Research Article: 2025 Vol: 29 Issue: 6

Technological Innovations Adopted for Supply Chain Improvement in Manufacturing Sector and its Impact on Firm Performance: A Bibliometric and Review Analysis

Nishant Maheshwari, School of Leadership and Management

Manav Rachna International Institute of Research and Studies, Faridabad

Bhakti Ranjit Pawar, School of Leadership and Management

Manav Rachna, International Institute of Research and Studies, Faridabad

Citation Information: Maheshwari, N., & Ranjit Pawar, B. (2025) Technological innovations adopted for supply chain improvement in manufacturing sector and its impact on firm performance: a bibliometric and review

analysis. Academy of Marketing Studies Journal, 29(6), 1-19.

Abstract

The supply chain management (SCM) practices in the manufacturing sector have been heavily optimized due to the advent of technology, largely in terms of efficiency, transparency of the process, and responsiveness of different processes of the supply chain and logistics within the industry. This research was an attempt to outline and classify the various technological changes that manufacturing companies applied during SCM and how they have influenced firm performance gauged through different firm performance parameter which includes, perceived productivity, cost effectiveness and profitability. The current research implemented a thorough bibliometric examination, both citation and co-citation, and keywords. The study carried out a systematic review of the available literature in an attempt to investigate the pattern of adoption and intellectual architecture of the technological innovations to SCM. The new technologies related to the improvement of the logistics are artificial intelligence (AI), the Internet of Things (IoT), blockchain, cloud computing, robotics, additive manufacturing (3D printing), and augmented reality (AR) and provide a good interaction to make better decisions, reduce uncertainty, and enable real-time monitoring. The innovative technologies have great benefits associated; however, these technologies present a temporal challenge in terms of privacy, data security, and implementation. The report outlines the four main research questions that refer to significant publications, thematic overviews, emerging issues, and the impact of performance of the innovations in supply chains. This paper is beneficial in that it tells how SCM inventions can be reviewed systematically and bibliometrically within manufacturing environment, offers an elaborate insight as to new technological innovations, and identifies future research agendas aimed at increasing the supply chain efficiency, its performance, and overall flexibility.

Introduction

Supply chain innovation through technology (SCM) has changed the business of logistics and operations dramatically and has made the chain progressively more efficient, transparent, and responsive. The innovations cover a broad spectrum of technologies all of which play a singular contribution towards the optimization and improvement of supply chain processes. Combination of these technologies enhances not only the efficiency of operations but also enhances strategic sense and risk management. Several innovations have been adopted lately in the supply chain in the manufacturing sector which is evident in the existing literature. Artificial intelligence and advanced analytics can be applied in making supply chains more efficient due to predictive analytics, demand modelling, and operational efficiency of logistics. They can enable decisions on the basis of data, render items more accurate, and reduce the number of uncertainties in the supply chain operations (Attaran, 2020) (Kersten et al., 2019). AI algorithms may be used to perform predictive risk modelling to help enterprises predict and inoculate potential disturbances before they could be full-blown (Odimarha et al., 2024). Using IoT technology, it is now feasible to monitor on-movement items in real-time and therefore provide full supply chain visibility and traceability. Real-time data collecting helps to augment the reactiveness of the overall supply chain and maximize the inventory level (Odimarha et al., 2024). The IoT sensors do their part in ensuring product safety and the quality of the products being shipped by monitoring the conditions like humidity and temperature (Wei et al., 2019). Blockchain keeps the record of transactions safe and transparent which is needed to enhance trust and accountability within the supply networks. The blockchain technology reduces fraud, increases traceability, and ensures compliance with the regulatory requirements (Odimarha et al., 2024). Considering that blockchain is decentralized, all the participants can access the same information. This reduces the diversity and enables individuals to transact in associating (Wei et al., 2019). Cloud computing provides the benefits of a scalable and flexible IT infrastructure, which helps in the ease of integration and joint activities between different functions involved in the supply chain. Cloud computing enables time-sensitive data dissemination and enhances the quickness of the supply chain procedures (Attaran 2020). The cloud-based platforms facilitate organization of the just-in-time delivery as well as reduced prices and amounts of the inventory (Franco, 2007). Robotics and automation simplify the work in a warehouse, ensure that the orders are fulfilled properly, and reduce labour expenses. Automated systems will streamline the processes in a supply chain, and manufacturing and distributions are the most affected by the speed and efficiency improvements (Attaran, 2020). The industrial systems are also more rivetable as well as reconfigurable, which gives them the ability to adapt to the market changes quickly, and these technologies have supported this as well (Dolgui & Proth, 2010). Additive manufacturing, AKA 3D printing, enables us to create items when we need them and not having to stock up. It also allows a person to customize the goods and this is perfect when it comes to prototyping and producing in small batches (Attaran 2020). It also lowers transport costs and lead times in that it enables local production (Wei et al., 2019). AR technologies will help in effective training and working with the employee providing them with real-time information and instruction to the warehouse and factory employees. This can make things more precise and minimise mistakes during strict proceedings (Attaran, 2020). Although the new forms of technologies come with significant benefits, they indeed have their challenges, like incompatibility issues, data security concerns, and the demand to acquire special skills to install and maintain such systems effectively (Odimarha et al., 2024). These technologies have to be employed in a plan manner to ensure that their application is in alignment with the objectives of the business and they make the most out of the possible advantages of the technologies. These technologies will require an integration due to the effects of change in supply chains with the aim of remaining competitive and robust in a highly dynamic market.

The objective of the study is the identification and classification of technical innovations exploited by the industrial sphere in order to improve supply chain as well as the focus on the adoption trends based on bibliometric analysis. The essay seeks to evaluate the effects of these innovations towards making the process of supply chains to be optimized and involve enhancing the business performance indicator, including productivity, cost efficiency, and profitability. By conducting a comprehensive literature review, the research seeks to understand the current state of technological applications in supply chains, identify gaps, and suggest future research directions to further advance supply chain performance in the manufacturing industry. Further, the synthesis of the literature performed apprises to acknowledge the following research questions.

RQ1: What are the influential aspects of this body of knowledge in respect of articles, authors and sources?

RQ2: What is the intellectual structure of supply chain innovations in manufacturing sector based key themes and disciplines involved?

RQ3: Which key topics are popular in this literature and what is the future research scope?

RQ4: What are the different supply chain innovations in manufacturing sector and how they influence the firm performance?

The literature available in the academic field was designed to deal with supply chain innovations in manufacturing and its effects on the firm performance. The difference between this study and previous studies is that, (1) the study is a comprehensive literature review on supply chain innovations on manufacturing sector, (2) we have made use of citation, co-citation and keywords analysis to capture the richness of the literature, unlike the conventional literature review as done in other studies, (3) the study attempts to systematically determine the key supply chain innovations in manufacturing sector determinants affecting and this study is the first systematic and bibliometric literature review done on supply chain innovations literature. The paper was important in identifying the supply chain innovations in manufacturing sector through the literature.

The rest of the paper is discussed as follows: Section 2 gives account of the data search, data, extraction and methods of analysis, section 3 gives the main findings of the bibliometric citation analysis based on publication trends, citation analysis, co-citation analysis and keyword analysis, section 4 gives a summary of the results of systematic review, section 5 provides the future research on the basis of the review and section 6 concludes the study.

