 | 27 | Huang Gq | 6 | 202 |

| 11 | Liu Y | 6 | 15 | Edgar Tf | 6 | 36 |

| 12 | Wang S | 5 | 362 | Hua Qs | 6 | 24 |

| 13 | Zhang C | 5 | 257 | Trentesaux D | 6 | 95 |

| 14 | Wuest T | 5 | 86 | Kumar A | 6 | 37 |

| 15 | Imran M | 5 | 34 | Liu Y | 6 | 34 |

| 16 | Yu H | 5 | 18 | Qi Ql | 5 | 83 |

| 17 | Chang Tw | 5 | 8 | Chien Cf | 5 | 45 |

| 18 | Kim T | 5 | 6 | Baldea M | 5 | 34 |

| 19 | Zhang J | 5 | 6 | Jung K | 5 | 23 |

| 20 | Lee H | 5 | 5 | Lee Jy | 5 | 8 |

Top Source Journal

In this section, the top 10 journals that published articles relating to Smart Manufacturing works are discussed. Table 6 elaborates on the TP and TC of the top 10 journals from both Scopus and WoS. The order is based on the number of Total Publications and Total Citations. Ifac-Papers online has the most published and cited papers with TP of 57 and TC of 191 in Scopus where IEEE Access tops the WoS database list with TP of 40. The same leading journal in WoS was ranked 5th in the Scopus database with 15 articles. The number of publications has no direct impact on the total citation. This has been proved by the International Journal of Production Research, from WoS, where the total TP is 17. However, TC is the highest among all the listed journals in the two databases. Procedia Manufacturing Journal was the second-highest publishing journaling Scopus with TP of 32 and TC of 188. On the other hand, the International Journal of Advance Manufacturing Technology has taken second place in the WoS database with 28 total publications and 125 total citations. In Scopus, the top 10 journals have contributed to 191 total articles representing almost 30% of the total publications. In contrast, WoS top-10 journals have contributed 203 publications that cover 33% of the total publications in the area of Smart manufacturing.

| Table 6 Top 10 Journal Publishing Works On Smart Manufacturing Area |

|||||

|---|---|---|---|---|---|

| Scopus | WoS | ||||

| Journal | TP | TC | Journal | TP | TC |

| Ifac - Papersonline | 57 | 191 | IEEE Access | 40 | 174 |

| Procedia Manufacturing | 32 | 188 | International Journal of Adv. Mfg. Technology | 28 | 125 |

| Manufacturing Letters | 19 | 56 | Journal of Intelligent Manufacturing | 25 | 215 |

| Sensors (Switzerland) | 18 | 35 | IEEE Transactions on Industrial Informatics | 20 | 123 |

| IEEE Access | 15 | 110 | Journal of Manufacturing Systems | 19 | 101 |

| IEEE Transactions on Ind. Informatics | 13 | 47 | Sensors | 18 | 18 |

| International Journal of Prod. Research | 12 | 87 | International Journal of Production Research | 17 | 216 |

| Journal of Intelligent Manufacturing | 9 | 23 | Computers & Industrial Engineering | 14 | 44 |

| Sustainability (Switzerland) | 8 | 18 | Journal of Ambient Intelligence & Humanized Computing | 12 | 6 |

| Applied Sciences (Switzerland) | 8 | 15 | International Journal of Computer Integrated Mfg. | 10 | 39 |

Top 15 Highly Influential Papers

In this part, 15 most significant and influential papers based on the number of citations are discussed. Table 7 and 8 depict the rank of the author from both journals. The tables are furnished with the name of the author, year of publication publishing source, and average total citation per year. A cursory glance indicates that the most influential paper is from the year 2016, wherein this year, Scopus has 6 papers and WoS has 5 papers from the record. The top 15 most influential papers recorded the total of 1,047 TC from Scopus and 1,033 TC from WoS.

Table 7 lists the top 15 most influential authors in Scopus. With an average TC of 74 per year, Wang et al. (2016) is at the top of the list. This paper, in general, touches the subject of Big Data in Smart Factory. This was followed by Kang, et al., (2016a) with 168 TC and an average of 56 TC per year. In this paper, the research of past, present and future directions of smart manufacturing was discussed, which has served as an eye-opener and direction to future researchers. Papers from other areas such as intelligent manufacturing, machine learning, IoT, digital factory and digital twin also were influential.

