Research Article: 2020 Vol: 24 Issue: 4

Survivability and Resilience of Supply Chain System Post-Pandemic in India

Ramanjaneyulu Mogili, National Institute of Technology Tiruchirappalli

Kashmira Ganji, ICFAI Business School (IBS), IFHE

G.V.R.K Acharyulu, University of Hyderabad

Abstract

Purpose: The Supply Chain (SC) in India will undergo a dramatic change in the future due to COVID 19 pandemic. Supply chains in collaboration with digital technologies have the potential survivability opportunities in the new normal environment. The paper provides a conceptual foundation on how India will cope with the current pandemic in the economic crisis. Design/methodology/approach: It is a conceptual paper, addressing the application of SC technology and concludes the proposed model with constructs and concepts that are useful for the renovation of the resilient post-COVID SC. The propositions are made to explore the impact of the Supply Chain (SC) on implementation of Resilience and survivability of the post-pandemic environment. Findings: The study shows the importance of technology adoption in building a resilient supply chain with outcomes like recovery, survivability, and improved performance of SC. The article discusses challenges and potential opportunities with the effect of COVID 19, to enable supply chain professionals for effective planning of operations in future. Research limitations/implications: The study is limited to a conceptual framework, wherein future there is scope of converting the propositions into a testable hypothesis. The proposed model can be applied to manufacturing and service industries with a global focus. Originality/Value: This is a novel study that aims to develop a conceptual model on building supply chain resilience with the effect of COVID 19 pandemic. This article elaborates on ongoing efforts to restart supply chains for survivability in the new normal situation

Keywords

COVID-19, Technology Adoption, Supply Chain Resilience.

Introduction

In the contemporary market environment, the competition is not just limited to firms or brands or stores but it is with supply chains (SC) (Guan et al., 2020). As the global competition growing, the organizations are compelled to incorporate integration and have strong ties among SC partners. (Mentzer et al., 2001), defined supply chain as a

“Set of three or more entities (organizations or individuals) directly involved in the upstream and downstream flows of products, services, finances, and/or information from a source to a customer”.

The strength of supply chains is handling risks, and building collaborative resilience (Aggarwal et al., 2020). However managing crises such as natural disasters, technological instability, economic crisis, or unprecedented acts of violence may either lead to disruptions or can offer opportunities for collaboration, consensus building, and accelerating social change (Ozawa et al., 2011). Since the last decade, we have seen the industries had a significant lift, where the technology started to have a much bigger role, specifically with supply chain implementation of technological solutions. At that time methodologies like Lean, just in time management was more than sufficient for supply chain professionals. The focus was mostly on cost-effectiveness, on reducing excess capacity and being efficient as much as possible. But now the scenario has changed that not only being efficient on supply chain methodologies but being economically and technically sustainable is important. Unlike the various supply chain risks and disruptions in the past, the coronavirus outbreak is first and foremost the human tragedy which has a growing impact on global supply chains.

The COVID-19 outbreak which was previously known as 2019- nCoV, is spreading rapidly which led to the closure of cities. The rate at which the spread of the virus to various countries across the globe led the World Health Organization (WHO) on 30th January of 2020 to declare Coronavirus outbreak a “Global Public Health Emergency”. On March 11, 2020, the WHO has marked the outbreak of novel coronavirus disease (nCoV or COVID-19 or SARS-CoV-2) a pandemic [The World Health Organization (2020), March 2020 Speeches, (WHO) [Online] (accessed on May 31, 2020)] and as of May 31, 2020, 6:30 PM Indian Standard time, there has been more than 5.9 million confirmed infections, 367,255 confirmed deaths and spread across 215 countries, areas or territories [The World Health Organization (2020) Coronavirus disease (COVID-19) Pandemic Coronavirus disease 2019, (WHO) [Online] (accessed on May 31, 2020)]. The COVID 19 has revealed the unfortunate fact that our supply chain is surprisingly running delicate and not as agile as it should be. Initially, it is only a health crisis, later it possesses a threat to the global economy, trade, and finance. This pandemic leads to an overwhelming drop in demand and disrupting global supplies and thereby putting lives at risk. Hence there is a huge requirement to address this supply chain disruption under new circumstances. The current article focuses on the restrictions and challenges, the Indian supply chain systems are facing and future predictions on how India can cope with surviving in a post-pandemic world. The study proposes a conceptual framework to analyze the enabler of technology adoption and SC resilience to mitigate SC risks. This article also addresses the new opportunities that are in hand in the near future to lead in the commercial supply chain system. This article elaborates on the ongoing efforts to restart supply chains and possible trends in supply chain management (SCM) for a post-COVID -19 environment.