Data and Methodology

Sample Selection

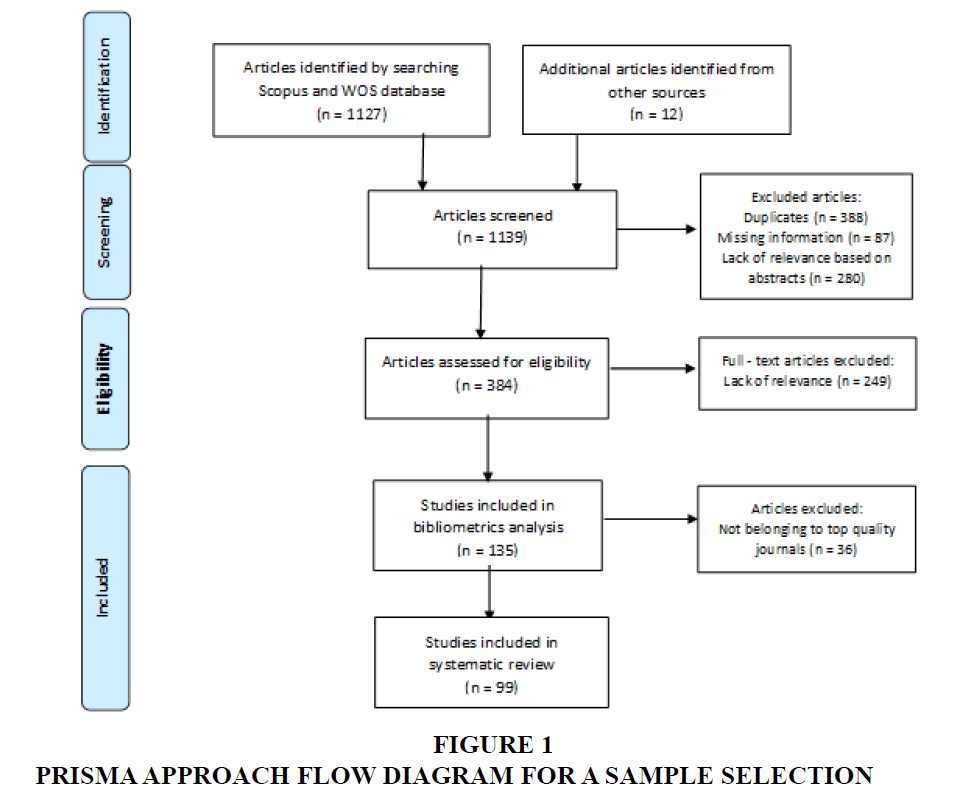

To perform the analysis, the paper systematically went through a sequence of steps when selecting the articles. The selection of the database is the first stage. We have browsed through articles in Scopus and Web of science (WoS) citation index. The combination of the two databases was useful enough to provide a broad coverage of the high-quality articles in high-ranking journals (Vieira and Gomes, 2009; Mongeon and Paul-Hus, 2016). Second, keywords are used with various combinations to do a literature search. In the databases, the search term was based on the keyword, namely, innovation and supply chain and manufacturing. Moreover, two filters were also used including English language and articles published after year 2010 because the latest innovations can be determined and analyzed. A total of 1127 articles were identified in the search (671 articles identified in Scopus and 456 articles in WoS). In order to identify all the potential articles on the subject, taking a limitation and bias of both databases into consideration (Mongeon and Paul-Hus, 2016), the same search process was conducted on the Publish and Perish software. The top 200 documents based on the number of citations have been screened resulting in addition of 12 more documents to our selected database of articles. The PRISMA approach is adopted for screening of the research papers to be included in the systematic review (Moher et al., 2010).

Figure 1 represents a four-step process as suggested by PRISMA guidelines. The first was that we found 1139 articles in the two databases and other sources. Second, after excluding duplicate articles, articles with missing information and irrelevant articles, 384 papers were left for further screening. In the third step, full-text screening of the articles was performed resulting in selection of final 135 articles for bibliometric analysis.

Fourth, 99 articles published in quality journals were shortlisted to conduct comprehensive review for the identification of drivers of credit rating of firms.

Methods of Data Analysis

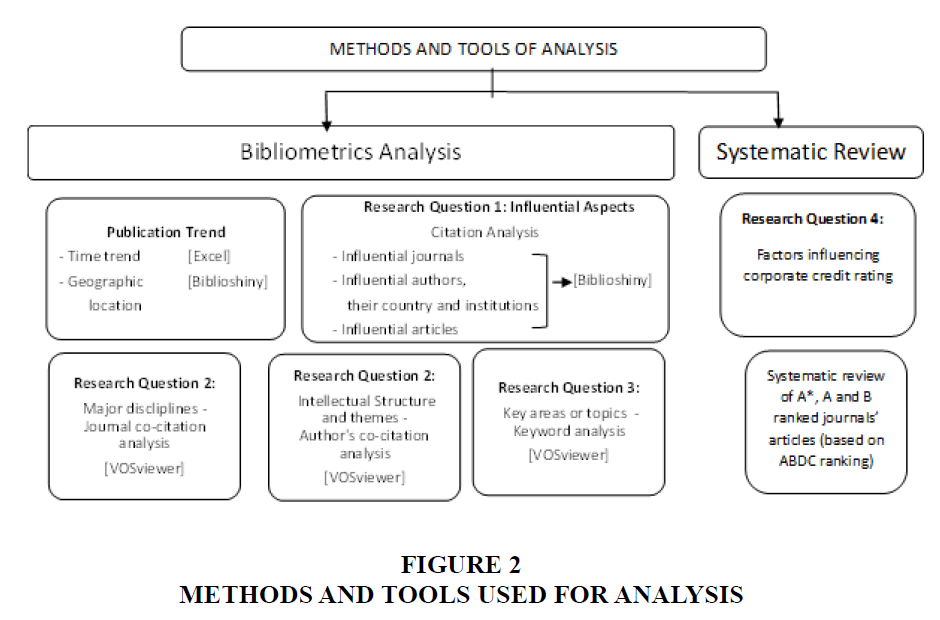

Bibliometric citation analysis along with systematic review of literature have been performed, where bibliometric analysis of articles is used to map the knowledge anatomy of the literature base (Li et al., 2017) and to determine the most important research topics/ themes, the literature review part is literature reviewing in order to put forth conclusions and get to know research gaps (Denyer & Tranfield, 2009). We applied publication trends, citation analysis, co-citation analysis and keyword analysis (Bahoo, 2020; Goyal & Kumar, 2021) using VOSviewer software and Biblioshiny package from R studio. Figure 2 provides information about the methodology, tools and software used for the analysis.

Results and Discussions

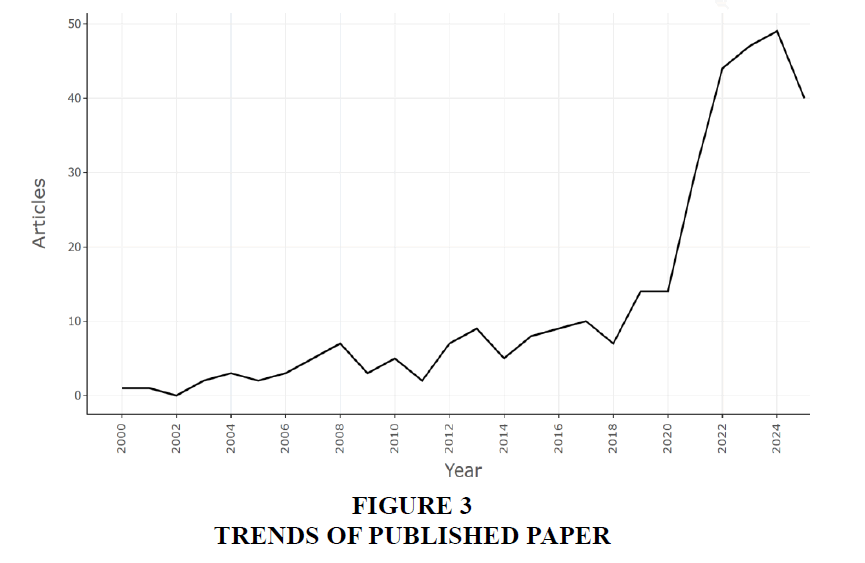

The included 99 documents for systematic literature review found to have 15.9% annual growth rate indicating the high publication records for new innovations. Around 369 authors made their significant contributions, where 16 documents were found to be single authored, 23.85 percent of the papers have multiple country authorship. The papers have 3.13 co-authors per document. The average citation of the documents is found as 19.22.

