Research Article: 2023 Vol: 27 Issue: 3S

Mapping of Human-Centric Worksystem Interactions in Industrial Engineering Sectors

Roli Dave, National Institute of Industrial Engineering (NITIE), Mumbai

Vivek Khanzode, National Institute of Industrial Engineering (NITIE), Mum-bai

Citation Information: Dave, R., & Khanzode, V. (2023). Mapping of human-centric worksystem interactions in industrial engineering sectors. Academy of Marketing Studies Journal, 27(S3), 1-19.

Abstract

Bartlett (1962) emphasized the primary aim of ergonomics to keep closely connect between technology advancements in worksystem and human efficiency and health. Worksystem creates and delivers value using interactions among its components viz. Human, Machine, Environment, Workspace and Work organization. Human is regarded as the fundamental value adder in a worksystem as the human interacts with every other component of the worksystem. Such worksystems may be termed as human-centric worksystems. Worksystem failures, which are out-comes of negative system-person interactions, such as accident, traumatic injuries, work-related musculoskeletal disorders, and occupational illness directly, affect human efficiency and health, leading to productivity losses. The purpose of this study is to assess human-centric Interactions in technology advancing heavy engineering sectors such as Railways, Aviation, Automobile, Construction Mining, and Shipping. In this work, we use Leamon model (1980) as the fundamen-tal worksystem model and map the interactions to summarize the focus of recent ergonomic stud-ies in the context of technology advancements. Our analysis indicates that the contemporary er-gonomics research in heavy industries is more focused on interactions such as human and work-space (classical work study), human and work environment (environmental norms and standards), human and work organization (behavioral safety, human factors, and macroergonomics). However, the evolving interactions between human and machine components due to the changing nature of worksystem (including advances in automation) are scarcely researched. Future ergonomic studies need to focus on human-machine interactions towards effective worksystem design.

Keywords

Leamon’s Model, Worksystem design, Heavy engineering, Human-machine interac-tion.

Introduction

Worksystem comprises of components - Human, Machine, Workspace, Environment & Work Organization; and their interactions (Leamon 1980). Worksystem Design (WSD) address-es design issues that arise out of the inter-component interaction of worksystem. The study of ‘human factor’ aims the well-being of individuals, organizations and national economies (Wilson, 2000). Human factor focuses on human characteristics and human-centric worksystems design (Wickens et al., 2004). With evolution in work design and technology, there is ongoing transition of worksystem. The changing worksystem has increased machine work content and diminished human work content (Onnasch et al., 2014). The jobs previously performed by hu-man are taken over by a machine (Bainbridget, 1983), and systems are becoming more and more automated. This change has resulted in new dimensions of interactions (Onnasch, 2015). Worksystem interactions have transformed from simple and loosely coupled to complex and tightly coupled interactions as predicted by Perrow (1984). Automation and complexity of worksystem inevitably yield unexpected interactions, which escalate rapidly into uncontrolled system failure (Rijpma, 1997).

Worksystems are significantly changing across the dimensions of complexity, coupling, and automation (Perrow, 1984; Rijpma, 1997). Based on the increasing interaction, technology and level of automation, worksystems are becoming complex, tightly coupled and autonomous. The advancements in the worksystems have updated the core of any worksystem- “Human-machine interaction.”

This study aims to assess work-related injuries and illness in the human-centric worksys-tems in heavy engineering sector. Heavy engineering sector is selected for the proposed assess-ment as- (i) The sector caters to infrastructural development projects forms the backbone of nation-building. (ii) The industrial operations are capital intensive and characterized by large human force and heavy mechanization in machines and processes. (iii) The technological ad-vancements and increasing level of automation have updated the traditional work content of heavy engineering industries. We also explicitly restrict the scope to the work-related injuries and illness with the prolonged exposure to the negative interactions.

Leamon’s Human-Machine (Leamon, 1980) Model is utilized to map the assessment of work-related injuries and illness. This worksystem model is regarded as the fundamental model illustrating the essential components of worksystem (Human: senses, process, effectors, Ma-chine: display, control process, controls, Environment: workspace, physical environment, work organizations) with explicit boundaries. Further, the model explains the process flow and inter-component interactions.

The significant contribution of this work can be summarized as follows- Firstly, a com-prehensive review of literature related to work-related injury and illness in various heavy engi-neering sectors is presented. Secondly, the key events of the researches identified as interactions of worksystem components. Thirdly, all the interactions were mapped on Leamon’s human-machine model (1980) specific to the industry. Finally, all the interactions summarized and the need for the studies on the human-machine interactions are highlighted.

This paper is organized as follows: The methodology of the research is presented in sec-tion 2. In Section 3, the literature on work-related injuries and illness are reviewed. Mapping of the interaction of worksystem components is discussed. Section 4 present the conclusion and future work.

Methodology

Review of Literature

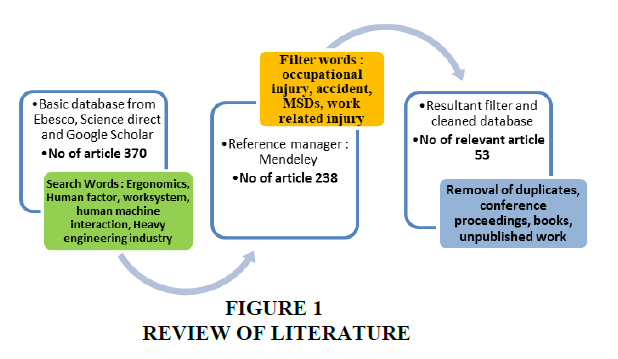

The scientific literature was searched using the key words, ergonomics, human factor, human-machine interaction, work system, and heavy engineering industry which were aligned to research objective. The combination of these has been used to search literature through science direct, EBSCO and google scholar. This has given a total of 370 relevant articles. The complete data was taken into reference manager software Mendeley to carry out a search for relevant arti-cles. This articles further refined through specific key words (occupational injury, accidents, work-related injury) related to the field and narrowed down the literature review bank to approx-imately 238 articles. These 238 articles were refined for duplicate papers, unpublished work, books and conferences proceeding etc and finally come to 53 articles were found very much rel-evant to the literature review for the subject research.

Literature Synthesis

Industry-wise study of literature review has given insight of industry specific focus area of research and their problems in terms of industrial ergonomics. It has also provided the evi-dence of industry wise researches in different countries. Bibliographic analysis carried out using Vantage point as follows:

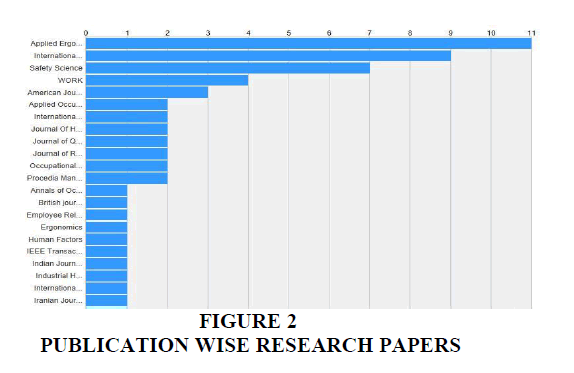

Publication Wise Research

The Vantage point bibliographic software was utilized to initially analyses ergonomics studies in industries. Descriptive analysis in Figure 1 shows that the subject is equally well pub-lished in all the top-rated international journals. In the literature review, the 60% publications were from top five journals.

