Review Article: 2022 Vol: 26 Issue: 3

Analyzing The Determinants Of Sustainability And Firm Performance In Automotive Supply Chains: A Delphi Approach

Mohit Saxena, Indian Institute of Foreign Trade (IIFT), New Delhi

Nitin Seth, Indian Institute of Foreign Trade (IIFT), New Delhi

Citation Information: Saxena, M., Seth, N. (2022). Analyzing The Determinants Of Sustainability And Firm Performance In Automotive Supply Chains: A Delphi Approach. Academy of Marketing Studies Journal, 26(3),1-16.

Abstract

Managing sustainability implementation in automotive environment and firm performance (FP) has always been an area of Interest for professionals & researchers. Accomplishing Sustainability Implementation in automotive context is very difficult and seeks to consider attention of suppliers, top management, dealers, government, regulators, and stakeholders. It is prudent that the Sustainability Implementation & FP is regularly assessed, supervised, and improved for gaining competitiveness & status for creating a point of differentiation. This paper tries to identify such Sustainability Implementation & FP criteria for Indian automotive industry. This study implemented Delphi approach through interview with 32 subject specialists. In this a list of 35 environmental,48 social, 33 economical sub- measures and 45 performance sub- measures identified from the literature was given to these experts from which initial measures and their sub – measures were to be identified and grouped for automotive sector. These Sustainability Implementation factors can additionally be utilized to design a model to apply Sustainability practices in auto industry. This study employs the Delphi approach to analyze and examine Sustainability Implementation ideas and Firm Performance factors for Indian automotive sector.

Keywords

Sustainability Implementation; Automotive Environment; Delphi Method; Firm Performance Measurement.

Introduction

India is the fourth largest auto market in 2019 superseding Germany, with about 3.99 million units sold in the commercial and passenger vehicles segment. It is expected that India would surpass Japan as the third biggest auto market by 2021. FDI inflow in auto industry remained at US dollar 24.21 billion between April 2000-March 2020. Indian automobile sector (including parts / subsystem manufacturing organisation) is expected to reach at Rs 16.16-18.18 trillion (US$ 251.4–282.8 billion) by 2026. India could be a leader in shared mobility by 2030, providing the opportunities for electric vehicles. Focus is shifting to electric vehicles to reduce emissions (Indian Brand Equity Foundation [online], 2020). The automotive industry has been under considerable pressure from governments and society to pursue a more sustainable model of growth. Transportation accounted for a quarter of the world’s global CO2 emissions, with road transportation alone accounting for 18%. The manufacturing of vehicles takes significant water, energy and other resources, thereby multiplying the carbon footprint. However, because of growing sales of SUVs after 2015, carbon emissions started to rise.

Rising environmental concerns have meant increased pressure from a variety of stakeholder groups like public – interest groups, investors, regulators, etc. (Capgemini, 2019).

Sustainability is considered “an important conceptual framework” for aligning economic, environmental and social dimensions (Dempsey et al., 2009) and these three “pillars” (TBL) are pervasive within sustainability literature ((Vachon & Mao, 2008); (Hutchins, & Sutherland, 2008).

1. To figure out sustainability implementation and firm performance in the Indian automotive environment.

2. To ascertain sustainability implementation criteria and firm performance measurement for automotive sector using the Delphi approach

Literature Review

Sustainability Implementation in Automotive Sector

Sustainability practices differ according to business processes complexities, organization structure, company size, level of business maturity, strategic planning, and stakeholder interests (mostly of the shareholders). “Firms that execute and implement sustainability, control their inclusion by delivering sustainability reports. Sustainability reports have increasingly expanded, with the most recognized report being the Global Reporting Initiative (GRI), utilized and acknowledged across the globe. There are no legal commitments in sustainability, so every firm utilizes its own reporting model” (Lucian-Ionel Cioca et al., 2019).

The brainstorming session with 32 subject experts were selected based on their expertise and having more than 15 years of experience in SCM, Marketing, EHS and academics, care was taken to invite only the concerned professionals to support us in identifying the elements and their sub-elements that will probably be vital for the sustainability and performance measurement for automotive environment in India. A list of 35 environmental,48 social, 33 economical sub- measures and 45 performance sub- measures identified from the literature was given to these experts from which initial measures and their sub – measures were to be identified and grouped for automotive sector.