Publication Trend in Time

Figure 3 depicts the trend in published papers focusing on innovations adopted for supply chain improvement in manufacturing sector during the period 2000 to 2025. The publications have grown since 2018. The inventions embraced in enhancing SCM in manufacturing. The results revealed an increase in firms after the year 2018. It has been attributed to various reasons which among them are the necessity to have greater efficiency, strength, and flexibility to accommodate the dynamic nature of the marketplace and consumer preferences advancements. These needs have been pointed out by the trade concerns, the global disruption including the pandemics, and increasing complexity of supply chains. Metis can be explained by the innovations provided by IoT, AI and machine learning which helped manufacturing firms to enhance the supply chain operations and reduce costs substantially and increase operational efficiency. As an example, IoT devices deliver real-time data, enabling proactive decisions making and maintenance, which eliminates downtime and maximises productivity (Ben-Daya et al., 2019). The increasing importance of more individualized products and quicker time of delivery necessitates a more pliant supply chain. Advanced robotics form of additive manufacturing enables the manufacturers to swiftly respond to changes without the whole chain of supply. (Frank et al., 2019). The covid pandemic shows that the supply chains of the world need complications. Firms within the manufacturing industry are employing the emerging technologies like blockchain to improve transparency and traceability as well as AI in predicting outcomes in a bid to improve supply chain resilience (Ivanov & Dolgui, 2020). As awareness and legislation around environmental impact increases, technology that enables mechanisms to reduce waste and [boost] sustainability has become key. For example, AI and advanced data analytics enable better resource management and reduction of carbon footprints (Dubey et al., 2019). These advances are not just stunts, and they are replacing the element of modern supply chain strategies which are being transformed to integrate into the changing challenges and opportunities of the global market.

Influential Aspects of the Literature

Table 1 represents the top 25 most influencing journals from the list of 105 different journals, publishing 99 articles. These journals were ranked as per two dimensions; the total number of articles published on the topic and total citations of the journal. Total citations include only the citations received by a paper from other papers in the selected dataset and not from all articles published in the database. The “Sustainability” is the most productive journal with 21 documents published in this journal and the “Journal of cleaner production” has the publication of the highest impact research articles (408 total citations). The remaining journals in the list have less publications, however few of them have high citations such as “Supply chain management” have only four publications but have 324 total citations and “International Journal of Information Management” have only two publications but have 440 total citations.

| Table 1 Top 25 Most Influencing Journals | ||||||

| Name of Journal (Source) | H index | G index | M index | Total Citation | Number of publications | Publication started from |

| Sustainability (Switzerland) | 9 | 16 | 1.125 | 282 | 21 | 2018 |

| Journal of Cleaner Production | 8 | 15 | 0.615 | 408 | 15 | 2013 |

| Environmental Science and Pollution Research | 4 | 6 | 1 | 121 | 6 | 2022 |

| Resources Policy | 4 | 4 | 0.8 | 85 | 4 | 2021 |

| Supply Chain Management | 4 | 4 | 0.222 | 324 | 4 | 2008 |

| Cogent Business and Management | 3 | 4 | 1.5 | 23 | 8 | 2024 |

| Energy Economics | 3 | 6 | 0.25 | 122 | 6 | 2014 |

| Energy Policy | 3 | 3 | 0.429 | 169 | 3 | 2019 |

| Frontiers In Environmental Science | 3 | 4 | 0.75 | 60 | 4 | 2022 |

| International Journal of Physical Distribution and Logistics Management | 3 | 3 | 0.429 | 103 | 3 | 2019 |

| International Journal Of Production Economics | 3 | 4 | 0.333 | 58 | 4 | 2017 |

| Renewable And Sustainable Energy Reviews | 3 | 3 | 0.3 | 54 | 3 | 2016 |

| Transportation Research Part E: Logistics and Transportation Review | 3 | 3 | 0.6 | 115 | 3 | 2021 |

| ACM International Conference Proceeding Series | 2 | 2 | 0.4 | 7 | 3 | 2021 |

| Annals Of Operations Research | 2 | 2 | 0.667 | 24 | 2 | 2023 |

| Climate Policy | 2 | 2 | 0.667 | 19 | 2 | 2023 |

| Environmental Science and Technology | 2 | 2 | 0.5 | 41 | 2 | 2022 |

| Heliyon | 2 | 2 | 1 | 9 | 2 | 2024 |

| IEEE Access | 2 | 3 | 0.5 | 12 | 3 | 2022 |

| Industrial Management and Data Systems | 2 | 3 | 0.4 | 9 | 3 | 2021 |

| International Journal of Environmental Research and Public Health | 2 | 2 | 0.222 | 65 | 2 | 2017 |

| International Journal of Information Management | 2 | 2 | 0.143 | 440 | 2 | 2012 |

| International Journal of Logistics Research and Applications | 2 | 2 | 0.667 | 22 | 2 | 2023 |

| International Journal of Manufacturing Technology and Management | 2 | 2 | 0.2 | 13 | 2 | 2016 |

| Journal Of Business Economics | 2 | 2 | 0.222 | 121 | 2 | 2017 |

Table 2 indicates the top 25 authors with maximum contribution in the research. The table represents the most influential authors based on the number of published documents and their total number of citations i.e. number of times a document is cited by other documents listed on the database used for the study. Authors affiliated academic institutes/universities and countries are also mentioned in the table. The highest number of documents are published by author Zhang Y (8), followed by Wang J (7), Li J (6), Li C (5) etc. In terms of citations, the top three authors are Zhang Y (116), Wang L (93) and Li B (76). The results reported that most of the authors belong to the “China” in both categories. In the report analysis, 8 out of 10 authors are affiliated to the China, the rest belonging to USA. Similarly, authors from the China have published highest number of articles followed by USA. Finally, “Youngstown State University”, “University of China”, and “University of Wyoming” are among the prominent affiliations of the authors working on this stream of research.

| Table 2 Influential Authors, their Affiliated Country and Institution | |||||||

| Name of Author | Institution, Nation | H index | G index | M index | Total Citation | Number of publications | Publication started from |

| Li Chuang | Jimei University, China | 4 | 5 | 1 | 65 | 5 | 2022 |

| Wang Jianning | University of China, China | 4 | 7 | 1 | 56 | 7 | 2022 |

| Wang Liping | Jimei University, China | 4 | 4 | 0.667 | 93 | 4 | 2020 |

| Zhang Chengyi | University of Wyoming, USA | 4 | 5 | 1 | 65 | 5 | 2022 |

| Zhang Yiyang | Youngstown State University, USA | 4 | 8 | 0.667 | 116 | 8 | 2020 |

| Guo Hongjuan | Industrial & Commercial Bank of China, China | 3 | 3 | 0.6 | 27 | 3 | 2021 |

| Li Baizhou | Harbin Engineering University, China | 3 | 4 | 0.5 | 76 | 4 | 2020 |

| Li Jingdong | Chinese Academy of Science, China | 3 | 6 | 0.158 | 60 | 6 | 2007 |

| Wang Zhijia | Henan Polytechnic University, China | 3 | 3 | 1 | 31 | 3 | 2023 |

| Xie Jiaping | Shanghai University of Finance & Economics, Shanghai | 3 | 3 | 0.75 | 13 | 4 | 2022 |

| Zhang W | 3 | 4 | 0.75 | 16 | 4 | 2022 | |

| Zhu Jingyu | School of Biology and the Environment, China | 3 | 3 | 0.75 | 58 | 3 | 2022 |

| Chen Jinhua | China University of Geoscience, China | 2 | 2 | 0.5 | 9 | 2 | 2022 |

| Chen Lei | South China University of Technology, China | 2 | 2 | 0.286 | 98 | 2 | 2019 |