Literature Review

The SC in India

SC is one of the important factors that lever to improve the profit and differentiating components in a complex business environment. The supply chains over the last century have undergone several dramatic changes in India. The six major trends identified with the evolution of SC studies are creation, integration, globalization, phases 1 & 2 of specialization, and SCM 2.0 (Bala, 2014). Later with the introduction of new technology like the Internet of things, Industry 4.0 brought new changes to the supply chain by emphasizing the global networks. The study by (Tjahjono et al., 2017), found that SCM 4.0 with a smart factory setting is capable of real-time exchange of information and controlling of smart machines autonomously. The functioning of supply chains has evolved amazingly in response to the challenges and opportunities posed by a changing world. According to the numerics reported in "Indian Logistics Industry Outlook, 2020", it is expected that India's GDP reaches more than 3 trillion in 2020, which represents 4 percent of global GDP. Out of it, the Indian industry spends 14 % of GDP in Supply chain logistics. The logistics and SC market in India is forecasted to grow at a CAGR of 10.5 percent between 2019 and 2025. This growth is possible with the help of strategies and strengthening factors followed in the organizations. The four major dimensions associated with the growth in SCM are strategic SC, SC integration, inventory management, and Information Technology in the Indian framework (Sahay & Mohan, 2003). The technology and digital solutions were used as a crutch for irrespective of what the problem was. But still, the two big constraints for digital supply chains today are inadequate technical skills by the workforce. Secondly, the employees do not have the imagination to make most of these digital tools. Thus, the SC leaders need to improve operations and their practices in order to address these limitations and then enable their workforce to make most of digital supply chain capabilities.

In a research framework developed by (Gunasekaran, Patel, & McGaughey, 2004), the supply chain metrics involved in four different processes like Planning, Sourcing, Make/Assemble, and Delivering. The approach in organizing the measures in the above four processes could be used in the organizations at any level like Strategic, Tactical, or Operational in the development of SC performance. The key driving forces of Indian SC are external influences such as technical advancements, increased competition from consumers across national boundaries, and internal factors such as potential strategic alignment (Fawcett et al., 2008).

According to (Sambasivan et al., 2009), organizations need to match the requirements of performance indicators and metrics with efficiency, effectiveness, and competitive advantages to avoid implementation disasters. His findings suggest that the six metrics: web-enabled service, data reliability, time and cost, e-response, invoice presentation and payment, and e-document management metrics are important to enhance the productivity and profitability of the supply chain.

In a research study by (Soni & Kodali, 2011), evidence for a positive relationship between competitive strategy and SC strategy in Indian firms. The study showed that, even in the presence of effective strategies, the major limiting factor in Indian industries is the hurdle in implementing the new SCM practices like Lean, JIT, etc. It is important for the SC organizations to analyze the risk factors involved to undergo smooth supply chain performance.