The process and practices in the automotive sector are very complex and highly technology oriented. All over the automotive sector, cost reduction activities and methods are emphasized. The automotive sector is an intricate system of indirect and direct products to create economic benefit. Automotive sector has a significant impact on the environment, social and economic elements of sustainable development. “Automobile system and subsystem manufacturing organisations are assessed by regulatory authorities to ensure they meet environmental standards and reduce the impact on both products and their manufacturing processes. This situation drives them to introduce innovative business strategies to achieve environmental and economic performance goals. Implementing sustainable development helps them reduce their organizational impact on the planet, profit, and people” (Lucian-Ionel Cioca et al., 2019).

Need and Rationale for Delphi

The sustainability deployment criteria are different according to the country and circumstances. Various authors have suggested that the model is customized accordingly. Delphi has been utilized by a few authors to explain the randomness.

“The Delphi approach permits us to get quantitative estimates from qualitative variables, building up the level of understanding among the experts on standard and established procedures” (Soria-García & Martínez-Lorente, 2014).

“Academicians have utilized Delphi approach in various domains, for example, education (Vakani & Sheerani 2012); (Sitlington & Coetzer, 2015) and healthcare (Mullen, 2003) services (Birdir and Pearson, 2000). Results from the Delphi technique are useful, since the opinions are from subject matter experts” (Ali, 2005). However, this methodology has not been used to study sustainability and firm performance in Indian context for the automobile industry. Thus, this study within the automobile industry is worthwhile.

Initial Identification of Sustainability and Firm Performance Measures

After the literature review, brainstorming session with the experts was carried out to identify the sustainability practices measures and sub-measures and performance measures for automotive environment. With emphasis on the various sustainability models and firm performance measures, conducted a brainstorming session with 32 subject experts (experts are selected based on their experience and having more than 15 years of experience in sourcing, care was taken to invite only the sourcing experts) to help us to identify the measures and their sub-measures that might be important for the sustainability and performance measurement for automotive environment in India. In this a list of 35 environmental,48 social, 33 economical sub- measures and 45 performance sub- measures identified from the literature was given to these experts from which initial measures and their sub – measures were to be identified and grouped for automotive sector. In this session, each measure and sub-measure was checked and rechecked for similar meaning and repetition which resulted in a basic Sustainability practices framework consisting of 3 measures and 35 environmental,48 social, 33 economical sub- measures (Table 1), and 45 firm performance sub-measures (Table 2).

| Table 1 Initial Sustainability Practices Measures And Sub-Measures For Automotive Environment |

||

|---|---|---|

| Environmental Practices | Social Practices | Economical Practices |

| Materials | Commitment to safety | Economic Performance |

| Energy | Community | Market Presence |

| Water and Effluents | Diversity | Indirect Economic Impacts |

| Biodiversity | Employee | Procurement Practices |

| Emissions | Human rights | Trade-offs and Spin-off |

| Waste | Employment | Anti-competitive Behavior |

| Environmental Compliance | Safety | Tax |

| Supplier Environmental Assessment | Work conditions | Investment |

| Environmental accidents | Support for community projects | Fine for environmental accidents |

| Hazardous/harmful/toxic materials | Health and safety policy and procedures | Fee for waste treatment and discharge |

| Environmental collaboration with suppliers | Workmanship insurance | Competitive advantage |

| Product environmental impact | Labor rights | Risk reduction |

| ISO 14001 certification | Qualified employment | Operating efficiency |

| Environmentally friendly packaging | Resource investment in social programs | Sales/Investment recovery |

| Climate change | Education Infrastructure | Operational and maintenance costs |

| Ozone depleting chemicals | Occupational Health and Safety | Market-based performance |

| Reuse | Social new product and process development | Operational-based Performance |

| Recycling | Social supply chain redefinition | Accounting-based Performance |

| Green product | Workers’ health | Cost, differentiation, and niche |

| Environmental audit | Safety Systems and Compliance | Plant performance (manufacturing costs, work-in process inventory) |