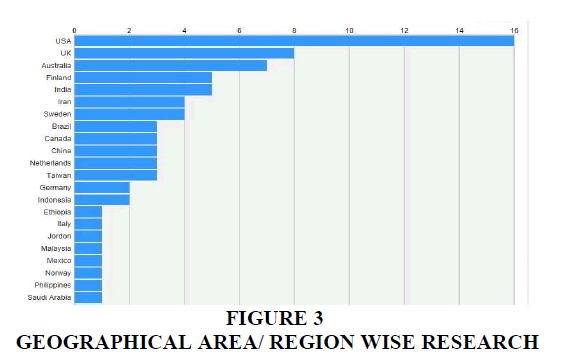

Geographical Region/ Area wise Research

The contribution in research in ergonomics and heavy engineering industries, across vari-ous countries, we plotted it on global map on the basis of first author’s affiliation country. Figure 2 shows that United States of America (USA), is ranking ahead, in the country wise efforts, However, increasing trends of research efforts from emerging economies like UK, Australia, Finland and India, are also present and worth noting.

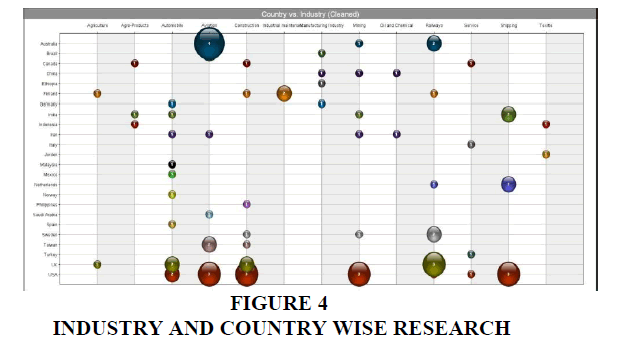

Industry and Country wise Research

Based on the current literature review, the industry wise research in various countries was plotted on global map, on the basis of first author’s affiliation country and Figures 3-6 shows that major contribution of USA, UK and Australia in the field of Aviation, Construction and Auto-mobile industries. However, increasing trend of research efforts in Finland, India, and China are worth noting.

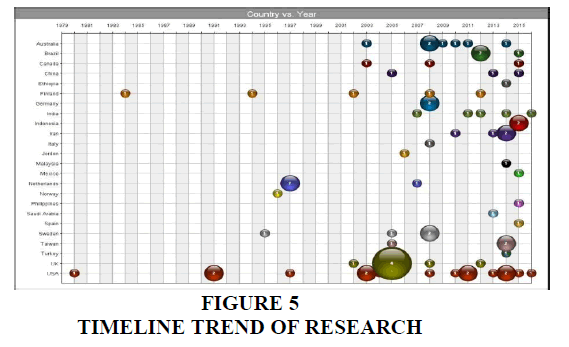

Time line Trend wise Research

Based on the current literature review, timeline tend shows that focus of researches to-wards ergonomics in industry has been more in last two decades. The trend shows the increased contribution of researches in USA and Australia in last decade. The trend shows that there was increased contribution from researchers form USA and Australia in last decade.

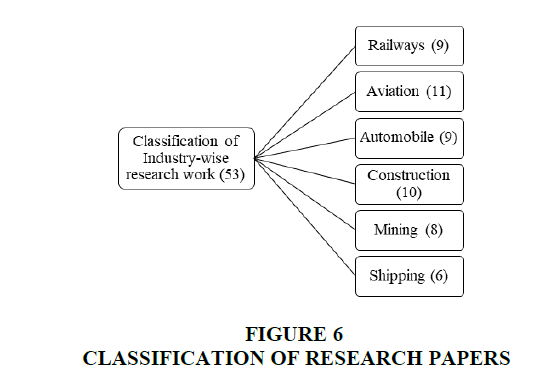

Classification of Research

After having the selected the 53 articles, the literature classified into industry wise research. Industry-wise research work was separated to understand the type and extent of research work conducted in context of the specific industry. Apart from general industry, the major focus has been made towards large industries with heavy engineering works, where the machine and human interaction is high.

Results

The purpose of this study is to assess human-centric interactions in technology advancing heavy engineering sectors such as Railways, Aviation, Automobile, Construction Mining, and Shipping. We select 53 papers and systematically assess work-related illness and injuries in the heavy engineering industries. We consider the occupational illness as the negative interactions among worksystem component, thus map and highlight the select individual paper on Leamon’s worksystem model. The results of this work can be presented considering- (a) Comprehensive review of heavy engineering industry wise research on work-related injuries and accident, (b) Mapping of the interaction of worksystem components and highlights. We further present the summary of the reviews and comment on the further developments in human-centric worksystem model.

A Comprehensive Review of Industry Wise Research on Work-Related Injuries and Accidents

A comprehensive review of the research work in across heavy engineering sectors, i.e. railways, aviation, automobile, construction, mining, and shipping is carried out. The focus of the study is maintained towards work-related injuries and illness in heavy engineering sectors in the last three decades. This review includes the year of research, country, publication journal, methodology, samples and a key outcome of research in heavy engineering sectors. This com-prehensive review of researches is tabulated industry wise and attached as Annexure A to this paper. This table may be referred for considering the serial number of papers while mapping on Leamon’s Model and discussion in section 3.2.

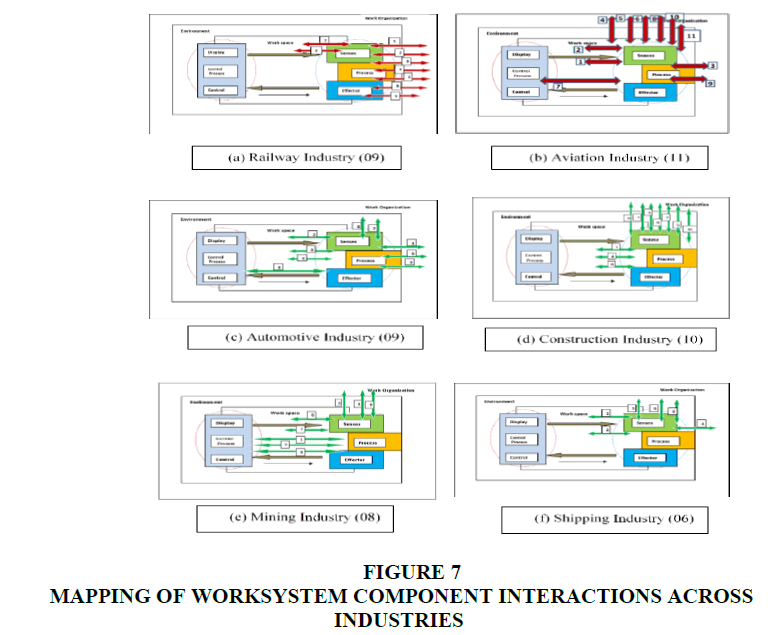

Mapping of Interaction of Worksystem Components and Highlights

Based on the key outcome of the research in heavy engineering sectors the worksystem components interactions are identified. These interactions are mapped on Leamon's Human Ma-chine model (1980) in the context of each heavy engineering sector.