The research model developed by (Mangla et al., 2015), to manage the risks in the SC under uncertain fuzzy environment. Their study revealed that Green and sustainable supply chain initiatives help to overcome risks effectively. (Hong et al., 2017), addresses that the information sharing among the various SC partners with technology adoption greatly reduces the hurdles in the Supply chain. It focuses on the benefits achieved by remanufacturing models, increased profits to manufacturers, and third parties under technology licensing. The research study by (Queiroz & Wamba, 2019), findings show that performance expectancy in the major factor influencing the Indian supply chains in the adoption of technologies like blockchain. This study compares the adoption behaviors of Indian based supply chains with USA based supply chain organizations. The research study developed by (Viswanathan et al., 2020), addresses that the 3 risk reduction attributes namely pre-project planning, local participation, and contract selection are majorly impacting helpful to drive the successful supply chain. This study focused on Indian construction firms with a sample of 105 firms were surveyed. The model generated helped to analyze the effective risk factors in order to improve overall project success criteria and success in project management.

Henceforth, the evidence from the prior studies shows that the Indian supply chain systems are adaptive to the new changes in their business processes. Decades of emphasis on SC optimization is to minimize costs, reduce stock levels, and boost resource efficiency have eliminated reserves and resilience to cope with disturbances. COVID-19 proves that several businesses are still not completely conscious of the threat of their supply chain networks to internal and external shocks. Although there are enough pieces of evidence of how risks and challenges are overcome with the disruptions created in the past, COVID 19 is the new situation, which the world has ever faced. Due to this pandemic, the supply chain professionals need to go for reinventing the wheel, because it is much different from the other problems or popups that they faced earlier.

COVID 19 and India Supply Chain System: Challenges

The sudden outbreak of COVID has brought huge pressure on the Supply chain in India and worldwide it had effected almost every industry as well as countries’ ability to find the virus. The stretch to the economy, according to the McKinsey Global Survey (March 2020), COVID 19 is the most cited and most serious threat to the global economy. India’s Manufacturing Purchase Manager Index slipped to 27.4 in April 2020 from 51.8 in the prior month, in the midst of national lockdown prohibitions to help in reducing the transmission of COVID-19. According to CMIE, the unemployment rate in India rose to 23.52% in April 2020 from 8.74% in March 2020. The Country’s economy is anticipated to rise by 1.5 percent to 2.8 percent in the 2020-21 fiscal year that began on April 1, the World Bank according to the South Asia Economic Focus report. Due to the countrywide lockdown, which leads to the abrupt halt in all economic activities, and thereby lack of demand. In addition to the unanticipated lack of demand, there is huge disruptions in supply chains, owing to the lack of accessibility with raw materials, a large number of outside immigrant workers especially in urban, a decline in foreign trade and travel restrictions imposed in all countries across the globe (Dev & Sengupta, 2020). According to a study published by the US Nations Conference on Trade and Development (UNCTAD), the effect of the coronavirus outbreak on trade in India is estimated to be about $348 million. Although supply chains are well established and cautious, with the sudden national lockdown imposed by the government, left no choice for the organizations to be prepared.

Some of the critical challenges in the Indian supply chain with the effect of COVID 19:

- The Involvement of several governmental organizations with the functions largely split between central and local, resulting in the crisis of ownership.

- The increased focus on Just in time deliveries to minimize the cost led to a reduction in inventory buffers and left no room for adequate buffers or safeguards.

- Many Indian industries depend on Chinese and other countries’ exports like Pharmaceuticals, Automobiles, Chemicals, and textiles, etc. With the closure of global foreign trade, these industries are under significant risk.

- Industry 4.0 is an upcoming area in the Indian supply chain system. Adequate manpower has to be ensured.

This global pandemic has underscored the need for rapid business and workforce transformation. In order to build resilience some of the key considerations of supply chains as we rebuild with an eye towards resilience are to leverage technology. Getting back to normal, to be more resilient, sustainable, supply chain professionals need to be open to new norms in adopting potential technological practices. Most importantly in going global, the supply chains need to have customers and suppliers in another region of the world. And the more global Indian supply chains are, there are a lot more opportunities. But at the same time, the opportunities possess risks like Risk of natural disasters, risk of political unrest, risk of currency, risk of terrorists, and risks like COVID 19 pandemics. To avoid the above risks, it is important to adopt new technology to ensure an integrated supply chain system. The use of technology will increase only if the members of supply chain organizations are willing to accept it. One of the most admired disciplines by professionals is Information technology as they always had a backup. In a similar way, supply chain practitioners have to do a better job from operations and supply chain standpoint for having a better backup. With the strong competition between the firms, they are being compelled that they should provide efficient SC. Nowadays, supply chain organizations are implementing various unique technology solutions and strategies that will help them to minimize costs and deliver quality services to customers at lower prices.