| Cleaner technologies | Social Audits | Anti-corruption |

| Life-cycle analysis | Social stakeholder development practice | Firm competitiveness |

| Greenhouse gas emission | Supplier social performance | Cost of equity and debt capital |

| Environmental logistics practices | Social welfare | Shareholder wealth |

| Environmental proactivity | Socially responsible investments | Stock market |

| Land use reduction | Philanthropy | Firm value |

| Pollution prevention | Motor carrier safety | Financial performance |

| Green purchasing | Labor/Management Relations | Transaction cost attributes |

| Chemical consumption | Fair treatment of customers | Lean performance |

| Environmental management systems | Harmonious relationship between company and employees | Strategic collaboration and Information sharing |

| Green logistics | Accident rate | Number of new patents |

| Green supply chain management | Working environment stress | Brand value |

| Alternative energy | Training and Education | |

| Depletion of natural resources | Diversity and Equal Opportunity | |

| Fuel consumption | Non-discrimination | |

| Freedom of Association and Collective Bargaining | ||

| Child Labor | ||

| Forced or Compulsory Labor | ||

| Security Practices | ||

| Rights of Indigenous Peoples | ||

| Human Rights Assessment | ||

| Local Communities | ||

| Supplier Social Assessment | ||

| Public Policy | ||

| Customer Health and Safety | ||

| Marketing and Labeling | ||

| Customer Privacy | ||

| Socioeconomic Compliance | ||

| Table 2 Initial Firm Performance Measures For Automotive Environment |

|---|

| Firm Performance Variables |

| Continuous Improvement |

| Marketing Planning |

| Branding |

| Advertising |

| Promotions |

| Channel marketing |

| Customer relationship management systems |

| Overall competitive position |

| Overall customer service levels |

| internal operational performance |

| customer satisfaction |

| customers enhancement |

| customer loyalty |

| new customers |

| products and services |

| Overall product quality |

| Recruitment |

| Training and retention |

| Appraisals |

| Incentives |

| Performance based reward |

| Corporate culture and external factors |

| Marketing |

| Operational |

| New product development |

| New market development |

| Level of Innovation |

| Labour productivity |

| product differentiation and technological transfer |

| Advanced manufacturing technologies |

| Information readiness |

| Brand awareness |

| Intra-regional geographic diversification |

| Research and development capability |

| Supply chain process integration |

| Supply Chain Capabilities |

| Operational Performance |

| Market Performance |

| Goods delivered on time |

| Inventory levels |

| Scrap rate |

| Capacity utilization |

| Employment opportunities |

| Human Resource performance |

| Production flexibility |

Methodology

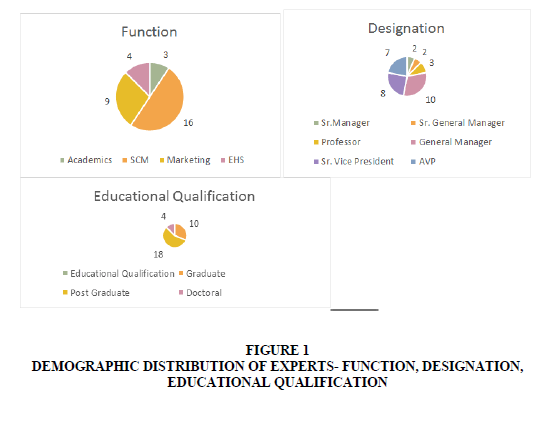

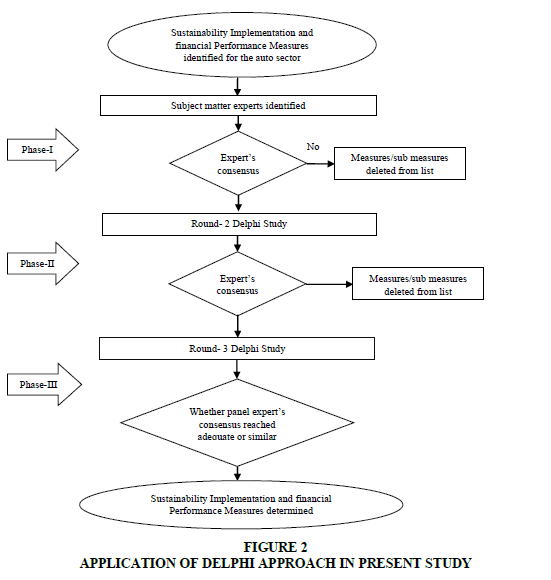

The Delphi is a quantitative approach based on a judgment from the subject matter experts. It is a methodical and iterative method for seeking viewpoints and common thoughts of the experts (Landeta, 1999). An idea-generation session was undertaken with 32 experts and their credentials are as portrayed in Figure 1. These experts were asked to categorise the elements into various groups of elements and sub-elements. Subsequently, 3 rounds of Delphi were executed to reach to a unanimous decision for the Indian automobile sector. The process flow of Delphi approach is portrayed in Figure 2.

In the current study, a group of 32 members was formed which included senior professionals (SCM, Marketing and EHS) from the industry and academicians. Sample size (no. of experts) varied from one survey session to the next due to absence of experts in subsequent rounds.