Railway Industry

The authors in the studies discussed the impact the work organization on the human factor. Sleep length, shift duration, night shift, and high workload were significant predictors of extreme tiredness/ exhaustion. Shift work disrupts the sleep-wake cycle (Ferguson et al., 2008; Tepas and Mahan, 1989; Dorrian et al., 2011), leading to sleepiness, fatigue and performance impairment. Similar observations were made by Härmä et al. (2002) in a study about shift duties and factors affecting sleepiness among 126 railway drivers and 104 railway traffic controllers. Privatization of industry may affect the safety culture of organization due to major focus on economic benefits, less manpower to work ratio and inexperience and contractual workforce (Chris Baldry, 2006; Sanne, 2008). Farrington-Darby et al. (2005) identified forty primary factors which affect the worker's safety behavior and the organization’s safety culture in railway industry. The effect of vibration of machine during the work on back pain and employability of workers returned to work after the cardiac event was discussed in studies (Dijk, Jaap Van, Jos Govaarts, Voumard, 2007; Eckardt Johanning, 2011). Hamilton and Theresa Clarke (2005) studied the ergonomics requirement of the driver to use sign and signals in terms of location and speed of the train.

As per Fig 3, (a) mapping of the interaction of research work of railway industry on Leamon's model shows that major studies have been conducted across the globe was on the organizational structure and management of the functioning/operation, where the subjects were mostly operators like drivers, signalers, etc. Rare literature indicated the effect of environment on the work system and repetitive strain injuries, apart from vibration as risk factor and its associa-tion with back problems. There were no studies, which brings out of human-machine interaction in the reviewed literature.

Aviation Industry

Aviation industry workers suffer from both traumatic as well as overuse injuries. Many risk factors including high-pressure strain and shift work have been identified by various researchers. Commonly identified risks were memory lapses, violations, and knowledge-based, mistakes, followed by slips and rule-based mistakes (Hobbs and Williamson, 2003). Noncompli-ance and ignorance about safety measures was also a significant reason (Neitzel et al. 2008) for worksystem failures. In Wang & Chuang’s (2014) survey, adequacy of Rest did not significantly affect fatigue level even with a high workload, whereas the workers’ work proficiency and coor-dination played a significant role. Aviation industry workers are exposed to high noise produced by the turbine, engine and rotors result in high percentage hearing loss (PHL) and deficiencies. High percentage PHL was documented by Guest et al. (2010) and more in middle and above middle age group whereas Noweir & Zytoon (2013) noted that use of protective aid reduces the incidence of hearing issues. Age, smoking, depression and use of anti-depressant drug also affect the hearing (Noweir and Zytoon, 2013). Aircraft workers involved in fueling, maintenance of fuel tank are parachute repair have carcinogenic exposer due to fabric, fumes, and solvents. High incidence rate of cancer, sexual dysfunction, erectile dysfunction, sperm motility is documented (Anthony Brown, et al., 2009; Catherine et al., 1999; Spirtas et al. 1991). Oliveira A, Nogueira, H, Diniz A, (2012) brought out that psychosocial factors such as low commitment, low job satis-faction, poor social support, low demand, and low decision-making are associated with the de-velopment of musculoskeletal disorders. High job engagement is negatively associated with WMSD in the presence of biomechanical factors (awkward posture, high physical loading work, long working hours) in aircraft maintenance workers (Kemp et al., 2010; Noueira et al., 2012).

As per Fig 3, (b) mapping of the interaction of research work of the aviation industry on Leamon's model shows that major studies have been conducted in the relation to human compo-nent and environment. In studies conducted 1, 2 by an author described the work-related MSDs in maintenance workers due to work place arrangement. Shift work, coordination, and communication within workers and organization and safety culture of the organization were discussed by authors in 7 and 3. It is pertinent to note that only author in 9 have discussed the incidences/accidents while human-machine interaction in terms of technical knowledge, exper-tise and training apart from secondary factors related to environment and fatigue, etc.

Automobile Industry

Automobile workers too will get exposed to various jobs of material handling (lift-ing/pushing), jobs of repetitive, use of vibrating tools and chemicals hazard, fumes, etc. Lee at al. (1997) well-designed maintainability (during manufacturing) can avoid injuries to workers. Vyas et al., (2011) reported high rate of MSD (85%) due to confined space and awkward posture, dur-ing maintenance. Additional factors noted as long working hours and inexperience worker re-sponsible for work-related MSD. The assembly/dismantling of the engine/electric generator and transmission system of hybrid vehicles also poses high risk for injury (Rubio-romero et al. 2015). Automobile maintenance workers also reported having a high risk of MSD mainly due to vibration and awkward posture(Emre Ozgür Bulduk , S?d?ka Bulduk, Tufan Süren, 2014; Faisal et al., 2014; Torp et al., 1999; Waters et al., 2015). Association between age, length of professional life and MSD was also reported by Choobineh et al. (2013). Ergonomics awareness between em-ployer and employee with training and information sharing should be encouraged to reduce the prevalence of MSD. Awareness measures such as pamphlets and lectures are good, but not as effective as a workshop (Aghilinejad et al. 2014).The incidence of respiratory disease ‘Asbesto-sis’ and asthma reported to be high in vehicle brake workers/mechanics in workshops where ventilation was poor (Arthur N Rohl and Langer, 1976; Cely-Garcia et al. 2012).

As per Fig 3 (c), mapping of the interaction of research work of automobile industry on Leamon's model shows that the major focus areas of studies were the interaction of the human component with work organization and work space component. Authors have discussed the im-pact MSD on automobile workers where 84% of workers were suffering from MSD as per stud-ies. The causes of accidents / injures were related to work space, work culture-specific safety issues. Authors in study 4 and 8 pointed out the issues related to the maintainability of machines; the injuries can be avoided if the maintainability aspect, e.g. confines space for work, etc, is con-sidered while designing. Environment aspects covered the impact of hazards material. The re-viewed literature presents the lack of studies of human-machine interactions in automobile indus-try.