Technology Adoption

Technology adoption played a crucial role in the development of business and SC as well. Risk mitigation in the SC can be well established with the adoption of appropriate innovations that may take place either at the design level or at the process level. Increased global competition has drawn attention to the necessity for technology adoption to go for an efficient supply chain innovative network. The need for an ambitious supply chain focused on technology has been first addressed by (Franks, 2000). He stated that

“The objective of the technology adoption in the supply chain is to make it innovative and thereby improve the customer service levels and/ or reduce costs”.

The research study by (Rajesh, 2017), investigated whether Technological capabilities improve SC to reduce the risks. The study found that the technical capabilities of the SC play a crucial role in deciding if the SC’s are in a condition to minimize the risks of developing a robust supply chain. Ivanov et al. (2019), depicted from their research framework that digitalization and industry 4.0 have the potential impact to mitigate the disruptions and thereby reduce the ripple effects in the supply chain. Their study reveals that digital technologies better supply chain visibility and flexibility, improve coordination which would in turn decrease the negative effect of the SC.

The research study by Kamble et al. (2019), empirically analyses that the supply chain performance can be improved with the adoption of blockchain technologies in the supply chain. The model they proposed was evaluated using structural equation modeling with a sample of 181 supply chain practitioners in India. The findings showed that technology adoption would help the practitioners to extract maximum benefits and thereby improve the supply chain effectiveness.

COVID 19 accelerates the trends transforming our supply chain world. The business organizations need to focus not only on the strategies but also on technological innovation to adapt to the new changes that happen post-pandemic world. Innovation is the way of transforming ideas or inventions into a service that creates value. Digitalization of SC has become one of the most critical focus for practitioners. Interestingly, new SC innovations are emerging which greatly improve efficiency across the end-to-end value chain and support businesses with their way towards surviving global shocks. The conventional standard SC model is to transition into virtual supply chains where operational silos are decomposed while companies were connected to their entire supply chain to allow end-to-end visibility, collaboration, agility, and optimization.

The literature shows the importance of technology to enhance visibility, agility, effectiveness, and resilience throughout SC.

Supply Chain Resilience

Firstly, resilience is

“The ability of an SC network to avoid disruptions as well as recover quickly from screw-ups” (Klibi et al., 2010).

Supply chain resilience defined by (Jüttner & Maklan, 2011), as the ability of SC to deal with the negative effects of inevitable risky situations in order to continue in its current operations or to transit to a bigger and more desirable state after being disturbed. According to (Ponomarov & Holcomb, 2009), the resilience in the organizational perspective is to gain characteristics like adaptability, maintenance, flexibility, and responsiveness.

Resilience is an important aspect in SC to handle the vulnerabilities and disruptions and thereby becoming successful firms. In order to attain resilience, it becomes important for firms to develop a predefined set of organizational capabilities among the SC partners to handle both predicted and unpredicted changes (Christopher & Peck, 2004; Sheffi & Rice Jr, 2005; Ponomarov & Holcomb, 2009; Pettit et al., 2010; Ali et al., 2017).

According to DuHadway et al. (2019), resilient supply chains help to detect the risks in advance and thereby control the drastic effects of mitigation. Hence the firms can undergo risk detection, mitigating risk, and recovering in a shorter time. Risk mitigation is one of the essential elements is building SC resilience. According to (Ivanov & Dolgui, 2020), risk mitigation strategies enhance the advantages like SC visibility, analysis of historical disruptions, real time disruption activities that can be assessed to continue the business activities. The study points out that analytics in risk mitigation help the businesses to develop resilience. Sometimes even the best risk mitigation strategy may not have sufficient strength to handle something on a large scale of COVID 19 in a short period. Hence the involvement of technology and digitalization of SC plays a crucial role in this context.