| Table 7 Highly Cited Papers In The Area Of Smart Manufacturing In Scopus |

|||||||

|---|---|---|---|---|---|---|---|

| No | Author & Year | Title | Source | TC | TC per year | ||

| 1 | Wang, et al., (2016) | Towards Smart Factory for Industry 4.0: A Self-Organized Multi-Agent System with Big Data Based Feedback and Coordination | Computer Networks | 221 | 74 | 221 | 74 |

| 2 | Kang, et al., (2016) | Smart Manufacturing: Past Research, Present Findings, And Future Directions | International Journal of Precision Engineering and Manufacturing - Green Technology | 168 | 56 | 168 | 56 |

| 3 | Zhong, et al., (2017) | Intelligent Manufacturing in The Context of Industry 4.0: A Review | Engineering | 104 | 52 | 104 | 52 |

| 4 | Li, et al., (2017) | A Review of Industrial Wireless Networks in The Context of Industry 4.0 | Wireless Networks | 96 | 48 | 96 | 48 |

| 5 | Wuest, et al., (2016) | Machine Learning in Manufacturing: Advantages, Challenges, And Applications | Production and Manufacturing Research | 58 | 19 | 58 | 19 |

| 6 | Zhong, et al., (2017) | Big Data Analytics for Physical Internet-Based Intelligent Manufacturing Shop floors | International Journal of Production Research | 55 | 28 | 55 | 28 |

| 7 | Zawadzki, et al., (2016) | Smart Product Design and Production Control for Effective Mass Customization in The Industry 4.0 Concept | Management and Production Engineering Review | 55 | 18 | 55 | 18 |

| 8 | Yue, et al., (2015) | Cloud-Assisted Industrial Cyber-Physical Systems: An Insight | Microprocessors and Microsystems | 46 | 12 | 46 | 12 |

| 9 | Odonovan, et al., (2015) | Big Data in Manufacturing: A Systematic Mapping Study | Journal of Big Data | 44 | 11 | 44 | 11 |

| 10 | Longo, et al., (2017) | Smart Operators in Industry 4.0: A Human-Cantered Approach to Enhance Operators Capabilities and Competencies Within the New Smart Factory Context | Annual Reviews in Control | 39 | 20 | 39 | 20 |

| 11 | Wan, et al., (2016) | Mobile Services for Customization Manufacturing Systems: An Example of Industry 4.0 | Ieee Access | 34 | 11 | 34 | 11 |

| 12 | Lee, et al., (2015) | Smart Factory Systems | Informatik-Spektrum | 33 | 8 | 33 | 8 |

| 13 | Negri, et al., (2017) | A Review of The Roles of Digital Twin in Cps-Based Production Systems | Procedia Manufacturing | 32 | 16 | 32 | 16 |

| 14 | Bertino, et al., (2016) | Internet of Things (IoT): Smart and Secure Service Delivery | Acm Transactions on Internet Technology | 32 | 11 | 32 | 11 |

| 15 | Krajcovic, et al., (2013) | Intelligent Manufacturing Systems in Concept of Digital Factory | Komunikacie | 30 | 5 | 29 | 29 |

Table 8 portrays the 15 most influential authors in WoS. Davies, et al., (2012a) was at the top-ranked in this repository. The published research on manufacturing intelligence and demanded dynamic performance was cited 156 times. While, Wang et al. (2016) have TC of 148 for the paper discussing smart factory implementation in Industry 4.0 and its outlook. Zhong, et al., (2015) ranked in third place with TC of 16118. Zhong, et al., have explored the area of Big Data for logistics. Other leading research areas identified in the top influential paper category are IoT, Cloud Manufacturing, Factory of Thing, Intelligent Manufacturing, Sensors and Wireless, and Supply Chain in the smart factory.

| Table 8 Highly Cited Papers In The Area Of Smart Manufacturing In Scopus |

|||||

|---|---|---|---|---|---|

| Author & Year | Title | Source | TC | TC per year | |

| Davis, et al., (2012) | Smart Manufacturing, Manufacturing Intelligence and Demand-Dynamic Performance | Computers & Chemical Engineering | 221 | 74 | 74 |

| Wang, et al., (2016) | Implementing Smart Factory of Industrie 4.0: An Outlook | International Journal of Distributed Sensor Networks | 168 | 56 | 56 |

| Zhong, et al., (2015) | A Big Data Approach for Logistics Trajectory Discovery from RFID-Enabled Production Data | International Journal of Production Economics | 104 | 52 | 52 |

| Wan, et al., (2016) | Software-Defined Industrial Internet of Things in The Context of Industry 4.0 | IEEE Sensors Journal | 96 | 48 | 48 |

| Ivanov, et al., (2016) | A Dynamic Model and An Algorithm for Short-Term Supply Chain Scheduling in The Smart Factory Industry 4.0 | International Journal of Production Research | 58 | 19 | 19 |

| Hofmann, et al., (2017) | Industry 4.0 And the Current Status as Well as Future Prospects on Logistics | Computers in Industry | 55 | 28 | 28 |

| Goodrich, et al., (2013) | Assessing the Drivers of Regional Trends in Solar Photovoltaic Manufacturing | Energy & Environmental Science | 55 | 18 | 18 |