Construction Industry

In addition to repetitive strain injuries, machine and equipment accidents and breakdown, fall from the high construction site is also a common reason for severe injuries and fatalities(Chia-Fen Chia, Tin-Chang, 2005; Liao and Chiang, 2015). Renier et al. (2015) cited Philippine Labour and Employment Authority Statistics (2011) that these workers are constantly exposed to dangerous environments and are at high risks for MSDs. Haslama et al. (2006) argued that attention to the originating influences is necessary for sustained improvement in construction safety to be achieved. The construction workers are also exposed to noise and vibration due to construction machinery and may suffer from vibration syndrome and other vibration-related inju-ries like carpal tunnel syndrome and different types of tendinitis (Eckardt 2011; Fritz et al., 2005). They have to adopt awkward posture while using a manual vibrating tool resulting in WMSD (Sengupta et al., 2014). Low back pain reported as most commonly WMSD (54.4%) and reason for absenteeism where Working in the same position for long periods” was the job factor identified as most problematic (David Goldsheyder, Shira Schecter Weiner, Margareta Nordin, 2004; Linda Delp, 2015; M Gervais, 2003; Minna and Mika, 2012). Working in the same position for long periods” was the job factor identified as most problematic. To overcome such issues, Gervais M (2003) suggested the implementation of administrative (by improved planning of work) or engineering controls in order to prevent accidents and injuries such as back disorders. There have been studies on intervention/ prevention measures to reduce occupational hazards in conduction industries. Many guidelines and safety measures have been suggested (Bust and Gibb, 2005; Gervais, 2003; Haslama, Hide, Gibb, et al., 2005). Eva Holmstro (2005) demonstrated that some form of physical exercises, in terms of warm-ups and stretching is bene-ficial in reducing physical strain and WMSD.

As per Fig, 3(d) mapping of the interaction of research work in the construction industry on Leamon's model shows that the major focus of the researches in the construction industry was towards the issue concerning with the organization and workspace. The studies 9 and 10 discuss the implementation of requisite guidelines and adopt a proper procedure for work to prevent accident and MSD to workers. Authors at 2, 3, 5 and 6 identified the risk factors for MSD and ac-cidents and also brought out the lack of use of PPE and supervision at work. Study 5 has shown marginal improvement in MSD due to intervention. Although the use of major equipment is in-volved in construction work, but there is a dearth of studies involving the interaction of human-machine components and human – environment components.

Mining Industry

Mining involves dealing with many uncontrollable parameters, such as handling heavy manual material and environment. This causes many occupational injuries and illnesses. Chen et al. (2013) found that miner’s occupational injuries in China accounted for 54% of the total coun-try’s occupational injuries. Though some research is done to analyze or predict accidents, still there is a dearth of data and study methods to anticipate occupational accidents in mining. Traffic accidents, cutting wire rupture and rock fall constituted towards maximum risk of occupational accidents in Iran (Yarahmadi et al., 2014). Machinery most often involved in mining accidents are conveyors, rock bolting machines, milling machines and haulage equipment such as trucks and loaders (Ruff et al. 2011). Operation of the machine and maintenance and repair were most common associated activities. Ruff et al. (2011) reported in their study of 8 years data in US miners (2000-2007), that out of 562 accidents that took place, 259 (46%) occurred during the operation of the machine and 139 (25%) occurred during maintenance or repair, 34 (6%) oc-curred during handling of supplies or materials. Most machines are electrically operated. Electric accidents are the 4th leading cause of death in mining (Cawley, 2003). Research has shown that working condition, job pattern does play a role in mining accidents. Shoveling had more physio-logical strain than drilling and loading (Saha et al. 2007). Contractual mining workers are more affected than regular miners (Blank et al. 1995), Polland & Heberger (2014), where 36 % of manual handling mining injuries were due to maintenance and repair related work.

As per Fig 3(e), mapping of the interaction of research work in the mining industry on Leamon's model shows that the Mining industry has been studied by the many authors focusing in all the area except interaction of human and environmental components. With advancement in mechanization-use of machines, a physical load of miners has reduced, but machines accidents have also raised. Machinery most often involved in mining accidents are conveyors, rock bolting machines, milling machines and haulage equipment Since the mining has major usage of ma-chines and equipment the authors have brought out in studies 1,2, and 8 that major accidents oc-curred while operating machines where fingers and hand injuries were the maximum. The overall accident data shows that electrical accidents were more common than others. Authors have iden-tified human work space interaction in 6 and 7 that working posture like sitting for long hours and job of shoveling caused most MSD, where work place modification plays an important role. The lack of safety culture and implementation of guidelines with the need for training, awareness, and automation is emphasized by authors in the relation of human organization com-ponents. Despite odd condition, literature review lacks the studies in the area of human-environment components.

Shipping Industry

The various activities of ship building, maintenance, and repair have to be carried out at heights, or in closed confined spaces along with the added risk of exposure to chemicals and metal fumes. These activities include Dry docking, and launching, fabricating and repairing large structural components, handling large materials, outfitting, surface preparation and scaling, elec-trical maintenance and repair, welding, electroplating, loading and unloading, and painting ex-poses the workers to various health hazards (Vaishali R Lokhande, 2014). A lot of manual mate-rial handling is involved in this sector, where at time load is more than the prescribed guidelines (De Joode et al., 1997). Exposure of hazards materials used in ship building causes asbestosis and lung cancers (D E Hickish, 1970; Rohl & Langer, 1976; Balmes et al. 1991; Mlynarek, Corn, & Blake, 1996, Selikoff et al. 1980); Mattorano et al. (2016) evaluated breath sample of workers and air samples of ship yard sites, where breaking is carried out. The high content of Lead, cop-per, magnesium and other heavy metal were noted, especially in confines spaces. Ship mainte-nance involves lifting, pushing and pulling activities sometimes exceeded published guidelines for manual material handling resulting in the high prevalence of MSD ((De Joode et al., 1997; Sharan, 2012). The most common hazards observed as awkward posture, noise and repetitive motion (Neitzel et al., 2013; Vaishali R Lokhande, 2014).

The interaction mapping of figure 7 shows that the researchers have focused mainly on environmental factors in 3, 5 and 8 where noise, the presence of lead and asbestos in the working environment were termed as hazardous for maintenance and repair workers in a shipping indus-try context. Awkward posture and heavy lifting and pushing of the load along with the location of controls have argued for better workplace design to improve effect on human-workspace in-teraction and prevent MSDs. Authors have also discussed the health of workers in term of the prevalence of hypertension, additions, and lack of use of PPE and questioned the organizational safety culture. In the current literature, authors have not torched the area of human-machine in-teraction in shipping industry.

In the human-centric worksystem of various heavy engineering industrial contexts, hu-man interactions with other worksystem components are summarized in terms of works related injuries and illness in table 1.