This study aims to determine the importance of technology adoption in building the resilient SC. This paper describes in which situations supply chain resilience can play a role in mitigating the risks involved with the effect of COVID 19.

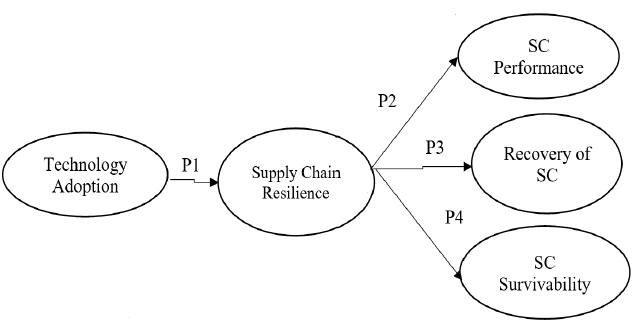

Proposition Development

According to the Theory of Technology Acceptance Model (TAM), when the organization finds it easy to use the technology, which includes all the interfaces in the technology, then the firm shows the intention to accept the technology (Venkatesh & Davis, 2000). With the adoption of new technology, can establish the following factors 1) able to achieve high collaboration and cooperation necessary to identify managerial risks, 2) Agile supply chain to react to unforeseen events, 3) Improve efficiency with distributed workload 4) Flexibility, 5) Redundancy, 6) Transparency (Cui, 2015). Henceforth, with the implementation of technology in supply chain systems will help in building a resilient SC.

P1: Technology adoption will lead to Supply chain resilience.

Supply chain performance focuses on the extent to which an SC meets the needs of the end customer on time (Harrison et al., 2005). With the available characteristics of SC resilience like flexibility, velocity, responsiveness, collaboration, visibility, and competitiveness will result in improved supply chain performance (Azevedo et al., 2010).

P2: Supply chain resilience will lead to supply chain performance.

With the characteristics like well-preparedness, and the use of the readily accessible resources required to diminish the impact of disruptions in the SC is possible. Hence supply chain resilience will help to take rapid and effective reactive actions (Kamalahmadi & Parast, 2016).

P3: Supply chain resilience will lead to the recovery of the supply chain.

According to Pettit et al. (2013), Resilience is defined as

“The ability of an organization to sustain, survive, adapt, and grow in the times of challenges and uncertainty.”

Hence the firms should have the ability to survive after the occurrence of disruption. The major characteristics of resilient SC are to respond, adapt, and survive to the changes, thereby can develop the capabilities to reduce the effects of disruptions.

P4: Supply chain Resilience will lead to Supply chain Survivability.

Research Model

The Outcomes of the Study and New Opportunities

As already mentioned above, building a technology-oriented resilience in the supply chain is highly challenging. But it is not an unrealistic term. With this crisis, almost everyone is forced into digital transformation to some degree. Therefore, the demand for proper tools like demand planning, forecasting, risk management is gradually increasing. The sharp focus on integrating, strategy, and planning procurement operations to reassess and to develop new platforms across all these supply chain functions helps to enhance the proper utilization of advanced digital platforms. The major purpose of this paper is to pinpoint the constructs which can act as enablers in building a resilient SC. And based on a thorough literature review, we identified construct definitions and proposed indicators that are significantly dependent on the rebuilding of the strengthened SC.

SC performance is an extent to which organizations undergo hassle-free operations and improve the effectiveness and efficiency of the supply chain. This indicates that the organizations are able to rebuild their supply chain even after the risks faced with the effect of the Covid-19 pandemic. The supply chain risk management could help the organizations in improving the performance by avoiding unexpected disruptions in SC and deal with a lack of transparency which most of the Indian SC’s are facing today.

