Review Article: 2023 Vol: 27 Issue: 6

Sustainability in Healthcare Supply Chain through the Lean and Resilient Method

Vijayalakshmi Iyengar, Lal Bahadur Shastri Institute of Management, New Delhi

Citation Information: Iyengar, V. (2023). Sustainability in healthcare supply chain management through lean and resilient method-an ism approach. Academy of Marketing Studies Journal, 27(6), 1-23.

Abstract

Purpose This paper aims to determine the impact of lean and resilient practices on the sustainability of supply chain management in the healthcare sector. The relationship between sustainability (economic, environmental, and social), lean and resilient factors is being analyzed to apprehend the dependency on each other. The integration of environmental and social aspects with economic considerations, known as the triple-bottom-line (TBL) has gained relevance for managerial decision-making in general and supply chain management (SCM) in particular. This process will help the healthcare professionals to take accurate decisions to focus on the most significant factor that influences the sustainability of Healthcare's Supply Chain management. Methodology The healthcare sector and its supply chain were chosen as lean and resilient practices have proven to be effective in this industry. To identify the relationships between lean and resilient supply chain practices and their impact on the three different dimensions of sustainability, a methodology based on the Interpretive Structural Modelling (ISM) Approach is used. Findings The results show a synergistic effect between lean and resilient practices. The former practice acts as a driving force for the latter practice. Therefore, lean practices, especially the use of electronic data interchange, have had a direct and indirect impact on supply chain sustainability. Research limitations The relationship between lean and resilient practices in the healthcare sector has been studied. Different sectors may produce different results because critical factors across sectors may differ, and the methodology implemented within each process may also differ. The environment, regulations, firm size and competition varies across sectors hence results of the present study cannot be generalized. Originality This study makes a significant contribution by considering larger number of practices in each paradigm to better reflect the existing relationships between practices. It is possible that this was overlooked previously. A total of 16 lean and agile SC practices and 15 sustainability measures have been identified and the relationship is studied using Interpretive Structural Modelling (ISM). ISM holds the strength of converting the mental models into structured hierarchical models and the current relationship between lean and resilient supply chain practices and their impact on sustainability is analyzed using ISM is a unique contribution to literature. In addition, several healthcare experts have been approached to provide their perspectives on various parameters. This data has been entered into the ISM model to assist experts in making better decisions. The creation of linkages between multiple lean and resilient strategies and sustainability measures through a single systemic framework is a major contribution of this research. The three sustainability dimensions were put into an ISM model. The ISM technique was used to accomplish this.

Keywords

Sustainability, Lean supply chain management, Resilient Supply Chain Management, Healthcare Sector, Interpretive Structural Modeling (ISM).

Introduction

The healthcare industry, also known as the medical industry, is a business that provides products and services to patients in need of curative, preventive, rehabilitative, or palliative care. To meet individual and collective health needs, the modern health sector is divided into many sub-sectors, relying on an interdisciplinary team of trained medical professionals and associates. It has grown into one of India's largest sectors in terms of income and employment. The competitive advantage lies in the large pool of well-trained medical professionals. A recently announced financial budget allocated

?86,200.65 crores to healthcare in 2022-23. That's about 16.59% more than last year's estimate of

?73,931.77 crores. Increasing civilization's illness, increasing demand for affordable healthcare systems due to rising healthcare costs, technological advances, the emergence of telemedicine, the rapid penetration of health insurance, and e-health with tax benefits and incentives are driving the healthcare market in India. The country has also made huge capital investments in advanced diagnostic facilities and has become one of the major destinations for high-end diagnostic services that serve many people. Also, consumers of medical services in India are becoming increasingly aware of their medical needs.

Healthcare is a necessity of life so; assessing the character of a healthy and resilient supply chain can help a nation develop ideas to combat the healthcare crisis. Healthcare is the most important industry, engaged in saving lives, hence crucial for any government, but the healthcare supply chain has been severely impacted over the past two decades by several disasters. The healthcare sector has been significantly affected by the world’s most contagious disease Covid-19 which has led to long-term strain on the healthcare supply chain (HCSC) and subsequent lack of basic healthcare facilities. It was apparent that supply chain disruptions due to very high consumption led to lack of medical supplies to cater to the critical needs of patients at the right time. The healthcare supply chain is responsible for delivering high-quality products and efficient services to patients at the lowest possible cost at the right time. Healthcare costs can be high, and surge quite often. Hospitals are looking at avenues within the healthcare supply chain where response times may be shortened, and demand can be satisfied consistently. We address this issue in this paper by focusing on lean and resilient supply chain management.

Lean supply chain management focuses on efficient, streamlined operations, and eliminates non-value-adding- time and redundant procedures to ensure timely delivery of products and services to customers. It also prioritizes dependability and predictability over flexibility and adaptability. The strategy is to plan everything ahead of time to deal with unforeseen situation like COVID-19. It aims to reduce the number of defects to zero, reduces wastes, and increases efficiency.

Supply chain resilience is defined as a system's adaptive ability to effectively respond, control and manage unexpected disruptions caused due to unforeseen situations, or even advantage from such times by maintaining operations at the desired level of connectedness and recover from them efficiently.

The concept of sustainable development has evolved over the past thirty years. It is based on the strong pillars of social progress, economic stability, and environmental conservation. Sustainable Development means the integration of Triple Bottom Line i.e., environmental, social, and economic development of mankind without causing any harm to nature. This is important for the performance of businesses and their supply chains. It is perhaps the only social development tool where all three of these work in unison. This makes sustainable development a very subtle way of achieving progress. Organizations and supply chain partners are held accountable for activities as they impact the environment, society, and economy. Sustainability in supply chain operations of businesses, has thus, emerged as a promising research subject. Adoption of sustainability practices improves the environmental, social, and skill-based performance of firms to gain competitive advantage over competitors. The present paper identifies significant social, economic and environmental factors for sustainability in supply chain healthcare sector.

Literature Review

Supply Chain Management

Supply Chain Management (SCM) is a widely accepted and practiced concept in many industries as they understand the need for demand integration, coordination, and supply relationships management. Literature available on SCM is proportionately high, and addresses contemporary issues on SCM, in a variety of sectors such as the manufacturing industry (Ogunlela and Lekhanya, 2016), automotive industry, agriculture sector, oil and gas, construction and project management, small and medium-sized industries and tech start-ups. The performance of the supply chain is influenced by managing and integrating the key elements of information into the company's supply chain (Gunasekaran and Ngai, 2004). Effective SCM is becoming increasingly important to build and sustain competitive advantage in the products and services of the business. It is important to adopt an appropriate SCM strategy to compete at the supply chain level and this strategy needs to be integrated and coordinated throughout the supply chain to extract the performance out of all the supply chain members ( Wisner, 2003). The adopted strategy should suit both the product as well as the marketplace (Mason-Jones, 2000). Considering the nature of demand for the product, be it functional or innovative, organization is the first step in developing an effective supply chain strategy (Fisher, 1997).