The systematic review of worksystem interactions of heavy engineering industry sector is carried out. It is evident from the summary of interactions that major focus of researchers was towards human - organization and human –workspace interactions. However, studies particularly focusing on human-machine interactions are relatively less and require further research consider-ing the transitions in worksystems across complexity, coupling, and level of automation Annex-ure Table 1.

| Table 1 Industry-Wise Summary Of Worksystem Interactions |

||||

|---|---|---|---|---|

| Interactions | Human- Machine |

Human- Environment |

Human-Work space | Human- Organization |

| Railway | - | - | 2 | 7 |

| Aviation | 1 | 6 | 2 | 2 |

| Automobile | 1 | 2 | 3 | 3 |

| Construction | - | - | 3 | 7 |

| Mining | 3 | - | 2 | 3 |

| Shipping | - | 3 | 2 | 1 |

| Total no of Interaction |

5 | 11 | 14 | 23 |

Conclusion

Despite changing worksystems and thereby increasing machine work content, the human role is going to be critical particularly during worksystem failures and failure retrievals. In this study, we assess human-centric interactions in technology advancing heavy engineering sectors such as Railways, Aviation, Automobile, Construction Mining, and Shipping using Leamon’s Human-machine model. The significant contribution of this work can be summarized as follows- Firstly, a comprehensive review of literature related to work-related injury and illness in various heavy engineering sectors is presented. Secondly, the key events of the researches identified as interactions of worksystem components. Thirdly, all the interactions were mapped on Leamon’s human-machine model (1980) specific to the industry. Finally, all the interactions summarized and the need for the studies on the human-machine interactions are highlighted.

In this work, we have considered the work-related injuries and illness as a result of the negative interactions with prolonged energy exposure limiting to heavy engineering industry context. Further studies can consider the catastrophic failures with acute energy exposure in mul-tiple industry contexts to determine invention possibilities.

Annexure

| Annexure Table 1 Industries |

|||

|---|---|---|---|

| Ser | Paper | Research Focus | Work system Interaction |

| Railway Industry | |||

| 1 | Farrington-Darby et al., 2005 | Railway maintenance, Factors affecting safety behavior and organization’s safety culture identified. | Human - Organization |

| 2 | Dorrian et al., 2011 | Work and sleep hours, work load, shift work attesting fatigue in rail employees. | Human - Organization |

| 3 | Sanne, 2008 | Work pressure and Risk taking behavior in railway maintenance workers | Human - Organization |

| 4 | Härmä et al., 2002 | Effect of shift work on sleepiness during work in train drivers and Traffic controller, | Human - Organization |

| 5 | Chris Baldry, 2006 | Effect of privatization of industry on organizational pressure and safety structure. | Human - Organization |

| 6 | Hamilton and Theresa Clarke, 2005 | Ergonomics issues of Railway driver's wrt location of signs and signals | Human - Workspace |

| 7 | Eckardt Johanning, 2011 | Effect of exposure of vibration on rail maintenance workers | Human - Workspace |

| 8 | Sarah M. Jay, Drew Dawson, Sally A. Ferguson, 2008 |

Effect of fatigue on performance of railway drivers | Human - Organization |

| 9 | Dijk, Jaap Van, Jos Govaarts, Voumard, 2007 | Safety and risk associated with drivers resume work after cardiac disease | Human - Organization |

| Aviation Industry | |||

| 1 | Noueira et al., 2012 | Prevalence of MSD. Psychosocial indicators such as Job demand, Job control, social support, work engagement. | Human - Workspace |

| 2 | Oliveira A, Nogueira, H, Diniz A, 2012 | Prevalence of MSD and job demand | Human - Workspace |

| 3 | Wang and Chuang, 2014 | Psychological & physiological fatigue variation in shift workers and the subjective factors affecting the fatigue | Human - Organization |

| 4 | Noweir et al., 2013 | Effect of noise on hearing impairment | Human - Organization |

| 5 | Anthony Brown, Richard Gibson, Meredith Tavener, Maya Guest, et al., 2009 | Sexual function in a male aircraft maintenance worker | Human - Organization |

| 6 | Spirtas et al., 1991 | Mortality in aircraft maintenance workers | Human - Organization |

| 7 | Neitzel et al., 2008 | Fall hazards; safety climate; aircraft maintenance workers. | Human - Machine |

| 8 | Lemasters et al., 1999 | Jet fuel and solvent exposure and effect on sperm motility | Human - Organization |

| 9 | Hobbs and Williamson, 2003 Human Factor | Errors of aircraft maintenance workers that lead to incidences and their contributing factors | Human - Organization |

| 11 | Maya Guest, May Boggess et al., 2010 | Noise-induced hearing loss, aircraft maintenance workers and effect of age smoking and anti-depressant drugs | Human - Organization |

| Automobile Industry | |||

| 1 | Vyas et al., 2011 | Occupational injury and their stressors in automobile workers, identified risk factors were your age, inexperience, long working hours and psychological distress. | Human - Organization |

| 2 | Faisal et al., 2014 | MSD due to Hand-arm vibrations in automobile workers | Human - Workspace |

| 3 | Waters et al., 2015 | Vibration/ shock and working posture associated with back and neck disorders among HEV operators. | Human - Workspace |

| 4 | Lee Jean Lin, H. Harvey Cohen, 1997 | Causes of accidents in the automobile industry, slip, fall and struck by the object are main reason. Maintainability while designing is important |

Human - Workspace |

| 5 | M Aghilinejad, Bahrami-Ahmadi, A Kabir Mokamelkhah, E Sarebanha, S Hosseini, HR Sadeghi, Z Sadeghi2014 | Risk of exposure to hazards material asbestos under poor ventilation conditions | Human - Organization |

| 6 | Cely-Garcia and Mauricio Sánchez, Patrick N Breysse, Juan P Ramos-Bonilla, 2012 | Exposure to asbestos in brake maintenance | Human - Environment |

| 7 | Mackie, 2008 | Occupational asthma in automobile workers like painters | Human - Environment |

| 8 | Chialastry, 2016 | Comparative risk assessment of vehicle maintenance activity of hybrid, electric and hydrogen fuel cell car | Human - Machine |

| 9 | Kurt Landau et al., 2008 | MSD in automobile assembly workers, effects of age and length of service | Human - Organization |

| Construction industry | |||

| 1 | Sengupta et al., 2014 |

Dry wall paneling, awkward postures, risk assessment, occupational risk. | Human - Workspace |

| 2 | R.A. Haslama, S.A. Hide, A.G.F. Gibb, D.E. Gyi, T.Pavitt, S.Atkinson, 2005 | Contributing factors to constructional accidents. | Human - Organization |

| 3 | M Gervais, 2003 | Integration of safety considerations into the design process and coordination of construction work and safety activities, and improved training | Human - Organization |

| 5 | Eva Holmstro, 2005 | Effect of warm-up and stretching exercises on flexibility and endurance of construction workers. | Human - Organization |

| 6 | Chia-Fen Chia, Tin-Chang, 2005 | Fall assessment in construction industry | Human - Organization |

| 7 | David Goldsheyder, Shira Schecter Weiner, Margareta Nordin, 2004 | WMSD and risk factors of concrete/cement workers. | Human - Organization |

| 8 | James Renier T. Domingo, Ma. Theresa S. De Pano, Dominic Aily G. Ecat, Nicole Ann D.G. Sanchez, 2015 | MSD and risk factors in construction workers, emphasis on objective assessment to measure risk | Human - Workspace |

| 9 | Minna and Mika, 2012 | MSD and risk factors in construction workers | Human - Organization |

| 10 | P D Bust, A G F Gibb, 2005 | The ergonomic risk in manual material handlers in construction workers. Education and training in manual handling is desirable | Human - Organization |

References

Anthony Brown, Richard Gibson, Meredith Tavener, Maya Guest, C.D., Julie Byles, John Attia, K. and Horsley, Warren Harrex, J.R. (2009), “Sexual function in F-111 maintenance workers: the study of health outcomes in aircraft maintenance personnel”, J Sex Med, Vol. 6 No. 6, pp. 1569–1578.