Recovery of the supply chain is described as the degree to which the SC system can be modified to gain the adaptability in order to restore the disrupted operations. Resilient SC’s help the organizations with better chances to withstand and thereby continue their operations flexibly and responsively. Survivability can be defined as the degree to which the organizations are able to deliver the goods and services even after the disasters such as global pandemics like COVID 19 have occurred. With the use of digital technologies and data-driven systems, they are able to continue to operate at full potential. The criteria for success can be elevated with the investments that the organizations have made in the technology that needs to be matched with the investments in professional development.

Some of the new opportunities in the implementation of risk-free supply chain systems:

- Finding the sources of supply in order to match the buyers with suppliers

- To reduce the touchpoints in avoiding the spread of the virus, Automation in handling systems would go through an accelerated trend. They include palletization of cargo, conveyor systems, robotics, drones, drop boxes, etc.

- Maintaining close tie-ups with tier 1 and tier 2 suppliers to ensure how strong they are during the times of disruptions in bouncing back. Make sure that they have the right people with the right skill set and processes humming, technological updating to maintain an efficient supply chain.

- Technology adoption such as the Internet of things, artificial intelligence, robotics, and 5G along with new supply chain strategies will help to combat supply chain vulnerabilities. Remote and digital workforce platform for supply chain professionals and executives not only help them to navigate through the crisis but to effectively plan for the future.

- Diversify SC from a global viewpoint in order to reduce supply-side risks from one area.

Managerial Implications

For building a resilient SC, management must invest in the adoption of new and smart technologies, as it is able to provide high returns later with improved performance in the process and design of the supply chain. Companies that are more resilient will be able to survive or even gain market shares. Thereby operations can be handled swiftly with more efficiency and productivity. This study helps the managers to understand the threats and challenges posed to Indian supply chains amid COVID 19 national lockdown. Thereby understanding the new opportunities can help the organizations to provide hassle-free and efficient supply chains post-COVID 19 environments.

Societal Implications

COVID 19 affected large number of people in the supply chains with unemployment. There are huge disturbances in the economic transactions with the imbalances created in demand and supply due to sudden lockdown. All private and government supply chain organizations need to work together in the future to have a better supply chain services for India. This study urges the businesses to enhance their operations by adopting digital transformations. The model proposed, helps to develop a proactive behavior among the people with the intention to maintain social and economic resilience. This study implicates on society to develop their online capabilities to undergo services in digital mode. Supply chains in building resilience must be able to detect the early warning signs of disruptions and thereby people can respond by shifting to alternative resources.

Academic Implications

Researchers and scholars can focus on the technological and managerial constraints in Indian supply chains, which are hurdles in the implementation of a resilient supply chain. In developing countries like India, with a wide variety of geographical locations, reach and conveying the importance of technology to workers is a major issue. The global pandemic and disruptions in the market and collapses in many SC’s indicate the importance of research in building resilient SC. Moreover, with the evolution of Industry 4.0, technology has a major role to play in building a resilient SC, which is an emerging area for upcoming research.

Directions for the Future Scope

The scope of converting the propositions into a testable hypothesis to be tested empirically. Data can be collected from various management of supply chain organizations focused with certain industry, for the dearth of empirical validation using Exploratory factor analysis (EFA), Confirmatory Factor Analysis (CFA), and Structural Equation Modelling (SEM), highlighting the paths and linkages to establish the relationship between the linkages. This study lacked in consideration of dimensions like industry focus. The proposed model developed can be applied to manufacturing and service industries like Retail supply chains, Automobile sector, food and agriculture supply chains, Healthcare, transportations, logistics, and warehousing. This model can be extended further in the context of global supply chains also, in building resilient SC.