| Du Bisheng | Ningbo University, China | 2 | 2 | 0.222 | 65 | 2 | 2017 |

| Guo Feng | Lowa State University, USA | 2 | 2 | 0.4 | 19 | 2 | 2021 |

| Guo Qing | Guangdong University of Foreign Studies, China | 2 | 2 | 0.667 | 18 | 2 | 2023 |

| Han Zishu | Shanghai University of Finance & Economics, China | 2 | 2 | 0.5 | 7 | 2 | 2022 |

| He Xixi | Shanghai University of International Business & Economics, China | 2 | 2 | 1 | 14 | 2 | 2024 |

| Hofmann Erik | University of St Gallen, Switzerland | 2 | 2 | 0.222 | 185 | 2 | 2017 |

| Hu Hui | Wuhan city College, China | 2 | 3 | 0.182 | 11 | 3 | 2015 |

| Li Huimin | North China University of Water Resources, China | 2 | 3 | 0.5 | 27 | 3 | 2022 |

| Li Xiaoping | Sichuan University, China | 2 | 2 | 0.111 | 123 | 2 | 2008 |

| Li Yuqiong | University of South China, China | 2 | 4 | 0.167 | 18 | 4 | 2014 |

| Li Zhi | University of Technology, China | 2 | 3 | 0.286 | 42 | 3 | 2019 |

The most influential articles in the literature were identified on the basis of total citations. The top 25 documents were reported in table 3 from the list of selected 99 articles for the analysis. Table reported the most influential documents along with their DOI, total citations, Total citation per year. The dominant position is attained by the articles Bumblauskas D, (2020), Int J Inf Manage, Kwak D-W, (2018), Int J Oper Prod Manage, Majid I, (2018), J Saudi Soc Agric Sci, Bardhan Ir, (2010), J Manage Inf Syst and Wu Y, (2013), J Supply Chain Manage. The majority of the documents which have top ranking in citation analysis study the innovations in supply chain management and its effect on firm performance using contemporary techniques. This highlights the important factors and techniques for determination and improvement of accuracy of innovations in supply chain management.

| Table 3 Influential Articles | |||

| Paper | DOI | Total Citations | TC per Year |

| Bumblauskas D, 2020, Int J Inf Manage | 10.1016/j.ijinfomgt.2019.09.004 | 412 | 68.67 |

| Kwak D-W, 2018, Int J Oper Prod Manage | 10.1108/IJOPM-06-2015-0390 | 291 | 36.38 |

| Majid I, 2018, J Saudi Soc Agric Sci | 10.1016/j.jssas.2016.11.003 | 248 | 31.00 |

| Bardhan Ir, 2010, J Manage Inf Syst | 10.2753/MIS0742-1222260402 | 214 | 13.38 |

| Wu Y, 2013, J Supply Chain Manage | 10.1111/j.1745-493x.2012.03287.x | 206 | 15.85 |

| Sandvik Im, 2019, J Fash Mark Manage | 10.1108/JFMM-04-2018-0058 | 202 | 28.86 |

| Alazab M, 2021, Cluster Comput | 10.1007/s10586-020-03200-4 | 180 | 36.00 |

| Goodrich Ac, 2013, Energy Environ Sci | 10.1039/c3ee40701b | 125 | 9.62 |

| Van Hoof B, 2013, J Clean Prod | 10.1016/j.jclepro.2012.09.023 | 119 | 9.15 |

| Oettmeier K, 2017, J Bus Econ | 10.1007/s11573-016-0806-8 | 114 | 12.67 |

| Tachizawa Em, 2015, Supply Chain Manage | 10.1108/SCM-03-2014-0108 | 108 | 9.82 |

| Melville N, 2008, Inf Syst J | 10.1111/j.1365-2575.2007.00260.x | 105 | 5.83 |

| Sueyoshi T, 2014, Energy Econ | 10.1016/j.eneco.2014.09.022 | 102 | 8.50 |

| Evangelista P, 2006, Int J Logist Manage | 10.1108/09574090610663437 | 97 | 4.85 |

| Li X, 2008, Supply Chain Manage | 10.1108/13598540810894979 | 95 | 5.28 |

| Khan Sar, 2021, Sustainability | 10.3390/su13158479 | 94 | 18.80 |

| Wei J, 2021, J Clean Prod | 10.1016/j.jclepro.2021.126578 | 85 | 17.00 |

| Fu C, 2019, J Nat Gas Sci Eng | 10.1016/j.jngse.2019.05.001 | 81 | 11.57 |

| Elia A, 2020, Energy Policy | 10.1016/j.enpol.2020.111912 | 78 | 13.00 |

| Quayson M, 2021, Ieee Trans Eng Manage | 10.1109/TEM.2020.2996003 | 78 | 15.60 |

| Wu C-M, 2019, Energy Policy | 10.1016/j.enpol.2019.01.026 | 78 | 11.14 |

| Benitez Gb, 2022, Supply Chain Manage | 10.1108/SCM-07-2020-0304 | 76 | 19.00 |

| Guo B, 2024, Int Rev Financ Anal | 10.1016/j.irfa.2024.103085 | 76 | 38.00 |

| Klumpp M, 2019, J Bus Logist | 10.1111/jbl.12198 | 74 | 10.57 |

| Mathauer M, 2019, Int J Phys Distrib Logist Manage | 10.1108/IJPDLM-02-2019-0064 | 71 | 10.14 |

The table 3 reported the contribution from the different countries in the area of innovations in supply chain management. The results indicated that the maximum publication came from China (140), followed by USA (19) and India (11). The 42.8% of the publications came from China, where 115 documents written by single country author and 25 documents were written by multiple country author Table 4.

| Table 4 Country Wise Publication Contribution | |||||

| Country | Articles | Articles % | Single Country Publication | Multiple Country Publication | MCP % |