Healthcare Supply Chain

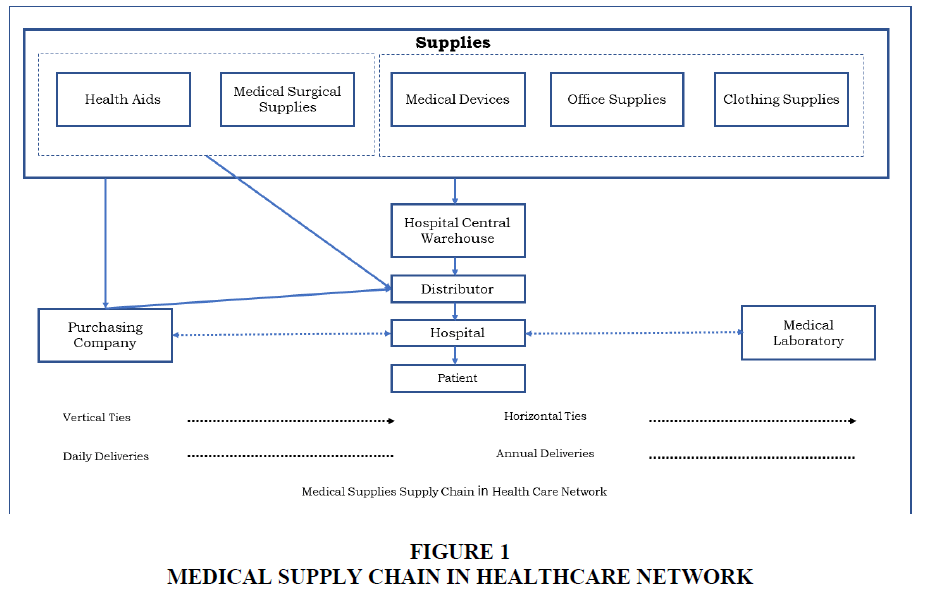

The Healthcare supply chain can be classified into three interdependent groups: 1) consumables and medical-surgical supplies, 2) pharmaceuticals and drugs, and 3) medical equipment and or medical devices. The consumables supply chain is influenced by many factors, and has a low allowable, 14-16 days of delivery time. The participation of governmental institutions, regulatory agencies, alliances, group purchasing organizations, and health management insurance are a part of the complex healthcare supply chain. The multiple factors in the medical supply chain result in irregularities or unwillingness to share economic, environmental, or societal information giving rise to problems associated with demand amplification or Bullwhip effect (Mason-Jones; Towill, 2000); and this is a major setback in supply chain sustainability. A literature review study uses content analysis that focuses on improvement in hospital supply chain performance to give important insights about the pharmaceutical supply chain concept (Narayana et al., 2014). Another empirical study evaluates the performance of hospital supply chain (Chen et al., 2013); using a research model considering IT integration in hospitals, suppliers, flow of information and trust. The interrelationship among factors and their effect was found crucial in hospital supply chain performance Figure 1.

Sustainable Healthcare Supply Chain Management

Environmental (pollution, carbon emission, global warming, greenhouse effect), ethical and social issues have received tremendous attention globally over the past few years (Bjørn and Hauschild, 2013). The growing interest in social and environmental issues is greatly inspired by the idea of sustainable development which is “development that meets the needs of the present generation without pulling down the needs of the future generation” (UN General Assembly, 1987). After the pandemic hit, many organizations responded by implementing business continuity plans and by conducting risk assessments to stabilize their supply chains. Many organizations responded by diversifying their product portfolio and using their existing resources to make new products; others utilized 3D printing technology to make products closer to demand to make their supply chains more responsive; while still others put emphasis on bringing production facilities back onshore or use nearshoring. Local and State governments are generally well equipped to identify the most affected groups and respond to their needs, circumstances, and preferences in a more targeted and agile fashion. (Burstrom & Tao, 2020) (Figure 1 and Table 1).

| Table 1 Sustainable Factors: Economic, Environmental And Social Dimensions |

|||

|---|---|---|---|

| Dimension | Code | Performance Measure |

References |

| Economic | EM1 | Decrease in cost for materials purchasing | Green et al. (2012),Prajogo et al. (2016), Zhu et al. (2008) |

| EM2 | Decrease in cost for energy consumption | Green et al. (2012), Zhu et al. (2008) | |

| EM3 | Decrease in fee for waste treatment | ||

| EM4 | Decrease in transportation cost | Chan and Qi (2003), Gunasekaran et al. (2001, 2004) | |

| EM5 | Decrease in production cost | Chan and Qi (2003), Gunasekaran et al. (2001, 2004), Prajogo et al. (2016) | |

| Environmental | ER1 | Reduction of air emissions | Green et al. (2012), Zhu et al. (2008) |

| ER2 | Reduction of wastes | ||

| ER3 | Decrease of frequency for environmental accidents | Green et al. (2012), Zhu et al. (2008) | |

| ER4 | Increase of recycled materials | Green et al. (2012), Zhu et al. (2008) | |

| ER5 | Decrease of energy consumption | Aras et al. (2010) | |

| Social | SA1 | Increase in worker’s motivation and participation | Gurumurthy and Kodali (2009), Martínez-Jurado and Moyano-Fuentes (2014), Treville and Antonakis (2006) |

| SA2 | Decrease in working environment stress | Martínez-Jurado and Moyano- Fuentes (2014) | |

| SA3 | Increase in safety and healthy working environment | Giannakis and Papadopoulos (2016), Martínez-Jurado and Moyano-Fuentes (2014),Vinodh et al. (2011) |

|

| SA4 | Increase in worker’s skills and training | Gurumurthy and Kodali (2009) | |

| SA5 | Increase in worker’s retribution | Aras et al. (2010), Giannakis and Papadopoulos (2016), Gurumurthy and Kodali (2009) | |

Lean and Resilient Methods

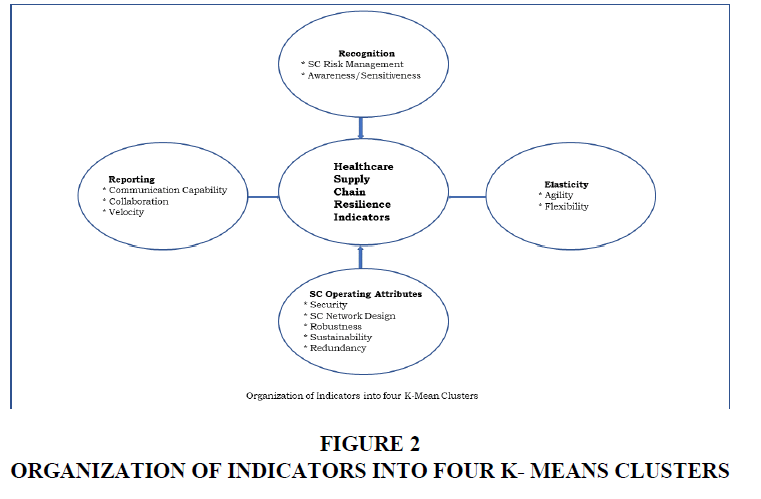

A Lean organization focuses on delivering best quality with minimum process waste within the shortest possible time. Minimizing waste to most means reducing inventory, but time, effort and people are also resources that need to be used properly. Analyzing how and how much time people spend on each process is an important step in reducing waste. We can apply Lean principles to supply chain planning, with the primary goal of reducing costs and improving customer service (Table 2 and Figure 2).