Conclusion

Covid-19 has brought up an enormous challenge to Indian SC systems. Despite the enormous distribution of the city, the vulnerable economic situation particularly the monetary sector in the pre-COVID 19 periods, and the dependence of the economy on informal labor, shutdowns and other social distance measures would be extremely disruptive. Especially it has become a threat to global and Indian supply chains. The national and local governments have acknowledged and reacted to the challenge but this response should be only the beginning. The organizations should restart with a different pace of change, reconfigure the crisis accelerate evolution. They must repair the disruptions that happened during the shutdown period thereby ensuring the viability and rethink about the changing customer behaviors and needs. Hence there is a need for an efficient decision-making system to envision the future in order to manage today and get back to new normal. The supply chain professionals need to develop a pervasive broad thinking, analytical capabilities to evaluate across an enterprise in knowing your customers, vendors, and the entire chain. The use of new technology such as the Internet of Things, artificial intelligence, robotics, 5G, DSN's is intended to foresee and address potential challenges. Technology-led business models will evolve as more crucial and relevant than ever before and will play an important role in shaping the vision as we re-imagine the global supply chains of tomorrow. If it's "black swan" cases like COVID-19, trade war, or terrorism regulatory reform, labor conflict, sudden demand spikes, or supplier bankruptcy, companies that deploy digital supply chain networks must be able to deal with unforeseen events. The post-COVID world will see emerging technology play a vital role in providing industry-wide changes, including more resilient supply chains, dramatically improved user interface, and intelligently engineered industry outcomes processes. In future economies will become more localized owing to the reconfiguration of SC. The SC management needs to look for new opportunities in building a hassle-free and efficient supply chain system. At the very, they should make sure that the responses remain firmly embedded in a policy framework and restrict the exercise of power in order to prevent the long-term harm to the economy.

References

- Aggarwal, S., Srivastava, M.K., & Bharadwaj, S.S. (2020). Towards a Definition and Concept of Collaborative Resilience in Supply Chain: A Study of 5 Indian Supply Chain Cases. International Journal of Information Systems and Supply Chain Management (IJISSCM), 13(1), 98-117.

- Ali, A., Mahfouz, A., & Arisha, A. (2017). Analysing supply chain resilience: integrating the constructs in a concept mapping framework via a systematic literature review. Supply chain management: An international journal.

- Azevedo, S.G., Carvalho, H., Cruz-Machado, V., & Grilo, F. (2010). The influence of agile and resilient practices on supply chain performance: an innovative conceptual model proposal. Paper presented at the Hamburg International Conference of Logistics.

- Bala, K. (2014). Supply chain management: Some issues and challenges-A Review. International Journal of Current Engineering and Technology, 4(2), 946-953.

- Christopher, M., & Peck, H. (2004). Building the resilient supply chain.

- Cui, Y. (2015). Improving supply chain resilience with employment of IOT. Paper presented at the International Conference on Multidisciplinary Social Networks Research.

- Dev, S.M., & Sengupta, R. (2020). Covid-19: Impact on the Indian economy. Indira Gandhi Institute of Development Research, Mumbai April.

- DuHadway, S., Carnovale, S., & Hazen, B. (2019). Understanding risk management for intentional supply chain disruptions: Risk detection, risk mitigation, and risk recovery. Annals of Operations Research, 283(1), 179-198.

- Fawcett, S.E., Magnan, G.M., & McCarter, M.W. (2008). Benefits, barriers, and bridges to effective supply chain management. Supply chain management: An international journal.

- Franks, J. (2000). Supply chain innovation. Work Study.

- Guan, Z., Zhang, X., Zhou, M., & Dan, Y. (2020). Demand information sharing in competing supply chains with manufacturer-provided service. International Journal of Production Economics, 220, 107450.

- Gunasekaran, A., Patel, C., & McGaughey, R.E. (2004). A framework for supply chain performance measurement. International Journal of Production Economics, 87(3), 333-347.

- Harrison, T.P., Lee, H.L., & Neale, J.J. (2005). The practice of supply chain management: where theory and application converge: Springer Science & Business Media.