| Zhong, et al., (2016) | Visualization of RFID-Enabled Shop floor Logistics Big Data in Cloud Manufacturing | International Journal of Advanced Manufacturing Technology | 46 | 12 | 12 |

| Wan, et al., (2017) | A Manufacturing Big Data Solution for Active Preventive Maintenance | IEEE Transactions on Industrial Informatics | 44 | 11 | 11 |

| Pach, et al., (2014) | Orca-Fms: A Dynamic Architecture for The Optimized and Reactive Control of Flexible Manufacturing Scheduling | Computers in Industry | 39 | 20 | 20 |

| Savazzi, et al., (2014) | Wireless Cloud Networks for The Factory of Things: Connectivity Modelling and Layout Design | IEEE Internet Of Things Journal | 34 | 11 | 11 |

| Palattella, et al., (2016) | On-The-Fly Bandwidth Reservation For 6Tisch Wireless Industrial Networks | IEEE Sensors Journal | 33 | 8 | 8 |

| Tao, et al., (2019) | New It Driven Service-Oriented Smart Manufacturing: Framework and Characteristics | IEEE Transactions on Systems Man Cybernetics-Systems | 32 | 16 | 16 |

| Jia, et al., (2014) | Therblig-Based Energy Demand Modelling Methodology of Machining Process to Support Intelligent Manufacturing | Journal of Intelligent Manufacturing | 32 | 11 | 11 |

| Li, et al., (2018) | China'S Manufacturing Locus In 2025: With A Comparison Of "Made-In-China 2025" And "Industry 4.0" | Technological Forecasting and Social Change | 29 | 29 | 29 |

Topmost Keyword in Scopus and WoS

Bibliometric data tools facilitate users to identify pertinent keywords. Figure 4 explains the topmost keywords used by the authors in both repositories. The graph is constructed based on similar keywords that were used in both databases. Industry 4.0 word was the most popular word used by most authors. Smart Factory and Smart Manufacturing were the second and third most popular keywords used, respectively.

Many authors are also using keywords such as Intelligent Manufacturing, Cyber-Physical System, and Big Data. Some authors prefer to use IoT and some prefer to spell it in full as Internet of Thing as their keyword. Machine learning and digital twin were the least used keywords used in both the repositories. However, these keywords are expected to gain more popularity in the future.

Smart Manufacturing: The Trend Outlook of Smart Manufacturing in the Era of Industrial 4.0

This section discusses Smart Manufacturing's outlook by expounding the core concepts and the pillars of smart manufacturing, which is also termed as Industrial 4.0. In many cases, the background, idea, concept and shifting trends of smart manufacturing are derived from the topmost influential papers, which top the list from both repertories. This section also discusses the rationale and technologies deliberated by prominent scholars in Smart Manufacturing.

Overview of Smart Manufacturing

In the near future, it is expected that the production will no longer rely on batch order (Lasi, Fettke, Kemper & Feld, 2014). A smarter alternative is crucial to meet customer-driven batch sizes while maintaining the economies of mass production. Such disruptive developments are quite common now. Smart solutions, innovative technologies, the internet, and cloud are believed to promote digitalization and automation with sensor-enabled technology as a driving force. These technology enablers foster the product development time as well as promotes customization and flexibility.

A smart factory comprises integrated systems from various components inside a factory that help the entire factory system be more flexible and reconfigurable (Wang, Wan, Zhang, et al., 2016). Wang, et al., (2016a) discussed the framework that incorporates and associates the industrial network, cloud, and supervisory control terminals with smart shop floor objects that lead to the autonomous decision-making process. This was solely to design a smarter factory system that gives high efficiency. Such an intelligent self -organized multi-agent system cannot be realized without cloud services, big data analysis, and network. Kang, et al., (2016b); Zhou, Liu & Zhou (2016) have insight into the past, present and future direction of smart manufacturing. Being the second highest cited paper in Scopus, Kang, et al., (2016b) argue that cutting-edge ICT technologies are enablers and drivers for the fourth revolution in the manufacturing industry. In this paper, the core concept of smart manufacturing in the era of industrial revolution 4.0 from several developed countries like Germany, USA, and South Korea was discussed.

Several publications that are worth mentioning to the readers are by Li et al. (2017), Negri, Fumagalli & Macchi (2017); Zhong, Xu, et al., (2017). An overall perspective on intelligent manufacturing that evolves from digital twin, cyber-physical system and IoT. The element that holds the promise of making the manufacturing system more flexible and smarter could promote the idea of mass customization with a shorter lead time to market while maintaining its high quality. Nevertheless, all of this is only possible when the manufacturing system's production is smart and quick enough to help humans make intelligent decisions. Zhong, Xu, et al., (2017) suggested tthat one should deal with a huge set of data to make an intelligent decision. Upon making intelligent manufacturing achievable, myriad of useful data are involved. Wan, Yi, et al., (2016b); Zhong, Xu, et al., (2017) agreed on common that the integration between IoT and Cloud would ease the transformation of data into action smoothly. However, Wan, Yi, et al., (2016b) have widened the research area by analyzing the method used for collecting data from the perspective of manufacturing big data.