Round 1 Delphi study

For the first round of the study, a survey instrument consisting of 3 sustainability practice measures, with 35 environmental, 48 social, 33 economical sub- measures and 45 firm performances sub- measures were developed. A total of 161 sub-measures were identified across the 4 measures. In this round, each expert received a statement of the problem and a questionnaire with which his or her independent views regarding the problem were elicited.

Round 1 Result

Varied responses were obtained from the experts, in which 57 of the 161 sub-measures were excluded and merged by more than 50% of the experts and many gave their valuable comments/suggestions for 4 measures and 161 sub-measures for sustainability practices and firm performances. A summary of the comments given by more than 50% experts about the measures is given below.

1. Most of the experts were of the view that the sub-measures should be specific to automotive environment and not generic.

2. Sub-measures should be given specific names and similar sub - measures should be combined together.

3. Some of the sub-measures having no relevance to automotive environment may be eliminated.

4. The most notable and repeated suggestion was that ‘automotive environment’ should be sub-characterized in greater depth, beyond the other measures currently present.

5. Some sub-measures need not be included as independent sub-measures under a particular measure as similar sub – measure is already existing elsewhere under some other measure.

6. Sub-measures may be moved /shuffled under appropriate measure.

7. Some sub-measures could be further broken into more sub-measures to convey specific meaning.

Wherever, more than 50% experts agreed on elimination of any particular measure / sub-measure, the same were eliminated. In the cases where, there were suggestions on renaming, shifting, more elaboration on measures / sub-measures, the list was again prepared with the suggestions from the experts.

Based on the Round 1 survey data we added, removed and renamed measures and sub-measures and reorganized the sustainability practices into 3 measures and 73 sub-measures (Table 3) and 31 sub-measures for firm Performance (Table 4).

| Table 3 After Round 1 – Sustainability Practices For Automotive Environment |

||

|---|---|---|

| Environmental Practices | Social Practices | Economical Practices |

| Materials | Commitment to safety | Economic Performance |

| Energy | Employment | Market Presence |

| Water and Effluents | Workmanship insurance | Indirect Economic Impacts |

| Biodiversity | Occupational Health and Safety | Procurement Practices |

| Emissions | Safety Systems and Compliance | Trade-offs and Spin-off |

| Waste | Social Audits | Anti-competitive Behavior |

| Environmental Compliance | Social stakeholder development practice | Tax |

| Supplier Environmental Assessment | Supplier social performance | Operational and maintenance costs |

| Environmental collaboration with suppliers | Social welfare | Cost, differentiation and niche |

| Product environmental impact | Philanthropy | Plant performance (manufacturing costs, work-in process inventory) |

| Green product | Motor carrier safety | Anti-corruption |

| Environmental audit | Labor/Management Relations | Firm competitiveness |

| Cleaner technologies | Fair treatment of customers | Cost of equity and debt capital |

| Life-cycle analysis | Training and Education | Shareholder wealth |

| Greenhouse gas emission | Diversity and Equal Opportunity | Stock market |

| Pollution prevention | Non-discrimination | Firm value |

| Green purchasing | Freedom of Association and Collective Bargaining | Financial performance |

| Green logistics | Child Labor | Transaction cost attributes |

| Green supply chain management | Forced or Compulsory Labor | Lean performance |