| China | 140 | 42.8 | 115 | 25 | 17.9 |

| Usa | 19 | 5.8 | 15 | 4 | 21.1 |

| India | 11 | 3.4 | 8 | 3 | 27.3 |

| United Kingdom | 10 | 3.1 | 5 | 5 | 50 |

| Indonesia | 7 | 2.1 | 6 | 1 | 14.3 |

| Germany | 6 | 1.8 | 5 | 1 | 16.7 |

| Hong Kong | 6 | 1.8 | 4 | 2 | 33.3 |

| Malaysia | 6 | 1.8 | 2 | 4 | 66.7 |

| Korea | 5 | 1.5 | 2 | 3 | 60 |

| Canada | 4 | 1.2 | 1 | 3 | 75 |

| Italy | 4 | 1.2 | 3 | 1 | 25 |

| Spain | 4 | 1.2 | 2 | 2 | 50 |

| Brazil | 3 | 0.9 | 2 | 1 | 33.3 |

| Finland | 3 | 0.9 | 3 | 0 | 0 |

| Hungary | 3 | 0.9 | 2 | 1 | 33.3 |

| Netherlands | 3 | 0.9 | 2 | 1 | 33.3 |

| Switzerland | 3 | 0.9 | 2 | 1 | 33.3 |

| Australia | 2 | 0.6 | 2 | 0 | 0 |

| Bangladesh | 2 | 0.6 | 0 | 2 | 100 |

| Denmark | 2 | 0.6 | 1 | 1 | 50 |

| France | 2 | 0.6 | 0 | 2 | 100 |

| Iran | 2 | 0.6 | 2 | 0 | 0 |

| Jordan | 2 | 0.6 | 2 | 0 | 0 |

| Kenya | 2 | 0.6 | 2 | 0 | 0 |

| Singapore | 2 | 0.6 | 2 | 0 | 0 |

Keywords

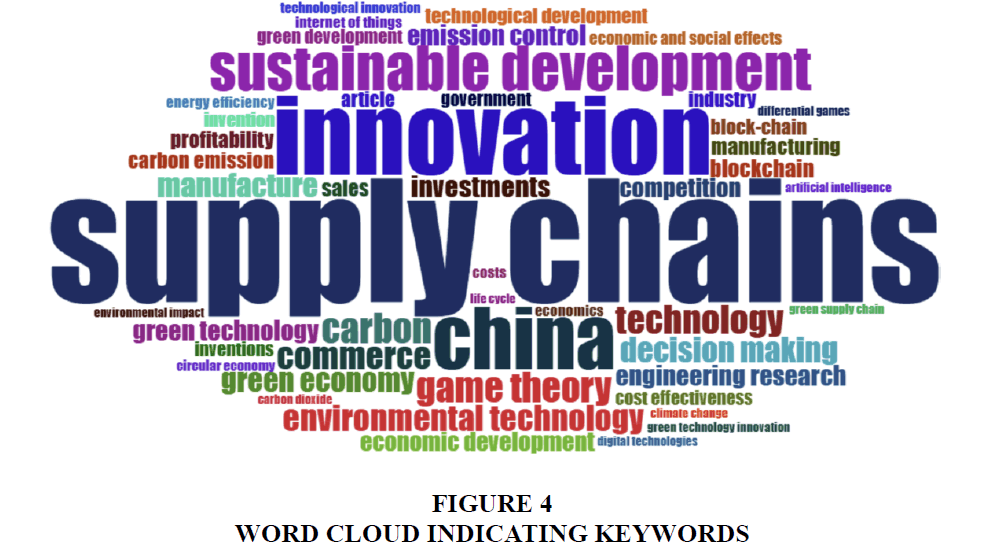

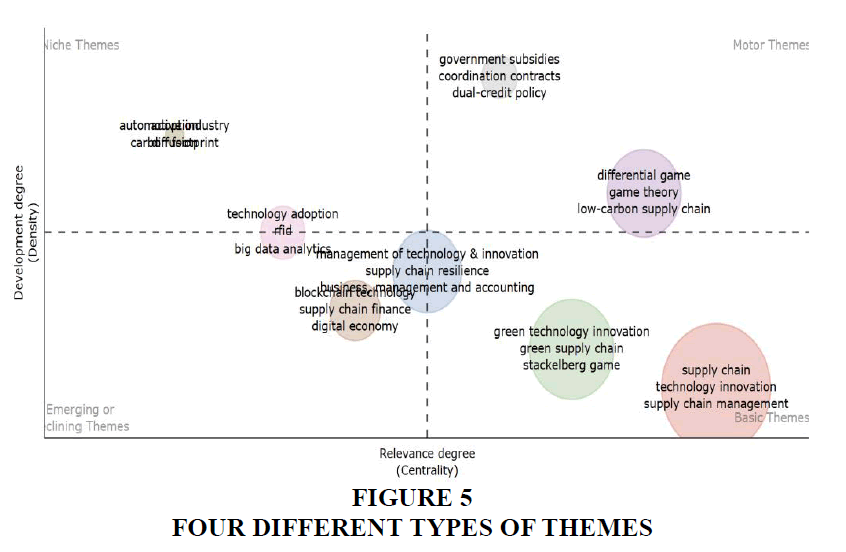

The study includes keywords analysis, which determines the most often used keywords in the chosen researches’ papers showing the pertinence of the word in the literature. Figures 4 & 5 shows the keywords dynamics presented through a word cloud where the size of a word corresponds to its frequency. The figure presents the top 40 most frequently used keywords. The term ‘Supply chain” appeared 15 times, followed by ‘Innovation’, ‘Sustainable development’, ‘China’, ‘Technology’ and ‘game theory’ etc. This highlights the importance of these factors for the supply chain management innovative practices. Apart from these, different keywords related to supply chain innovations like the blockchain, green technology, internet of things, artificial intelligence, carbon emission etc are indicated by the word cloud.

Major Disciplines

Thematic analysis was performed to understand the different emerging themes related to the innovations in supply chain management in the manufacturing sector. The paper used the existing literature to identify the research themes, sub-fields and disciplines (Osareh, 1996; Small, 1973). Figure 5 depicts the different types of themes related to the subject area of innovations in the manufacturing sector. The figure shows four different categories of themes namely emerging themes, Niche themes, Basic themes and Motor themes. The classification of these themes is based on two dimensions: relevance and development. The basic themes are helpful of the researcher to identify the themes which are highly relevant but not much developed. The basis themes as shown in figure are ‘supply chain technology innovations’, green technology innovations, green supply chain, Stackelberg game etc. These themes need in-depth research for better understanding of the topics.

Supply Chain Innovations in Manufacturing Sector and their Influence on Firm Performance

This section discusses the different supply chain innovations in manufacturing sector and their influence on firm performance. Table 5 mention the different identified technological innovations from the existing literature review along with the explanation and the reference of the papers explaining them. These innovations are named as Green Technology Innovation System (GTIS) based on Multi-Agent Cooperation, Nanocomposite Packaging, Modular Manufacturing Platforms for Vaccines, Blockchain-Based Food Traceability System, Augmented Reality (AR) in the Food Supply Chain, Re-distributed Manufacturing (RDM), Information Requirements Paradigm for IT Innovation Diffusion, Cloud Computing for Supply Chain Information Systems, Service-Oriented Architecture (SOA) and the Emergence of Service Science, RFID as a Disruptive Information Technology, Supply Chain (SC) Innovation for Risk Management and Competitive Advantage, Human–Computer Interaction (HCI) Framework for AI in Logistics, Collaborative New Product Development with Forecast and Resource Sharing, Manufacturing Servitization via an Innovative Product Development Model Using TAM, Energy Access Innovation Centers (EAICs) for Universal Clean Energy, Interaction Mechanism for Carbon Reduction Technology Innovation Using Differential Game Theory and Enterprise Framework for Renewable Energy Using SCOR Model.

| Table 5 Supply Chain Innovations in Manufacturing Sector | ||

| Technological Innovation | Meaning of Innovation | Citation |

| Green Technology Innovation System (GTIS) based on Multi-Agent Cooperation | Innovation refers to a conceptual and operational framework where multiple stakeholders (agents)—such as governments, businesses, universities, research institutions, and the public. Focuses on technologies that reduce environmental impacts, improve resource efficiency, or support sustainable development. | (Yin et al., 2021), (Liu, Wei, & Wang, 2019), (Zhao et al., 2020); (Zhang & Duan, 2021) |

| Nanocomposite Packaging | Involves incorporating nanoparticles into traditional packaging materials to enhance strength, barrier properties, and functionality. It extends shelf life, improves product safety, and reduces environmental impact, benefiting industries like food, pharmaceuticals, and electronics. | (Majid et al., 2016), (Rhim, Park, & Ha, 2013). |

| Modular Manufacturing Platforms for Vaccines | Flexible, scalable systems for vaccine production built from interchangeable, pre-designed modules. They enable rapid setup, relocation, and adaptation to different vaccine types, enhancing responsiveness and efficiency across various locations. | (Pagliusi, Che, & Dong, 2019), (Kis, Rizvi, & Langer, 2021), (Peplow, 2021) |

| Blockchain-Based Food Traceability System | Founded on technology to trace and track the movement of food products through the supply chain- the production process, the process of distribution, retail, and the final consumer. It gives an immutable, clear and safe chronicle of all transaction in the food lifecycle. | (Tian, 2017), (Kamble, Gunasekaran, & Sharma, 2020) |

| Augmented Reality (AR) in the Food Supply Chain | Enables the overlay of digital information onto real-world environments throughout production, processing, distribution, and retail. This integration boosts operational efficiency, transparency, and consumer engagement across the entire supply chain. | (Poushneh & Vasquez-Parraga, 2017), (Zhang, Li, & Zhang, 2020) |

| Re-distributed Manufacturing (RDM) | Is an innovative approach that brings production closer to the point of use, using flexible, often digital-enabled systems. It enables localized, demand-driven manufacturing tailored to specific regional or individual needs. | (Holmström, Holweg, Khajavi, & Partanen, 2016), (Ford & Despeisse, 2016) |