Indexed at, Google Scholar, Cross Ref

Arthur N Rohl, A.M. and Langer. (1976), “Asbestos Exposure during Brake Lining and Repai r1 Maintenance”, Vol. 128, pp. 110–128.

Indexed at, Google Scholar, Cross Ref

Bainbridget, L. (1983), “Ironies of Automation”, Automatica, Vol. 19 No. 6, pp. 775–779.

Indexed at, Google Scholar, Cross Ref

Balmes, J.R., Daponte, A. and Cone, J.E. (1991), “Asbestos-related disease in custodial and building maintenance workers from a large municipal school district.”, Annals of the New York Academy of Sciences, Vol. 643, pp. 540–9.

Indexed at, Google Scholar, Cross Ref

Catherine D’Este, John R. Attia, Anthony M. Brown, Richard Gibson, Grad Dip, Robert Gibberd, Meredith Tavener, Maya Guest, Keith Horsley, Warren Harrex, J.R. (2008), “Cancer Incidence and Mortality in Aircraft Maintenance Workers”, American Journal of Industrial Medicine, Vol. 51, pp. 16–23.

Indexed at, Google Scholar, Cross Ref

Cawley, J.C. (2003), “Electrical accidents in the mining industry, 1990-1999”, IEEE Transactions on Industry Applications, Vol. 39 No. 6, pp. 1570–1577.

Indexed at, Google Scholar, Cross Ref

Cely-Garcia, M.F. and Mauricio Sánchez, Patrick N Breysse, Juan P Ramos-Bonilla. (2012), “Personal exposures to asbestos fibers during brake maintenance of passenger vehicles”, Annals of Occupational Hygiene, Vol. 56 No. 9, pp. 985–999.

Indexed at, Google Scholar, Cross Ref

Chia-Fen Chia, Tin-Chang, H.-I.T. (2005), “Accident patterns and prevention measures for fatal occupational falls in the construction industry”, Applied Ergonomics, Vol. 36, pp. 391–400.

Indexed at, Google Scholar, Cross Ref

Chialastry, A. (2016), “Automation in Aviation”, RFID Technology, Security Vulnerabilities, and Countermeasures, available at:https://doi.org/10.5772/711.

Chow, D.H.K., Li, M.F., Lai, A. and Pope, M.H. (2011), “International Journal of Industrial Ergonomics Effect of load carriage on spinal compression”, International Journal of Industrial, Vol. 41, pp. 219–223.

Chris Baldry, J.E. (2006), “Off the rails: factors affecting track worker safety in the rail industry”, Employee Relations, Scotland, Vol. 28 No. 3, pp. 255–272.

Indexed at, Google Scholar, Cross Ref

D E Hickish, K.L.K. (1970), “Exposure to asbestos during brake maintenance.”, Annals of Occupational Hygiene, Vol. 13 No. 1, pp. 17–21.

Indexed at, Google Scholar, Cross Ref

David Goldsheyder, Shira Schecter Weiner, Margareta Nordin, R.H. (2004), “Musculoskeletal symptom survey among cement and concrete workers”, Work, USA, Vol. 23, pp. 111–121.

Dijk, Jaap Van, Jos Govaarts, Voumard, P. (2007), “Vocational rehabilitation of locomotive engineers with ischaemic heart disease”, Occupational Medicine, Vol. 57 No. January, pp. 131–136.

Indexed at, Google Scholar, Cross Ref

Dorrian, J., Baulk, S.D. and Dawson, D. (2011), “Work hours , workload , sleep and fatigue in Australian Rail Industry employees”, Applied Ergonomics, Elsevier Ltd, Australia, Vol. 42 No. 2, pp. 202–209.

Indexed at, Google Scholar, Cross Ref

Eckardt Johanning. (2011), “Vibration and shock exposure of maintenance-of-way vehicles in the railroad industry”, Applied Ergonomics, Elsevier Ltd, USA, Vol. 42 No. 4, pp. 555–562.

Indexed at, Google Scholar, Cross Ref

Emre Ozgür Bulduk , Sıdıka Bulduk, Tufan Süren, F.O. (2014), “Assessing exposure to risk factors for work-related musculoskeletal disorders using Quick Exposure Check ( QEC ) in taxi drivers”, International Journal of Industrial Ergonomics, Vol. 44, pp. 817–820.

Indexed at, Google Scholar, Cross Ref

Eva Holmstro, B.A. (2005), “Morning warming-up exercise — effects on musculoskeletal fitness in construction workers”, Applied Ergonomics, Vol. 36, pp. 513–519.

Indexed at, Google Scholar, Cross Ref

Faisal, A., Nasaruddin, A., Bahri, S. and Tamrin, M. (2014), “The Prevalence of Musculoskeletal Disorder and the Association with Risk Factors among Auto Repair Mechanics in Klang Valley , Malaysia”, Iranian Journal of Public Health, Malaysia, Vol. 43 No. 3, pp. 34–41.

Farrington-Darby, T., Pickup, L. and Wilson, J.R. (2005), “Safety culture in railway maintenance”, Safety Science, UK, Vol. 43 No. 1, pp. 39–60.

Indexed at, Google Scholar, Cross Ref

Hamilton, W.I. and Theresa Clarke. (2005), “Driver performance modelling and its practical application to railway safety”, Applied Ergonomics, UK, Vol. 36, pp. 661–670.

Indexed at, Google Scholar, Cross Ref

Härmä, M., Sallinen, M., Ranta, R., Mutanen, P. and Müller, K. (2002), “The effect of an irregular shift system on sleepiness at work in train drivers and railway traffic controllers”, Journal of Sleep Research, Finland, Vol. 11, pp. 141–151.

Indexed at, Google Scholar, Cross Ref

Hobbs, A. and Williamson, A. (2003), “Associations between errors and contributing factors in aircraft maintenance.”, Human Factors, Australia, Vol. 45 No. 2, pp. 186–201.

Indexed at, Google Scholar, Cross Ref

Hong Chen, Q.F., Long, R. and Hui Qi. (2013), “Focusing on coal miners’ occupational disease issues: A comparative analysis between China and the United States”, Safety Science, Elsevier Ltd, Vol. 51 No. 1, pp. 217–222.