| Alternative energy | Security Practices | Strategic collaboration and Information sharing |

| Depletion of natural resources | Rights of Indigenous Peoples | Number of new patents |

| Human Rights Assessment | Brand value | |

| Local Communities | ||

| Supplier Social Assessment | ||

| Public Policy | ||

| Customer Health and Safety | ||

| Marketing and Labeling | ||

| Customer Privacy | ||

| Socioeconomic Compliance | ||

| Table 4 After Round 1 – Firm Performance Measures For Automotive Environment |

|---|

| Firm Performance Variables |

| customer satisfaction |

| customers enhancement |

| customer loyalty |

| new customers |

| products and services |

| Overall product quality |

| Recruitment |

| Corporate culture and external factors |

| Marketing |

| Operational |

| New product development |

| New market development |

| Level of Innovation |

| Labour productivity |

| product differentiation and technological transfer |

| Advanced manufacturing technologies |

| Information readiness |

| Brand awareness |

| Intra-regional geographic diversification |

| Research and development capability |

| Supply chain process integration |

| Supply chain performance |

| Operational Performance |

| Market Performance |

| Goods delivered on time |

| Inventory levels |

| Scrap rate |

| Capacity utilization |

| Employment opportunities |

| Human Resource performance |

| Production flexibility |

Round 2 – Delphi study

Some of the Delphi panel members who were selected to participate in the study did not respond in the Round 2, and hence the Delphi panel was reduced from 26 members to 22 members for second round.

For the second round of the study, experts were asked to rate importance of particular sustainability practices and firm Performance measure using a 7- point Likert scale (Appendix I (c) and I (d)). The following scale of importance was assigned to the responses provided on the questionnaire: 7 = Extremely important, 6 = Very important, 5 = Important, 4 = Moderately important 3 = Somewhat important 2 = Slightly important 1 = Not important

Round 2 Results

A total of 22 completed surveys in Round 2 were received. Of the 4 measures and 104 sub-measures, 59 sub-measures received < 3.5 mean score (MS) so they were removed from the Sustainability practices and firm performance framework.

To obtain convergence of opinion, the mean of the standard deviation was calculated. A decrease in the mean standard deviation value indicated a greater convergence of opinion among the experts. A list of measures / sub-measures for sustainability practices and firm performance measures for automotive environment based on mean and standard deviation scores is given in (Table 5) and (Table 6) respectively. Measures which have higher mean score, lower standard deviation were considered to be important measures as there was relative agreement among experts on their importance. Measures which had higher mean score, higher standard deviation were also considered to be important measures but there was less relative agreement among experts on their importance (Shah et al., 2011).

| Table 5 Mean And Standard Deviation Scores For Sustainability Practices And Sub-Measures |

||||||||

|---|---|---|---|---|---|---|---|---|

| Environmental Practices | Mean | SD | Social Practices | Mean | SD | Economical Practices | Mean | SD |

| Materials | 5.29 | 0.967 | organizational Work Culture and environment | 6.71 | 0.381 | Financial & Marketing practices | 5.16 | 1.256 |

| Green Operational Practices | 6.13 | 0.654 | Community and diversity | 5.42 | 0.882 | Indirect Economic Impacts | 5.73 | 0.554 |

| Water and Effluents | 6.12 | 0.536 | Training and Education | 5 | 1.426 | Operational efficiency | 4.67 | 1.803 |

| Biodiversity | 6.39 | 0.582 | Occupational Health and Safety | 6.53 | 0.422 | Collaboration & Information sharing | 4.1 | 2.018 |

| Green supply chain practices | 6.09 | 0.607 | Diversity and Equal Opportunity | 5.03 | 1.112 | Anti-competitive Behavior | 3.64 | 2.585 |

| Waste | 4.23 | 1.982 | Social stakeholder development practices | 5.87 | 0.748 | Tax | 5.57 | 0.855 |

| Environmental compliance | 6.15 | 0.421 | Freedom of Association and Collective Bargaining | 5.23 | 0.922 | |||

| Supplier Environmental Assessment | 4.02 | 2.148 | Child Labor | 4.86 | 1.634 | |||