Another smart manufacturing interrelated studies was conducted by Davis, et al., (2012b). The author highlighted that smart manufacturing will lead and responds to dramatic and fundamental business transformation to demand dynamic economies with the help of IT-enable Smart factories. This article was the topmost cited paper in the area of smart manufacturing in the WoS repository. In response to this demand dynamic economic model, extensively research was done on vertical integration and horizontal integration that helps end-to-end integration (Wang, Wan, Zhang, et al., 2016). The main outline of the technical features and beneficial outcomes of industrial revolution 4.0 is asserted in the present work.

On the other hand, Lee, Bagheri & Kao, (2015) has proposed a guideline for the implementation of CPS. Shukla, et al., (2019); Zhou et al., (2015) examined the novel method, practical challenges, and opportunities in the use of big data analytics that could improve decision making in manufacturing. The authors summarize the discussion on the use of big data analytics in manufacturing. In a study conducted by Haseeb, et al., (2019), a survey has been done to understand how the Small medium enterprise in Thailand cope with the technological adoption toward realizing the concept of industrial 4.0. Mittal, et al., (2019) have provided a solid basis within the research and industrial community by defining characteristics, technologies and enabling smart manufacturing factors. Another detailed survey was done by Frank, et al., (2019) to understand the adaptation pattern of industry 4.0. In this study, 92 companies were involved and a conceptual framework on systematic technological adaptation was proposed.

Industrial 4.0 Pillars in Crafting Smart Manufacturing

Starting with the steam power's first revolution to the fourth revolution, which is being driven by automation and digital transformation, we can look to the not-very-distant future and see a smarter manufacturing system that is integrated with robots and sensors playing a pivotal role in the next-generation manufacturing. With the birth of 5G technology, machines can interact, visualize the production chain, and make crucial decision accurately and timely. Industrial 4.0 is being backed by the combination of several new technology enablers as well as some existing technological apparatus. By enlarge, it is being repacked with the combination of capabilities and technologies that serve as the pillar in making smart manufacturing happens.

In principle, nine pillars are commonly discussed. Frank, et al., (2019) presented a detail discussion of the key pillars of industrial revolution 4.0. IoT, Robotic, Cloud computing, Big Data analytics, Virtual Reality (VR) & Augmented Reality (AR), System integration, Additive manufacturing, Cyber Security, and Cyber-Physical system are among the backbone that stands as the pillars. Simulation technology is added technology that to be assumed as an additional component to the existing pillars. All the components in these pillars expected to have a great impact across all industries and society as a whole.

Shifting Trends in Smart Manufacturing

The manufacturing system today is smarter than ever. With the embedment of Industrial 4.0 pillars element in their process, it is becoming increasingly more efficient. Slow adoption as a considerable investment remains the primary concern of the manufacturing companies (Hanes, Carpenter, Riddle, Graziano & Cresko, 2019). Nevertheless, this scenario is expected to rise the competitive pressure mount on the shoulder of the manufacturer. This healthy pressure will inspire the manufacturing company to evolve. Embracing the shift of technology will keep manufacturing be at its best. The following section provides a brief explanation of the current shifting trends in the smart manufacturing environment.

Unmanned Aerial Vehicle (UAV) in Manufacturing

An unmanned aerial vehicle is best known as a drone (Maghazei & Netland, 2019). The extensive usage of drones in the agriculture and logistic industry has passed its best. The current usage of a drone is mainly for outdoor usage. Drone technologies can also be considered as an aide to boost productivity in manufacturing lines. At the current usage, the drone is being used in the warehouse for the physical count as well as intra logistic purposed for parts picking purposed (Companik, Gravier & Farris, 2018). Drones also can be best used for 3D factory layout planning barth (Barth & Michaeli, 2018). The drone is best to replace the eye of a human while doing an inspection. The likelihood of using the thermal camera in a drone can undoubtedly replace humans in performing dangerous tasks. The drone can also be deployed to detect or sense a problem with a piece of equipment in a production line. The drone could promote predictive maintenance. Besides, the ability to quickly fly at high altitude are the advantages that could be utilized further.

Mixed Reality

Virtual Reality (VR) and Augmented Reality (AR) is growing at a rapid pace. VR and AR are changing the way humans use screens by creating new exciting interactive experiences. Having not being explored to the full potential, Mixed Reality (MR) is now paving its way into the market. MR, also identified as hybrid realities, exhibits the virtual object interactively with the real world (Guzman, Thilakarathna & Seneviratne, 2019). Figure 5 exhibits the relativity of the three realities.