| Table 2 Lean Factors |

|||

|---|---|---|---|

| ID | Lean Factors | Description | References |

| LE1 | Supplier Selection Evaluation and Monitoring | Factors to be considered while selecting a supplier are: - 1.Strict Selection Process. 2.Supplier Evaluation and Certification. 3.Whether the supplier is following sustainable protocols for raw material |

Azevedo et al. (2012), Azevedo et al. (2016), Cabral et al. (2012), Campos and Vazquez- Brust (2016), Jajja et al. (2016), Jasti and Kodali (2015), Kou and Lee (2015), Maleki and CruzMachado (2013), Qrunfleh and Tarafdar (2013), Shah and Ward (2007), Simpson and Power (2005), So and Sun (2010), So (2010), Wiengarten et al. (2013). |

| LE2 | Suppliers and company involvement in New Product Development (NPD): | A buyer-supplier relationship focused on quality, directly impacts the buyer's operational effectiveness and the quality of the final product. In these scenarios, suppliers are involved from the beginning of the project instead of being sub- contracted with already parts. High level of risks and shared benefits and joint discussion towards cost savings because of frequent participation of suppliers and company from an early stage in the process. | Cabral et al. (2012), Campos and Vazquez-Brust (2016), Jasti and Kodali (2015), Kou and Lee (2015), Maleki and Cruz- Machado (2013), Qrunfleh and Tarafdar (2013), Shah and Ward (2007), Simpson and Power (2005), So and Sun (2010), So (2010), Wiengarten et al. (2013). |

| LE3 | Communication and Information Exchange between suppliers and company | The primary objective of the lean supply chain is to develop people and develop structures processes to minimize wasteful activities. Frequent communication and information sharing between suppliers and companies. Exchange of technical assistance, knowledge transfer, and lean training are frequent between the parties. Adoption of multifunctional supplier- company equipment. Frequent feedback on results derived from lean, such as delivery time, quality indicators, inventory details, etc. |

Cabral et al. (2012), Campos and Vazquez-Brust (2016), Jasti and Kodali (2015); Kou and Lee (2015), Madu and Kuei (2014), Maleki and Cruz-Machado (2013), Qrunfleh and Tarafdar (2013), Shah and Ward (2007), Simpson and Power (2005), Singh and Pandey (2015), So and Sun (2010), So (2010), Wiengarten et al. (2013). |

| LE4 | Use of Electronic Data Interchange | To share the hardware, software, and network tools that facilitate the electronic integration of supply chain, avoid creating multiple purchase orders, storing outdated and unnecessary documents, etc. The use of e-business systems and sharing information allows better integration of production planning and scheduling to improve operational efficiency and increase the efficiency of information and material flows. This process will help to reduce paper waste. It facilitates a contactless process that aligns with Covid-19 protocols. | Anand and Kodali (2008), Azevedo et al. (2012), Campos and VazquezBrust (2016), Chen et al. (2013), Gorane and Kant (2016), Hong et al. (2010), Jasti and Kodali (2015), So and Sun (2010), So (2010). |

| LE5 | Just-In-Time Delivery | Frequent deliveries of small quantities from suppliers to production line, avoiding storing more than what is required by the customers at various stages of the supply chain. This is done by calculating lead time, best and worst time, percent-on-time delivery. | Agus and Hajinoor (2012), Anand and Kodali (2008), Azevedo et al. (2012), Azevedo et al. (2016), Cabral et al. (2012), Campos and Vazquez- Brust (2016), Govindan et al. (2015, 2014), Jasti and Kodali (2015), Maleki and Cruz- Machado (2013), Shah and Ward (2003, 2007), Wiengarten et al. (2013). |

| LE6 | Production pull systems | Controlling the flow of resources by replacing only what the customer has consumed, thus eliminating the waste as well its sources; contributes to the reduction of inventory in the supply chain. This in turn reduces space and extra money required. | Agus and Hajinoor (2012), Anand and Kodali (2008), Azevedo et al. (2016), Campos and Vazquez-Brust (2016), Crute et al. (2003), Jasti and Kodali (2015), Marodin et al. (2016), Perez et al. (2010), Shah and Ward (2003, 2007). |

| LE7 | Value stream mapping (VSM) | Visual tools like IoT can be used to represent the flow of information and material from the supplier to the customer. This supports the lean supply chain and identifies potential opportunities for continuous improvements to eliminate lean supply chain wastes. | Campos and Vazquez-Brust (2016), Chen et al. (2013), Hines and Rich (1997), Seth et al. (2008), Singh and Pandey (2015), Taylor (2005), Wee and Wu (2009). |

| LE8 | Supplier training lean initiatives | Processes to enable an exchange of experiences and to propose goals to extend lean manufacturing practices. This training matrix can be used by companies working with their suppliers to create lean capabilities and to determine the number of employees who have undergone lean and/or Six Sigma training. | (Campos and Vazquez-Brust (2016), Lopes de Sousa Jabbour et al. (2014), Stewart et al. (2010). |

Operational risk and disruption can threaten multiple areas of the supply chain. As we saw in COVID- 19, global disasters can have widespread global impacts on supply chain logistics, suppliers, and workers. Other supply chain disruptions can occur in the form of unexpected competition, sudden market trends, or rapid changes in customer purchasing behaviour. Resilience is defined by the ability to withstand or avoid the effects of supply chain disruptions and the ability to recover quickly from disruptions Figure 2.

Methodology and Data Set

Objectives of the Study

1. To study the impact of lean and resilient supply chain practices on healthcare supply chain sustainability.

2. To study the relationship between lean supply chain practices and resilience and their impact on all three dimensions of sustainability using ISM Approach.

Research Design

We have focused on supply chain management in the healthcare sector, where it is important to achieve lean and resiliency for smooth operations. To do this, we analyzed the combined impact of lean and resilient SCM (Supply Chain Management Practices) on SC (Supply Chain) sustainability. In the healthcare sector, resilience is of great importance not only in the production settings but also in the supply chain function. In addition, the lives of patients are at great risk in this type of supply chain sector, hence it is imperative to find ways to reduce this risk through lean and resilient supply chain management. After analyzing the health sector, we saw the need for more sustainability studies in this area. In addition, the healthcare industry is committed to reducing the environmental impact of all aspects of the production of pharmaceuticals and medical supplies such as surgical instruments. Therefore, the health sector was selected to research the relationship between lean SC practices and resilience and their impact on sustainability.