- Hong, X., Govindan, K., Xu, L., & Du, P. (2017). Quantity and collection decisions in a closed-loop supply chain with technology licensing. European Journal of Operational Research, 256(3), 820-829.

- Ivanov, D., & Dolgui, A. (2020). A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control, 1-14.

- Ivanov, D., Dolgui, A., & Sokolov, B. (2019). The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. International Journal of Production Research, 57(3), 829-846.

- Jüttner, U., & Maklan, S. (2011). Supply chain resilience in the global financial crisis: an empirical study. Supply chain management: An international journal.

- Kamalahmadi, M., & Parast, M.M. (2016). A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. International Journal of Production Economics, 171, 116-133.

- Kamble, S., Gunasekaran, A., & Arha, H. (2019). Understanding the Blockchain technology adoption in supply chains-Indian context. International Journal of Production Research, 57(7), 2009-2033.

- Klibi, W., Martel, A., & Guitouni, A. (2010). The design of robust value-creating supply chain networks: a critical review. European Journal of Operational Research, 203(2), 283-293.

- Mangla, S.K., Kumar, P., & Barua, M.K. (2015). Prioritizing the responses to manage risks in green supply chain: An Indian plastic manufacturer perspective. Sustainable Production and Consumption, 1, 67-86.

- Mentzer, J.T., DeWitt, W., Keebler, J.S., Min, S., Nix, N.W., Smith, C.D., & Zacharia, Z.G. (2001). Defining supply chain management. Journal of Business Logistics, 22(2), 1-25.

- Ozawa, C., Zellner, M., Hoch, C.J., Welch, E.W., Kaufman, S., Carp, J., . . . Weber, E.P. (2011). Collaborative resilience: Moving through crisis to opportunity: MIT press.

- Pettit, T.J., Croxton, K.L., & Fiksel, J. (2013). Ensuring supply chain resilience: development and implementation of an assessment tool. Journal of Business Logistics, 34(1), 46-76.

- Pettit, T.J., Fiksel, J., & Croxton, K.L. (2010). Ensuring supply chain resilience: development of a conceptual framework. Journal of Business Logistics, 31(1), 1-21.

- Ponomarov, S. Y., & Holcomb, M. C. (2009). Understanding the concept of supply chain resilience. The International Journal Of Logistics Management.

- Queiroz, M.M., & Wamba, S.F. (2019). Blockchain adoption challenges in supply chain: An empirical investigation of the main drivers in India and the USA. International Journal of Information Management, 46, 70-82.

- Rajesh, R. (2017). Technological capabilities and supply chain resilience of firms: A relational analysis using Total Interpretive Structural Modeling (TISM). Technological Forecasting and Social Change, 118, 161-169.

- Sahay, B., & Mohan, R. (2003). Supply chain management practices in Indian industry. International Journal of Physical Distribution & Logistics Management.

- Sambasivan, M., Mohamed, Z.A., & Nandan, T. (2009). Performance measures and metrics for e?supply chains. Journal of Enterprise Information Management.

- Sheffi, Y., & Rice Jr, J.B. (2005). A supply chain view of the resilient enterprise. MIT Sloan Management Review, 47(1), 41.

- Soni, G., & Kodali, R. (2011). The strategic fit between “competitive strategy” and “supply chain strategy” in Indian manufacturing industry: an empirical approach. Measuring Business Excellence.

- Tjahjono, B., Esplugues, C., Ares, E., & Pelaez, G. (2017). What does industry 4.0 mean to supply chain? Procedia Manufacturing, 13, 1175-1182.

- Venkatesh, V., & Davis, F.D. (2000). A theoretical extension of the technology acceptance model: Four longitudinal field studies. Management Science, 46(2), 186-204.

- Viswanathan, S.K., Tripathi, K.K., & Jha, K.N. (2020). Influence of risk mitigation measures on international construction project success criteria–a survey of Indian experiences. Construction Management and Economics, 38(3), 207-222.