Labour Augmentation and Management

The industrial robot we introduced to the world intending to assist humans in the production line. This scenario has changed where humans are now assisting the robot in theirs. It is more to returning to human function with the assist of technology. Exploration in exosuite for assembly workers is the way forward to ensure safer, better, and accurate work are carried out (Lee et al., 2018; Xiloyannis, Chiaradia, Frisoli & Masia, 2019). Linking exosuite with AR and VR will enhance labor management and maximize operator performance without harming a worker's safety (Dahmen, Wöllecke & Constantinescu, 2018; Kiml, Xiloyannis, Accoto & Masia, 2018; Masood et al., 2019; Xiloyannis et al., 2019). Worker maximization and utilization are made easy by the exosuite as worker strength and fatigue level can be monitored (Karvouniari, Michalos, Dimitropoulos & Makris, 2018).

Smart Trucking and Fleet Telematics

Technology and globalization are changing the industrial common as well as forcing a transformation on how goods are being produced. The use of sensors, online platforms, data analytics, Industrial Internet of Things (IIoT), and Artificial Intelligence (AI) are surely pushing the way how industrial used to operate to how the industry should operate (Olson & Belton, 2019). Similarly, Smart trucking and fleet telematics will change the perspective in the supply chain. The usage of software and IIoT in goods transportation will expend significant in time to come. As the supply chains get decentralize and automated, autonomous trucking can pave its ways to realization. Several studies are being conducted on how IIoT and AI can bolster the industry shortage of driver issues (Hatani, 2020; Khayyam, 2013; Khayyam, Bahman Javadi & Jazar, 2020; Lu et al., 2019). Winlaw, et al., (2019) have reported that the fleet operation's efficiency will be increased, and telematic could improve the vehicle and freight's safety. Besides reducing the operating cost, telematic may also monitor safe driving habits as well as optimize vehicle performance.

Hybrid Data Modeling Approach in Decision Making

Discrete Event Simulation (DES) and System Dynamic (SD) have played an integral role in a manager's decision making in the industry over the decade. DES and SD is a widely used simulation model to interpret the outcome (Maidstone, 2012; Tako & Robinson, 2008). However, the increasing interest in Big Data analytics has made it an avenue to investigate. DES has permit numerous “What if?” situation to be tested, whereas SD is a method to understand the non-linear behavior of a complex system. In manufacturing, DES and SD encourage decision-makers to assess alternative ways of understanding and solving issues. The combined usage of simulation modelling and big data modelling approach will provide complementary cooperation (Kim, Kang, Choi & Kim, 2017). The hybrid approach will compensate for the limitation of each approach in helping a better industrial decision making. Figure 6 depicts the hybrid model flow for data prediction in decision making.

Computer Vision (CV) and Machine Vision (MV)

Smart Manufacturing are in the beginning era of enhancing CV technology. Njaastad & Egeland (2019) has reported that robotic inspection with RGBD camera attached robot are being used to inspect and perform a quality check of the final product. This approach may also be extended to inspect the geometric parameter of a product. Since human eyes are subject to imperfection, cameras using Artificial Intelligence (AI) and machine learning technology are being deployed in the production line. A CV can be a stand-alone unit without needing to be attached to a large machine, whereby MV is part of a large machine by itself. A major component of MV is illumination, lenses, camera, measurement software, and image processing. This component is in collective use to measure vibration, ambient light, temperature, dust particle, water, oil, and even electromagnetic radiation. One of the major concerns in MV is the difficulty of making the machine speak the same language with another machine (Williamson, 2018). Both technologies go beyond image processing with the integration technology of deep learning, AI, Machine learning, and cloud computing will surely speed up the future of these vision technologies.

Hybrid Technique Machine Learning Cobots

As the world is yet to unleash the true potential of AI, it is already beginning to gain popularity in engineering. Machine Learning (ML) is now being supported with Supervised Learning, Unsupervised learning, Semi-Supervised learning, and then it comes to the Reinforcement learning. Such ML technique is commonly used in the gaming industry, and now the researcher is extending this method to be applied to the industrial Cobots. In today's Smart Manufacturing environment, Cobots is used to perform the daily task with a human (El Makrini et al., 2018). Cobots limitation is spotted where the robots are still doing a monotonous task in the production line. Furthermore, the safety concern of the Cobots has encouraged the researcher world to explore more on the hybrid teaching technique where it is believed to allow the Cobots to adapt to the situation and free to make a safe decision in interacting with the human in the production line. The reinforcement learning method is the answer to such a problem in future Cobots development (El Makrini et al., 2018).