Data Collection – Variables of the Study

Pre-examination of industry practices and measures as shown in Tables 1-3, a total of 16 lean and agile SC practices and 15 sustainability measures were identified. This number should be conveniently reduced for two reasons. On one hand, it is necessary to determine which of these practices and measures are appropriate in the field under study and therefore necessary to achieve the objective of the paper. On the other hand, it is necessary to reduce the complexity of the resulting model to make it easier for the managers to take decisions and to derive useful information from the model. Too much complexity can hide important relationships and effects in the model and make it impractical. Hence, six senior experts were chosen to identify which of those practices and measures are relevant in the healthcare sector. A questionnaire was created in the five-point Likert scale to measure the importance of each practice and their performance measure in the healthcare sector, and their degree of implementation in the sector. Finally, personal interviews were conducted to collect experts' opinions. Those practices were selected that had both an importance and a degree of implementation greater than the global mean value; these results are shown in Tables 4 and 5.

| Table 3 Resilient Supply Chain Factors |

|||

|---|---|---|---|

| ID | Resilient SC Practices | Description | References |

| RE1 | Use of information control systems | Technology can be used to detect and monitor disruptions so that decisions could be taken for unforeseen situations like Covid-19 pandemic, earthquakes, extreme weather conditions at any point in the supply chain. | Birkie (2016), Chowdhury and Quaddus (2015), Elzarka (2013), Guojun and Caihong (2008), Pettit et al. (2010) (2013), Rice and Caniato (2003), Romano et al. (2013), Stecke and Kumar (2009), Tang (2006), Tukamuhabwa et al. (2015). |

| RE2 | Flexible supply base | The firm should have a flexible group of suppliers to mitigate challenges in its material procurement in case of a supply chain disruption. | Azevedo et al. (2016), Chopra and Sodhi (2004), Govindan et al. (2014), Guojun and Caihong (2008), Hasani and Khosrojerdi (2016), Iakovou et al. (2007), Kamalahmadi and MellatParast (2016), Rajesh et al. (2015), Spiegler et al. (2012), Stecke and Kumar (2009), Tang (2006). |

| RE3 | Resilient transparency | Emerging technologies can be used to improve visibility, collaboration, coordination, and understanding between suppliers and healthcare firms when a supply chain disruption happens. | Azevedo et al. (2016), Birkie (2016), Chowdhury and Quaddus (2015), Christopher and Peck (2004), Elzarka (2013), Govindan et al. (2015, 2014), Hohenstein et al. (2015), Iakovou et al. (2007), Pettit et al. (2010, 2013), Ponomarov and Holcomb (2009), Rajesh et al. (2015), Scholten et al. (2014), Soni et al. (2014), Soni and Jain (2011), Spiegler et al. (2012), Stecke and Kumar (2009), Tang (2006), Tukamuhabwa et al. (2015). |

| RE4 | Safety stock | The firm maintains excess capacity in the production storage, handling, and/or transport to absorb the effects of supply chain disruption. | Azevedo et al. (2016), Chopra and Sodhi (2004), Chowdhury and Quaddus (2015), Christopher and Peck (2004b), Correia et al. (2017), Elzarka (2013), Hasani and Khosrojerdi (2016), Hohenstein et al. (2015), Iakovou et al. (2007), Juttner et al. (2003), Pettit et al. (2010),(2013), Rajesh et al. (2015), Rice and Caniato (2003), Romano et al. (2013), Soni et al. (2014), Spiegler et al. (2012), Stecke and Kumar (2009), Tang (2006), Tukamuhabwa et al. (2015). |

| RE5 | Security measures | Set of rules targeted at reinforcing supply chain security against deliberate disruptions like terrorist attacks, intrusions, etc | Hasani and Khosrojerdi (2016), Stecke and Kumar (2009), Tukamuhabwa et al. (2015). |

| RE6 | Contingency planning | Supply chain partners implement a contingency plan which includes a wide range of actions aimed at identifying and minimizing the effects of potential supply chain risks throughout the entire process from manufacturing to distribution | (Birkie (2016), Hohenstein et al. (2015), Kamalahmadi and Mellat-Parast (2016), Pettit et al. (2010) (2013), Tukamuhabwa et al. (2015). |

| RE7 | Disaster recovery plan | The supply chain partners can carry out a disaster recovery plan to counteract when disruption takes place; this includes a wide range of actions aimed at restoring the normal activities in the supply chain as soon as possible. | Birkie (2016), Pettit et al. (2010, 2013), Romano et al. (2013). |

| RE8 | Alternative transportation routing | Alternative transportation routes should be planned and programmed to avoid any delay in deliveries in case of a supply chain disruption. | Azevedo et al. (2016), Chowdhury and Quaddus (2015), Govindan et al. (2015) (2014), Kamalahmadi and Mellat-Parast (2016), Pettitte al. (2013, 2010), Rajesh et al. (2015), Rice and Caniato (2003), Romano et al. (2013), Spiegler et al. (2012), Stecke and Kumar (2009), Tang (2006), Wang et al.(2016). |

Sample Selection

ISM models are built based on opinions of experts. Previous ISM studies consulted a panel of experts having recognized knowledge in their domain (Attri et al., 2013). These comprised a lower number of participants as compared to empirical studies. Improper selection of experts would risk the validity of the research. To ensure this, the group of participants should comprise of 5 – 10 experts (Kapse et al., 2018). The composition of the panel of experts is also important hence multiple choices were considered. It is recommended to have a diverse group of experts (López and Ishizaka, 2019), thereby reducing the number of participants required. Finally, 6 experts pertaining to different manufacturing plants in the sector were selected and they agreed to participate in the present study. The main selection criteria were current position, academic background and experience in lean management and resilience. We also selected the participating experts based on their designation and level of their organization in the SC. All the levels in the healthcare manufacturing industry were well represented. The number of participants at every level were around the same. The final ISM was representative of the entire SC in the sector.

Data Collection -Tools and Techniques

This research design follows Interpretive Structural Modelling (ISM). This analytical tool was selected as ISM supports the objective of this research paper that includes modelling the relations between lean and resilient practices and their combined effect in all the three dimensions of SC sustainability.

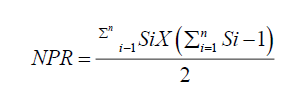

This method has several challenges that had to be overcome. Firstly, the pre-test revealed the model might contain 153 potential relationships.

Where NPR which is the total number of potential relationships between pairs of elements, and Si represents element ith in the model. ISM has proved to be an excellent mechanism for converting very complex systems into visible and well-defined hierarchical problems showing direct and indirect relationships between elements (Attri et al., 2013; Diabat et al., 2014). Second, with the aim of guaranteeing robustness in the model and generalization of its results across the entire healthcare manufacturing SC, this method was found successful in aggregating knowledge of a heterogeneous group of experts. ISM uses a structured and iterative learning process to aggregately represent knowledge of the experts on a set of elements that define a system and how their relationships are, with each other.