| Information Requirements Paradigm for IT Innovation Diffusion | Innovation refers to a theoretical framework that focuses on the type, amount, and flow of information needed for an innovation to be successfully adopted and diffused within an organization or across a system. | (Melville & Ramirez, 2008), (Rogers, 2003), (Gallivan, 2001) |

| Cloud Computing for Supply Chain Information Systems | Use internet platforms to store, manage, and process supply chain data in real time across all partners. They provide on-demand access to computing resources like storage, analytics, and applications, enhancing collaboration without relying on local infrastructure. | (Wu, Cegielski, Hazen, & Hall, 2013), (Sahay & Mohan, 2020) |

| Service-Oriented Architecture (SOA) and the Emergence of Service Science | Approach where components are organized as loosely coupled, reusable services that communicate over a network. The services work independently and each of them covers a certain business function that is to be deployed, used and linked to other programs. | (Papazoglou & van den Heuvel, 2007), (Erl, 2005) |

| RFID as a Disruptive Information Technology | Technology which transformed how data is collected, tracked, and managed across various industries—especially in supply chain management, logistics, retail, and healthcare. | (Ngai, Moon, Riggins, & Yi, 2008), (Chao, Yang, & Jen, 2007) |

| Supply Chain (SC) Innovation for Risk Management and Competitive Advantage | Strategic use of new technologies, processes, and models to enhance supply chain performance, flexibility, and resilience. It supports proactive risk management and builds competitive advantage by enabling rapid adaptation to disruptions. | (Kwak, Seo, & Mason, 2018) (Dubey et al., 2020) |

| Human–Computer Interaction (HCI) Framework for AI in Logistics | Technique of accommodating, testing and refining the way humans perceive and perceive anthropogenic intelligence systems. It strives to ensure the practicality, sense, trustworthiness and moral integrity with the idea of user experience (UX) and social and cognitive settings in which AI is assisted/utilized. | (Ehsan et al., 2021), (Liao et al., 2020) |

| Collaborative New Product Development with Forecast and Resource Sharing | Innovation refers to a strategic and integrated approach where multiple partners—such as manufacturers, suppliers, designers, and retailers—jointly plan, develop, and launch new products by actively sharing market forecasts, capacity data, technical knowledge, and resources. | (Jha et al., 2017), (Zhang & Zhang, 2017), (Zhang & Zhang, 2017) |

| Manufacturing Servitization via an Innovative Product Development Model Using TAM | Is a strategic transformation in which manufacturing firms evolve from solely producing physical goods to offering integrated products and services, using digital technologies and guided by user acceptance frameworks like TAM. | (Hsu, 2016), (Zheng et al., 2018) |

| Energy Access Innovation Centers (EAICs) for Universal Clean Energy | They are the centers of excellence, which are used to speed up innovation and deployment of clean energy to ensure that everyone has access especially those in underserved or inaccessible locations. They also support the sharing of resources between stakeholders to design, demonstrate, deploy and test the affordable renewable energy technologies. | (Nathwani & Kammen, 2019), (UNIDO, 2021), (World Bank, 2020), (IEA, 2021) |

| Interaction Mechanism for Carbon Reduction Technology Innovation Using Differential Game Theory | Refers to a mathematical and strategic modelling approach that helps analyse and optimize the behaviour of multiple stakeholders (e.g., governments, firms, investors) involved in the development and diffusion of low-carbon technologies over time. | (Wei & Wang, 2021), (Xu & Zhang, 2021), (Wang et al., 2021), (Gao et al., 2020) |

| Enterprise Framework for Renewable Energy Using SCOR Model | Formalized method of planning, examining and optimizing renewable energy activity. It combines the best practice of supply chain with the goal of clean energy to achieve better production efficiency, promotion of delivery as well as the pursuit of sustainability purposes. | (Moktadir et al., 2018), (Ahmad & Wong, 2019), (Habib et al., 2020) |

Impact of Technological Innovations in Supply Chain in Manufacturing Industry on the Firm Performance

Multi-agent cooperation by integrating global technological innovation systems (GTIS) has a massive impact on firm performance, as it leads to increased collaboration in innovation significantly lowering the costs of development, increasing resource efficiencies, development of dynamic capabilities high environment compliance levels and increased competitive advantage leading to improved financial performance. Companies adopting nano-composite packaging perform better since it retains products, reduces waste products, and reduces the product and transportation costs. The method comprehensively sustains the goals of sustainability, promotes brand image, and offers the opportunity to differentiate products with high quality of packaging features hence market expansion and profitability. This is because the adoption of a new manufacturing concept called ‘Modular Manufacturing Platforms’ (MMPs) in the vaccine manufacturing improves the performance of firms in terms of agility, scalability, and cost-performance. The platforms ensure a stable production switch, minimized infrastructure expenditure, enhanced supply chain resilience, and faster innovation cycles leading to a more powerful market position and economic profits. The use of the ‘Blockchain-Based Food Traceability Systems’ (BFTS) will improve the performance of companies through increased transparency in SCM, a decline in the fraud, and enhanced consumer trust.

It YouTube Clean cuts operation, facilitates regulatory compliance, and premium positioning of the products, and eventually results in cost savings and achievement of better financial performance. Usage of Augmented Reality (AR) in the food supply chain can improve the performance of companies by boosting consumer communication, improving efficiency and building better brand differentiation. AR allows customers to have a sensory product experience, increases logistics and training, and contributes to better traceability, thus resulting in a greater customer satisfaction and profitability. Re-distributed Manufacturing (RDM) increases the performance of the companies to a great extent as it allows flexible and localized production processes that are more responsive to the needs of the market and have less logistic expense and demand-driven production. It also increases resilience, innovation and customer satisfaction, in addition to reducing lead time, transportation costs, enhancing sustainability and helping in mass customization. Information Requirements Paradigm (IRP) is strengthening organizational performance since it ensures a proper alignment between the implementation of IT innovations and the knowledge requirements and organizational decision-making frameworks. This convergence lowers uncertainty, enhances stakeholder alignment, and makes implementation easier leading to an increase in rate of adoption, better system integration and return on investment (ROI). Another area that Cloud Computing has boosted the functions of the supply chain information systems (SCIS) is the improvement of real time visibility, collaboration and scalability of the organizations. This will allow predictability to be enhanced, supply chains to be more cost effective, innovation to be achieved faster, and resilience of supply chains to higher levels and thus greater efficiency and better financial results. The establishment of a Service-Oriented Architecture (SOA) and the progression of service science can boost efficiency in the organization through greater flexibility which involves integration of processes and the creation of new innovative services. Such methodologies ensure the creation of a modular IT infrastructure, enhance value co-creation and increase the efficiency of operations. This culminates into superior client experience and competitive advantage that is long-lasting. Radio-frequency identification (RFID) improves the performance of the organization as it facilitates real-time monitoring, minimizes human errors and improves supply chain visibility. It improves operational efficiency, supports automation and enables data driven decision-making so that higher production, lower cost and higher customer satisfaction can be achieved.

Supply chain innovation enhances corporate performance by strengthening risk management, increasing agility, and sustaining competitive advantage over time. Organizations can enhance profitability and market responsiveness by leveraging innovative technologies and collaborating to improve visibility, reduce expenses, and bolster their operational durability. Integrating a Human–Computer Interaction (HCI) framework for AI systems in logistics enhances organizational performance by improving human-AI collaboration, decision-making, and operational efficiency. Intuitive interfaces reduce training time, increase task accuracy, and support adaptability, thereby leading to lower costs, faster deliveries, and higher customer satisfaction. The New Product Development (NPD) with forecasting and resources sharing techniques not only increase the quality of innovation but these factors improve the organization performance by shortening time to market and maximizing efficiency of resources. It also enhances the demand planning and reduces the risks, building up long term relationships resulting in enhanced responsiveness, customer satisfaction, and competitive advantage. An Innovative Product Development Model with the aid of the Technological Acceptance Plane (TAM) and with the support of Manufacturing servitization, as proposed in this study, produces enhanced performance within an organization through the alignment of smart product design with the customer needs and usability. The strategy advances service adoption, increases customer loyalty, and makes recurring revenues, hence creates a more responsive market, high operational efficiency, and earnings in the long run.