Inscribed Production

Minimum order quantity is no longer a concern. Manufacturing now are realizing the true meaning of “Voice of the Customer”. Credits to the global competition where today's manufacturing on the brink of meeting their customer's personalized demand (Kuo & Kusiak, 2019). Manufacturing are obliged to meet the unit of one demand without a hike in selling price. Additive manufacturing technologies are the answer to such demand. Nevertheless, this highly sophisticated solution is facing some challenges that may turn out to be an opportunity to improve on. Srivastava & Rathee (2020) have listed top five challenges that arises, which are (1) Cost of material, (2) The durability of the equipment, (3) A limited selection of material, (4) non-optimal build speed, and (5) Cost of pre- and post-processing topic of Smart Manufacturing in both databases, while IFAC-papers online were the most preferred journal publisher in Scopus whereas IEEE Access was the journal publisher in WoS databases which has published more papers in Smart Manufacturing topic. This bibliometric analysis has provided an inherent and general background formation of the publications in a Smart Manufacturing environment. The finding indicates the worth of the bibliometric studies being applied in SM so that the future research community could explore and expand the knowledge in this area. Besides discussing the papers contributed to Scopus and WoS, the future trends that support smart manufacturing are being restressed to give the reader a better future outlook. Nonetheless, as this study is limited by years and databases (Scopus and WoS), more index databases within a more significant period should be added in the evaluation in the future work.

References

- Ahmi, A., Elbardan, H., & Raja, M.A.R.H. (2019). Bibliometric analysis of published literature on industry 4.0. ICEIC 2019 - International Conference on Electronics, Information, and Communication, 0, 1–6.

- Bagheri, B., Yang, S., Kao, H.A., & Lee, J. (2015). Cyber-physical systems architecture for self-aware machines in industry 4.0 environment. IFAC-PapersOnLine.

- Bertoncel, T., & Meško, M. (2019). Early warning systems in industry 4.0: A bibliometric and topic analysis. International Journal of E-Services and Mobile Applications, 11(2), 56–70.

- Cabeza, L.F., Frazzica, A., Chàfer, M., Vérez, D., & Palomba, V. (2020). Research trends and perspectives of thermal management of electric batteries: Bibliometric analysis. Journal of Energy Storage, 32, 101976.

- Cancino, C., Merigó, J.M., Coronado, F., Dessouky, Y., & Dessouky, M. (2017). Forty years of computers & industrial engineering: A bibliometric analysis. Computers and Industrial Engineering, 113, 614–629.

- Caviggioli, F., & Ughetto, E. (2019). A bibliometric analysis of the research dealing with the impact of additive manufacturing on industry, business and society. International Journal of Production Economics, 208, 254–268.

- Companik, E., Gravier, M.J., & Farris, M.T. (2018). Feasibility of warehouse drone adoption and implementation. Journal of Transportation Management, 28(2), 31–48.

- Dahmen, C., Wöllecke, F., & Constantinescu, C. (2018). Challenges and possible solutions for enhancing the workplaces of the future by integrating smart and adaptive exoskeletons. Procedia CIRP, 67, 268–273.

- Davis, J. (2017). Smart manufacturing. Encyclopedia of Sustainable Technologies, 7543(July), 417–427.

- Davis, J., Edgar, T., Porter, J., Bernaden, J., & Sarli, M. (2012). Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Computers and Chemical Engineering, 47, 145–156.

- documentation, A. P.-J. of, & 1969, undefined. (n.d.). Statistical bibliography or bibliometrics. Researchgate.Net.

- El Makrini, I., Elprama, S.A., Van Den Bergh, J., Vanderborght, B., Knevels, A.J., Jewell, C.I.C., … & Jacobs, A. (2018). Working with Walt: How a cobot was developed and inserted on an Auto Assembly Line. IEEE Robotics and Automation Magazine, 25(2), 51–58.

- Frank, A.G., Dalenogare, L.S., & Ayala, N.F. (2019). Industry 4.0 technologies: Implementation patterns in manufacturing companies. International Journal of Production Economics, 210(September 2018), 15–26.

- Guzman, J.A.D.E., Thilakarathna, K., & Seneviratne, A. (2019). Security and privacy approaches in mixed reality: A literature survey. ACM Computing Surveys, 52(6).

- Hanes, R., Carpenter, A., Riddle, M., Graziano, D.J., & Cresko, J. (2019). Quantifying adoption rates and energy savings over time for advanced energy-efficient manufacturing technologies. Journal of Cleaner Production, 232, 925–939. https://doi.org/10.1016/j.jclepro.2019.04.366

- Haseeb, M., Hussain, H.I., ?lusarczyk, B., & Jermsittiparsert, K. (2019). Industry 4.0: A solution towards technology challenges of sustainable business performance. Social Sciences, 8(5).

- Hatani, F. (2020). Artificial Intelligence in Japan: Policy, Prospects, and Obstacles in the Automotive Industry.

- Hozdi?, E. (2015). Smart factory for industry 4.0: A review. International Journal of Modern Manufacturing Technologies, 7(1), 28–35.