One of its main characteristics is that when experts receive feedback reports, they can modify their answers. The ISM approach does not offer experts the possibility of modifying their former opinions to reach a consensual model, but the final result does represent all their inputs in an aggregated manner. Finally, managers, stakeholders and other agents in the society might have difficulties understanding these complex models while making appropriate decisions. Cognitive maps also produce a static model based on the knowledge of the experts where nodes are connected directionally by links. As compared to cognitive maps, ISM holds the strength of converting the mental models into structured hierarchical models. The method allows to impose order on the complexity of the casual relationship represented in the diagraph (Sage, 1977). The role of each element in the system can therefore be more easily interpreted. For the complex problem considered here, a high number of interlinked practices may be influencing sustainability. The direct and indirect links between them describe this problem far more precisely than the individual practices taken in isolation or ill-structured models. ISM will thus provide insights into findings of these relationships. This would also assist managers to spot patterns within the diagraph and help them make informed decisions based on the dimension that they want to improve. This method has been successfully adopted to achieve a more sustainable SC in various sectors (Diabat et al., 2014).

Results And Discussions

The practices in bold represent the grade of implementation and their respective importance of both lean and resilient supply chain practices. Table 4 below highlights the figures.

| Table 4 Lean And Resilient Sc Practices |

||

|---|---|---|

| Practices | Grade of Implementation | Importance |

| LE1 | 4.5 | 4.67 |

| LE2 | 3.67 | 4.17 |

| LE3 | 4.5 | 5 |

| LE4 | 4.33 | 4.83 |

| LE5 | 4.67 | 4.83 |

| LE6 | 4.5 | 4.67 |

| LE7 | 4.17 | 4.67 |

| LE8 | 3.17 | 3.33 |

| RE1 | 4.67 | 4.83 |

| RE2 | 4 | 4.67 |

| RE3 | 4.67 | 4.33 |

| RE4 | 4.17 | 4.33 |

| RE5 | 4.17 | 4.33 |

| RE6 | 4 | 4.17 |

| RE7 | 4.33 | 5 |

| RE8 | 4.83 | 5 |

The sustainability performance measures across their implementation, importance classified into high and low is represented in Table 5 below. The bold figures have emerged high on importance and implementation.

| Table 5 Sustainability Performance Measures |

|||

|---|---|---|---|

| Measure | Implementation | Importance | Quadrant |

| EM1 | 4.5 | 4.83 | High |

| EM2 | 4.67 | 4.33 | High |

| EM3 | 4.5 | 4.67 | High |

| EM4 | 4.33 | 4.67 | High |

| EM5 | 3.83 | 4 | Low |

| ER1 | 4.5 | 4.83 | High |

| ER2 | 4.5 | 4.83 | High |

| ER3 | 4.5 | 4.67 | High |

| ER4 | 4.5 | 4.5 | Low |

| ER5 | 4.5 | 4.83 | Low |

| SA1 | 3.83 | 3.67 | Low |

| SA2 | 3.67 | 4 | Low |

| SA3 | 4.33 | 5 | High |

| SA4 | 3.67 | 3.5 | High |

| SA5 | 3.17 | 3.33 | Low |

Structural Self-Interaction Matrix (SSIM)

The ISM model represents a finite set of n elements in a system represented by S = (s1,…, si …, sn). The SSIM is built based on the relationships of any pair of elements (si and sj) representing that si drives sj. Experts were asked to fill out pairwise relationships among units of the system in an 18×18 SSIM. Considering this in mind, we have provided them with the following four symbols:

V: element i drives element j; A: element j drives element i;

X: elements i and j are mutually dependent on each other

O: elements i and j are independent of each other.

A total of 6 SSIM were gathered from experts that were combined by a simple averaging process to obtain the final SSIM.

Final Reachability Matrix

The SSIM is reborn into a binary matrix by work V, A, X and O by one and zero. For a much better understanding, the subsequent guideline for translating symbols into binary digits is given:

1. if the (i, j) entry within the SSIM is V, the (i, j) entry within the reachability matrix becomes one and therefore the (j,i) entry becomes 0.

2. if the (i, j) entry within the SSIM may be a, the (i, j) entry within the reachability matrix becomes zero and therefore the (j.i) entry becomes 1.

3. if the (i, j) entry within the SSIM is X, the (i, j) entry within the reachability matrix becomes one and therefore the (j,i) entry becomes 1; and

4. if the (i, j) entry within the SSIM is O, the (i, j) entry within the reachability matrix becomes zero and therefore the (j.i) entry becomes 0.

5. The final reachability matrix was obtained by applying the transitivity property; this suggests that if si results in sj, and sj results in sk, then si ought to cause sk.

Level Partitions

This step consists in segregating the ultimate reachability matrix obtained higher than into completely different levels. First, the reachability and antecedent set for every part (i.e., si) were known. These area units delineate by (1) and (2), respectively:

R(si) = {sj € S/eij=1} U {si € S}, (1)

A(si) = {sj € S/eji =1} U {si € S}, (2)

The intersection set of every part is computed as follows:

I(Si)= R(si) ∩ A(si), (3)

The table 6 and 7 shows simply the intersection sets for every part within the system. Part is premeditated within the high position of the school of thought model (level I), if R(si) = I(si); so is separated out from the remaining elements’ sets. This method is recurrent to assign parts in Level II, these then being deleted. This unvarying method finishes, once each part has been already assigned to grade.

| Table 6 Final Reachability Matrix |

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LE1 | LE3 | LE4 | LE5 | LE6 | RE1 | RE3 | RE7 | RE8 | EM1 | EM2 | EM3 | EM4 | ER1 | ER2 | ER3 | SA3 | SA4 | DRIVING POWER | |

| LE1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 9 |

| LE3 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 8 |

| LE4 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 9 |

| LE5 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 6 |

| LE6 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 6 |

| RE1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 12 |

| RE3 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 12 |

| RE7 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 5 |

| RE8 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 9 |

| EM1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| EM2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 4 |

| EM3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 4 |

| EM4 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 5 |

| ER1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 6 |

| ER2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 5 |

| ER3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 3 |

| SA3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 3 |

| SA4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 4 |

| DEPENDENCE POWER | 6 | 6 | 1 | 9 | 7 | 2 | 7 | 6 | 5 | 4 | 4 | 4 | 13 | 7 | 11 | 12 | 6 | 2 | |

| Table 7 Level Partitions In The Ism Model (Reduced Version) |

||||

| Level | Reachable Set | Antecedent Set | Intersection | Variable |

| 9th | LE1 | LE1, RE3, RE7, EM1, EM4, ER1 | LE1 | LE1 |

| 7th | LE3, RE3, RE7 | LE1, LE3, LE4, RE1, RE3, RE8 | LE3, RE3 | LE3 |

| 10th | LE4, RE1 | LE4 | LE4 | LE4 |

| 6th | LE5, ER1 | LE1, LE3, LE4, LE5, LE6 RE1, RE3, RE7, RE8 |

LE5 | LE5 |

| 5th | LE5, LE6 | LE1, LE3, LE5, LE6 RE1, RE3, RE8 |

LE6, LE5 | LE6 |

| 9th | RE1 | LE4, RE1 | RE1 | RE1 |

| 8th | LE1, RE3, RE8 | RE7, RE8 | RE3, LE1, RE8 | RE3 |

| 7th | LE1, RE3, RE7 | LE3, LE4, RE1, RE3, RE7, RE8 | RE7, RE3 | RE7 |

| 8th | RE3, RE8 | LE1, LE4, RE1, RE3, RE8 | RE8, RE3 | RE8 |

| 1st | LE1 | LE1, RE1, RE3, EM1 | LE1 | EM1 |

| 5th | EM2 | LE5, RE3, EM2, EM4 | EM2 | EM2 |

| 2nd | EM3, ER1, ER2 | LE6, EM3, ER1, ER2 | EM3, ER1, ER2 | EM3 |

| 1st | LE1, EM2, EM4, ER1, ER2 | LE1, LE3, LE4, LE5, LE6, RE1, RE3, RE8, EM2, EM3, EM4, ER1, ER2 | EM4, LE1, EM2, ER1, ER2 | EM4 |