Indexed at, Google Scholar, Cross Ref

James Renier T. Domingo, Ma. Theresa S. De Pano, Dominic Aily G. Ecat, Nicole Ann D.G. Sanchez, B.P.C. (2015), “Risk assessment on Filipino construction workers”, Procedia Manufacturing, Elsevier B.V., Vol. 3 No. Ahfe, pp. 1854–1860.

Indexed at, Google Scholar, Cross Ref

De Joode, B.V.W., Burdorf, A. and Verspuy, C. (1997), “Physical load in ship maintenance: Hazard evaluation by means of a workplace survey”, Applied Ergonomics, Netherlands, Vol. 28 No. 3, pp. 213–219.

Indexed at, Google Scholar, Cross Ref

Kemp, P.A., Burnham, B.R., Copley, G.B. and Shim, M.J. (2010), “Injuries to air force personnel associated with lifting, handling, and carrying objects.”, American Journal of Preventive Medicine, Elsevier Inc., USA, Vol. 38 No. 1 Suppl, pp. S148-55.

Indexed at, Google Scholar, Cross Ref

Kristy N. Carlisl, A.W.P. (2014), “Psychological Distress and Pain Reporting in Australian Coal Miners”, Safety and Health at Work, Elsevier Ltd, Vol. 5 No. 4, pp. 203–209.

Indexed at, Google Scholar, Cross Ref

Kurt Landau, H.R., Herwig Meschke, Gabriele Winter, Karlheinz Schaub, M.G., Ingo Moelbert, Michael Sommer, J. and Schulze. (2008), “Musculoskeletal disorders in assembly jobs in the automotive industry with special reference to age management aspects”, International Journal of Industrial Ergonomics, Vol. 38 No. 7–8, pp. 561–576.

Indexed at, Google Scholar, Cross Ref

Kushwaha, Deepak Kumar, Prasad V Kane. (2016), “Ergonomic assessment and workstation design of shipping crane cabin in steel industry”, International Journal of Industrial Ergonomics, Elsevier Ltd, Vol. 52, pp. 29–39.

Indexed at, Google Scholar, Cross Ref

Leamon, T.B. (1980), “The organisation of industrial ergonomics — A human: machine model”, Applied Ergonomics, Vol. 11 No. 4, pp. 223–226.

Indexed at, Google Scholar, Cross Ref

Lee Jean Lin, H. Harvey Cohen. (1997), “Accidents in the trucking industry”, International Journal of Industrial Ergonomics, USA, Vol. 20 No. 4, pp. 287–300.

Indexed at, Google Scholar, Cross Ref

Lemasters, G.K., Olsen, D.M., Yiin, J.H., Lockey, J.E., Shukla, R., Selevan, S.G., Schrader, S.M., et al. (1999), “Male reproductive effects of solvent and fuel exposure during aircraft maintenance.”, Reproductive Toxicology (Elmsford, N.Y.), Vol. 13 No. 3, pp. 155–166.

Indexed at, Google Scholar, Cross Ref

Liao, C. and Chiang, T. (2015), “The examination of workers ’ compensation for occupational fatalities in the construction industry”, Safety Science, Elsevier Ltd, Vol. 72, pp. 363–370.

Indexed at, Google Scholar, Cross Ref

Linda Delp, K.R. (2015), “Worker Engagement in the Health and Safety Regulatory Arena under Changing Models of Worker Representation”, Labor Studies Journal, Vol. 40 No. 1, pp. 54–83.

Indexed at, Google Scholar, Cross Ref

Mackie, J. (2008), “Effective health surveillance for occupational asthma in motor vehicle repair.”, Occupational Medicine (Oxford, England), Vol. 58 No. 8, pp. 551–5.

Indexed at, Google Scholar, Cross Ref

M Gervais. (2003), “Good management practice as a means of preventing back disorders in the construction sector”, Safety Science, Vol. 41, pp. 77–88.

Indexed at, Google Scholar, Cross Ref

Mattorano, D., Harney, J., Cook, C., Roegner, K., Mattorano, D., Harney, J., Cook, C., et al. (2016), “Metal Exposure During Ship Repair and Shipbreaking Procedures and Shipbreaking Procedures”, Applied Occupational and Environmental Hygiene ISSN:, Vol. 898 No. July, available at:https://doi.org/10.1080/10473220117911.

Indexed at, Google Scholar, Cross Ref

Maya Guest, May Boggess, J.A., D’Este, C., Anthony Brown, R.G., Meredith Tavener, I.G., Warren Harrex, K.H. and James Ross. (2010), “Hearing Impairment in F-111 Maintenance Workers: the Study of Health Outcomes in Aircraft Maintenance Personnel (SHOAMP) General Health and Medical Study”, American Journal of Industrial Medicine, Vol. 53 No. 11, pp. 1159–1169.

Indexed at, Google Scholar, Cross Ref

Minna, S. and Mika, N. (2012), “Relationship between construction workers â€TM musculoskeletal disorders and occupational health service activities”, Work, Vol. 41, pp. 3753–3756.

Indexed at, Google Scholar, Cross Ref

Mlynarek, S., Corn, M. and Blake, C. (1996), “Asbestos exposure of building maintenance personnel.”, Regulatory Toxicology and Pharmacology : RTP, Vol. 23 No. November, pp. 213–224.

Indexed at, Google Scholar, Cross Ref

Neitzel, R.L., Crollard, A., Dominguez, C., Stover, B. and Seixas, N.S. (2013), “A mixed-methods evaluation of health and safety hazards at a scrap metal recycling facility”, Safety Science, Elsevier Ltd, Vol. 51 No. 1, pp. 432–440.

Indexed at, Google Scholar, Cross Ref

Neitzel, R.L., Seixas, N.S., Harris, M.J. and Camp, J. (2008), “Exposure to fall hazards and safety climate in the aircraft maintenance industry”, Journal of Safety Research, Vol. 39, pp. 391–402.

Indexed at, Google Scholar, Cross Ref

Noueira, H.C., Diniz, A.C. parose and Dechristian França Barbieri, Rosimeire Simprini Padula, R.L.C. and A.B. de O. (2012), “Musculoskeletal disorders and psychosocial risk factors among workers of the aircraft maintenance industry”, Work, Brazil, Vol. 41, pp. 4801–4807.

Indexed at, Google Scholar, Cross Ref

Noweir, M.H., Alidrisi, M.M., Al-Darrab, I. a. and Zytoon, M. a. (2013), “Occupational safety and health performance of the manufacturing sector in Jeddah Industrial Estate, Saudi Arabia: A 20-years follow-up study”, Safety Science, Elsevier Ltd, Vol. 53, pp. 11–24.

Indexed at, Google Scholar, Cross Ref

Oliveira A, Nogueira, H, Diniz A, B.D. (2012), “Psychosocial indicators among aircraft maintenance workers with and without neck and shoulder musculoskeletal symptoms”, Work, Brazil, Vol. 41, pp. 5699–5701.

Indexed at, Google Scholar, Cross Ref

Onnasch, L. (2015), “Crossing the boundaries of automation - Function allocation and reliability”, International Journal of Human Computer Studies, Elsevier, Vol. 76, pp. 12–21.