- Jalali, M.S., Razak, S., Gordon, W., Perakslis, E., & Madnick, S. (2019). Health care and cybersecurity: Bibliometric analysis of the literature. Journal of Medical Internet Research, 21(2).

- Kang, H.S., Lee, J.Y., Choi, S., Kim, H., Park, J.H., Son, J.Y., … & Noh, S.D. (2016). Smart manufacturing: Past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing - Green Technology, 3(1), 111–128. https://doi.org/10.1007/s40684-016-0015-5

- Kaplan, G. (1985). Industrial electronics. IEEE Spectrum, 22(1), 68–71.

- Karakus, M., Ersozlu, A., & Clark, A.C. (2019). Augmented reality research in education: A bibliometric study. Eurasia Journal of Mathematics, Science and Technology Education, 15(10).

- Karvouniari, A., Michalos, G., Dimitropoulos, N., & Makris, S. (2018). An approach for exoskeleton integration in manufacturing lines using Virtual Reality techniques. Procedia CIRP, 78(i), 103–108.

- Khayyam, H. (2013). Adaptive intelligent control of vehicle air conditioning system. Applied Thermal Engineering, 51(1–2), 1154–1161.

- Khayyam, H., Bahman, M.J., & Jazar, R.N. (2020). Artificial intelligence and internet of things for autonomous vehicles. 39–68.

- Kim, B.S., Kang, B.G., Choi, S.H., & Kim, T.G. (2017). Data modeling versus simulation modeling in the big data era: Case study of a greenhouse control system. Simulation, 93(7), 579–594.

- Kiml, Y.G., Xiloyannis, M., Accoto, D., & Masia, L. (2018). Development of a soft exosuit for industriale applications. Proceedings of the IEEE RAS and EMBS International Conference on Biomedical Robotics and Biomechatronics, 2018-Augus(August), 324–329.

- Kiraz, M., & Demir, E. (2020). A bibliometric analysis of publications on spinal cord injury during 1980–2018. World Neurosurgery, 136, e504–e513.

- Kumar, N.M., & Mallick, P.K. (2018). The internet of things: Insights into the building blocks, component interactions, and architecture layers. Procedia Computer Science, 132, 109–117.

- Kumar, S., Marrone, M., Liu, Q., & Pandey, N. (2020). Twenty years of the international journal of accounting information systems: A bibliometric analysis. International Journal of Accounting Information Systems, 39, 100488.

- Kuo, Y.H., & Kusiak, A. (2019). From data to big data in production research: The past and future trends. International Journal of Production Research, 57(15–16), 4828–4853.

- Lasi, H,, Fettke, P., Kemper, H., & Feld, T.H.M. (2014). Indusrtry 4.0 in business & information system engeineering. Business& Information System Engineering, 6(4), 239–242.

- Lee, J., Bagheri, B., & Kao, H.A. (2015). A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manufacturing Letters.

- Lee, S., Kim, J., Baker, L., Long, A., Karavas, N., Menard, N., … & Walsh, C. J. (2018). Autonomous multi-joint soft exosuit with augmentation-power-based control parameter tuning reduces energy cost of loaded walking. Journal of NeuroEngineering and Rehabilitation, 15(1), 1–9.

- Li, D., Zhou, M. T., Zeng, P., Yang, M., Zhang, Y., & Yu, H. (2016). Green and reliable software-defined industrial networks. IEEE Communications Magazine, 54(10), 30–37.

- Li, X., Li, D., Wan, J., Vasilakos, A.V., Lai, C. F., & Wang, S. (2017). A review of industrial wireless networks in the context of Industry 4.0. Wireless Networks, 23(1), 23–41.

- Lu, H., Liu, Q., Tian, D., Li, Y., Kim, H., & Serikawa, S. (2019). The cognitive internet of vehicles for autonomous driving. IEEE Network, 33(3), 65–73.

- Maghazei, O., & Netland, T. (2019). Drones in manufacturing: Exploring opportunities for research and practice. Journal of Manufacturing Technology Management.

- Maidstone, R. (2012). Discrete event simulation, system dynamics and agent based simulation: Discussion and comparison. System, (March 2012), 1–6.

- Manu, S., & Sandeep, R.S.M. (2020). Additive manufacturing fundamentals and advancements. In Journal of Visual Languages & Computing.

- Masood, J., Dacal-Nieto, A., Alonso-Ramos, V., Fontano, M.I., Voilqué, A., & Bou, J. (2019). Industrial wearable exoskeletons and exosuits assessment process. In Biosystems and Biorobotics.

- Merigó, J.M., Pedrycz, W., Weber, R., & de la Sotta, C. (2018). Fifty years of Information Sciences: A bibliometric overview. Information Sciences, 432, 245–268.

- Mittal, S., Khan, M.A., Romero, D., & Wuest, T. (2018). A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for Small and Medium-Sized Enterprises (SMEs). Journal of Manufacturing Systems, 49(October), 194–214.