| 6th | LE1, ER1 | LE5, RE8, EM3, EM4, ER1, ER2, ER3 | ER1 | ER1 |

| 4th | ER1, ER2 | LE3, LE5, LE6, RE1, RE3, EM2, EM3, EM4, ER1, ER2, SA4 | ER2, ER1 | ER2 |

| 3rd | ER1, ER3 | LE1, LE3, LE4, RE1, RE3, RE7, RE8, EM2, ER2, ER3, SA3, SA4 |

ER3 | ER3 |

| 1st | ER3, SA4 | LE6, RE1, ER1, ER3, SA3, SA4 | ER3, SA4 | SA3 |

| 5th | SA4 | SA3, SA4 | SA4 | 0 SA4 |

ISM Digraph

An initial diagraph is formed based on each element's level partition and the reachability matrix's conical form. Each element is represented in its respective level, as well as relationships between them, to create the original diagraph.

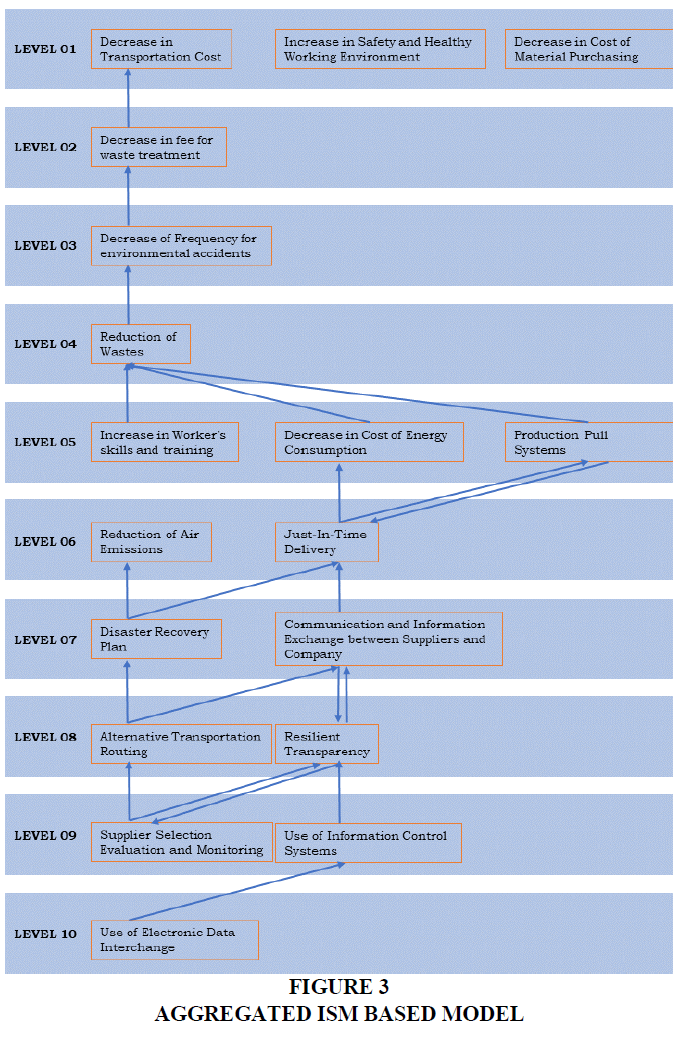

Following this, the model's transitiveness was removed, and each ID node was replaced with its appropriate description. Finally, the model was examined for conceptual flaws. Figure 3 shows the final diagraph.

The driving power and dependence power of 5 lean, 4 resilient and 9 sustainable factors representing the social, environmental, and economic dimensions is highlighted in bold in Table 6 given below.

Analyzing the Aggregated ISM based Model

The final ISM model contains 5 lean, 4 resilient and 9 sustainable factors representing the social, environmental, and economic dimensions. Looking at the Figure 3, SA3 and EM1 are disconnected from the remaining elements. EM1 i.e., decrease in cost for materials purchasing and SA3 i.e., increase in safety and healthy working environment are the least important factors as they are present on level 1. We see from the level partition diagram that LE4 i.e., use of electronic data interchange is the most important factor as they are present on level 10 and drives other factors. Figure 3 also states that LE4 leads to RE1, which in turn will facilitate RE3 and so on. LE4 may thus lead to any element in the ISM model, either by direct influence or by indirect impact. From level 9 to 11, other factors have been represented from lean and resilient practices. They have a big driving power associate degree thus lean practices exert an influence on the remaining components – resilient practices, economic performance measures, environmental performance measures and social performance measures. The ISM also reflects that any lean practice will help to improve the SC sustainability in its economic, environmental, and social dimensions. Therefore, sustainable SCM demands the best efforts in lean implementation.

Resilient practices mainly fall under Level 7 and Level 8, highlighting those lean practices that are related to resilient practices, the former activating the latter. Nevertheless, resilient practices do not prompt lean practices. Regarding the influence of RE3, RE7 and RE8 on SC sustainability, these impact the environmental dimension in disparate ways.

Level 5 and Level 6 locates significant factors in lean, social, environmental, and economic factors which affects sustainability in supply chain which are particularly interrelated with each other. These factors mainly affect the environmental factor in Level 4.

The aggregated ISM model represents economic performance measures mainly from levels 5 to 6. EM2, EM3 were found to have a significant influencing power to affect the environmental and social performance measures. As a result, managers should focus their efforts on achieving economic SC sustainability because this may lead to improvements in environmental and social sustainability. ER3 facilitates EM3 which leads to SA3, thus environmental sustainability may lead to social sustainability as well. Finally, EM1 and SA3 are located at the top level and so does not have any influence capacity on the remaining measures. SA3 and EM1 are also the sustainability performance measures least affected by lean and resilient practices and it therefore has a limited impact on social SC sustainability.

We see from the level partition diagram that LE4 i.e., use of electronic data interchange is the most important factor as they are present on level 10 and drives other factors. Hence, electronic data interchange should be considered the most significant factor in the supply chain management of healthcare sector.

Conclusion

Theoretical Implications

This is the joint influence of lean and resilient strategies on sustainability where the measures have been modelled from an academic standpoint. As a result, our study adds to earlier studies linking operational lean and resilience approaches to SC (Birkie, 2016). The creation of linkages between multiple lean and resilient strategies and sustainability measures through a single systemic framework is a major contribution of this research.