| Rights of Indigenous Peoples | 5.85 | 0.757 | ||||||

| Human Rights Assessment | 6.18 | 0.502 | ||||||

| Local Communities | 5.37 | 0.512 | ||||||

| Supplier Social Assessment | 6.08 | 0.76 | ||||||

| Public Policy | 4.32 | 0.778 | ||||||

| Customer Health and Safety | 4.29 | 1.868 | ||||||

| Marketing and Labeling | 5.02 | 2.258 | ||||||

| Customer Privacy | 4.03 | 2.389 | ||||||

| Socioeconomic Compliance | 4.13 | 2.029 | ||||||

| Table 6 Mean And Standard Deviation Scores For Firm Performance Measures |

||

|---|---|---|

| Firm Performance Variables | Mean | SD |

| new customers | 5.19 | 1.222 |

| Overall product quality | 4.32 | 0.558 |

| Corporate culture and external factors | 4.12 | 0.632 |

| New product development | 6.37 | 2.525 |

| New market development | 5.02 | 1.325 |

| Advanced manufacturing technologies | 5.08 | 1.255 |

| Research and development capability | 5.18 | 1.305 |

| Operational Performance | 4.18 | 1.259 |

| Market Performance | 4.02 | 0.548 |

| Supply chain performance | 4.01 | 0.506 |

| Human Resource performance | 5.72 | 0.933 |

Round 3 Delphi study

The third-round questionnaire was very similar to that of the first round. For this round, framework “after Round 2 - sustainability practices and firm performance and sub-measures for automotive environment” was given to the experts who were asked to rate them as “Yes” (the sustainability practices and firm performance measures must be included for automotive environment) or “No” (the sustainability practices and firm performance measures need not be included for automotive environment). Measures were selected when at least 80% of the experts agreed that they must be a part for automotive environment.

Round 3 Results

A total of 21 survey responses were received from experts in round 3. No measures and sub-measures received less than 80% of the expert’s opinion to be sustainability practices and firm Performance measures for automotive environment. Analysis of results from the third round should be the “consensus” opinion of all panel members. If the consensus reached was not adequate or similar, then there will be a possibility of fourth round.

After three rounds of Delphi study and analysis, 3 measures and 10 sub-measures were finalized as the Sustainability practices for automotive environment (Table 7) Similarly, after three rounds of Delphi study and analysis, 4 sub-measures were finalized as the firm Performance measures for automotive environment (Table 8).

| Table 7 Final Sustainability Practices For Automotive Environment |

||

|---|---|---|

| Environmental Practices | Social Practices | Economical Practices |

| Green Operational Practices | Occupational Health & Safety | Financial & Marketing practices |

| Green supply chain practices | Social Stakeholder development practices | Operational efficiency |

| Environmental compliance | organizational Work Culture and environment | Collaboration & Information sharing |

| Community and diversity | ||

| Table 8 Final Firm Performance Measures For Automotive Environment |

|---|

| Firm Performance Variables |

| Operational Performance |

| Market Performance |

| Human Resource performance |

| Supply chain performance |

Implications

This study helps the available literature in this field by expanding the knowledge of sustainability implementation automotive sector of India and enhancing the field of supply chain management incrementally from operational and firm performance. This encourages researchers to further work on sustainability implementation in the field of automotive Industry. This study can have a beneficial impact on the automotive industry and academicians in the below manner:

1. Suggested sustainability implementation elements and firm performance elements will be meaningful in developing the sustainability implementation in automotive industry.

1. Deploying the suggested sustainability implementation elements and firm performance elements will lead to enhance the efficiency, productivity and meeting the expectations of stakeholders, additional analysis may be carried out in this context.

2. Automotive industries can develop the cause-and-effect relationship of indicators to analyse the root cause. Will be able to analyse the cause and effect between variation and its indicator to ascertain the root cause.

3. Emphasis on sustainability practices deployment and firm performance will lead to an increased competition. A healthy competition in the automotive market will result in improved service levels.

Conclusion

The paper tried to evolve an inclusive list of 3 sustainability implementation elements (10 Sub elements) and 4 Performance elements for automobile sector in India. Subsequently all sustainability implementation elements have been further bifurcated into multiple sub-elements.