- Mittal, S., Khan, M.A., Romero, D., & Wuest, T. (2019). Smart manufacturing: Characteristics, technologies and enabling factors. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 233(5), 1342–1361.

- Moher, D., Liberati, A., Tetzlaff, J., Altman, D.G., Altman, D., Antes, G., … & Tugwell, P. (2009). Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Medicine.

- Muhuri, P.K., Shukla, A.K., & Abraham, A. (2019). Industry 4.0: A bibliometric analysis and detailed overview. Engineering Applications of Artificial Intelligence, 78(September 2018), 218–235.

- Negri, E., Fumagalli, L., & Macchi, M. (2017). A review of the roles of digital twin in cps-based production systems. Procedia Manufacturing, 11(June), 939–948.

- Njaastad, E.B., & Egeland, O. (2019). Planning of robotic inspection from visual tracking of manual surface finishing tool. Proceedings - 3rd IEEE International Conference on Robotic Computing, IRC 2019, 277–281.

- Plageras, A.P., Psannis, K.E., Stergiou, C., Wang, H., & Gupta, B.B. (2018). Efficient IoT-based sensor BIG Data collection–processing and analysis in smart buildings. Future Generation Computer Systems, 82, 349–357.

- Rejeb, A., Simske, S., Rejeb, K., Treiblmaier, H., & Zailani, S. (2020). Internet of things research in supply chain management and logistics: A bibliometric analysis. Internet of Things, 12, 100318.

- Roldán, J.J., Crespo, E., Martín-Barrio, A., Peña-Tapia, E., & Barrientos, A. (2019). A training system for industry 4.0 operators in complex assemblies based on virtual reality and process mining. Robotics and Computer-Integrated Manufacturing.

- Shukla, N., Tiwari, M.K., & Beydoun, G. (2019). Next generation smart manufacturing and service systems using big data analytics. Computers and Industrial Engineering, 128(December 2018), 905–910.

- Sierra-Huelsz, J.A., & Kainer, K.A. (2018). Tourism consumption of biodiversity: A global exploration of forest product use in thatched tropical resort architecture. Geoforum, 94(September 2017), 1–11.

- Tako, A.A., & Robinson, S. (2008). Model building in system dynamics and discrete-event simulation: A quantitative comparison. Analysis.

- Thoben, K.D., Wiesner, S.A., & Wuest, T. (2017). “Industrie 4.0” and smart manufacturing-a review of research issues and application examples. International Journal of Automation Technology, 11(1), 4–16.

- Tsai, F.M., Bui, T.D., Tseng, M.L., Lim, M.K., & Hu, J. (2020). Municipal solid waste management in a circular economy: A data-driven bibliometric analysis. Journal of Cleaner Production, 275, 124132.

- Wan, J., Tang, S., Shu, Z., Li, D., Wang, S., Imran, M., & Vasilakos, A.V. (2016). Software-defined industrial internet of things in the context of industry 4.0. IEEE Sensors Journal, 16(20), 7373–7380.

- Wan, J., Yi, M., Li, D., Zhang, C., Wang, S., & Zhou, K. (2016). Mobile services for customization manufacturing systems: An example of industry 4.0. IEEE Access, 4(c), 8977–8986.

- Wang, S., Wan, J., Li, D., & Zhang, C. (2016). Implementing smart factory of industrie 4.0: An Outlook. International Journal of Distributed Sensor Networks.

- Wang, S., Wan, J., Zhang, D., Li, D., & Zhang, C. (2016). Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Computer Networks, 101, 158–168.

- Winlaw, M., Steiner, S.H., MacKay, R.J., & Hilal, A.R. (2019). Using telematics data to find risky driver behaviour. Accident Analysis and Prevention, 131(June), 131–136.

- Xiloyannis, M., Chiaradia, D., Frisoli, A., & Masia, L. (2019). Physiological and kinematic effects of a soft exosuit on arm movements. Journal of NeuroEngineering and Rehabilitation, 16(1), 1–15.

- Zhong, R.Y., Xu, C., Chen, C., & Huang, G.Q. (2017). Big data analytics for physical internet-based intelligent manufacturing shop floors. International Journal of Production Research, 55(9), 2610–2621.

- Zhong, R.Y., Xu, X., Klotz, E., & Newman, S.T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616–630.

- Zhou, K., Zhou, L., & Liu, T. (2015). Industry 4.0: Towards and future industrial opportunities challenges: FSKD 2015: 15-17 August, Zhangjiajie, China. 12th International Conference on Fuzzy Systems and Knowledge Discovery.

- Zhou, K., Liu, T., & Zhou, L. (2016). Industry 4.0: Towards future industrial opportunities and challenges. 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery, FSKD 2015, 2147–2152.