The ISM technique was used to accomplish this. The three sustainability dimensions were put into an ISM model. Both lean and resilience strategies aid in the development of more sustainable SCs, yet their effects are somewhat different. All performance measures examined in the economic, environmental, and social dimensions may be affected by lean approaches. Resilient SC practices, on the other hand, have a limited influence on social sustainability. The relationship between lean and resilient paradigms is another result of this study: its findings show that lean and resilient practices are intertwined, with the former leading to the latter. As a result, the lean methods investigated may have an impact on SC vulnerability. This study makes a significant contribution by considering a larger number of practices in each paradigm to better reflect the existing relationships between practices. It is possible that this was overlooked previously.

Implications for Managers and Policymakers and Future Research

The conclusions of this study have a few major practical and policy implications for increasing SC sustainability in the healthcare industry. Managers have the option of implementing a set of lean and resilient practices that will improve SC sustainability. The study emphasizes how economic, environmental, and social sustainability may be attained more efficiently in this way. These insights can also help policymakers design particular policies and activities to make the healthcare supply chain more sustainable. Implementing lean and resilient SC practices is the most straightforward way to achieve economic sustainability. If a management wishes to considerably increase economic sustainability, it should adopt suitable supplier selection, assessment and monitoring, as well as supplier involvement in NPD and training. When effectively applied, these methods can assist in minimizing waste disposal expenses hence, production costs. All SC dealers, if share, a similar culture of lean thinking and risk management, it can well support these gains. This being said, policymakers can work to promote knowledge transfer and best practices through collaborative research and development projects.

Lean and resilient SC techniques can also help to increase environmental sustainability. Managers should employ electronic data interchange or effective supplier selection, evaluation and monitoring strategies, maintain good communication and information sharing with their suppliers, to reduce the consumption of hazardous/toxic materials. This decreases itself, in turn, has evidenced to cause the reduction of liquid wastes. On the other hand, Just-In-Time delivery practices cause reduction in solid waste attributable to lower lot size and inventory levels. Each training in lean initiatives and a correct supplier choice, evaluation and monitoring have shown a decrease in the frequency of environmental accidents. The impact of these practices may be strengthened with a lot of restrictive legislation concerning treatment and disposal of solid and liquid wastes. Additionally, scientists in universities and analysis centers ought to participate within the development of advances for reducing these wastes and therefore the consumption of hazardous/toxic materials.

In contrast, the results show that it is difficult to achieve social improvements through a lean and resilient SCM. The only social improvement that can be achieved through lean or resilient initiatives is increasing worker’s skills and provide training. The factor healthy work environment is unlikely to be improved by a lean or resilient SCM. Therefore, managers willing to improve their social sustainability directly, may put to use practices such as information control systems and resilient transparency. All SC partners, as well as public safety officers, can be encouraged to resume normal operations in SC, within shortest possible time, after a disruption and avoid as much as possible, if there is, a felt- impact on society.

Research Limitations

The relationship between lean and resilient practices in the healthcare sector has been studied. Different sectors may produce different results because the factors considered important in each sector may differ. Methodology through which each process within a supply chain is implemented can vary across each sector. ISM can also be substituted with other tools of analysis to see sustainability impact.

References

Anand, G. and Kodali, R. (2008), “A conceptual framework for lean supply chain and its implementation”, International Journal of Value Chain Management.

Aras, G., Aybars, A., and Kutlu, O. (2010), “Managing corporate performance”, International Journal of Productivity and Performance Management.

Attri, R., Dev, N., & Sharma, V. (2013), “Interpretive structural modelling (ISM) approach: an overview”,Research Journal of Management Sciences.

Azevedo, S.G., Carvalho, H., & Cruz-Machado, V. (2016), “LARG index: a benchmarking tool for improving the leanness, agility, resilience, and greenness of the automotive supply chain", An International Journal.

Birkie, S.E. (2016), “Operational resilience and lean: in search of synergies and trade-offs”, Journal of Manufacturing Technology Management.

Bjørn, A., & Hauschild, M. Z. (2013), “Absolute versus Relative Environmental Sustainability: What can the cradle?to?cradle and eco?efficiency concepts learn from each other?”,Journal of Industrial Ecology.

Burström, B., & Tao, W. (2020), “Social determinants of health and inequalities in COVID-19”,European Journal of Public Health.

Cabral, I., Grilo, A. and Cruz-Machado, V. (2012), “A decision-making model for lean, agile, resilient and green supply chain management”, International Journal of Production Research.

Campos, L.M.S., and Vazquez-Brust, D.A. (2016), "Lean and green synergies in supply chain management”, Supply Chain Management: An International Journal.

Indexed at, Google Scholar, Cross Ref

Chan, F.T.S. and Qi, H.J. (2003), “An innovative performance measurement method for supply chain management”, Supply Chain Management: An International Journal.

Chen, D. Q., Preston, D. S., & Xia, W. (2013), “Enhancing hospital supply chain performance: A relational view and empirical test”,Journal of Operations Management.

Chen, J.C., Cheng, C.H. and Huang, P.B. (2013), “Supply chain management with lean production and RFID application: a case study”, Expert Systems with Applications.

Indexed at, Google Scholar, Cross Ref

Chopra, S. and Sodhi, M.S. (2004), “Managing risk to avoid supply-chain breakdown”, MIT Sloan Management Review.

Chowdhury, M.M.H. and Quaddus, M.A. (2015), "A multiple objective optimizations based QFD approach for efficient resilient strategies to mitigate supply chain vulnerabilities: the case of garment industry of Bangladesh”, Omega.

Diabat, A., Kannan, D., & Mathiyazhagan, K. (2014), “Analysis of enablers for implementation of sustainable supply chain management–A textile case”,Journal of Cleaner Production.

Indexed at, Google Scholar, Cross Ref

Elzarka, S.M. (2013), “Supply chain risk management: the lessons learned from the Egyptian revolution 2011”, International Journal of Logistics Research and Applications.

Fisher, M. L. (1997), “What is the right supply chain for your product”?,Harvard business review.

Govindan, K., Azevedo, S.G., Carvalho, H. and Cruz-Machado, V. (2015), “Lean, green and resilient practices influence on supply chain performance: interpretive structural modeling approach”, International Journal of Environmental Science and Technology.

Indexed at, Google Scholar, Cross Ref

Green, K.W., Zelbst, P.J., Meacham, J., & Bhadauria, V.S. (2012), “Green supply chain management practices: impact on performance”, Supply Chain Management: An International Journal.

Gunasekaran, A. and Ngai, E.W.T (2004), “Information systems in supply chain integration and management”, European Journal of Operations Research.

Guojun, J. and Caihong, Z. (2008), “Study on supply chain disruption risk management strategies and Management model”, International Conference on Service Systems and Service Management.

Gurumurthy, A. and Kodali, R. (2009), “Application of benchmarking for assessing the lean supply manufacturing implementation”, Benchmarking: An International Journal.

Hasani, A. and Khosrojerdi, A. (2016), “Robust global supply chain network design under disruption and uncertainty considering resilience strategies: a parallel memetic algorithm for a real-life case study”, Transportation Research Part E: Logistics and Transportation Review.