Energy Access Innovation Centers (EAICs) improve the performance of organizations by facilitating faster clean energy innovation, decreasing the expenses of research and development, and climbing the product-market flash in underserved locations. They promote collaboration, contribute to inclusive design, and make scaling in the market a possibility, enhancing the competitiveness, efficiency in the operations, and impacts on sustainability among energy-sector enterprises. The use of the theory of differential games to model the technological innovation of reducing carbon makes organizational behavior perform better in terms of determining the best investments, collaboration, and regulation alignment. This will allow the firms to achieve a balance between competition and cooperation, mitigate risks, and provide sustainable innovation, improving efficiency, compliance, and strategic advantage. Enterprise Framework of Renewable Energy, implemented according to the SCOR model, improves the organizational performance through simplifying the processes in the supply chain and improving the efficiency of its operational sphere, and contributing to sustainability. It will involve improved planning, sourcing and delivery, more innovation, compliance with rules and regulations and increase its competitiveness in the green energy sector in the long term Table 6.

| Table 6 Impact of Technological Innovations in Supply Chain in Manufacturing Industry on the Firm Performance | ||

| Technological Innovation | Impact on firm performance | Reference |

| Green Technology Innovation System (GTIS) based on Multi-Agent Cooperation | Enhances firm performance by enabling collaborative innovation, reducing development costs, and improving resource efficiency and enhances dynamic capabilities, boosts environmental compliance, and strengthens competitive advantage, ultimately leading to better financial outcomes. | (Wang et al., 2022), (Zhang & Yu, 2020), (Huang & Li, 2023) |

| Nanocomposite Packaging | Packaging improves company performance by increasing shelf life and cutting costs, while also supporting sustainability and enhancing brand value. These benefits help companies stand out in the market and boost profitability. | (Duncan, 2011), (Silvestre et al., 2011), (Rhim et al., 2013) |

| Modular Manufacturing Platforms (MMP) for Vaccines | Improves company performance by enabling flexible, scalable, and cost-effective operations. This enhances supply chain resilience, accelerates innovation, and strengthens market competitiveness and profitability. | (Zhang et al., 2021), (Chaves et al., 2022), (Preiss et al., 2022). |

| Blockchain-Based Food Traceability System | Improves organizational efficiency by increasing transparency, reducing fraud, and building consumer trust. It also enhances operational efficiency, ensures compliance, and enables premium branding, leading to improved financial results. | (Carrefour, 2020), (Kamble et al., 2020), (Lin et al., 2020) |

| Augmented Reality (AR) in the Food Supply Chain | Enhances company performance by increasing consumer engagement and operational efficiency. It offers immersive experiences, improves traceability and training, and strengthens brand value, resulting in greater customer satisfaction and profitability. | (Dwivedi et al., 2021), (Tang et al., 2020), (Rauschnabel et al., 2022) |

| Re-distributed Manufacturing (RDM) | Drives operational excellence by supporting local, flexible, and demand-responsive production. It minimizes lead times and transport costs, enhances sustainability and customization, and strengthens resilience and customer satisfaction. | (Zhou et al., 2021), (Bauer et al., 2017), (Smith et al., 2020) |

| Information Requirements Paradigm for IT Innovation Diffusion | Accelerates value creation by aligning IT adoption with organizational knowledge and decision-making needs. This reduces uncertainty, enhances stakeholder coordination, and improves integration, resulting in higher adoption success and stronger returns. | (Rogers, 2003), (Gallivan, 2001), (Wu et al., 2007). |

| Cloud Computing for Supply Chain Information Systems | Promotes sustainable performance by improving real-time visibility, collaboration, and scalability. It enables cost reduction, better forecasting, and faster innovation, resulting in greater efficiency and stronger financial returns. | (Ali et al., 2021), (Hofmann & Rüsch, 2017), (Kamble et al., 2019). |

| Service-Oriented Architecture (SOA) and the Emergence of Service Science | Strengthens competitive positioning by enabling agile, integrated, and innovative service delivery. They foster modular IT systems, value co-creation, and efficiency, resulting in enhanced customer experiences and long-term competitiveness. | (Bohmann et al., 2014), (IfM & IBM, 2008), (Spohrer & Maglio, 2010). |

| RFID as a Disruptive Information Technology | Enhances company performance by enabling real-time tracking and reducing manual errors. It improves supply chain visibility, drives automation, and supports data-driven decisions, resulting in higher efficiency, cost savings, and customer satisfaction. | (Zebra Technologies, 2017), (Kumar et al., 2009), (Thiesse et al., 2011) |

| Supply Chain (SC) Innovation for Risk Management and Competitive Advantage | Elevates corporate success by enhancing risk management, agility, and long-term competitiveness. Through advanced technologies and collaboration, firms achieve greater visibility, efficiency, and resilience, resulting in higher profitability and responsiveness. | (Ivanov et al., 2019), (Pettit et al., 2010), (Golini et al., 2014) |

| Human–Computer Interaction (HCI) Framework for AI in Logistics | Drives operational excellence by enhancing human-AI collaboration and decision-making. User-friendly interfaces improve accuracy and adaptability, resulting in reduced costs, faster deliveries, and greater customer satisfaction. | (Calvaresi et al., 2021), (Ghosh et al., 2020), (Benlian, 2020) |

| Collaborative New Product Development with Forecast and Resource Sharing | Improves organizational efficiency by improving innovation quality and speeding up time-to-market. It optimizes resource use, strengthens planning, and builds partnerships, resulting in higher responsiveness and competitive edge. | (Swink & Song, 2007), (Droge et al., 2012), (Zhang et al., 2016). |

| Manufacturing Servitization via an Innovative Product Development Model Using TAM | Strengthens competitive positioning by aligning smart product design with user needs. It promotes service adoption, builds customer loyalty, and supports recurring revenue, driving efficiency and long-term profitability. | (Coreynen et al., 2017), (Rymaszewska et al., 2017) |

| Energy Access Innovation Centers (EAICs) for Universal Clean Energy | Accelerates value creation by driving clean energy innovation, cutting R&D costs, and tailoring solutions for underserved markets. They promote partnerships and scalable, inclusive design, enhancing competitiveness, efficiency, and sustainability impact. | (IEA, 2021), (ESMAP, 2020), (World Bank, 2021) |

| Interaction Mechanism for Carbon Reduction Technology Innovation Using Differential Game Theory | Enhances business outcomes by optimizing investments and encouraging strategic collaboration. It helps balance competitive and cooperative actions, improving efficiency, regulatory compliance, and long-term sustainability advantage. | (Huang et al., 2020), (Zhao et al., 2021), (Liu et al., 2022) |

| Enterprise Framework for Renewable Energy Using SCOR Model | Promotes sustainable performance by optimizing supply chain planning, sourcing, and delivery. It enhances efficiency, supports sustainability, and drives innovation and compliance, strengthening long-term competitiveness in the green energy sector. | (Yadav & Desai, 2016), (Khan et al., 2017), (Ahi & Searcy, 2013) |

Conclusion

This study discusses a comprehensive bibliometric and systematic review of selected research papers based on the technological innovations in supply chain management (SCM) within the manufacturing sector.