Indexed at, Google Scholar, Cross Ref

Onnasch, L., Wickens, C.D., Li, H. and Manzey, D. (2014), “Human Performance Consequences of Stages and Levels of Automation”, Human Factors, Vol. 56 No. 3, pp. 476–488.

Indexed at, Google Scholar, Cross Ref

P D Bust, A G F Gibb, R.A.H. (2005), “Manual handling of highway kerbs — focus group findings”, Applied Ergonomics, Vol. 36, pp. 417–425.

Indexed at, Google Scholar, Cross Ref

Perrow, C. (1984), “Normal Accidents”.

Pollard, J., Heberger, J. and Dempsey, P.G. (2014), “Maintenance and repair injuries in US mining”, Journal of Quality in Maintenance Engineering, USA, Vol. 20 No. 1, pp. 20–31.

Indexed at, Google Scholar, Cross Ref

R.A. Haslama, S.A. Hide, A.G.F. Gibb, D.E. Gyi, T.Pavitt, S.Atkinson, A.R.D. (2005), “Contributing factors in construction accidents”, Applied Ergonomics, Vol. 36, pp. 401–415.

Indexed at, Google Scholar, Cross Ref

Rijpma, J.A. (1997), “Complexity, Tight-Coupling and Reliability: Connecting Normal Accidents Theory and High Reliability Theory”, Journal of Contingencies and Crisis Management, Vol. 5 No. 1, pp. 15–23.

Indexed at, Google Scholar, Cross Ref

Rubio-romero, J.C., Manuel Súarez-cebador and María Carmen Pardo-ferreira. (2015), “Comparative risk assessment of vehicle maintenance activities : Hybrid , battery electric , and hydrogen fuel cell cars”, International Journal of Industrial Ergonomics, Spain, Vol. 47, pp. 53–60.

Indexed at, Google Scholar, Cross Ref

Ruff*, T. and Martini, P.C. and L. (2011), “Machine-related injuries in the US mining industry and priorities for safety research.”, International Journal of Injury Control and Safety Promotion, Vol. 18 No. 1, pp. 11–20.

Indexed at, Google Scholar, Cross Ref

Saha R, Dey N C, Samanta A, B.R. (2007), “A Comparative Study Of Physiological Strain Of Underground Coal Miners In India”, J. Human Ergol., India, Vol. 36, pp. 1–12.

Indexed at, Google Scholar, Cross Ref

Sanne, J.M. (2008), “Framing risks in a safety-critical and hazardous job : risk-taking as responsibility in railway maintenance”, Sweden, Vol. 11 No. 5, pp. 645–657.

Indexed at, Google Scholar, Cross Ref

Sarah M. Jay, Drew Dawson, Sally A. Ferguson, N.L. (2008), “Driver fatigue during extended rail operations”, Applied Ergonomics, Vol. 39, pp. 623–629.

Indexed at, Google Scholar, Cross Ref

Selikoff, I.J., Nicholson, W.J. and Lilis, R. (1980), “Radiological Evidence of Asbestos Disease Among Ship Repair Workers”, Vol. 22 No. 1 980, pp. 9–22.

Indexed at, Google Scholar, Cross Ref

Sengupta, P., Fulmer, S., Jing, X., Punnett, L., Kuhn, S. and Buchholz, B. (2014), “Assessing the ergonomic exposures for drywall workers”, International Journal of Industrial Ergonomics, Elsevier Ltd, Vol. 44 No. 2, pp. 307–315.

Indexed at, Google Scholar, Cross Ref

Sharan, D. (2012), “Effect of Ergonomic and Workstyle Risk Factors on Work Related Musculoskeletal Disorders among IT Professionals in India”, Vol. 41, pp. 2872–2875.

Indexed at, Google Scholar, Cross Ref

Spirtas, R., Stewart, P.A., Lee, J.S., Marano, D.E., Forbes, C.D., Grauman, D.J., Pettigrew, H.M., et al. (1991), “Retrospective cohort mortality study of workers at an aircraft maintenance facility. I. Epidemiological results.”, British Journal of Industrial Medicine, Vol. 48 No. 8, pp. 515–30.

Indexed at, Google Scholar, Cross Ref

Torp, S., Riise, T. and Moen, B.E. (1999), “How the psychosocial work environment of motor vehicle mechanics may in ¯ uence coping with musculoskeletal symptoms”, Work & Stress, Vol. 13 No. 3, pp. 193–204.

Indexed at, Google Scholar, Cross Ref

Vaishali R Lokhande. (2014), “Health profile of workers in a ship building and repair industry”, Indian Journal of Occupational and Environmental Medicine, Vol. 18 No. 2, p. 89.

Indexed at, Google Scholar, Cross Ref

Vera L.G. Blank, Ragnar Andersson, Arvid Lind, B.C.N. (1995), “Hidden accident rates and patterns in the Swedish mining industry due to involvement of contractor workers”, Safety Science, Vol. 21 No. 1, pp. 23–35.

Indexed at, Google Scholar, Cross Ref

Vyas, H., Das, S. and Mehta, S. (2011), “Occupational Injuries in Automobile Repair Workers”, Industrial Health, India, Vol. 49, pp. 642–651.

Indexed at, Google Scholar, Cross Ref

Wang, T.C. and Chuang, L.H. (2014), “Psychological and physiological fatigue variation and fatigue factors inaircraft line maintenance crews”, International Journal of Industrial Ergonomics, Elsevier Ltd, Taiwan, Vol. 44 No. 1, pp. 107–113.

Indexed at, Google Scholar, Cross Ref

Waters, T., Genaidy, A. and Viruet, H.B. (2015), “The impact of operating heavy equipment vehicles on lower back disorders”, Ergonomics, USA, Vol. 51 No. May, pp. 37–41.

Indexed at, Google Scholar, Cross Ref

Wickens, C.D., Lee, J. and Becker, S.G. (2004), An Introduction to Human Factors Engineering Second Edition, Second Edi., Pearson Prentice HallTM, New Jersey.

Wilson, J.R. (2000), “Fundamentals of ergonomics in theory and practice”, Applied Ergonomics, Vol. 31 No. 6, pp. 557–567.

Indexed at, Google Scholar, Cross Ref

Yarahmadi, R., Bagherpour, R. and Khademian, A. (2014), “Safety risk assessment of Iran’s dimension stone quarries (Exploited by diamond wire cutting method)”, Safety Science, Elsevier Ltd, Vol. 63, pp. 146–150.

Indexed at, Google Scholar, Cross Ref

Received: 08-Jan-2023, Manuscript No. AMSJ-22-13105; Editor assigned: 09-Jan-2023, PreQC No. AMSJ-22-13105(PQ); Reviewed: 21-Jan-2023, QC No. AMSJ-22-13105; Revised: 24-Jan-2023, Manuscript No. AMSJ-22-13105(R); Published: 10-Feb-2023