Indexed at, Google Scholar, Cross Ref

Hines, P. and Rich, N. (1997), “The seven value stream mapping tools”, Journal of Operations & Production Management.

Iakovou, E., Vlachos, D., & Xanthopoulos, A. (2007), “An analytical methodological framework for the optimal design of resilient supply chains”, International Journal of Logistics Economics and Globalisation.

Jajja, M.S.S., Kannan, V.R., Brah, S.A. and Hassan, S.Z. (2016), “Supply chain strategy and the role of suppliers: evidence from the Indian sub-continent”, Benchmarking: An International Journal.

Jasti, N.V.K., and Kodali, R. (2015), “A critical review of lean supply chain management frameworks: proposed framework”, Production Planning and Control.

Indexed at, Google Scholar, Cross Ref

Kamalahmadi, M. and Mellat-Parast, M. (2016), “Developing a resilient supply chain through supplier flexibility and reliability assessment”, International Journal of Production Research.

Indexed at, Google Scholar, Cross Ref

Kapse, C. P., Kumar, A., Dash, M. K., Zavadskas, E. K., & Luthra, S. (2018), “Developing textile entrepreneurial inclination model by integrating experts mining and ISM-MICMAC”,International Journal of Production Research.

Kou, T.C. and Lee, B.C.Y. (2015), “The influence of supply chain architecture on new product launch and performance in the high-tech industry”, Journal of Business & Industrial Marketing.

Lopes de Sousa Jabbour, A.B., Omodei Junior, C., and Chiappetta Jabbour, C.J. (2014), “Extending lean manufacturing in supply chains: a successful case in Brazil”, Benchmarking: An International Journal.

López, C., & Ishizaka, A. (2019), “A hybrid FCM-AHP approach to predict impacts of offshore outsourcing location decisions on supply chain resilience”,Journal of Business Research.

Indexed at, Google Scholar, Cross Ref

Maleki, M. and Cruz-Machado, V. (2013), “Generic integration of lean, agile, resilient, and green practices in the automotive supply chain", Review of International Comparative Management.

Martínez-Jurado, P.J. and Moyano-Fuentes, J. (2014), “Lean management, supply chain management, and sustainability: a literature review”, Journal of Cleaner Production.

Narayana, S. A., Pati, R. K., & Vrat, P. (2014), “Managerial research on the pharmaceutical supply chain–A critical review and some insights for future directions”, Journal of Purchasing and Supply Management.

Ogunlela, G. O. and Lekhanya, L.M. (2016), “The use of integrated supply chain management model for promoting competitiveness in the fast-moving consumer goods (FMCG) manufacturing industry in Nigeria”, Problems and Perspectives in Management.

Indexed at, Google Scholar, Cross Ref

Prajogo, D., Oke, A. and Olhager, J. (2016), “Supply chain processes”, International Journal of Operations & Production Management.

Qrunfleh, S. and Tarafdar, M. (2013), “Lean and agile supply chain strategies and supply chain responsiveness: the role of strategic supplier partnership and postponement”, Supply Chain Management: An International Journal.

Rachel Mason-Jones, Ben Naylor & Denis R. Towill(2000), “Lean, agile or leagile? Matching your supply chain to the marketplace”,International Journal of Production Research.

Indexed at, Google Scholar, Cross Ref

Rajesh, R., Ravi, V. and Venkata Rao, R. (2015), “Selection of risk mitigation strategy in electronic supply chains using grey theory and digraph-matrix approaches”, International Journal of Production Research.

Rice, B.J.B. and Caniato, F. (2003), “Building a secure and resilient supply network”, Supply Chain Management Review.

Romano, E., Chiocca, D., Santillo, L.C. and Guizzi, G. (2013), “A resilient approach to manage a supply chain network”, IEEE 12th International Conference on Intelligent Software Methodologies, Tools and Techniques (SoMeT).

Sage, A. P. (1977),“Methodology for large-scale systems’, McGraw-Hill College.

Scholten, K., Scott, P.S. and Fynes, B. (2014), “Mitigation processes – antecedents for building supply chain resilience”, Supply Chain Management.

Indexed at, Google Scholar, Cross Ref

Seth, D., Seth, N. and Goel, D. (2008), “Application of value stream mapping (VSM) for minimization of wastes in the processing side of the supply chain of the cottonseed oil industry in Indian context", Journal of Manufacturing Technology Management.

Shah, R. and Ward, P.T. (2007), “Defining and developing measures of lean production”, Journal of Operations Management.

Singh, S.C., and Pandey, S.K. (2015), "Lean supply-chain: a state-of-the-art literature review", Journal of Supply Chain Management Systems.

So, S. and Sun, H. (2010), “Supplier integration strategy for lean manufacturing adoption in electronic-enabled supply chains”, Supply Chain Management: An International Journal.

Spiegler, V.L.M., Naim, M.M. and Wikner, J. (2012), “A control engineering approach to the assessment of supply chain resilience”, International Journal of Production Research.

Indexed at, Google Scholar, Cross Ref

Stewart, P., Danford, A., Richardson, M. and Pulignano, V. (2010), “Workers’ experiences of skill, training, and participation in lean and high -performance workplaces in Britain and Italy", Employee Relations.

Tang, C. (2006), “Robust strategies for mitigating supply chain disruptions”, International Journal of Logistics.

Taylor, D.H. (2005), “Value chain analysis: an approach to supply chain improvement in agri-food chains”, International Journal of Physical Distribution & Logistics Management.

Indexed at, Google Scholar, Cross Ref

Treville, S. and Antonakis, J. (2006), “Could lean production job design be intrinsically motivating? Contextual, configurational, and levels-of-analysis issues”, Journal of Operations Management.

Tukamuhabwa, B.R., Stevenson, M., Busby, J. and Zorzini, M. (2015), “Supply chain resilience: definition, review and theoretical foundations for further study”, International Journal of Production Research.

Indexed at, Google Scholar, Cross Ref

Vinodh, S., Arvind, K.R. and Somanaathan, M. (2011), “Tools and techniques for enabling sustainability through lean initiatives”, Clean Technologies and Environmental Policy.

Indexed at, Google Scholar, Cross Ref

Wiengarten, F., Fynes, B. and Onofrei, G. (2013), “Exploring synergetic effects between investments in environmental and quality/lean practices in supply chains”, Supply Chain Management: An International Journal.

Wisner, Joel D. (2003), “A structural equation model of supply chain management strategies and firm performance”, Journal of Business Logistics.

Zhu, Q., Sarkis, J. and Lai, K. (2008), “Confirmation of a measurement model for green supply chain management practices implementation”, International Journal of Production Economics.

Indexed at, Google Scholar, Cross Ref

Received: 26-Apr-2023, Manuscript No. AMSJ-23-13530; Editor assigned: 10-May-2023, PreQC No. AMSJ-23-13530(PQ); Reviewed: 26-Jun-2023, QC No. AMSJ-22-13530; Revised: 03-Aug-2023, Manuscript No. AMSJ-23-13530(R); Published:10-Sep-2023