The analysis indicates a strong growing trend in research contributions especially post-2018, driven by the growing need for agility, resilience, and digital transformation in global supply chains. The COVID-19 pandemic, global trade disruptions, and sustainability imperatives have intensified the adoption of innovations such as AI, IoT, blockchain, cloud computing, and AR. The most influential authors, journals, and countries identified—particularly from China and the United States—indicate a global academic and industrial commitment to SCM innovation. Keyword co-occurrence and thematic mapping revealed a multidisciplinary convergence around themes like green innovation, risk management, digital transformation, and sustainability. Moreover, various technological innovations were identified and categorized based on their functional contributions to firm performance. Innovations such as modular manufacturing, nanocomposite packaging, and blockchain for traceability demonstrate tangible benefits in terms of agility, cost reduction, regulatory compliance, and customer engagement. These innovations are not only enhancing operational efficiency but are also reshaping the strategic orientation of firms toward sustainability and digital maturity. The research concludes that technological innovation is a key enabler of competitive advantage and improved firm performance in the manufacturing supply chain domain. This study is different from the existing research to combine bibliometric mapping and systematic literature review methods to categorize and quantify technological innovations in SCM. The insights offer a holistic view of how firms leverage these innovations to enhance productivity, cost-efficiency, resilience, and sustainability. As such, it contributes significantly to both academic understanding and managerial practice in the evolving digital supply chain landscape.

Managerial Implications

The paper suggests the manufacturing firms to align technological adoption with firm-level goals such as cost leadership, customer responsiveness, and sustainability compliance. Firms must invest in interoperable platforms and scalable digital infrastructure (e.g., cloud systems) to unify various supply chain technologies. Training programs and change management initiatives are critical to overcoming skill gaps and resistance associated with new technologies. Managers should use advanced analytics and AI to transition from reactive to predictive and prescriptive decision-making models. The implementation of blockchain, IoT, and digital twins can help companies pre-empt disruptions and build supply chain resilience.

Future Research Agenda

Future studies can explore integrated frameworks that combine AI, blockchain, IoT, and cloud computing to maximize SCM performance. There is scope to empirically examine how green technologies affect environmental KPIs and long-term competitiveness. Extending the analysis beyond manufacturing to sectors like healthcare, agriculture, and retail could offer a broader perspective on supply chain innovation. In-depth research is needed to identify contextual factors (e.g., firm size, region, industry type) that hinder or facilitate innovation adoption. Studies focusing on human-computer interaction (HCI) and AI ethics can inform user-centric design for digital SCM platforms. Finally, the researchers are recommended to run longitudinal studies that may monitor the ROI and a long-term strategic effect following the sorting of new technologies in the supply chain.

References

Ahi, P., & Searcy, C. (2013). A comparative literature analysis of definitions for green and sustainable supply chain management. Journal of Cleaner Production, 52, 329–341.

Indexed at, Google Scholar, Cross Ref

Ahmad, N., & Wong, K. Y. (2019). An application of interpretative structural modelling (ISM) for analysing barriers to sustainable manufacturing in Malaysian SMEs. Sustainable Production and Consumption, 17, 128–146.

Ali, O., Shrestha, A., Narayan, B., & Muhammad, N. (2021). Exploring the barriers and enablers of digital transformation in the manufacturing sector. Sustainability, 13(14), 7893.

Bauer, M., Derksen, L., Kaganer, E., & Kude, T. (2017). Agile at scale: How to go from a few teams to hundreds. McKinsey & Company. https://www.mckinsey.com

Ben-Daya, M., Hassini, E., & Bahroun, Z. (2019). Internet of Things and supply chain management: A literature review. International Journal of Production Research, 57(15–16), 4719–4742.

Indexed at, Google Scholar, Cross Ref

Benlian, A. (2020). A model for understanding the influence of service quality on user satisfaction in software-as-a-service (SaaS). Information Systems Journal, 30(3), 533–560.

Chaves, B. D., Ribeiro, H. L., & Silva, A. L. (2022). Integration of 3D printing and bioplastics for sustainable food packaging: A review. Trends in Food Science & Technology, 124, 103–117.

Denyer, D., & Tranfield, D. (2009). Producing a systematic review. In D. A. Buchanan & A. Bryman (Eds.), The SAGE handbook of organizational research methods (pp. 671–689). SAGE Publications.

Majid, I., Nayik, G. A., & Nanda, V. (2016). Nano-encapsulation of bioactive compounds for the food industry: A review. International Journal of Pharma and Bio Sciences, 7(4), 354–364.

Melville, N., & Ramirez, R. (2008). Information technology innovation diffusion: An information requirements paradigm. Information Systems Journal, 18(3), 247–273.

Indexed at, Google Scholar, Cross Ref

Moher, D., Liberati, A., Tetzlaff, J., Altman, D. G., & The PRISMA Group. (2010). Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. International Journal of Surgery, 8(5), 336–341.

Indexed at, Google Scholar, Cross Ref

Nathwani, J., & Kammen, D. M. (2019). A climate solution where all sides can win. Nature, 568(7750), 26–28.

Ngai, E. W. T., Moon, K. K. L., Riggins, F. J., & Yi, C. Y. (2008). RFID research: An academic literature review (1995–2005) and future research directions. International Journal of Production Economics, 112(2), 510–520.

Indexed at, Google Scholar, Cross Ref

Odimarha, D., Zhang, Y., Chen, Y., & Bai, Y. (2024). Emerging technologies in supply chain risk management: A review of AI, IoT, and blockchain applications. International Journal of Production Research. Advance online publication.

Pagliusi, S., Che, R., & Dong, X. (2019). Manufacturing innovations for vaccines: The case for modularity. Vaccine, 37(37), 5575–5578.

Rymaszewska, A., Helo, P., & Gunasekaran, A. (2017). IoT powered servitization of manufacturing–an exploratory case study. International Journal of Production Economics, 192, 92–105.

Indexed at, Google Scholar, Cross Ref

Sahay, B. S., & Mohan, R. (2020). Managing supply chains in times of crisis: A review and research agenda. Journal of Supply Chain Management, 56(3), 71–82.

Smith, A., Stirling, A., & Berkhout, F. (2020). Grassroots innovation for sustainable development: An introduction. Journal of Cleaner Production, 119, 75–82.

Spohrer, J., & Maglio, P. P. (2010). Toward a science of service systems: Value and symbols. In P. P. Maglio, C. A. Kieliszewski, & J. C. Spohrer (Eds.), Handbook of service science (pp. 157–194). Springer.

Swink, M., & Song, M. (2007). Effects of marketing-manufacturing integration on new product development time and competitive advantage. Journal of Operations Management, 25(1), 203–217.

Indexed at, Google Scholar, Cross Ref

Tang, S. Y., Li, Z., & Zhao, Y. (2020). Low-carbon innovation strategies and technology diffusion in supply chains. Sustainability, 12(6), 2448.

Thiesse, F., Buckel, T., & Staake, T. (2011). Privacy concerns in RFID-enabled supply chains: A conceptual framework. Journal of Strategic Information Systems, 20(3), 225–239.

Tian, F. (2017). A supply chain traceability system for food safety based on HACCP, blockchain & Internet of Things. Proceedings of the International Conference on Service Systems and Service Management (ICSSSM), 1–6.

Indexed at, Google Scholar, Cross Ref

Vieira, E. S., & Gomes, J. A. N. F. (2009). A comparison of Scopus and Web of Science for a typical university. Scientometrics, 81(2), 587–600.

Zhang, X., & Yu, H. (2020). Exploring the mechanisms of digital innovation capabilities on firm performance in manufacturing industries. Journal of Business Research, 112, 109–118.

Zhang, Y., & Duan, Y. (2021). A bibliometric analysis of green innovation: Current status, development, and future directions. Journal of Cleaner Production, 287, 125398.

Zhang, Y., & Zhang, M. (2017). Integration of forecasting and resource sharing for collaborative product development. Computers & Industrial Engineering, 112, 756–766.

Zhang, Y., Li, D., & Zhang, L. (2020). Enhancing supply chain visibility through Internet of Things and blockchain technology.

Received: 25-Aug-2025, Manuscript No. AMSJ-25-16156; Editor assigned: 26-Aug-2025, PreQC No. AMSJ-25-16156(PQ); Reviewed: 28-Aug-2025, QC No. AMSJ-25-16156; Revised: 19-Sep-2025, Manuscript No. AMSJ-25-16156(R); Published: 27-Sep-2025