The Delphi approach was effectively implemented in this analysis to establish sustainability implementation elements and firm performance elements for automotive sector in India. The useful inputs received from the group of experts assisted in formulating the framework. Organisations can use this outcome as a reference in crafting the strategy and sustainability mission.

This framework may be of some help to researchers and professional in other industry beyond automotive.

The paper is an investigation to determine sustainability implementation elements and firm performance elements for automobile sector in India. The present study is limited to the Indian context, however, when conducted in other parts of the world, it would prove to be a great avenue for a more holistic comparison and strengthening of the current model.

This study presented a holistic approach in supply chain for sustainability implementation with Indian automotive sector which is currently more leaning towards operational & financial efficiency.

To prioritize the action hierarchy and allocating the resources accordingly the importance of criteria will be a bearing in decision making.

References

Ali, A. K. (2005). Using the Delphi technique to search for empirical measures of local planning agency power.The Qualitative Report,10(4), 718–744.

Capegemini. (2019). The Automotive Industry in the era of Sustainability.

Cioca, I., Turi, A., & G?man. (2019). Sustainable Development Model for the Automotive Industry.Sustainability,11(22), 6447.

Indexed at, Google Scholar, Cross Ref

Dempsey, N., Bramley, G., Power, S. & Brown. (2009). 'The social dimension of sustainable development: Defining urban social sustainability.Sustainable Development,19(5), 289–300.

Indexed at, Google Scholar, Cross Ref

Hutchins, M.J., & Sutherland, J.W. (2008). An Exploration of Measures of Social Sustainability and Their Application to Supply Chain Decisions.Journal of Cleaner Production,16, 1688–1698.

Indian Brand Equity Foundation [online]. (2020). India-automobiles.aspx. Retrieved December 1, 2021, from www.ibef.org website: http//www.ibef.org/industry/india-automobiles.aspx

Indexed at, Google Scholar, Cross Ref

Joshi, V., & Seth, N. (2018). Identification of total quality management constructs for Indian schools.Int. J. Intelligent Enterprise,Vol. 5(4), 385–406.

Landeta, J. (1999). The Delphi Method. A Forecasting Technique for the Future.Ariel, Barcelona.

Linstone, H.A., & Turoff, M. (2002).The Delphi Method: Techniques and Applications [online]. Retrieved from https://web.njit.edu/~turoff/pubs/delphibook/delphibook.pdf

Lucian-Ionel Cioca, Larisa, I., Attila, T., Alin, A., & George, A.G. (2019). Sustainable Development Model for the Automotive Industry.Sustainability 2019,11.

Indexed at, Google Scholar, Cross Ref

Mullen, P.M. (2003). Delphi: myths and reality.Journal of Health Organization and Management,Vol. 17(1), 37–52.

Indexed at, Google Scholar, Cross Ref

Shah, A., Munir, A., Khan, S., & Abbas, Z. (2011). Do industries predict the stock market due to slow diffusion of information.African Journal of Business Management,Vol. 5(34), 12958–12965.

Sitlington, H., & Coetzer, A. (2015). Using the Delphi technique to support curriculum development.Education+ Training,57(3), 306–321.

Indexed at, Google Scholar, Cross Ref

Soria-García & Martínez-Lorente. (2014). Development and validation of a measure of the quality management practices in education.Total Quality Management & Business Excellence,25(1-2), 57–79.

Indexed at, Google Scholar, Cross Ref

Vachon, S., & Mao, Z. (2008). Linking Supply Chain Strength to Sustainable Development: A Country-level Analysis.Journal of Cleaner Production,16(15), 1552–1560.

Indexed at, Google Scholar, Cross Ref

Vakani, F., & Sheerani, M. (2012). How to gain consensus from a group of non?experts – an educationist perspective on using the Delphi technique.Development and Learning in Organizations,26(4), 20–22.

Indexed at, Google Scholar, Cross Ref

Received: 02-Mar-2022, Manuscript No. AMSJ-22-11742; Editor assigned: 04-Mar-2022, PreQC No. AMSJ-22-11742(PQ); Reviewed: 22-Mar-2022, QC No. AMSJ-24-11742; Published: 26-Mar-2022